Rover 200 BRM - 1.8 K-Series turbo project

Discussion

Evoluzione said:

Did you log intake temps, if so what were they?

Not logged as such but have a video with torque app overlay showing intake temps on a power run. Starts off at 40-odd degrees dropping to 17 degrees at full power.https://youtu.be/ePW-UKV95sc

(ignore the afr - mine wasn't plugged in at this point).

Ive said:

don't use a shim to reduce CR or shorter rods. it will make your knock problems even worst.

Been there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

Thanks MarkoBeen there, done that. on a Rover K, albeit with a Rotrex C30-94. Removing a 1mm shim allowed for increased timing and resulted in more power.

Water methanol works really well on a FI K. Just juse direct port injection with 4 jets on top of the lower part of the VVC plenum just behind the injectors.

I was running close to 15PSI at the rev limiter with power rising to 7000 rpm and then staying flat to 7500.

No dyno, just a virtual dyno runs. I got 240HP at the wheels.

Stu, do you have a 2.5" or bigger exhaust system all the way to the back? Going from 2.25" to 2.5" really freed up the top of the rpm range. Cams were similar to yours, Newman ph2.

I'd also say you run into a restriction from back pressure.

For 7PSI, this is a nice result and about what to expect.

Good idea for now to build trust in this iteration at that level and then optimize once you know more about the system.

I think I remember you saying direct port injection is best as the runners on the K-series have quite a tight bend and the vapour condenses on the inner surface. Have I remembered correctly?

I have a 3" downpipe then after the flexi under the sump it drops to 2.5 all the way back (via a sports cat). I guess my turbo is the restriction. It's a GT2560R. I ported the turbine housing and opened up the internal wastegate aperture to eliminate boost creep at high rpm (which worked) and present less of a restriction. There's only do much you can do though.

Took the BRM to Pride of Longbridge yesterday. It's a show for all cars built at the Longbridge factory in Birmingham and held on the anniversary of MG Rover's closure in 2005. There's always a nice turnout from the local community who were obviously massively affected by the closure at the time.

Had a great day. Car was faultless and it was fun to show it off a bit and talk to people about the build. Amazing to see 21 BRMs lined up and some great cars on display.

Had a great day. Car was faultless and it was fun to show it off a bit and talk to people about the build. Amazing to see 21 BRMs lined up and some great cars on display.

Edited by Stuballs on Monday 7th August 09:06

Edited by Stuballs on Monday 7th August 09:13

BricktopST205 said:

Wow. It is quite amazing how many cars and how big the fan base is. I have been a member of several car clubs and you always see the numbers drop off after 10-15 years due to the less number of cars on the road but that is something else

Yeah it's pretty special. Real mix of cars too. British Leyland, Austin, MG, Mini, as well as modern stuff. Huge metro turnout. Special groups for the later z-cars just because they had a special type of monogram paint. ZRs, ZSs, ZTs. The new MG3 and MG6. We had a few of the awesome and hugely ill-advised SV-Rs including Rowan Atkinson's old car. Rusty sheds on their last legs and loved low-mileage restored minters side-by-side. All once made on the same site by one community.

Fans tend to be fairly die-hard.

BRM has been running well and pretty much just been enjoying it and going to car shows, meets, etc. Engine's covered around 3,000 miles now and hasn't blown up yet! Still sounds like a diesel with the noisy head but I'll be changing that when I take her off the road for winter.

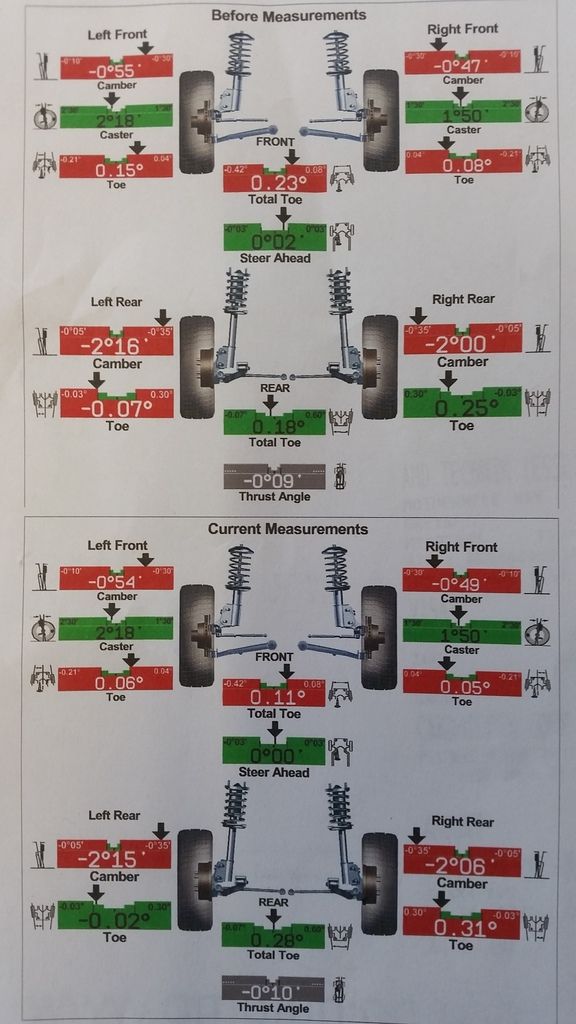

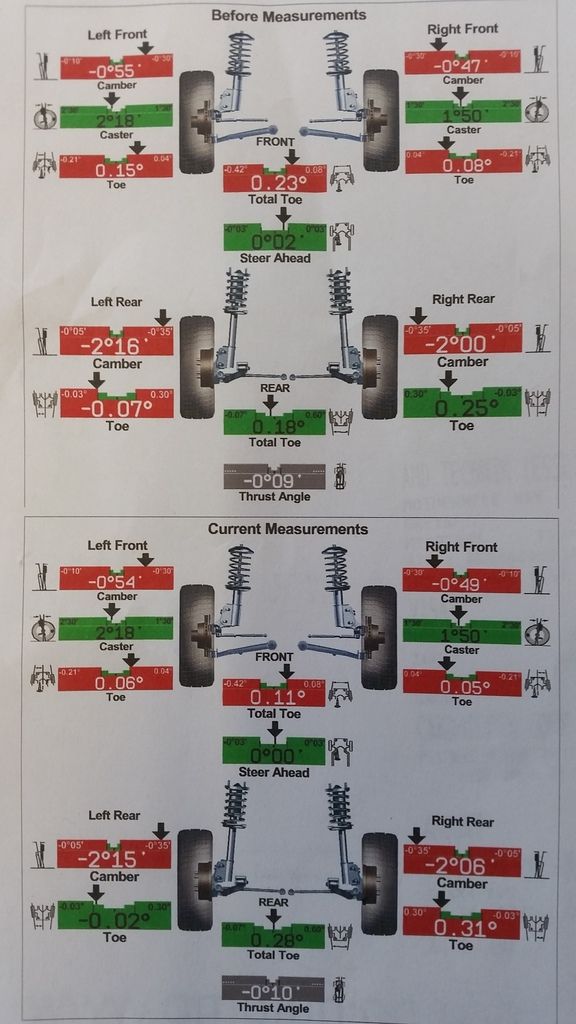

I'm at Tunerfest at Brands Hatch tomorrow and I thought I'd try out a public track session. It's only 15 minutes but it'll give me a chance to open up the taps a bit. Knowing I had this coming up, I booked into AMD Essex for an alignment check. Results:

Nothing especially concerning. Being solid rear axle you can only adjust the front toe,which they tweaked. The front camber being a little more negative than spec is due to being lowered but actually a desired outcome so not studied about that.

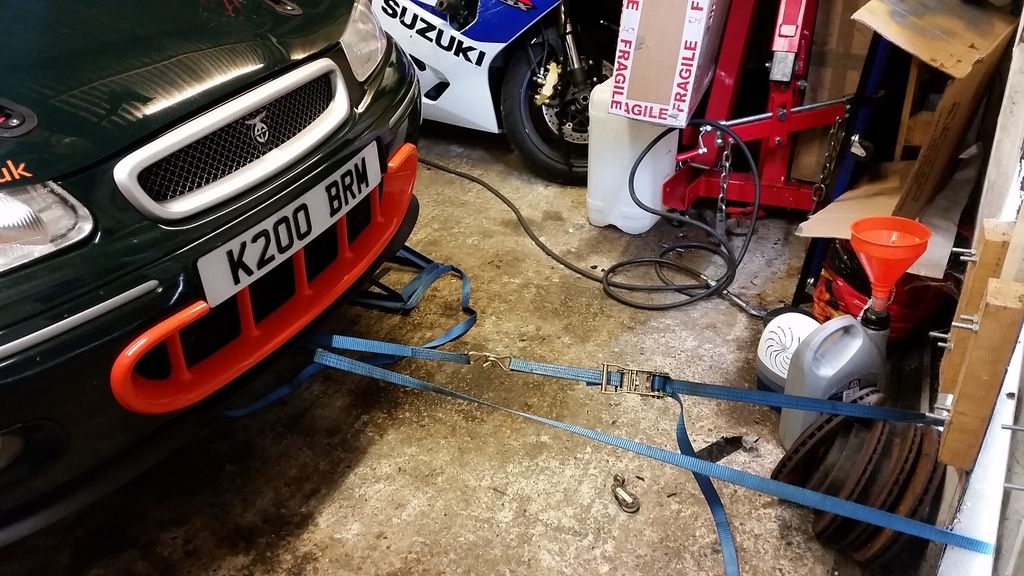

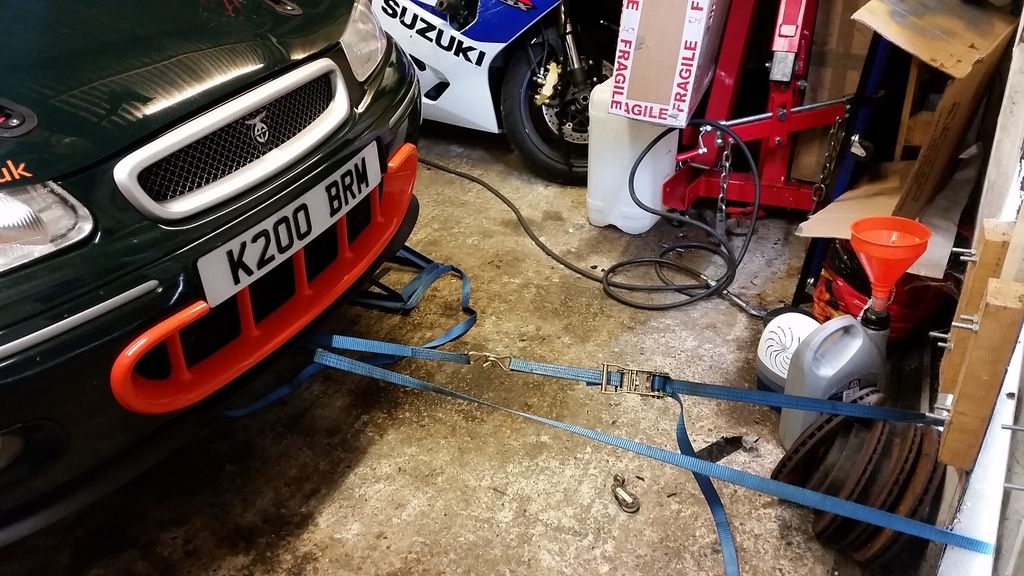

Rear camber is way out of spec which is deliberate - I have camber plates. However, the rear being slightly toe-out on the left, and too far toe-in on the right, is a bit of a pain because it's not adjustable as such. That said, I know the rear beam mounts to brackets which themselves mount to the chassis, and the mounting holes in those brackets allow a little movement. Seeing as I had some time today, I thought I'd try lining it up.

I took some base measurements using fishing line and some axle stands. I just measured how far away the line was from the sill at a point near the front of the car. Sure enough, the line was 10mm closer to the sill on the right hand side (indicating that wheel is toeing-in more than the left). I slackened off the brackets (thankfully you can get to them without removing the rear beam) then hooked up a series of ratchet straps to pull everything in the right direction before re-tightening! It's proper ghetto but seemed to do the trick. I could see the brackets had moved and I kept measuring throughout. When I was done and had dropped the car back down and let it settle, the lines were exactly the same distance from the sill on both sides. I'll have the alignment checked again at some point to see what effect it had, and maybe dial in very slight toe out on the front which the brm manual specifies.

(Axle stands were in use - you just can't see them!)

Catching some rays with my daily scooby (love that car!)

If you see me at Brands feel free to come and say hello.

I'm at Tunerfest at Brands Hatch tomorrow and I thought I'd try out a public track session. It's only 15 minutes but it'll give me a chance to open up the taps a bit. Knowing I had this coming up, I booked into AMD Essex for an alignment check. Results:

Nothing especially concerning. Being solid rear axle you can only adjust the front toe,which they tweaked. The front camber being a little more negative than spec is due to being lowered but actually a desired outcome so not studied about that.

Rear camber is way out of spec which is deliberate - I have camber plates. However, the rear being slightly toe-out on the left, and too far toe-in on the right, is a bit of a pain because it's not adjustable as such. That said, I know the rear beam mounts to brackets which themselves mount to the chassis, and the mounting holes in those brackets allow a little movement. Seeing as I had some time today, I thought I'd try lining it up.

I took some base measurements using fishing line and some axle stands. I just measured how far away the line was from the sill at a point near the front of the car. Sure enough, the line was 10mm closer to the sill on the right hand side (indicating that wheel is toeing-in more than the left). I slackened off the brackets (thankfully you can get to them without removing the rear beam) then hooked up a series of ratchet straps to pull everything in the right direction before re-tightening! It's proper ghetto but seemed to do the trick. I could see the brackets had moved and I kept measuring throughout. When I was done and had dropped the car back down and let it settle, the lines were exactly the same distance from the sill on both sides. I'll have the alignment checked again at some point to see what effect it had, and maybe dial in very slight toe out on the front which the brm manual specifies.

(Axle stands were in use - you just can't see them!)

Catching some rays with my daily scooby (love that car!)

If you see me at Brands feel free to come and say hello.

Edited by Stuballs on Monday 7th August 09:14

Had a blast at Tunerfest yesterday. Took the BRM around the track during the public track time in the morning. Thought it would be fun to push it a bit and see how it faired under stress.

Stock suspension (albeit mg zr struts with X-power springs) was woefully inadequate and I had a bit of a moment on paddock Hill bend when I didn't even feel I was pushing it. So coilovers are defo in the future. Also very scary moment when the guy in the mx-5 behind me didn't notice everyone bunching up on the sighting lap and nearly rear-ended me!

Oil temps got a bit silly. 116 degrees peak. If I was doing more track timeI would refit the oil cooler (which I removed because it was over cooling oil on the road). As it is, I think I'll fit an oil/water laminova which will also help warm the oil up from cold.

Cheeky video with a posh data overlay:

https://youtu.be/fm1eZc_S4Ng

Stock suspension (albeit mg zr struts with X-power springs) was woefully inadequate and I had a bit of a moment on paddock Hill bend when I didn't even feel I was pushing it. So coilovers are defo in the future. Also very scary moment when the guy in the mx-5 behind me didn't notice everyone bunching up on the sighting lap and nearly rear-ended me!

Oil temps got a bit silly. 116 degrees peak. If I was doing more track timeI would refit the oil cooler (which I removed because it was over cooling oil on the road). As it is, I think I'll fit an oil/water laminova which will also help warm the oil up from cold.

Cheeky video with a posh data overlay:

https://youtu.be/fm1eZc_S4Ng

Edited by Stuballs on Monday 26th June 10:06

Edited by Stuballs on Monday 7th August 09:10

Guys sorry about all the broken images on here. Stitched up by the photobucket ransom demand as many have been recently! Working on a solution!

In the meantime, not much to report - I was planning some coilovers until the guy I have booked in to do my respray said he could fit me in end of September. So all of my attention and funds are going into that for now. I have a few ideas for subtly tweaking the styling but will be mostly staying true to the BRM design.

Once that's done it'll pretty much be time to take her off the road over winter and will fit the new head. Considering running shorter rods for less compression and possibly milder cams. I noticed I have quite a lot of blowby so that'd be a good chance to have everything checked over (cylinders round, etc. Chassis-wise I'm going to fit an MG ZR steering rack (not a simple swap) and KW coilovers.

More to follow...

In the meantime, not much to report - I was planning some coilovers until the guy I have booked in to do my respray said he could fit me in end of September. So all of my attention and funds are going into that for now. I have a few ideas for subtly tweaking the styling but will be mostly staying true to the BRM design.

Once that's done it'll pretty much be time to take her off the road over winter and will fit the new head. Considering running shorter rods for less compression and possibly milder cams. I noticed I have quite a lot of blowby so that'd be a good chance to have everything checked over (cylinders round, etc. Chassis-wise I'm going to fit an MG ZR steering rack (not a simple swap) and KW coilovers.

More to follow...

gweaver said:

I've read that the newer rack doesn't rattle like the older one sometimes did - that was certainly something that was noticeable with my 200vi on very rough roads. I thought the steering feel on the 200 was excellent and I don't recall the ZR being any better, but the larger tyres on the ZR probably didn't help.

Apparently the ZR rack is 2.8 turns lock to lock, whereas the 200 rack is 3 turns, but that might reflect reduced lock (so the larger wheels don't rub) rather than a quicker rack. Irrespective of those details, I'm sure either rack gives more feedback than any modern EPAS and most contemporary hydraulic systems too.

I'll report back once I've switched over. The zr rack is supposed to be quicker AND at the same time have different stops to restrict the amount of lock to stop tyres rubbing the inner arches. Internet hearsay mostly though. If that was the case, I can't imagine the rack being that much quicker, if at all. Generally, it seems to be the case that you either get good steering or sloppy steering with ZRs. But that might not be the rack and could be any component in the steering or suspension. They're getting on a bit now and, let's be fair, they were made by Rover. I'll take my rack from a donor car I'll strip myself after driving it and making sure it's nice and tight working fine.Apparently the ZR rack is 2.8 turns lock to lock, whereas the 200 rack is 3 turns, but that might reflect reduced lock (so the larger wheels don't rub) rather than a quicker rack. Irrespective of those details, I'm sure either rack gives more feedback than any modern EPAS and most contemporary hydraulic systems too.

Ive said:

If you just fit shorter rods, you reduce squish/quench. I found my SC Rover K engine to be less knock sensitive AFTER removing a 1mm shim despite the now increased compression ratio.

I did consider this. With my rod piston combo as it is, my squish clearance is too high for squish to be effective and I actually think that's a source of the epic detonation. To be honest Marko, I'm so det limited I can't imagine a setup that eliminates squish completely could be worse. With 2mm shorter rods and the head gasket I want to run, clearance will be more like 4mm - I.e. Zero squish.The stock rover k-series turbo is not a "detty" engine, and they have 1.5mm shorter rods and no squish. I've basically managed to build a forged engine that's less reliable that the stocker!

My only reservation about the shorter rods, is the increased side load on the thin liners. We'll just see what happens!

Quick little update. Took the old girl up to Santa Pod on Saturday. Whilst I've had a few issues with pressurising the coolant, I thought I'd chance a gentle run.

Video:

https://youtu.be/PUE4D1QAtWM

Ran a 14.7 at 96mph. Launched fairly easy. Never launched this car before and never been on a drag strip myself! It was serious fun I wanted to do more but didn't want to push my luck.

On the drive home I lost a fair bit of coolant out the expansion cap. So it's time to ditch this high compression setup and fit shorter rods to lower the compression. That can wait until after the respray which is starting next week!

Plan for the rebuild is taking shape. I'm actually considering a slightly bigger turbo at the same time to reduce back pressure - gt2871r. I have a low mileage vvc head which I'll port match and fettle slightly. It comes with the vvc mechs and cams so I'm considering going back to the vvc setup, at least use them for running in the bottom end before I switch to new solid cams. Spec still to be decided. I may need a clutch upgrade. And might fit a lightweight flywheel. I'll probably have everything balanced again too.

For now I'm just stripping done bits off the car ready for the respray.

Video:

https://youtu.be/PUE4D1QAtWM

Ran a 14.7 at 96mph. Launched fairly easy. Never launched this car before and never been on a drag strip myself! It was serious fun I wanted to do more but didn't want to push my luck.

On the drive home I lost a fair bit of coolant out the expansion cap. So it's time to ditch this high compression setup and fit shorter rods to lower the compression. That can wait until after the respray which is starting next week!

Plan for the rebuild is taking shape. I'm actually considering a slightly bigger turbo at the same time to reduce back pressure - gt2871r. I have a low mileage vvc head which I'll port match and fettle slightly. It comes with the vvc mechs and cams so I'm considering going back to the vvc setup, at least use them for running in the bottom end before I switch to new solid cams. Spec still to be decided. I may need a clutch upgrade. And might fit a lightweight flywheel. I'll probably have everything balanced again too.

For now I'm just stripping done bits off the car ready for the respray.

Thanks for the replies guys.

The only issue I'm actually having is pressurising the coolant. It's not actually overheating. It's getting worse so I'm working on the assumption that the high compression is giving me excessively high cylinder pressures - maybe that's lifting the head and/or killing the gasket.

227bhp thanks for the tip re flywheel/clutch combo. What you say about squish is very interesting. A lot of my own reading led me to the same conclusions - squish is nice to have on a turbo for off-boost performance and emissions but it's not essential.

Marko I've never run a shim. As Lee says my issue is primarily the high static compression ratio from these pistons, then a corresponding high dynamic cr from mild cams, then apparently compounded by relatively high back pressures. Added to that is that my "squish" clearance is too wide to actually squish and just causes det. My setup just doesn't work.

TB thanks for the reference I'll check it out. Cooling has never been an issue on my setup I run a pressure release thermostat and a massive copper radiator. I also run a thermal gasket on the exhaust side to prevent heat transfer back into the head. Even on track when oil shot up to 116 degrees, coolant only prodded 95. On the rollers it sat at 92, same story on the road however I drive it - always around 90. It's one thing I got right!

I knew I'd likely find myself in this situation when I decided to use these pistons I'd ended up with. It's made it through the year. I've been on the track, done a quarter mile at Santa Pod, been to loads of shows, and just really enjoyed driving it. It's going in for the respray next week. Once that's done I'll crack on over winter with fixing all the things I'm not happy with.

The only issue I'm actually having is pressurising the coolant. It's not actually overheating. It's getting worse so I'm working on the assumption that the high compression is giving me excessively high cylinder pressures - maybe that's lifting the head and/or killing the gasket.

227bhp thanks for the tip re flywheel/clutch combo. What you say about squish is very interesting. A lot of my own reading led me to the same conclusions - squish is nice to have on a turbo for off-boost performance and emissions but it's not essential.

Marko I've never run a shim. As Lee says my issue is primarily the high static compression ratio from these pistons, then a corresponding high dynamic cr from mild cams, then apparently compounded by relatively high back pressures. Added to that is that my "squish" clearance is too wide to actually squish and just causes det. My setup just doesn't work.

TB thanks for the reference I'll check it out. Cooling has never been an issue on my setup I run a pressure release thermostat and a massive copper radiator. I also run a thermal gasket on the exhaust side to prevent heat transfer back into the head. Even on track when oil shot up to 116 degrees, coolant only prodded 95. On the rollers it sat at 92, same story on the road however I drive it - always around 90. It's one thing I got right!

I knew I'd likely find myself in this situation when I decided to use these pistons I'd ended up with. It's made it through the year. I've been on the track, done a quarter mile at Santa Pod, been to loads of shows, and just really enjoyed driving it. It's going in for the respray next week. Once that's done I'll crack on over winter with fixing all the things I'm not happy with.

Christmas update!

Picked the car up from paint this week. Merry Christmas to me!!

The guy I went to specialises in restoring classic cars. He's a one-man-band and very familiar with rusty cars. Good thing as my BRM had it's fair share of rot (and dodgy MOT patch repair as you'll see). Not as bad as some but still needed dealing with appropriately. He took most of it to bare metal. Fitted new wings. Cut the rust out the rear arches and welded in new metal. Fabricated new sills on both sides front to back. shot blasted the roof drains and welded new metal in there.

I wanted to modernise the rear end as it's the only pat of the BRM I was never really a fan of. So went with a facelift Zr rear bumper. Whilst a direct fit, it has a number plate recess which needed filling. I taught myself plastic welding (which is easier than it sounds and basically involves melting plastic with a soldering iron) and made the best start of it I could so the paint man has as little to do as possible to make it nice. Very pleased with the outcome. You'll see I'm also running a ZR rear spoiler (which never would have looked right with the little Rover 200 bumper) and I'll also be fitting ZR facelift side skirts to match the bumper (paint man still has one of them - dropped it during final polishing!

All-in-all I'm extremely happy. I'll get some better pictures of the final product once I've got it all together. In the meantime:

Next: I need to fit my shorter conrods and new head so I'll be popping the engine out soon.

Picked the car up from paint this week. Merry Christmas to me!!

The guy I went to specialises in restoring classic cars. He's a one-man-band and very familiar with rusty cars. Good thing as my BRM had it's fair share of rot (and dodgy MOT patch repair as you'll see). Not as bad as some but still needed dealing with appropriately. He took most of it to bare metal. Fitted new wings. Cut the rust out the rear arches and welded in new metal. Fabricated new sills on both sides front to back. shot blasted the roof drains and welded new metal in there.

I wanted to modernise the rear end as it's the only pat of the BRM I was never really a fan of. So went with a facelift Zr rear bumper. Whilst a direct fit, it has a number plate recess which needed filling. I taught myself plastic welding (which is easier than it sounds and basically involves melting plastic with a soldering iron) and made the best start of it I could so the paint man has as little to do as possible to make it nice. Very pleased with the outcome. You'll see I'm also running a ZR rear spoiler (which never would have looked right with the little Rover 200 bumper) and I'll also be fitting ZR facelift side skirts to match the bumper (paint man still has one of them - dropped it during final polishing!

All-in-all I'm extremely happy. I'll get some better pictures of the final product once I've got it all together. In the meantime:

Next: I need to fit my shorter conrods and new head so I'll be popping the engine out soon.

Thanks guys. Can't wait to get it all back together and sitting right. Paint man did a cracking job. He had the car for 10 weeks working on its exclusively and I was expecting a much larger bill than I got. It hasn't been baked so I have to be super careful with it for a few weeks! Considering having it ceramic coated before exposing it to the elements.

Yeah the rust repairs were horrific but that's fairly typical for cheap MOT repairs I guess. As the customer all you see when you get it back is splodge of seam sealer!

Yeah the rust repairs were horrific but that's fairly typical for cheap MOT repairs I guess. As the customer all you see when you get it back is splodge of seam sealer!

mk2 24v said:

Where abouts did the paintwork on it? As I need mine respraying at some point in the new year

Was a chap near Staplehurst in Kent. Classic Workshop. Has a long old waiting list now something like several months. Before I remove this engine to fit my shorter con rods, I thought I'd do a leak down test so I had some data to support any visual issues identified during the strip down.

So the engine's done over 3k miles now and my only issues have been excessive blow-by-blow and pressurising the coolant on boost.

The test results:

1: 14%

2: 14%

3: 11 %

4: 14 %

Not great figures for a fairly new build but rather than hinting at a serious problem with one cylinder, suggests more of a general lack of ring sealing. Either I gapped my rings too wide (I knew they were on the large side at the time) or the rings just never bedded in properly. No sign of any air escaping the inlet, exhaust, or coolant system - its all coming out the crankcase. This doesn't explain why I'm pressurising the coolant. My main suspect for that now is the inlet gasket. I doubt I'm lifting the head at 7psi, even with my high cr.

Anyway thought I'd share the result. Now to pull the engine and see what's what...

So the engine's done over 3k miles now and my only issues have been excessive blow-by-blow and pressurising the coolant on boost.

The test results:

1: 14%

2: 14%

3: 11 %

4: 14 %

Not great figures for a fairly new build but rather than hinting at a serious problem with one cylinder, suggests more of a general lack of ring sealing. Either I gapped my rings too wide (I knew they were on the large side at the time) or the rings just never bedded in properly. No sign of any air escaping the inlet, exhaust, or coolant system - its all coming out the crankcase. This doesn't explain why I'm pressurising the coolant. My main suspect for that now is the inlet gasket. I doubt I'm lifting the head at 7psi, even with my high cr.

Anyway thought I'd share the result. Now to pull the engine and see what's what...

227bhp said:

Are you going to do a normal compression test hot and cold before disassembly? Might be useful.

Agree it would have been useful and was going to but then couldn't find my compression tester. I figured since I'm completely rebuilding the engine and I had the leak down results I could do without. I'm going to replace the rings so I can gap a bit tighter anyway. Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff