Rover 200 BRM - 1.8 K-Series turbo project

Discussion

Stuballs said:

227bhp said:

Lol, that's not a steep power curve, it is linear though so will probably suit a FWD car.

The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

I meant steep at the top as in it isn't starting to fall off. Yep still has the hig-lift cams in. I'm going to have a go with a mechanics stethoscope to see if I can isolate the noise.The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

The noise shouldn't be parts colliding as there's a couple of mm piston-valve clearance and the rods were not fouling the liner or piston skirt when I built it (again, loads of clearance). It also doesn't get better or worse with temperature.

To me it sounds like top end. Could it be the aggressive ramp with the relatively low duration and high high lift cams? Or maybe the Rover hydraulic followers don't like the running-in oil...

I can't be bothered to go back along all the pages of highs and lows in this thread, but seem to remember solid lifters being mentioned, I don't know this engine, but surely someone will know what to recommend? It isn't a bucket being pushed so far it's hitting something is it? I can't imagine CRO 10/40 being a problem and the noise would change with the oil temp so it sounds like it's not oil related.

Stuballs said:

I meant steep at the top as in it isn't starting to fall off. Yep still has the hig-lift cams in. I'm going to have a go with a mechanics stethoscope to see if I can isolate the noise.

The noise shouldn't be parts colliding as there's a couple of mm piston-valve clearance and the rods were not fouling the liner or piston skirt when I built it (again, loads of clearance). It also doesn't get better or worse with temperature.

To me it sounds like top end. Could it be the aggressive ramp with the relatively low duration and high high lift cams? Or maybe the Rover hydraulic followers don't like the running-in oil...

Its not something like cam lobe on the cam cover is it? I have had that problem with a pinto and race cam in the past. The noise shouldn't be parts colliding as there's a couple of mm piston-valve clearance and the rods were not fouling the liner or piston skirt when I built it (again, loads of clearance). It also doesn't get better or worse with temperature.

To me it sounds like top end. Could it be the aggressive ramp with the relatively low duration and high high lift cams? Or maybe the Rover hydraulic followers don't like the running-in oil...

If the base circle of the cams is significantly smaller than original, the lifters will sit in a different static position when inflated - there was issues of misalignment of the oil drillings in the head that would cause this issue.

DVA's website details it, involves a bit of burr action on the ends of the drillings in the lifter tubes.

If you're running hydraulic lifters and they're clattering to the point that the dyno operator is worried about the engine, I wouldn't be running it until you've fixed it. You're losing valve lift, if nothing else.

DVA's website details it, involves a bit of burr action on the ends of the drillings in the lifter tubes.

If you're running hydraulic lifters and they're clattering to the point that the dyno operator is worried about the engine, I wouldn't be running it until you've fixed it. You're losing valve lift, if nothing else.

bgunn said:

If the base circle of the cams is significantly smaller than original, the lifters will sit in a different static position when inflated - there was issues of misalignment of the oil drillings in the head that would cause this issue.

Thats a actually a really good shout. I'd heard that before but forgotten all about it. It can also be caused by the head itself just being drilled wrong. Easy to test for this - rocker cover off and see if any followers can be pushed down when cam is at fully closed (lobe pointing away). I'd not heard the fix though. Head off yet again if that is the cause. It would actually be easier to fit solid followers. Taking the head off is now an epic task with my new exhaust manifold (that's why I fitted everything to the engine before fitting the engine in the car).

Solid lifters would also not be that much more expensive when you factor in the cost of new head gasket and bolt set. Plus other gaskets, sealants and fresh coolant.

If the aggressive ramp on the cams (low duration and high lift) is causing the cams to -"pump-out", the only fix for that is new cams or sold lifters.

It's not a cam lobe fouling something - the head has been stripped previously and no sign of any contact.

I've found a couple of examples of vvc heads having excessive clearance in the cam bearing surfaces, which allows a slight wobble of the camshaft. I suppose it could be that. I'd have to whip the cams out and measure. If it is that, it's time for a new head.

Stuballs said:

Thats a actually a really good shout. I'd heard that before but forgotten all about it. It can also be caused by the head itself just being drilled wrong. Easy to test for this - rocker cover off and see if any followers can be pushed down when cam is at fully closed (lobe pointing away).

....

I've been reading your rollercoaster ride as if it were the newest Dan Brown novel. Man what a story. ....

How's the progress going? Or have you switched to a different topic. Hope all is well! Greetings, a fellow BRM owner and driver

Googolplex said:

I've been reading your rollercoaster ride as if it were the newest Dan Brown novel. Man what a story.

How's the progress going? Or have you switched to a different topic. Hope all is well! Greetings, a fellow BRM owner and driver

Greetings fellow BRM'er!How's the progress going? Or have you switched to a different topic. Hope all is well! Greetings, a fellow BRM owner and driver

It's been fairly quiet since I don't want to drive it on salt-covered roads and makes the rust any worse before the respray in July.

She's currently in bits again too as the tubular manifold warped slightly and develop a leak. The manifold-turbo gasket also disintegrated! I had to take the whole front end off to get to all the bolts! While it's off its going to zircotec for ceramic coating.

One I have the manifold back I'll finish the running in then go back to Emerald for full mapping.

227bhp said:

Where was the manifold warping and leaking?

By cylinder 1 head mating surface. To be honest I suspect the surface wasn't completely flat to start with although it wasn't actually blowing initially. When I got it all off the blow there was minor compared to the blown gasket with the turbo. I had it wrapped so the extra heat won't have helped. I've had it skimmed by Modus Engineering in Tunbridge Wells now and it's completely flat.

Planning on running the manifold-turbo join without a gasket now.

Stuballs said:

227bhp said:

Where was the manifold warping and leaking?

By cylinder 1 head mating surface. To be honest I suspect the surface wasn't completely flat to start with although it wasn't actually blowing initially. When I got it all off the blow there was minor compared to the blown gasket with the turbo. I had it wrapped so the extra heat won't have helped. I've had it skimmed by Modus Engineering in Tunbridge Wells now and it's completely flat.

Planning on running the manifold-turbo join without a gasket now.

Have you checked the turbo flange for straight? I guess you would, I found they bow with the heat and then it burns the gasket out.

227bhp said:

It's less likely to blow against the head as they are usually more flexible and well bolted, be aware (if you're thinking of spending on coatings) that if it's the heat which has done that then it's possible it will do it again. Some gaskets are better than others, some have a steel ring around the exhaust port which are good, even MLS are available with a soft core for some cars too.

Have you checked the turbo flange for straight? I guess you would, I found they bow with the heat and then it burns the gasket out.

Flanges at turbo are both flat. I think it was just a duff gasket. Replacement gasket at head is a genuine land rover item with the steel rings you mention so hopefully that will help.Have you checked the turbo flange for straight? I guess you would, I found they bow with the heat and then it burns the gasket out.

The wrap held in an awful lot of heat. I'm hoping the ceramic coating is a good halfway-house.

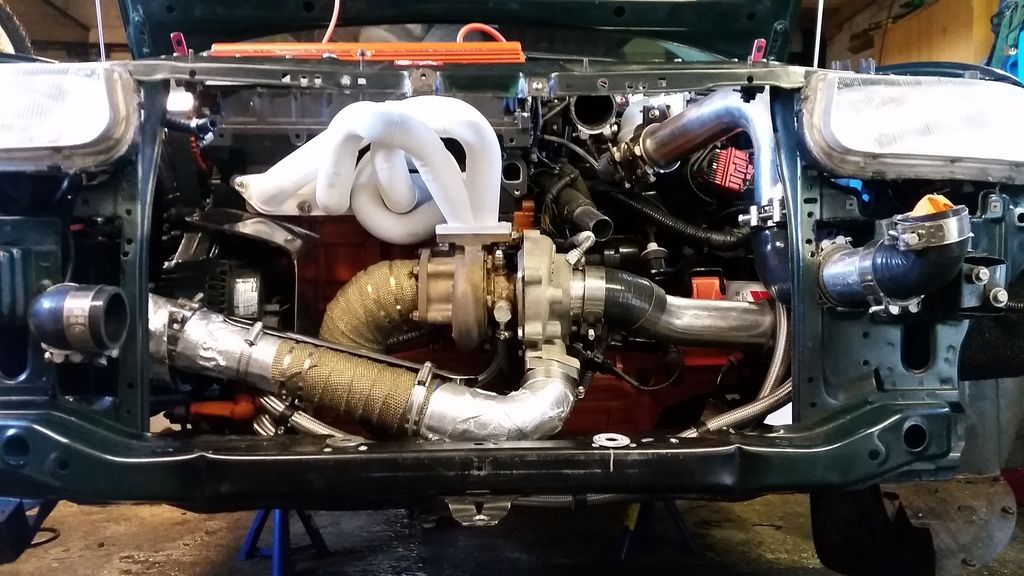

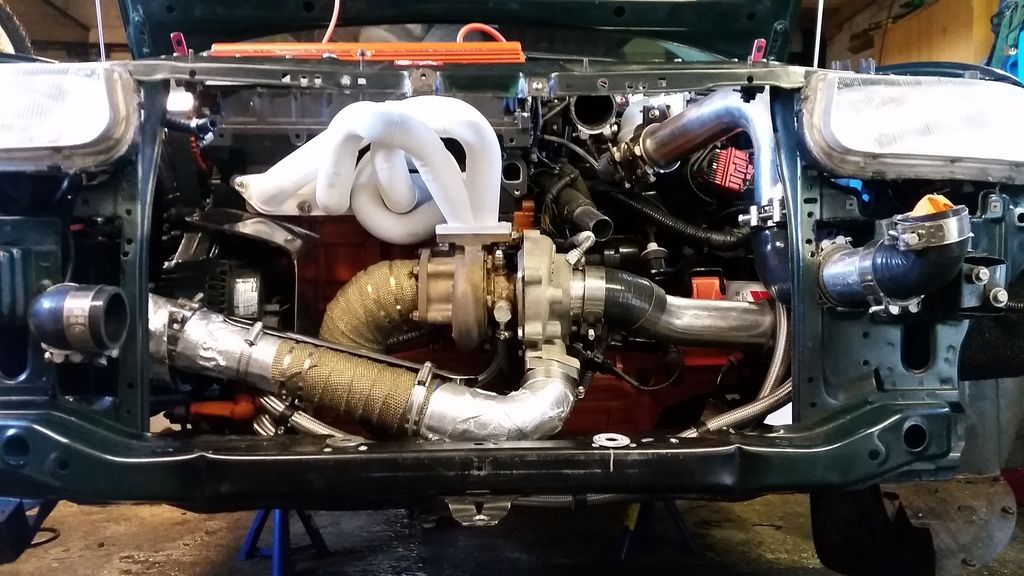

Manifold back from zircotec and fitted:

Pics taken before I actually finished putting it back together but you get the idea! Thankfully the manifold doesn't leak. I was worried it might still blow between mani and turbo now I'm running that joint gasket-less but it's all good. Fingers crossed it stays like that!

One I've got the MOT done (which ran out while it was VOR) I can finish running in and get back to Emerald for a proper map before summer! You will recall it's currently only mapped for half throttle and 5KRPM so it'll be nice to open the taps a bit.

Pics taken before I actually finished putting it back together but you get the idea! Thankfully the manifold doesn't leak. I was worried it might still blow between mani and turbo now I'm running that joint gasket-less but it's all good. Fingers crossed it stays like that!

One I've got the MOT done (which ran out while it was VOR) I can finish running in and get back to Emerald for a proper map before summer! You will recall it's currently only mapped for half throttle and 5KRPM so it'll be nice to open the taps a bit.

Read the whole lot and its an epic thread! Just done a rebuild on my TVR recently and love an engine rebuild story!

Did you solve the head noise if its ready for the remap soon? Have you gone solid lifters?

Where are going to for the remap?

Im off to JDM soon for my remap once my engine is run in.

Did you solve the head noise if its ready for the remap soon? Have you gone solid lifters?

Where are going to for the remap?

Im off to JDM soon for my remap once my engine is run in.

Willfin said:

Read the whole lot and its an epic thread! Just done a rebuild on my TVR recently and love an engine rebuild story!

Did you solve the head noise if its ready for the remap soon? Have you gone solid lifters?

Where are going to for the remap?

Im off to JDM soon for my remap once my engine is run in.

Thanks Did you solve the head noise if its ready for the remap soon? Have you gone solid lifters?

Where are going to for the remap?

Im off to JDM soon for my remap once my engine is run in.

Although I'd have preferred one less rebuild in this particular tale

Never solved the noisy head issue. It's annoying as hell though. Embarrassing too. Runs fine just sounds like a diesel. I have sourced a low mileage unskimmed vvc head which I'll fit at some point. Couldn't go solid lifters as that would have required new cams. I'll probably go milder on the cams when I fit the new head but I'll decide on that nearer the time.

Engine has just over 1,000 miles on it now. Mapping is this Wednesday and going direct to Emerald again. Staying with low boost for now though.

I'll post up results.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff