Rover 200 BRM - 1.8 K-Series turbo project

Discussion

Stu,

the dipstick breather as you have implemented it will cause serious issues. Every time you accelerate some liquid oil will be pushed up that breather. I know this for sure as I used the very same breather on m SC K.

Others like RobC on SELOC have observed the same.

This dip stick breather configuration works well if you mount a small catch tank 20-30cm above the base of that breather. the catch tank is then vented from its top into your vent line. Mine was mounted with its top about as high as the bottom of the plenum. Every time it coughs up some oil, the catch tank will "catch" it and afterwards the oil will flow straight back into the oil pan. A small 500ml unit will do.

the dipstick breather as you have implemented it will cause serious issues. Every time you accelerate some liquid oil will be pushed up that breather. I know this for sure as I used the very same breather on m SC K.

Others like RobC on SELOC have observed the same.

This dip stick breather configuration works well if you mount a small catch tank 20-30cm above the base of that breather. the catch tank is then vented from its top into your vent line. Mine was mounted with its top about as high as the bottom of the plenum. Every time it coughs up some oil, the catch tank will "catch" it and afterwards the oil will flow straight back into the oil pan. A small 500ml unit will do.

Ive said:

Stu,

the dipstick breather as you have implemented it will cause serious issues. Every time you accelerate some liquid oil will be pushed up that breather. I know this for sure as I used the very same breather on m SC K.

Others like RobC on SELOC have observed the same.

This dip stick breather configuration works well if you mount a small catch tank 20-30cm above the base of that breather. the catch tank is then vented from its top into your vent line. Mine was mounted with its top about as high as the bottom of the plenum. Every time it coughs up some oil, the catch tank will "catch" it and afterwards the oil will flow straight back into the oil pan. A small 500ml unit will do.

Thanks for that mate. I did wonder if that would happen and had planned on blocking it off if it did - it's probably overkill anyway on my build. There's not really much room to play with under there but I do like the catch can idea. I'll have a look and see what's possible.the dipstick breather as you have implemented it will cause serious issues. Every time you accelerate some liquid oil will be pushed up that breather. I know this for sure as I used the very same breather on m SC K.

Others like RobC on SELOC have observed the same.

This dip stick breather configuration works well if you mount a small catch tank 20-30cm above the base of that breather. the catch tank is then vented from its top into your vent line. Mine was mounted with its top about as high as the bottom of the plenum. Every time it coughs up some oil, the catch tank will "catch" it and afterwards the oil will flow straight back into the oil pan. A small 500ml unit will do.

I needed that additional breather going past 0.8bar of boost.

And my crank seal is bolted in with 4x M2.5 screws.

The catch tank I used was the size of a Red bull can.

A simple container with a barbed inlet on the bottom and a barbed outlet on top filled with a stainless sponge will perfectly do.

As long as the container is 20-30cm above oil level and the oil can flow back, its location is not that relevant.

And my crank seal is bolted in with 4x M2.5 screws.

The catch tank I used was the size of a Red bull can.

A simple container with a barbed inlet on the bottom and a barbed outlet on top filled with a stainless sponge will perfectly do.

As long as the container is 20-30cm above oil level and the oil can flow back, its location is not that relevant.

Ive said:

I needed that additional breather going past 0.8bar of boost.

And my crank seal is bolted in with 4x M2.5 screws.

The catch tank I used was the size of a Red bull can.

A simple container with a barbed inlet on the bottom and a barbed outlet on top filled with a stainless sponge will perfectly do.

As long as the container is 20-30cm above oil level and the oil can flow back, its location is not that relevant.

Wow really? That good Intel! I'll have a proper look this weekend and see what I can work out... And my crank seal is bolted in with 4x M2.5 screws.

The catch tank I used was the size of a Red bull can.

A simple container with a barbed inlet on the bottom and a barbed outlet on top filled with a stainless sponge will perfectly do.

As long as the container is 20-30cm above oil level and the oil can flow back, its location is not that relevant.

She runs!!

Started first time. No leaks or funny noises. Top end is quite tappy but hoping that's just the hydraulic lifters needing to sort themselves out.

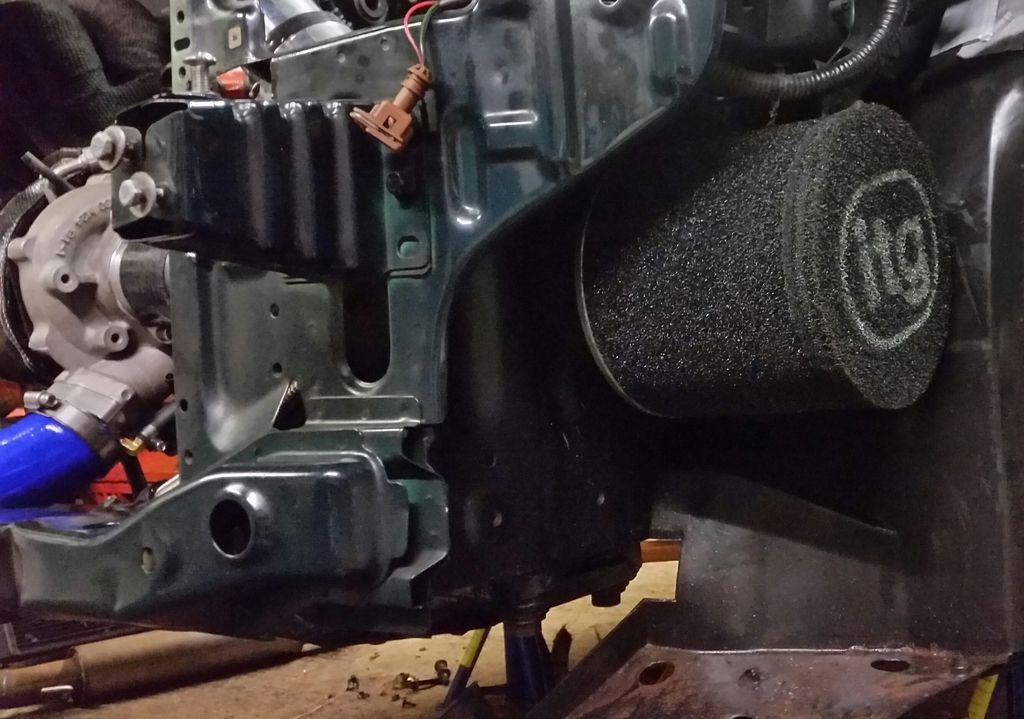

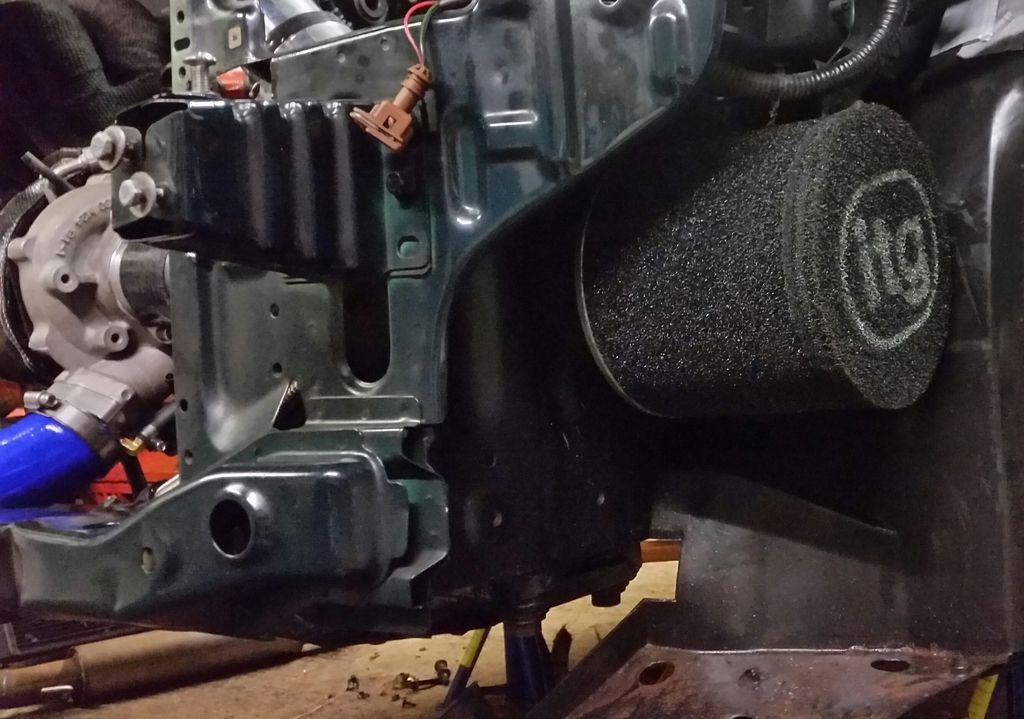

New pipework routing. Air filter now in passenger wing to help reduce intake temps.

Wiring needs some tidying as the new layout exposes the unsightly loom adapter. Eventually I'll just transfer all the wires into the Emerald plug and re-wrap the loom but that can wait.

Thought it would be a good idea to test for boost leaks before mapping so I knocked this up. I've made one of these before and it worked a treat but couldnt find it!

And I thought it would be a good idea to monitor crankcase pressures, at least during mapping. I'll connect this to boost gauge.

I actually did some testing with an exhaust venturi fitting (for venting crankcase) and my air compressor to mimic exhaust flow. It didn't matter what I did I couldn't get it to pull a vacuum so decided to leave it. I'll just vent to atmosphere via the catch tank.

It looks liked this if anyone is interested:

I did implement ive's recommendation fitted the bottom breather. Thanks dude!

Fitted my new tyres to the superleggeras - Federal 595 RS-R

Extra 10bhp from white lettering

Just a few bits to finish off before the mapping on 22nd Nov. Transport booked. I'll run around the block on Saturday just to make sure everything will be ok for the drive back from Emerald after the mapping.

Started first time. No leaks or funny noises. Top end is quite tappy but hoping that's just the hydraulic lifters needing to sort themselves out.

New pipework routing. Air filter now in passenger wing to help reduce intake temps.

Wiring needs some tidying as the new layout exposes the unsightly loom adapter. Eventually I'll just transfer all the wires into the Emerald plug and re-wrap the loom but that can wait.

Thought it would be a good idea to test for boost leaks before mapping so I knocked this up. I've made one of these before and it worked a treat but couldnt find it!

And I thought it would be a good idea to monitor crankcase pressures, at least during mapping. I'll connect this to boost gauge.

I actually did some testing with an exhaust venturi fitting (for venting crankcase) and my air compressor to mimic exhaust flow. It didn't matter what I did I couldn't get it to pull a vacuum so decided to leave it. I'll just vent to atmosphere via the catch tank.

It looks liked this if anyone is interested:

I did implement ive's recommendation fitted the bottom breather. Thanks dude!

Fitted my new tyres to the superleggeras - Federal 595 RS-R

Extra 10bhp from white lettering

Just a few bits to finish off before the mapping on 22nd Nov. Transport booked. I'll run around the block on Saturday just to make sure everything will be ok for the drive back from Emerald after the mapping.

Edited by Stuballs on Monday 14th November 22:45

Went for a quick test drive today to check all is in order before the mapping. Had another look at the map and pulled a bit more ignition timing out so it looks a lot like the first map it had. Stuck the Emerald in closed loop mode for fueling for the whole map and it worked really well. I used the closed loop settings from Marko which are Give improvements over Emerald's bar settings (thanks bud!) I kept throttle input sensible but gave it a little load and some engine breaking to help with initial ring bedding. I was very careful though, remembering the compression ratio is now higher at 10:1 and it really needs mapping properly.

Initial impressions are good. Motor is much nicer to drive and picks up much better than before. It's also smoother which is nice considering I've now poly bushed every engine mount.

The new Federal tyres are so much better. I've now got 7mm spacers on the front and whopping 15mm spacers on the back. It feels more planted but with more direct steering at the same time. Much nicer to drive. It'll be interesting to see how it feels when I can push it a bit more.

Fresh oil in. Full tank of v-power. Ready for mapping!

Initial impressions are good. Motor is much nicer to drive and picks up much better than before. It's also smoother which is nice considering I've now poly bushed every engine mount.

The new Federal tyres are so much better. I've now got 7mm spacers on the front and whopping 15mm spacers on the back. It feels more planted but with more direct steering at the same time. Much nicer to drive. It'll be interesting to see how it feels when I can push it a bit more.

Fresh oil in. Full tank of v-power. Ready for mapping!

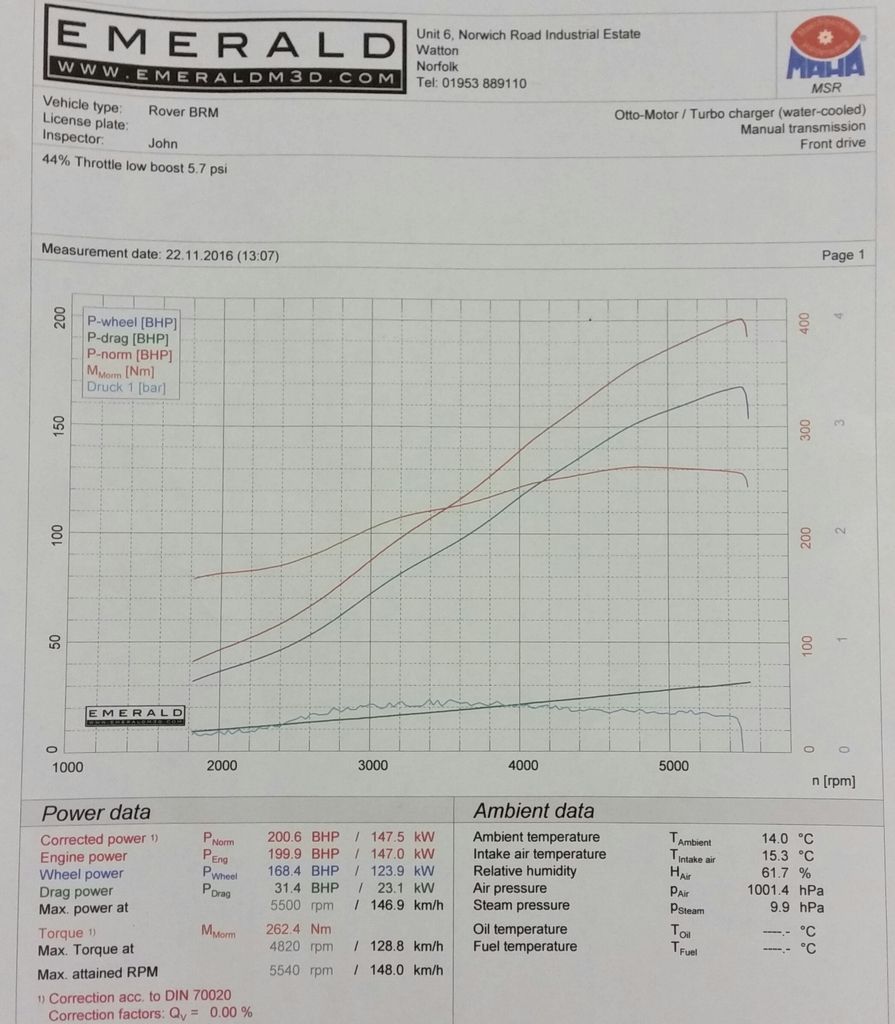

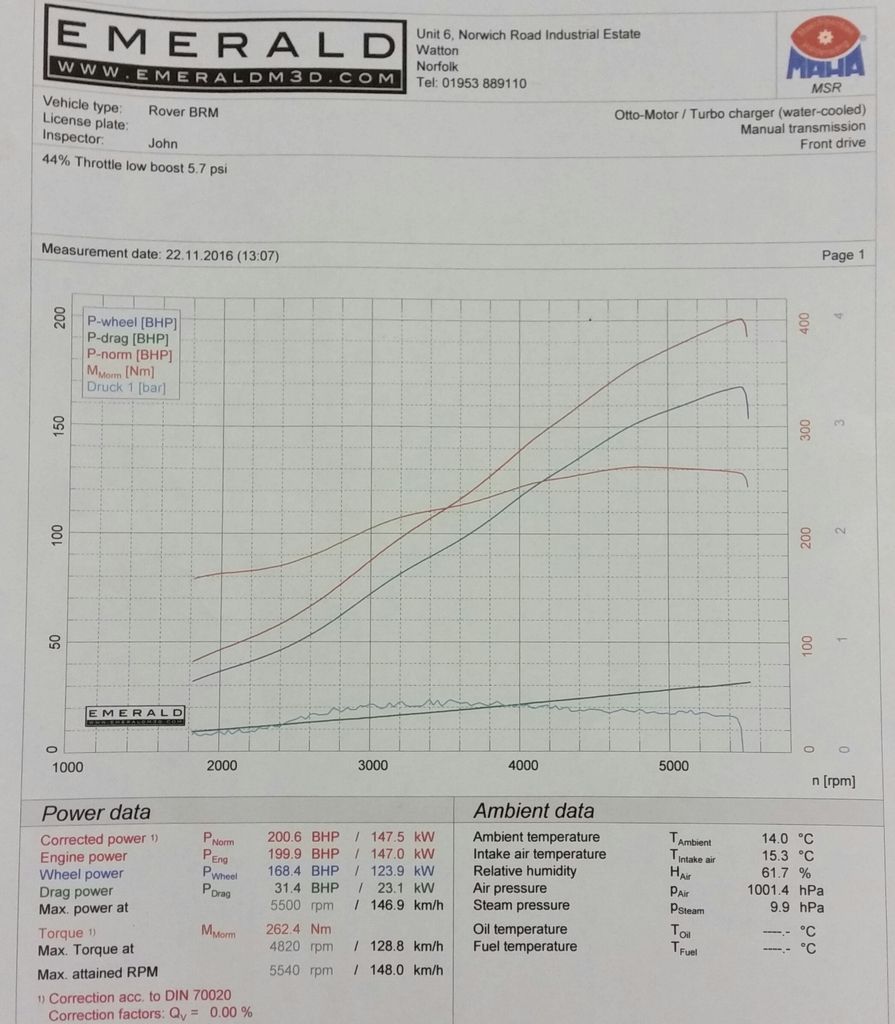

Thanks guys. Mapping went well today. When I first got there, the guys at Emerald were a bit concerned by the tappy engine. I still think it's the top end but they suspected a deeper problem so did a leak down test before they would put it under any stress. Results were what you would expect for a new forged build with large-ish ring gaps that's only done a few miles - around 10%. Satisfied, they strapped her in and cracked on with the mapping.

My brief was "safe, safe, safe!". They suggested that whilst I don't baby it, I limit the revs and throttle input while I run the engine in (I know many advocate the "run it in hard" method but I just can't bring myself to do that after everything that's happened). As such they spent most of the time sorting the bottom half of the map. They did a few runs up to the top to check it wouldn't melt or detonate to oblivion if I did happen to overdo it with the loud pedal.

The mapper said he could tell it was high compression as it was very responsive low down and very det limited up towards 5.5k rpm. Actually surprised it was as low as 10:1. They pulled ignition back by a safe margin up top.

Here's one of the half-throttle runs. Only went up to 5,500rpm here:

https://youtu.be/YsHIy-QRRVY

Results? Fairly meaningless at this stage. This is at 44% throttle. It made 200bhp and about 195lbft torque at the flywheel at 5,500 rpm with 5.7psi boost. Rev limit is actually 7,200 and you can see the power curve is dead steep (and nice and smooth). 300bhp should be quite doable on this setup, if I ever develop testicles large enough to go there.

I then drove the 140-odd miles home from Emerald and had a blast! It's so nice to drive now! I kept the load and rpm varied despite doing most of it on the motorways and a-roads. The only thing that I would change is the gearing - the ratios are too close and 5th gear is no good for cruising. This isn't a mile muncher though so I'll live with it. If anything ever happens to the box I'll look into changing it.

The noise from the engine is still playing on my mind a bit. It really does sound like a diesel! The old engine was just as noisy and we all know how that ended! I've no intention of stripping it down again though so I'll just keep an eye on it.

When I got home I dropped the oil and stuck in another fresh batch of Millers running-in oil, with another filter. Now I just need to pick my days to drive it - sunny and dry so as not to make the rust any worse! That reminds me: must book that respray...

My brief was "safe, safe, safe!". They suggested that whilst I don't baby it, I limit the revs and throttle input while I run the engine in (I know many advocate the "run it in hard" method but I just can't bring myself to do that after everything that's happened). As such they spent most of the time sorting the bottom half of the map. They did a few runs up to the top to check it wouldn't melt or detonate to oblivion if I did happen to overdo it with the loud pedal.

The mapper said he could tell it was high compression as it was very responsive low down and very det limited up towards 5.5k rpm. Actually surprised it was as low as 10:1. They pulled ignition back by a safe margin up top.

Here's one of the half-throttle runs. Only went up to 5,500rpm here:

https://youtu.be/YsHIy-QRRVY

Results? Fairly meaningless at this stage. This is at 44% throttle. It made 200bhp and about 195lbft torque at the flywheel at 5,500 rpm with 5.7psi boost. Rev limit is actually 7,200 and you can see the power curve is dead steep (and nice and smooth). 300bhp should be quite doable on this setup, if I ever develop testicles large enough to go there.

I then drove the 140-odd miles home from Emerald and had a blast! It's so nice to drive now! I kept the load and rpm varied despite doing most of it on the motorways and a-roads. The only thing that I would change is the gearing - the ratios are too close and 5th gear is no good for cruising. This isn't a mile muncher though so I'll live with it. If anything ever happens to the box I'll look into changing it.

The noise from the engine is still playing on my mind a bit. It really does sound like a diesel! The old engine was just as noisy and we all know how that ended! I've no intention of stripping it down again though so I'll just keep an eye on it.

When I got home I dropped the oil and stuck in another fresh batch of Millers running-in oil, with another filter. Now I just need to pick my days to drive it - sunny and dry so as not to make the rust any worse! That reminds me: must book that respray...

Lol, that's not a steep power curve, it is linear though so will probably suit a FWD car.

The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

227bhp said:

Lol, that's not a steep power curve, it is linear though so will probably suit a FWD car.

The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

Yeah, that will help the rings bed in. Bearings don't even get run in as such. I would have a thorough inspection to find the cause of the tapping and get back to do a full power run ASAP so you know it's safe on full throttle. Sounds like it has great potential but kinda like it wasn't worth taking it with the tapping noise as you're only going to have to go again. The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

227bhp said:

Lol, that's not a steep power curve, it is linear though so will probably suit a FWD car.

The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

I meant steep at the top as in it isn't starting to fall off. Yep still has the hig-lift cams in. I'm going to have a go with a mechanics stethoscope to see if I can isolate the noise.The only thing which would have stopped me doing the full map on that is the tapping, apart from that there is no reason why it couldn't have been done. The engine is almost fully run in now anyhow, half an hour of acceleration and deceleration, some max rpm and it's done, end of story, it isn't opinion, it's fact.

You will have thought about the obvious and it isn't something internally hitting something it shouldn't?

Did you keep the performance cams in?

The noise shouldn't be parts colliding as there's a couple of mm piston-valve clearance and the rods were not fouling the liner or piston skirt when I built it (again, loads of clearance). It also doesn't get better or worse with temperature.

To me it sounds like top end. Could it be the aggressive ramp with the relatively low duration and high high lift cams? Or maybe the Rover hydraulic followers don't like the running-in oil...

To be honest, I think the noise the engine was making put them off a bit. Can't blame them - Noone wants the potential hassle of an engine popping on their Dyno. I actually thought they were going to refuse to map it at one point.

I'd had a good listen to the engine from every possible angle at home. I even knocked up a listening device from some copper pipe bolted to the block, piping and some ear defenders so I could listen to the engine from inside the car. Poor man's det cans! (although i made them so i could listen to the engines general noise during the first short test drive, rather than specifically listening for det) You couldn't really hear this noise through them. And the frequency was different. That's why I think it's in the head.

Time will tell. I'm not stripping it now its running so I'll just drive it with a degree of mechanical sympathy for a while and see how it goes.

I'd had a good listen to the engine from every possible angle at home. I even knocked up a listening device from some copper pipe bolted to the block, piping and some ear defenders so I could listen to the engine from inside the car. Poor man's det cans! (although i made them so i could listen to the engines general noise during the first short test drive, rather than specifically listening for det) You couldn't really hear this noise through them. And the frequency was different. That's why I think it's in the head.

Time will tell. I'm not stripping it now its running so I'll just drive it with a degree of mechanical sympathy for a while and see how it goes.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff