Rover 200 BRM - 1.8 K-Series turbo project

Discussion

Brilliant stuff. Have 3 switchable maps on my emerald K-turbo, quite a handy feature - but only up to 200hp for me. Good work with the heat shielding, good to take an extra check on all cables, fuel line routing etc.

If you get cooling problems which you probably wont with a copper radiator you can always add a couple more louvres centrally on the bonnet.

Epic project and results.

If you get cooling problems which you probably wont with a copper radiator you can always add a couple more louvres centrally on the bonnet.

Epic project and results.

Megaflow said:

Close. It's the H16. An even wackier concept than the V16.

The later H16 engines had 64 valves! https://en.wikipedia.org/wiki/British_Racing_Motor...Apparently the H16 wasn't very reliable. You'd think they'd have learnt their lesson after the V16! I wonder what it sounded like?

Love it! Had my first taste of a BRM yesterday at a Brands Hatch Trackday. Was so impressed with how it went for a bog standard shed I drove it onto the weigh bridge in the pits and it came out at just 1070 kgs despite the plush leather interior and 3/4 tank of fuel. We had some crazy cornering angles thanks to the Quaife LSD, I was just thinking one of these would be so cool with another 100bhp......

Edited by Furyblade_Lee on Saturday 5th December 21:32

Stuballs said:

You guys are too kind and I am unworthy of such high praise!

Much credit goes to the members of rovertech.net who have endured my endless stupid questions!

Anyone can ask endless questions, its the guy that puts the answers to use and builds something from it.Much credit goes to the members of rovertech.net who have endured my endless stupid questions!

That would be you then.

First start!

Got the Emerald installed with the supplied adapter loom for plug and play (although they forgot to install the boost control solenoid wiring so it had to go back) . They also supplied a 3 bar MAP sensor and a boost control solenoid. The first mapping will be at actuator pressure (about 8psi) so the solenoid is not doing anything at the moment. After run in I'll map for full power at around 16psi.

Filled up with Millers running in oil and coolant and she's ready to go. Disable injectors and ignition and turn over on the key to check it turns over and to get oil pressure. All fine so far. I'm getting nervous. I've never done this before. Maybe I should wait to get a couple of buddies round to act as extra pairs of eyes during this delicate time. I man up, plug everything back in, and turn the key.

BINGO! Fired up instantly!

A few tweaks of the Emerald to lower the Idle and then my eyes are trying to look at a million things at once! You really want minimal running at idle on a new build. The sooner you can get the engine under load and start bedding the rings in the better. So I checked for fuel, oil and coolant leaks and checked all temps and pressures were fine. Oil was struggling to get above 60 degrees C and it was clear the "thermostatic" oil cooler setup was over cooling (or the sensor was faulty). I had a couple of small coolant leaks that were sorted by nipping up clamps but other than that everything was fine.

And little vid of it running:

http://www.youtube.com/watch?v=O-zvICWkZ24

My initial reaction was "Jesus that top end is noisy". I assumed it was the VVC mechanisms as they are notoriously rattly and I've never heard a quiet setup - This is particularly bad though. That said, they hardly ever fail completely so my intention was to crack on with mapping and see how it goes. This, it turns out, was a mistake...

Rattling aside, I think it sounds great. The dump valve is a lot louder than I expected given its a recirculating system, but I kinda like it.

Time for mapping...

Booked in to see HT Racing who are based at Brands Hatch and had it trailered down there. Things were going well... At first...

A little vid of one of the runs:

http://www.youtube.com/watch?v=vGEZjrXCSKk

Then it all went a bit wrong...

We were almost done but then for no reason she developed a misfire at idle and low rpm. Lost compression in cylinder 3.

F#&k

Ok not the end of the world - might just be a sticky lifter. Definitely mechanical though so obviously I'm thinking "what have I done wrong?"!

Load back on the trailer and return home somewhat dejected with some further investigations to do.

I ran a compression leak down test. This is basically where you add compressed air to the cylinder with the piston at top dead centre on the compression stroke (so all the valves should be closed) and measure how quickly it leaks away. Around 10% would be normal on a new build and you want consistency across all cylinders. On cylinder 1,2, and 4 I had about 10%. On cylinder 3 I had 60%!

The clever bit about a leak down test is that you can tell what kind of problem you have by where the air is coming out. In my case it was rushing out of the throttle body, telling me I had an inlet valve stuck open. This could be a number of things so time to whip the head off.

Head off. Firstly, I obviously got a bad batch of valve stem oil seals as most of them are leaking! Pistons are coated although cleaned up nicely.

Looking at the head without the cams in and the problem is immediately obvious. One of the lifters on the inlet on cyl 3 is sitting high so with the cams torqued down its holding that valve open at all times. That'll do it!

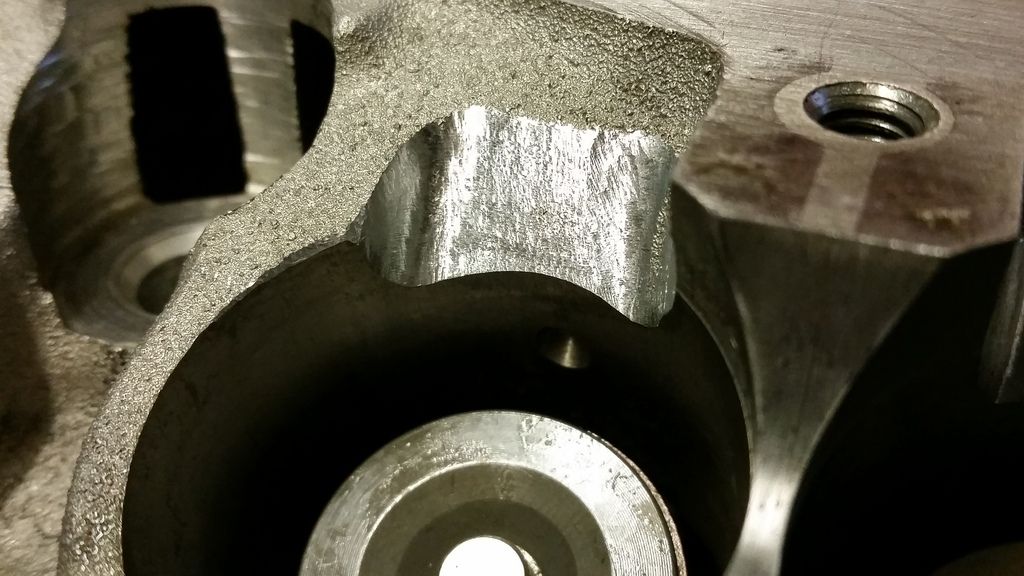

Popped valve out and found this cheeky little blighter:

The valve spring cap has cracks all around it and this has let the valve slip off the collets but somehow had not come all the way off. Damn lucky as if it had completely failed, the valve would have dropped into the piston and pretty much destroyed the engine.

What caused this? Unknown although I suspect the vibration caused by the play in the VVC cams may have had something to do with it. Or maybe it was just bad luck?

Only thing for it is to replace all the caps with uprated steel caps to stop this happening again. Since I'm really not happy with the rattly VVC mechanisms, I'll also replace the variable valve system with a solid cam conversion kit supplied by Piper. Since I'm doing all that I'll replace the valve springs and have a look at upgrading the valves too.

Watch this space!

Got the Emerald installed with the supplied adapter loom for plug and play (although they forgot to install the boost control solenoid wiring so it had to go back) . They also supplied a 3 bar MAP sensor and a boost control solenoid. The first mapping will be at actuator pressure (about 8psi) so the solenoid is not doing anything at the moment. After run in I'll map for full power at around 16psi.

Filled up with Millers running in oil and coolant and she's ready to go. Disable injectors and ignition and turn over on the key to check it turns over and to get oil pressure. All fine so far. I'm getting nervous. I've never done this before. Maybe I should wait to get a couple of buddies round to act as extra pairs of eyes during this delicate time. I man up, plug everything back in, and turn the key.

BINGO! Fired up instantly!

A few tweaks of the Emerald to lower the Idle and then my eyes are trying to look at a million things at once! You really want minimal running at idle on a new build. The sooner you can get the engine under load and start bedding the rings in the better. So I checked for fuel, oil and coolant leaks and checked all temps and pressures were fine. Oil was struggling to get above 60 degrees C and it was clear the "thermostatic" oil cooler setup was over cooling (or the sensor was faulty). I had a couple of small coolant leaks that were sorted by nipping up clamps but other than that everything was fine.

And little vid of it running:

http://www.youtube.com/watch?v=O-zvICWkZ24

My initial reaction was "Jesus that top end is noisy". I assumed it was the VVC mechanisms as they are notoriously rattly and I've never heard a quiet setup - This is particularly bad though. That said, they hardly ever fail completely so my intention was to crack on with mapping and see how it goes. This, it turns out, was a mistake...

Rattling aside, I think it sounds great. The dump valve is a lot louder than I expected given its a recirculating system, but I kinda like it.

Time for mapping...

Booked in to see HT Racing who are based at Brands Hatch and had it trailered down there. Things were going well... At first...

A little vid of one of the runs:

http://www.youtube.com/watch?v=vGEZjrXCSKk

Then it all went a bit wrong...

We were almost done but then for no reason she developed a misfire at idle and low rpm. Lost compression in cylinder 3.

F#&k

Ok not the end of the world - might just be a sticky lifter. Definitely mechanical though so obviously I'm thinking "what have I done wrong?"!

Load back on the trailer and return home somewhat dejected with some further investigations to do.

I ran a compression leak down test. This is basically where you add compressed air to the cylinder with the piston at top dead centre on the compression stroke (so all the valves should be closed) and measure how quickly it leaks away. Around 10% would be normal on a new build and you want consistency across all cylinders. On cylinder 1,2, and 4 I had about 10%. On cylinder 3 I had 60%!

The clever bit about a leak down test is that you can tell what kind of problem you have by where the air is coming out. In my case it was rushing out of the throttle body, telling me I had an inlet valve stuck open. This could be a number of things so time to whip the head off.

Head off. Firstly, I obviously got a bad batch of valve stem oil seals as most of them are leaking! Pistons are coated although cleaned up nicely.

Looking at the head without the cams in and the problem is immediately obvious. One of the lifters on the inlet on cyl 3 is sitting high so with the cams torqued down its holding that valve open at all times. That'll do it!

Popped valve out and found this cheeky little blighter:

The valve spring cap has cracks all around it and this has let the valve slip off the collets but somehow had not come all the way off. Damn lucky as if it had completely failed, the valve would have dropped into the piston and pretty much destroyed the engine.

What caused this? Unknown although I suspect the vibration caused by the play in the VVC cams may have had something to do with it. Or maybe it was just bad luck?

Only thing for it is to replace all the caps with uprated steel caps to stop this happening again. Since I'm really not happy with the rattly VVC mechanisms, I'll also replace the variable valve system with a solid cam conversion kit supplied by Piper. Since I'm doing all that I'll replace the valve springs and have a look at upgrading the valves too.

Watch this space!

Edited by Stuballs on Friday 11th December 06:53

Edited by Stuballs on Monday 22 January 13:07

Very lucky, here is what happened when our old Fiat 500 dropped a valve.

http://retrorides.proboards.com/thread/105433

http://retrorides.proboards.com/thread/105433

J4CKO said:

Very lucky, here is what happened when our old Fiat 500 dropped a valve.

http://retrorides.proboards.com/thread/105433

Jeez what a mess! What happened to it. http://retrorides.proboards.com/thread/105433

I'd have been tempted to whack a hayabusa engine in it. Maybe even turbo if for maximum giggles. Might have just found my next project...

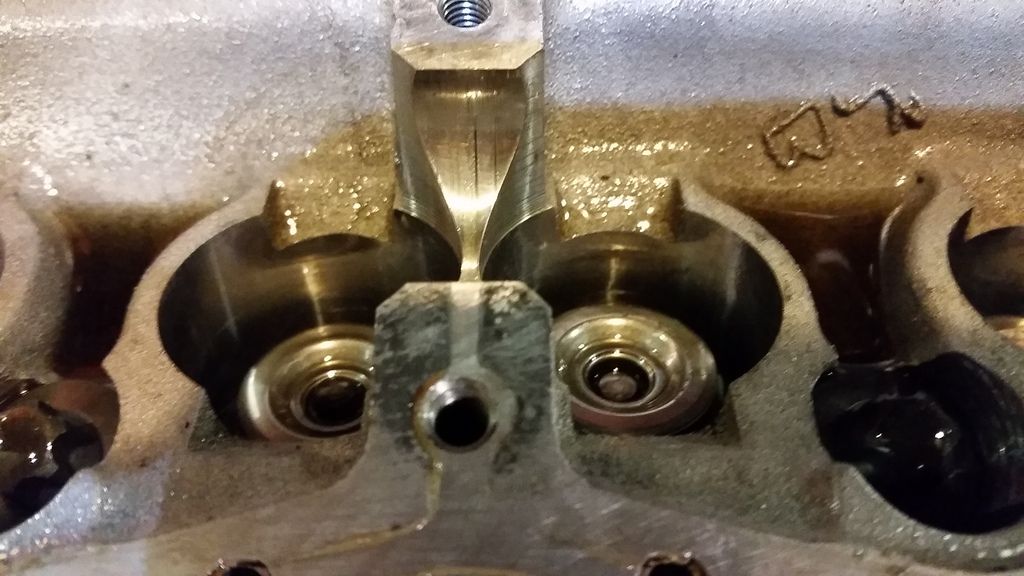

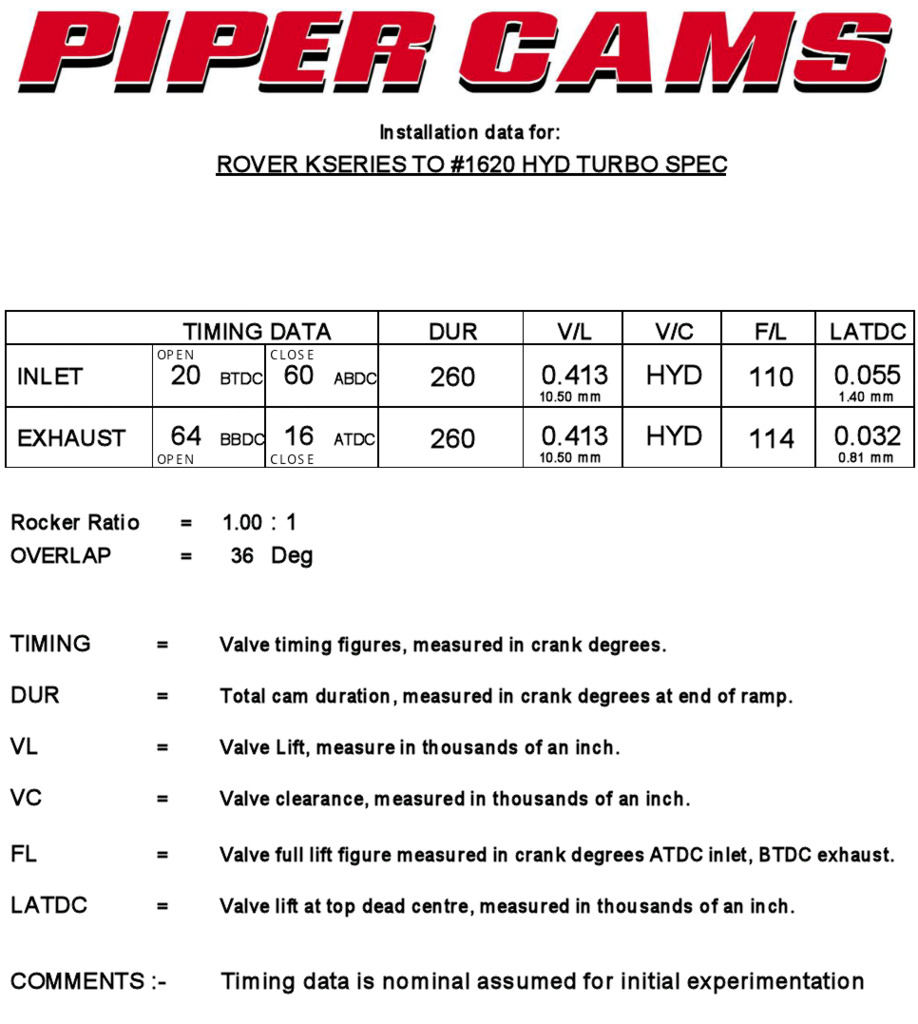

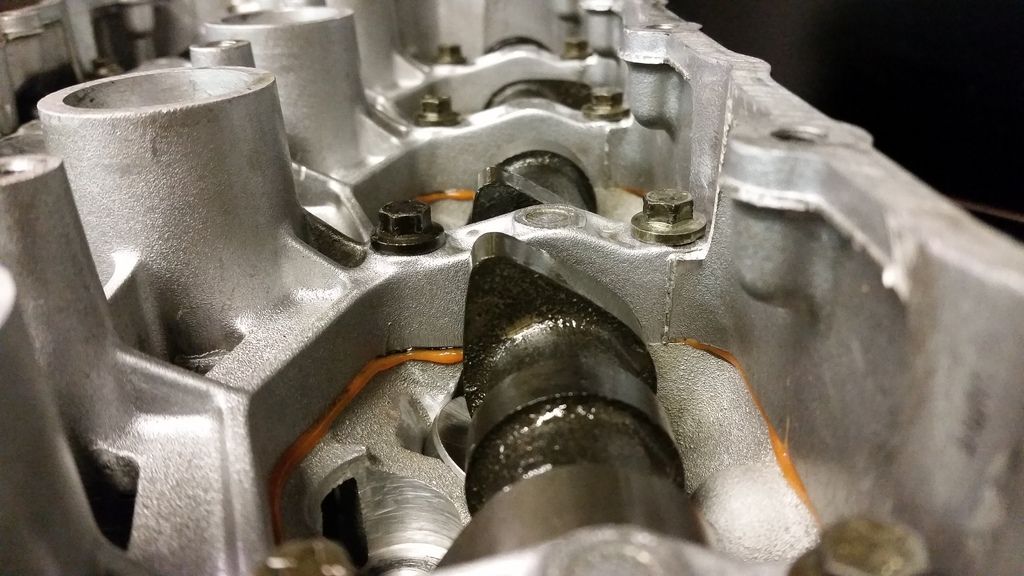

Piper sorted me out with some custom ground cams. They have fairly conservative duration given the forced induction with small turbo I'm running, but lift is a bit higher than stock. To compare against the VVC - they had 9.5mm lift with duration on the inlet ranging from 220 to 295 degrees.

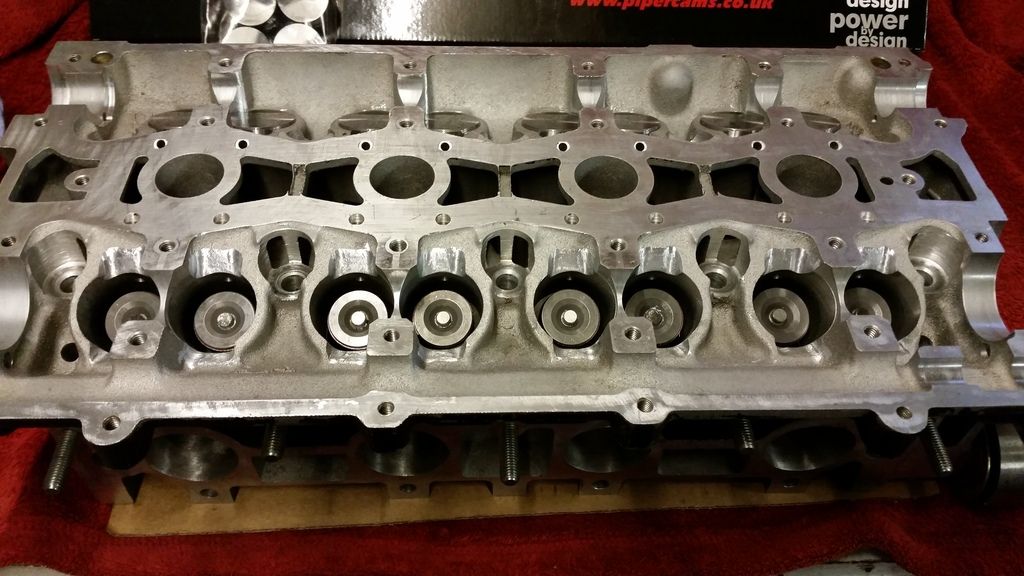

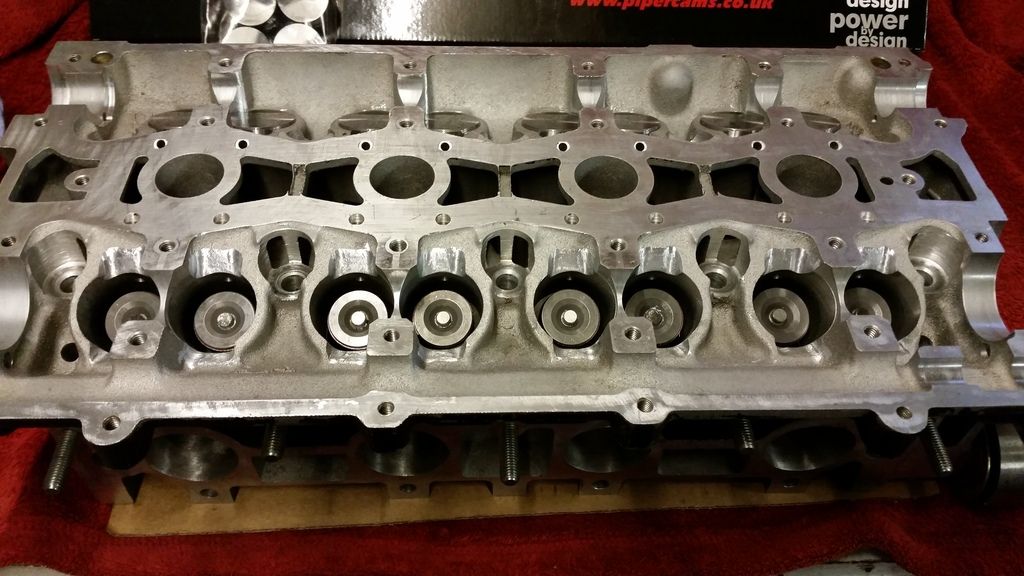

Note the larger journals at each end of the inlet cam. This is why piper cams are the only option if ditching the split inlet cams the VVC system uses.

Also, the lack of position sensor pickup on the inlet means I have to revert to batch fuel injection. Shouldn't be a problem.

Spec:

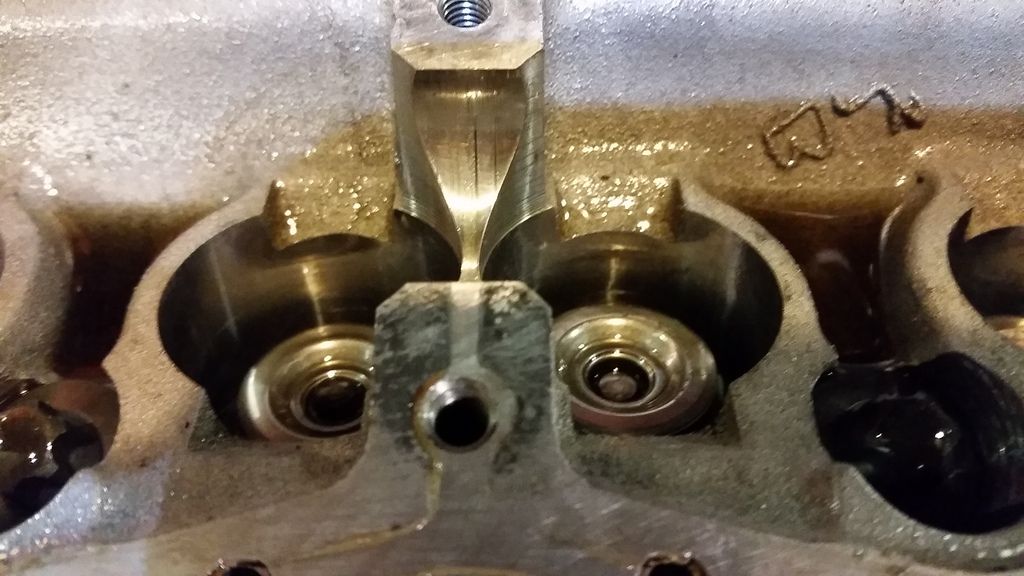

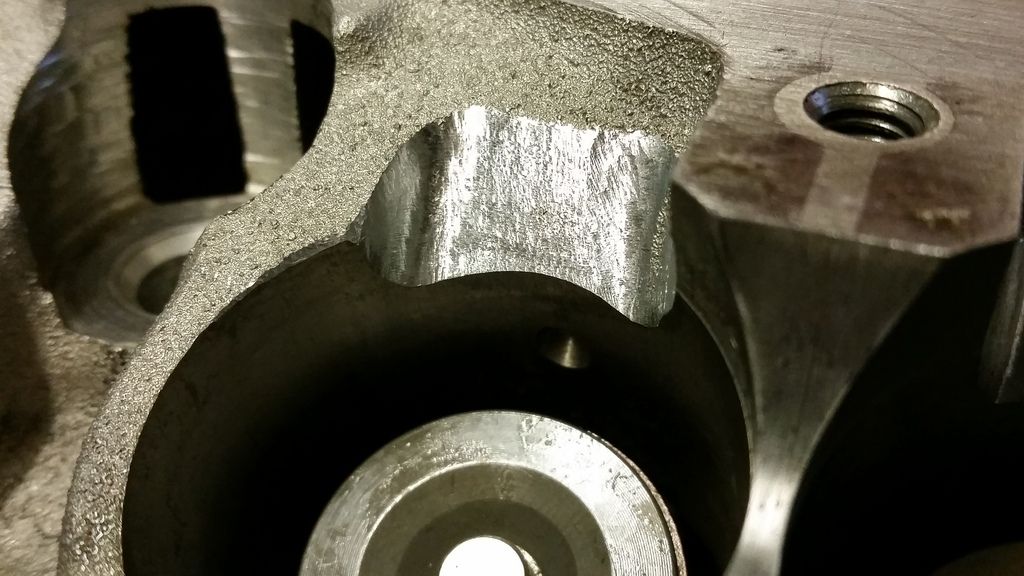

The extra lift and width of the cam lobes meant I had to fettle the head to provide adequate clearance!

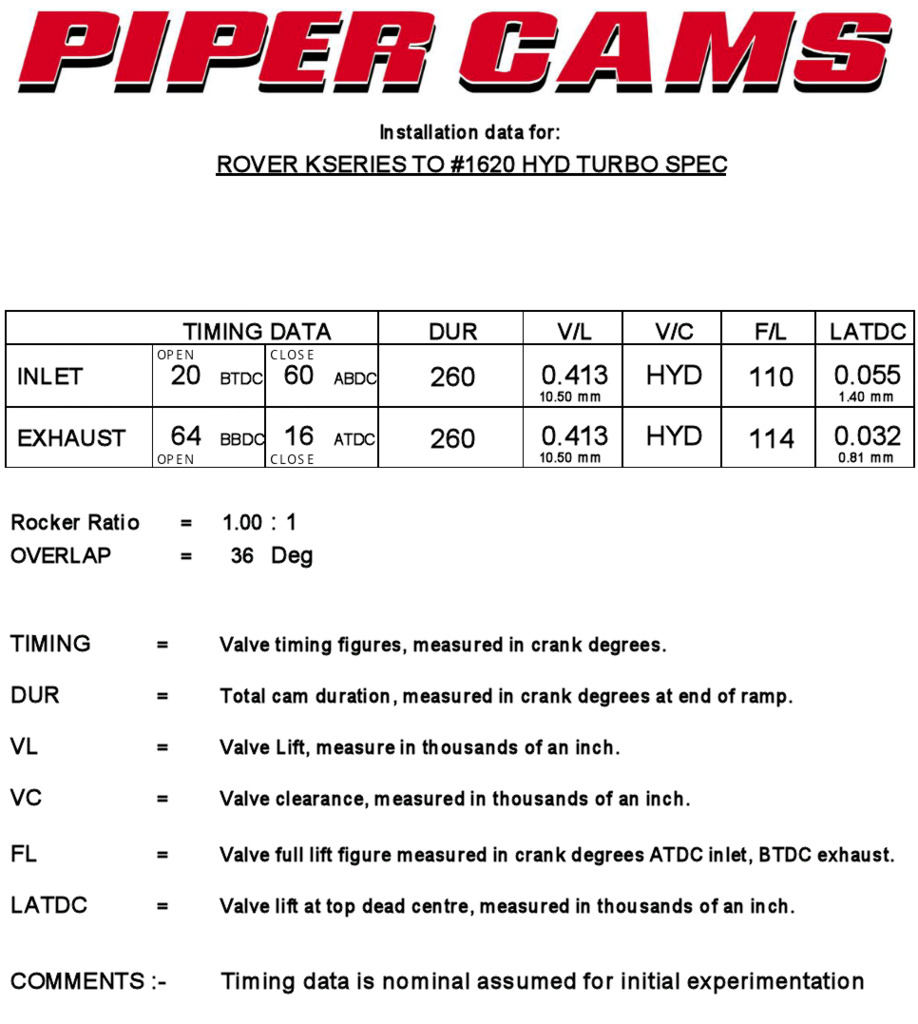

Uprated hydraulic followers from Piper going in.

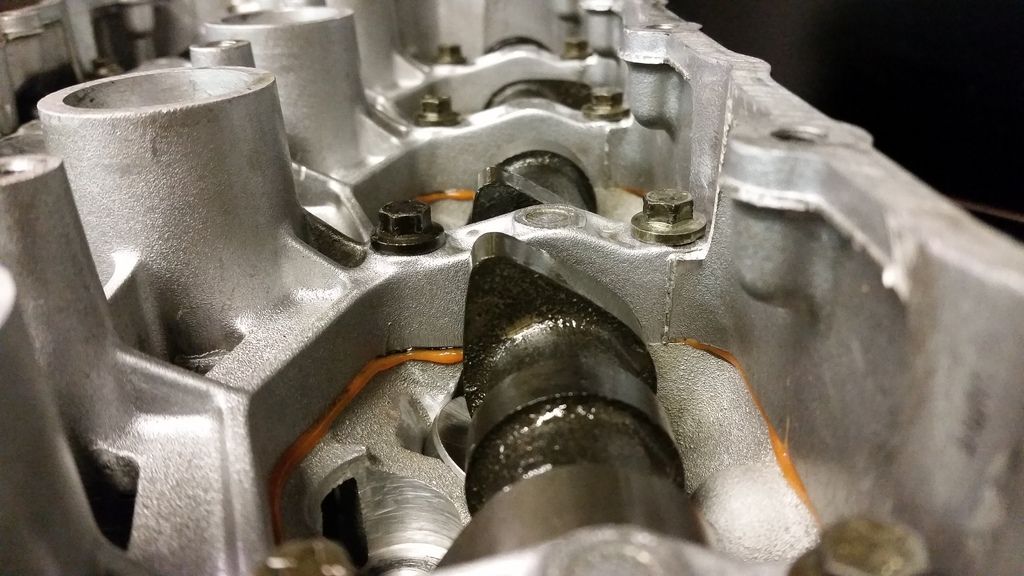

Cams and VVC blanking kit going in. The blanking kit is just three machined plates.

Next job is to get these timed in and finish putting her back together.

Note the larger journals at each end of the inlet cam. This is why piper cams are the only option if ditching the split inlet cams the VVC system uses.

Also, the lack of position sensor pickup on the inlet means I have to revert to batch fuel injection. Shouldn't be a problem.

Spec:

The extra lift and width of the cam lobes meant I had to fettle the head to provide adequate clearance!

Uprated hydraulic followers from Piper going in.

Cams and VVC blanking kit going in. The blanking kit is just three machined plates.

Next job is to get these timed in and finish putting her back together.

Edited by Stuballs on Monday 22 January 13:09

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff