Rover 200 BRM - 1.8 K-Series turbo project

Discussion

.Adam. said:

Think I saw you on the A21 today, car looked good and sounded nice as I went by!

Probably was me, so thanks! I made an early start this morning heading up to Emerald for mapping. Then headed back through that way about 4pm ish I think... ... Which links nicely into an update:

With the engine having covered just over a 1000 miles it was time to head back to Emerald for a full map. The running in map was only meant for half throttle and up to 5,500RPM, which was a bit painful on an engine that has no midrange!

So I changed the oil for some fully synthetic and checked everything over. Satisfied that she was in tip top condition for the rigors of the rolling road (and trying not to think of what happened the last time this car had a full mapping session), there was nothing left to do but pray to the car gods.

Photo whoring op. All ready to go:

Arrived safely at Emerald having battled through rush hour traffic. They wasted no time strapping her down. After a good talk about the build and my goals (just don't blow her up - safe, safe, safe!) we were ready to go:

The plan was to stick with actuator pressure (7psi) and see what happens.

If you've ever had a car you've piled a lot of time and money into (especially one you built yourself), mapped on a dyno in front of you, you might know how I was feeling. Slightly excited, but mostly nervous and a little bit sick. This was amplified by the memory of my last engine failing in a similar setting (the image of that smashed in spark plug as he removed it from the bore and held it aloft like some sacred talisman of evil still haunts me). As my senses were assailed by a barrage of unfamiliar noises smells and vibrations, I just kept telling myself "this is normal. That noise... That's normal... ".

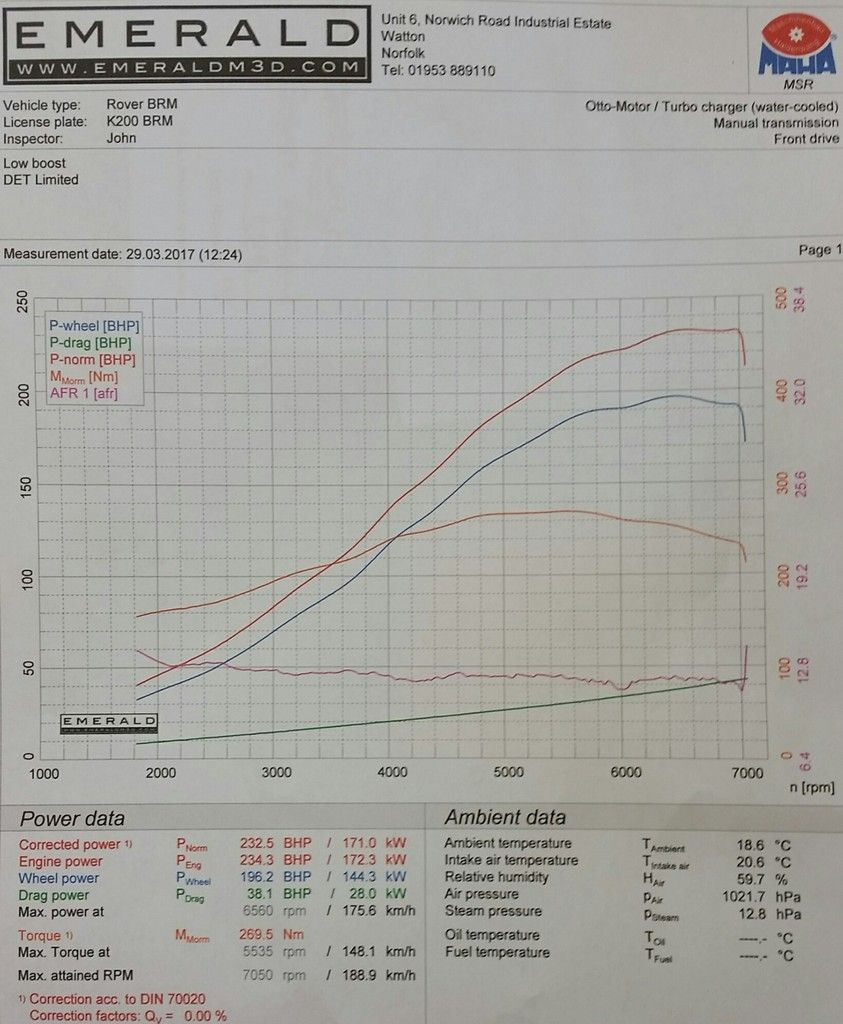

As it happens, everything was fine. The high compression is causing us to have to retard the timing to avoid detonation to such a degree that power is affected (as with the running-in map - I expected that). That means the engine is just quite lazy before 4krpm with a slow rising torque curve and slow turbo spool. I can live with that though. Above 4krpm it's mental and screams like a banshee. The det-limited timing causes the power to drop off after 6,500rpm.

Plot:

And video of one of the power runs:

https://youtu.be/CQJ0tyMRpb4

The plan is to eventually fit water/methanol injection - probably after this year's nice weather is out of the way. That will surpress the detonation and allow us to crank up the boost and rev higher. For now though, I'm just going to enjoy driving it (heading up to the Fast Show at Santa Pod this weekend where I certainly shall not be "running what I brung").

Thanks for reading

Edited by Stuballs on Monday 7th August 09:07

Edited by Stuballs on Monday 7th August 09:09

Good stuff

Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Edited by Yazza54 on Wednesday 29th March 22:03

Yazza54 said:

Good stuff

Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Yeah mapper said its behaving more like 11.5:1. I have warmer cams but by no means extreme, so maybe that's the difference? Piper bp270h. Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Edited by Yazza54 on Wednesday 29th March 22:03

Stuballs said:

Yazza54 said:

Good stuff

Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Yeah mapper said its behaving more like 11.5:1. I have warmer cams but by no means extreme, so maybe that's the difference? Piper bp270h. Surprised that 10:1 is causing issues tbh with a modern mappable ECU. Lots of guys on the Honda forums with b16s and b18s are making way over 300 hp on that kind of compression and even slightly higher. Maybe they have lower dynamic compression in VTEC though. Hmm. Have you got aftermarket cams fitted?

Edited by Yazza54 on Wednesday 29th March 22:03

I'm sure there must be a lot more to come from that engine as Dave Walker mapped my mates car (Thruxton Kit Car) with a standard K series turbo (only mod really was the Emerald ECU and exhaust) at 200bhp

http://www.emeraldm3d.com/articles/july2011/

http://www.emeraldm3d.com/articles/july2011/

rdodger said:

I'm sure there must be a lot more to come from that engine as Dave Walker mapped my mates car (Thruxton Kit Car) with a standard K series turbo (only mod really was the Emerald ECU and exhaust) at 200bhp

http://www.emeraldm3d.com/articles/july2011/

There is alot of potentail from the rover k series, it just takes someone to push it into the 400bhp+ rangehttp://www.emeraldm3d.com/articles/july2011/

It may also be your turbo which is restrictive. I don't think your cam profiles look too bad, the basic rule is small turbo, small cam, big modern turbo, big cam, there is no point in having large duration cams when the ex housing causes a back up of gasses.

Fixed duration/lift cams are very much give & take, you either have it there, or there, you can't have both. As has already been pointed out a linear power delivery is what you want in a fwd car, try more overlap (say inlet at 2mm, ex 1mm lift at TDC) and it'll spool up earlier and more viciously, but it would be of no use in the lower gears. The other downside is a lumpy idle, difficulty or maybe impossibility of getting an MOT due to emissions and less bottom end. You can harness that kind of spool up behaviour with in gear boost control though, but it's more expense and stuff to go wrong.

It hasn't blown up yet and that is something.

Fixed duration/lift cams are very much give & take, you either have it there, or there, you can't have both. As has already been pointed out a linear power delivery is what you want in a fwd car, try more overlap (say inlet at 2mm, ex 1mm lift at TDC) and it'll spool up earlier and more viciously, but it would be of no use in the lower gears. The other downside is a lumpy idle, difficulty or maybe impossibility of getting an MOT due to emissions and less bottom end. You can harness that kind of spool up behaviour with in gear boost control though, but it's more expense and stuff to go wrong.

It hasn't blown up yet and that is something.

Evoluzione said:

It hasn't blown up yet and that is something.

Amen brother!

And thanks for your input as always.

rdodger said:

I'm sure there must be a lot more to come from that engine

Hopefully. My previous 9:1 engine was making around 270bhp at the flywheel at 12psi (until it melted). I've got a few options for the next stage. Water/methanol injection, 1.5mm head spacer, or shorter rods. No need to decide now. If the engine holds together I will try water/meth first seeing as that will always be nice to have even if I later lower the cr with rods or a head shim. Yazza54 said:

Might be worth looking into other options for the cams, I know some manufacturers make "turbo" cams with higher lift but next to no overlap to build cylinder pressure.

I think I'll leave the cams alone for now. I showed Emerald the specs and they didn't seem to think they were the problem or needed changing. My cams are "fast road" with a bit more duration and overlap than stock and relatively high lift. At worst, it's been suggested they might be causing the noisy top end by accelerating the valve too quickly over a short duration to get to the high lift and back down again. They are a custom grind and I don't know if anyone else with this spec. It's worth considering what happens when you advance ignition angle, and where the heat goes!

As you advance the ignition angle (ie, you light the charge earlier) you have a hotter average charge temperature at any given chamber volume. And as PV = nRT, a hotter charge means higher pressure so mechanical loads. But often the real killer is the change in the path of the heat flux. Assuming you have the same charge mass, then the TOTAL heat release is the same, however, where that heat goes is very very different. For a retarded ignition, the heat goes out the exhaust port due to the late burn. This pushes up EGT, but as long as you are below sensible limits (lets say 975degC turbine inlet) then that's all ok. But advance the ignition and the charge burns hotter (a higher percentage of the charge will have been burnt at TDC) and at a bigger average chamber volume (because you started the burn earlier), and hence the heat transferred into the chamber walls is increased. This pushes metal temps in the engine up and this extra thermal stress is added to the extra mechanical stress (pressure loads). On a relatively 'flimsy' engine like the K series, which was never designed for high thermal or pressure loads, then it's not un-expected to see component failures (plugs, valves, valve seats,pistons etc) due to this extra load, even when no abnormal combustion (pre-ignition / det etc) occurs!

Plenty of turbo engines survive simply because they are run retarded, and hence run with what i would call (and you can hear it) a "soft burn" ie a low, long, lazy burn (cylinder pressure) profile. Fully optimised engines with aggressive burnrates (modern DI turbo's) sound "Hard" and often quite like diesels, and although powerful and efficient, push high thermal and mechanical loads into their engine components. This is fine if the engine has been designed for it, but causes issues if it hasn't!

In your case, as you don't really care about efficiency, it will be better to run more boost and less ignition to limit engine component peak loads.

Separately, it think it is unlikely your CR is causing the high rpm retard, as unless you are running really low grade fuel or massive boost, anything above 5000 (ish) rpm should be MBT rather than BLD. It's much more likely to be a result of excessive internal EGR due to the turbine restriction resulting in poor cylinder scavanging and hence a high exhaust residual percentage. You will probably find that some cam timing optimisation could make a big difference here!

As you advance the ignition angle (ie, you light the charge earlier) you have a hotter average charge temperature at any given chamber volume. And as PV = nRT, a hotter charge means higher pressure so mechanical loads. But often the real killer is the change in the path of the heat flux. Assuming you have the same charge mass, then the TOTAL heat release is the same, however, where that heat goes is very very different. For a retarded ignition, the heat goes out the exhaust port due to the late burn. This pushes up EGT, but as long as you are below sensible limits (lets say 975degC turbine inlet) then that's all ok. But advance the ignition and the charge burns hotter (a higher percentage of the charge will have been burnt at TDC) and at a bigger average chamber volume (because you started the burn earlier), and hence the heat transferred into the chamber walls is increased. This pushes metal temps in the engine up and this extra thermal stress is added to the extra mechanical stress (pressure loads). On a relatively 'flimsy' engine like the K series, which was never designed for high thermal or pressure loads, then it's not un-expected to see component failures (plugs, valves, valve seats,pistons etc) due to this extra load, even when no abnormal combustion (pre-ignition / det etc) occurs!

Plenty of turbo engines survive simply because they are run retarded, and hence run with what i would call (and you can hear it) a "soft burn" ie a low, long, lazy burn (cylinder pressure) profile. Fully optimised engines with aggressive burnrates (modern DI turbo's) sound "Hard" and often quite like diesels, and although powerful and efficient, push high thermal and mechanical loads into their engine components. This is fine if the engine has been designed for it, but causes issues if it hasn't!

In your case, as you don't really care about efficiency, it will be better to run more boost and less ignition to limit engine component peak loads.

Separately, it think it is unlikely your CR is causing the high rpm retard, as unless you are running really low grade fuel or massive boost, anything above 5000 (ish) rpm should be MBT rather than BLD. It's much more likely to be a result of excessive internal EGR due to the turbine restriction resulting in poor cylinder scavanging and hence a high exhaust residual percentage. You will probably find that some cam timing optimisation could make a big difference here!

Thanks Max_Torque. That's proper interesting. I probably should have asked Emerald to play around with the cam timing. To be honest, I was so glad it survived the mapping and it was running well, I just wanted to grab the keys and run! I timed the cams as per the spec provided by piper and, having seen the spec sheet, Emerald thought it was about right. Would you retard exhaust, advance inlet, or both?

The mapping was on a fresh tank of BP Ultimate. I'm not a fan of that stuff usually (my Scooby hates it) but the Shell garage was out of Vpower.

Do you think it's even worth running water/meth injection on this setup as it is?

I got to wondering if the detonation is worse than expected due to the respective shapes of the piston and head. Obviously the k-series combustion chamber was never designed to work with dished pistons. The head is a typical pent roof with squish pads on both inlet and exhaust.

Head:

Piston:

The resultant side profile is something like this (exaggerated proportions obviously):

Just a thought. I had det on both squish pads on my last build. Granted though in that build the squish clearance was too big at circa 2mm. Or maybe the fuel was just not a particularly good batch...

The mapping was on a fresh tank of BP Ultimate. I'm not a fan of that stuff usually (my Scooby hates it) but the Shell garage was out of Vpower.

Do you think it's even worth running water/meth injection on this setup as it is?

I got to wondering if the detonation is worse than expected due to the respective shapes of the piston and head. Obviously the k-series combustion chamber was never designed to work with dished pistons. The head is a typical pent roof with squish pads on both inlet and exhaust.

Head:

Piston:

The resultant side profile is something like this (exaggerated proportions obviously):

Just a thought. I had det on both squish pads on my last build. Granted though in that build the squish clearance was too big at circa 2mm. Or maybe the fuel was just not a particularly good batch...

Edited by Stuballs on Monday 7th August 09:11

Evoluzione said:

Did you log intake temps, if so what were they?

Not logged as such but have a video with torque app overlay showing intake temps on a power run. Starts off at 40-odd degrees dropping to 17 degrees at full power.https://youtu.be/ePW-UKV95sc

(ignore the afr - mine wasn't plugged in at this point).

don't use a shim to reduce CR or shorter rods. it will make your knock problems even worst.

Been there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

Been there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

Ive said:

don't use a shim to reduce CR or shorter rods. it will make your knock problems even worst.

Been there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

Thanks MarkoBeen there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

I think I remember you saying direct port injection is best as the runners on the K-series have quite a tight bend and the vapour condenses on the inner surface. Have I remembered correctly?

I have a 3" downpipe then after the flexi under the sump it drops to 2.5 all the way back (via a sports cat). I guess my turbo is the restriction. It's a GT2560R. I ported the turbine housing and opened up the internal wastegate aperture to eliminate boost creep at high rpm (which worked) and present less of a restriction. There's only do much you can do though.

Yes, that is one of the main reasons to go for direct port.

I have tried all variations from pre compressor to direct port inkl. Good and poor nozzle locations. The set-up with the jets close to the fuel injectors worked best and as expected.

Again, for 7 PSI this is a fine result. I would drive it over summer and build confidence.

I have tried all variations from pre compressor to direct port inkl. Good and poor nozzle locations. The set-up with the jets close to the fuel injectors worked best and as expected.

Again, for 7 PSI this is a fine result. I would drive it over summer and build confidence.

Edited by Ive on Tuesday 4th April 07:28

Took the BRM to Pride of Longbridge yesterday. It's a show for all cars built at the Longbridge factory in Birmingham and held on the anniversary of MG Rover's closure in 2005. There's always a nice turnout from the local community who were obviously massively affected by the closure at the time.

Had a great day. Car was faultless and it was fun to show it off a bit and talk to people about the build. Amazing to see 21 BRMs lined up and some great cars on display.

Had a great day. Car was faultless and it was fun to show it off a bit and talk to people about the build. Amazing to see 21 BRMs lined up and some great cars on display.

Edited by Stuballs on Monday 7th August 09:06

Edited by Stuballs on Monday 7th August 09:13

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff