Turbo Fireblade Engined Locost

Discussion

EDIT: looks like this now. Shame for the first picture in the thread to be that orange mess!

I didn't build this locost, I bought it from a member on here unseen and my brother drove it 200miles back for me. A text book example on how not to buy a car but I though whatever is wrong with it, I will enjoy fixing. I have had the car just over a month so far.

The car:

This is just after my brother stepped out the car at my parents house, he refused to drive it 20miles further south to my house. I don't blame him and I really owe him a trackday in it.

Immediate issues when he got back were, the car was very loud, the speedometer didn't work, the tacho didn't work, no neutral and gear indication, stalls when cold, the brakes were woeful and the clutch was digital. Good news though, engine runs well and the chassis is very well made with excellent welding.

The magnetic pickup for the speedo was in but just not set up, no idea why. Easy fix, I drove along with my phone taped to the dash measuring GPS speed and adjusted accordingly.

The exhaust had a pretty serious crack in it so I welded that up, now it's much quieter.

I adjusted the clutch and lubricated the cable, again easy fix.

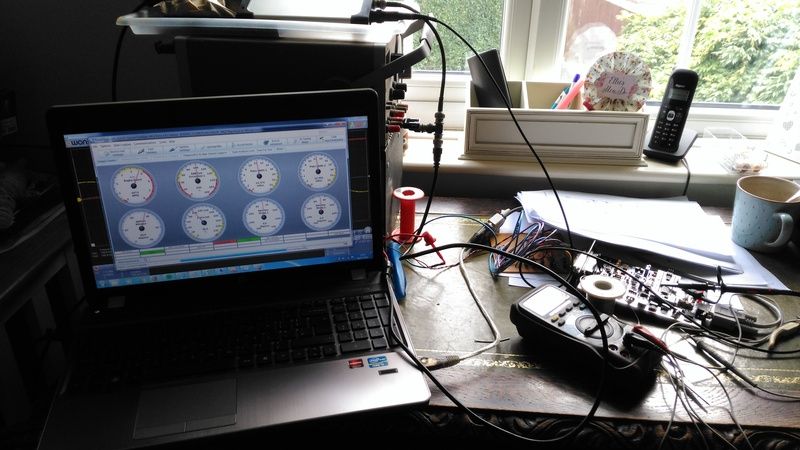

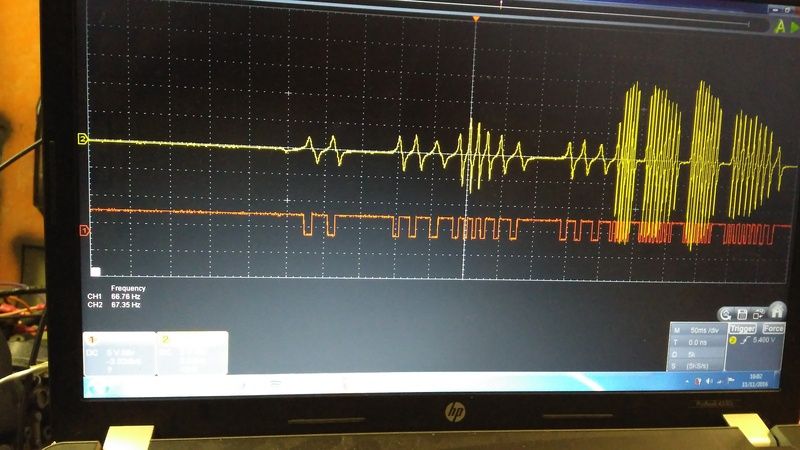

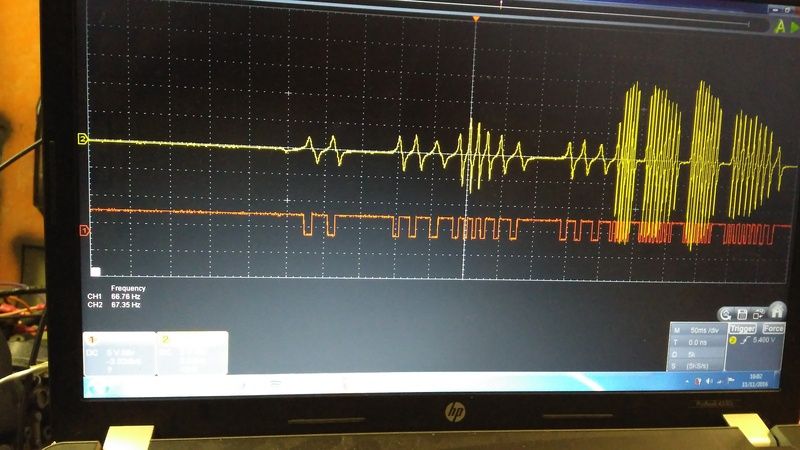

The tacho was a bit more of an issue, I got the car two weeks before going on holiday so I only had limited time to play. It was dancing around on the Acewell dash, I put an old oscilloscope on the signal and could see it was going between 14V and 5V. A function generator connected to the dash confirmed it would be happy with 0 - 5V so I dropped a Zener in but no luck. I tried to design a filter when that didn't work I changed components on a breadboard until it did work. Ended up using a high pass RC filter with another cap across the resistor. Not something you would ever design, but it works.

The neutral switch simply wasn't connected to the right harness, the neutral input connected to somewhere daft (can't remember now).

At this point the car was fairly drivable but made a terrible banging/scraping noise going around a corner hard, I had a look under the car and a number of bolt threads had been left long and were clearly scraping on the ground. So I remade the exhaust bracket as the one on the car was rough and put and extra bolt in the passenger seat to make the required 4.

New bracket (wet paint still) and old bracket:

I had noticed that the chassis moved a lot on the rear axle and I could see the diff and prop had been hitting the chassis. I know only a bit about live axle suspension but I had watched enough Motor Trent Youtube videos to know about Panhard rods so I was a bit surprised there wasn't one.

No rod:

I took the rear of the car off and found a number of other issues; heavily leaking wheel cylinders (later realised this was the wheel bearing), fuel tank attached with loose m4 machine screws, roll bar rear stays not attached, poor welding on the roll bar.

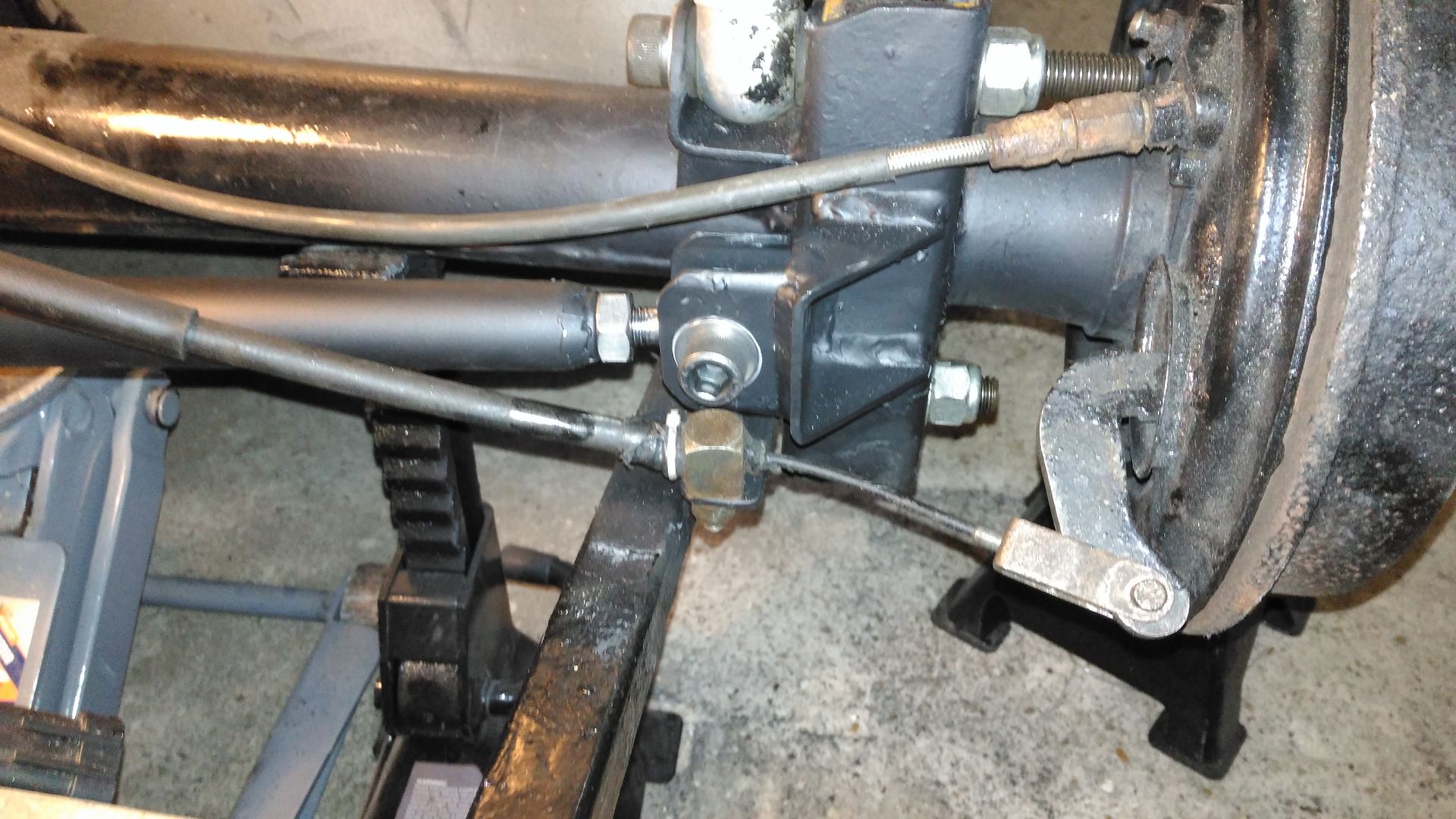

I ordered rose joints from McGill Motorsports and set about making the brackets required:

Next was the roll cage that wasn't attached at the rear, made some filler pieces and closed the box at the top (not a fan of this arrangement).

Replaced the rear bodywork supports, removed old cage welds and re-welded:

Replaced brake cylinders and adjusted brakes:

Moved the fuel tank forward to clear the Panhard rod and so I could attach it to the chassis rather than a thin bit of aluminium, used some M8 and M6 A2 stainless set screws.

At the point of putting the rear back on I couldn't bring myself to use the old bracket that attached the bodywork and numberplate light which can be seen in the picture below above the new bracket I made:

Painted and fitted, I neatened the wire up with heatshrink and braid too:

I did a few other jobs also, such as attaching wires and fuel lines with P clips and fixing some of the poor wiring. I took the wheel spacers off the rear, and realised I really need narrower wheel arches:

Went out for a drive and it feels so much better, very composed now. The original chassis builder did a great job but unfortunately some of work since (by subsequent owners) has been a lot of ambition but not enough skill and there are still things to put right. I'm enjoying working on it as much as driving it.

Plans (at the time): Bodywork, dynojet kit, neaten the dash, tidy the wiring, drive it.

A few more posts to come to bring it up to date.

I didn't build this locost, I bought it from a member on here unseen and my brother drove it 200miles back for me. A text book example on how not to buy a car but I though whatever is wrong with it, I will enjoy fixing. I have had the car just over a month so far.

The car:

This is just after my brother stepped out the car at my parents house, he refused to drive it 20miles further south to my house. I don't blame him and I really owe him a trackday in it.

Immediate issues when he got back were, the car was very loud, the speedometer didn't work, the tacho didn't work, no neutral and gear indication, stalls when cold, the brakes were woeful and the clutch was digital. Good news though, engine runs well and the chassis is very well made with excellent welding.

The magnetic pickup for the speedo was in but just not set up, no idea why. Easy fix, I drove along with my phone taped to the dash measuring GPS speed and adjusted accordingly.

The exhaust had a pretty serious crack in it so I welded that up, now it's much quieter.

I adjusted the clutch and lubricated the cable, again easy fix.

The tacho was a bit more of an issue, I got the car two weeks before going on holiday so I only had limited time to play. It was dancing around on the Acewell dash, I put an old oscilloscope on the signal and could see it was going between 14V and 5V. A function generator connected to the dash confirmed it would be happy with 0 - 5V so I dropped a Zener in but no luck. I tried to design a filter when that didn't work I changed components on a breadboard until it did work. Ended up using a high pass RC filter with another cap across the resistor. Not something you would ever design, but it works.

The neutral switch simply wasn't connected to the right harness, the neutral input connected to somewhere daft (can't remember now).

At this point the car was fairly drivable but made a terrible banging/scraping noise going around a corner hard, I had a look under the car and a number of bolt threads had been left long and were clearly scraping on the ground. So I remade the exhaust bracket as the one on the car was rough and put and extra bolt in the passenger seat to make the required 4.

New bracket (wet paint still) and old bracket:

I had noticed that the chassis moved a lot on the rear axle and I could see the diff and prop had been hitting the chassis. I know only a bit about live axle suspension but I had watched enough Motor Trent Youtube videos to know about Panhard rods so I was a bit surprised there wasn't one.

No rod:

I took the rear of the car off and found a number of other issues; heavily leaking wheel cylinders (later realised this was the wheel bearing), fuel tank attached with loose m4 machine screws, roll bar rear stays not attached, poor welding on the roll bar.

I ordered rose joints from McGill Motorsports and set about making the brackets required:

Next was the roll cage that wasn't attached at the rear, made some filler pieces and closed the box at the top (not a fan of this arrangement).

Replaced the rear bodywork supports, removed old cage welds and re-welded:

Replaced brake cylinders and adjusted brakes:

Moved the fuel tank forward to clear the Panhard rod and so I could attach it to the chassis rather than a thin bit of aluminium, used some M8 and M6 A2 stainless set screws.

At the point of putting the rear back on I couldn't bring myself to use the old bracket that attached the bodywork and numberplate light which can be seen in the picture below above the new bracket I made:

Painted and fitted, I neatened the wire up with heatshrink and braid too:

I did a few other jobs also, such as attaching wires and fuel lines with P clips and fixing some of the poor wiring. I took the wheel spacers off the rear, and realised I really need narrower wheel arches:

Went out for a drive and it feels so much better, very composed now. The original chassis builder did a great job but unfortunately some of work since (by subsequent owners) has been a lot of ambition but not enough skill and there are still things to put right. I'm enjoying working on it as much as driving it.

Plans (at the time): Bodywork, dynojet kit, neaten the dash, tidy the wiring, drive it.

A few more posts to come to bring it up to date.

Edited by Murdoc on Sunday 2nd December 10:01

I am helping a mate with his unfinished project Fireblade engined Westfield Megablade.

We have had a great deal of good advice from Andy Bates of AB performance of Stowmarket.

He does a carb kit similar to Dynojet but tailored specifically to installation in a car where the fuelling requirements are different, the jets and custom made needles are the result of scores of dyno runs and no more costly than a Dynojet kit.

We have had a great deal of good advice from Andy Bates of AB performance of Stowmarket.

He does a carb kit similar to Dynojet but tailored specifically to installation in a car where the fuelling requirements are different, the jets and custom made needles are the result of scores of dyno runs and no more costly than a Dynojet kit.

I then replaced the radiator fan switch, had a poke around the carbs and adjusted the throttle. The throttle was only opening about 70% so the car is a fair bit quicker at high rpm now. The airbox wasn't attached to the carbs also for some reason, it just came off in my hand, not sure if the screws worked loose.

I have gone out for a few blasts in the car, with the suspension fixed, the brakes biting well and the extra power it really feels great and a lot more in control.

I went out for a spirited drive with a friend on the weekend, only 10 miles or so. On the way back I could smell gear oil. The insides of the rear wheels are coated, it seems the seals have gone on the bearing on the half shafts. I ordered a slide hammer but in the mean time managed to come up with a way to press them out.

It seems an attempt has been made to 'weld' the retaining collar in. Hopefully I can grind the pigeon poo out and get the collar off.

I built a manometer to balance the carbs, acquiring the raw materials wasn't much of a hardship.

I replaced the coolant (it was just plain water), fixed the choke, bought a second hand K&N filter ready for the dynojet kit but I'm considering converting the engine to fuel injection instead. I have seen a 929 intake with injectors etc for £100.

I have gone out for a few blasts in the car, with the suspension fixed, the brakes biting well and the extra power it really feels great and a lot more in control.

I went out for a spirited drive with a friend on the weekend, only 10 miles or so. On the way back I could smell gear oil. The insides of the rear wheels are coated, it seems the seals have gone on the bearing on the half shafts. I ordered a slide hammer but in the mean time managed to come up with a way to press them out.

It seems an attempt has been made to 'weld' the retaining collar in. Hopefully I can grind the pigeon poo out and get the collar off.

I built a manometer to balance the carbs, acquiring the raw materials wasn't much of a hardship.

I replaced the coolant (it was just plain water), fixed the choke, bought a second hand K&N filter ready for the dynojet kit but I'm considering converting the engine to fuel injection instead. I have seen a 929 intake with injectors etc for £100.

Spoke to Steve at SP Components and went for a SKF bearing kit, the other options seemed to be a bad idea. Steve's a really nice guy and helped me out getting the bearings on. The diff had around 20ml of oil in it when I pumped it out :/

I spent quite a while making the wheel arches fit correctly, I had them on and off quite a few times and trimmed a lot of material out. The arches had a flair out on the inside which was causing them to angle in, someone pointed this out earlier and I dismissed it as an illusion but it wasn't.

I had to trim the flair out by hand, then made a jig to take some width out:

Sliced some off the front to make them look less heavy using a similar jig:

End result looks a lot better I think:

The full beam lights wouldn't stay on so I took the scuttle off, decided I really need to rewire the car from scratch. The bike harness is still in there mostly complete and has been modified over the years. Easiest way to get rid of the bike harness is to convert it to run on a megasquirt.

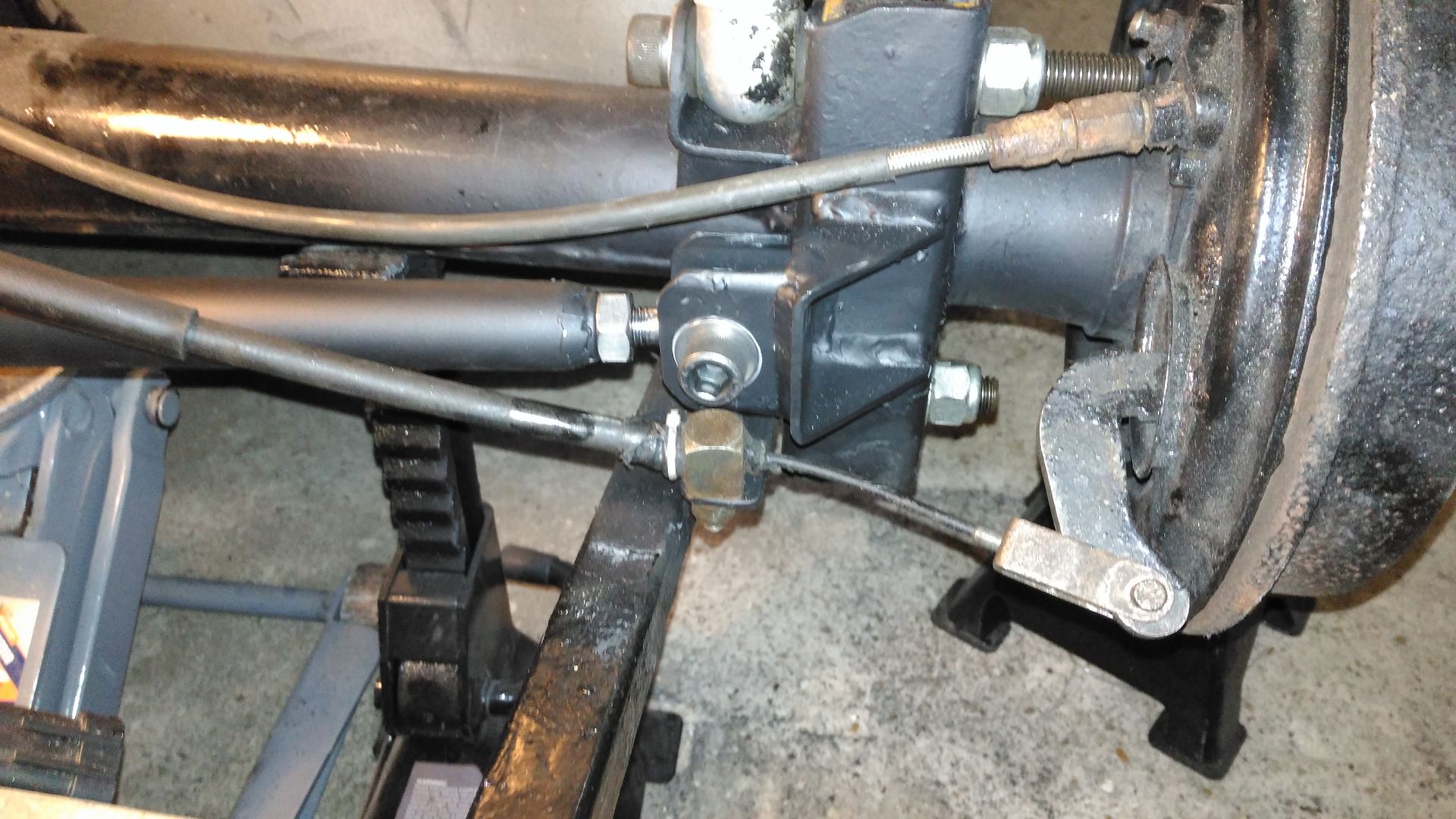

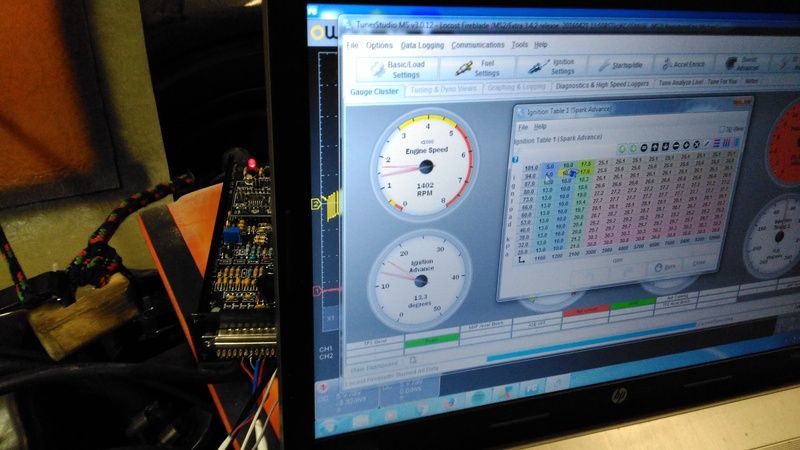

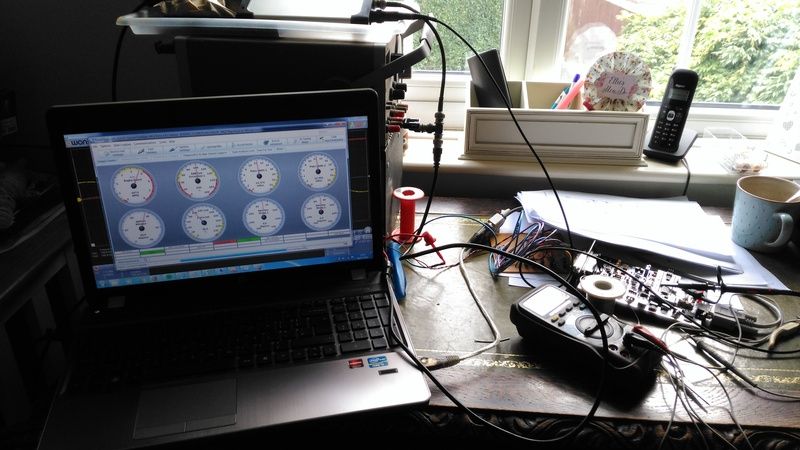

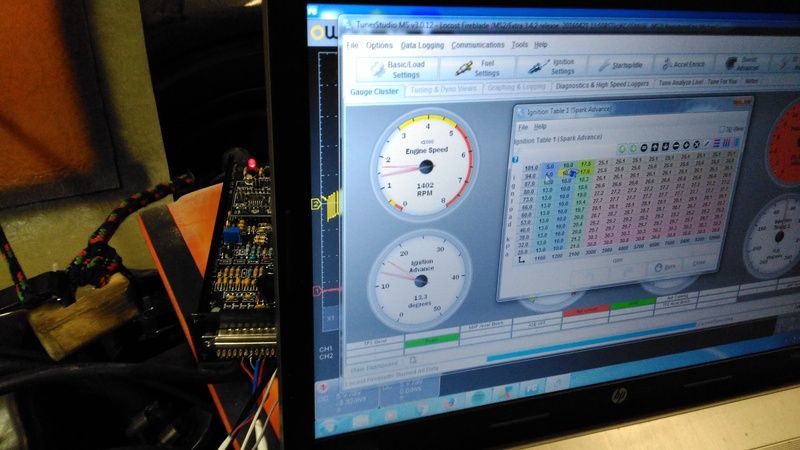

I built this one for an MX-5 so had to swap the rpm input circuit from optical to VR in, using the latest MSII V3.0 filter it works great. Few different parts using what I had to hand or could get easily.

VR sensor output in yellow, signal to microcontroller in orange:

I didn't want to pass a large current through the MS so rather than fit a coil driver/IGBT in the MS I bought a MX-5 1.6 ignition amplifier off ebay, it works well. After poking around a fair bit, measuring toothed wheels on my spare engine and a few backfires the engine is running:

I have now bought 954cc throttle bodies, air box, got an MX-5 fuel pump, lengths of new fuel hose, a load of sealed connectors for the harness and I'm converting it over to injection. At the moment I'm drawing up a system diagram and wiring harnesses. It looks like the harness will be split in to 3 or 4 parts for ease of maintenance. I have a Zeitronix wideband controller and need to order the sensor.

I spent quite a while making the wheel arches fit correctly, I had them on and off quite a few times and trimmed a lot of material out. The arches had a flair out on the inside which was causing them to angle in, someone pointed this out earlier and I dismissed it as an illusion but it wasn't.

I had to trim the flair out by hand, then made a jig to take some width out:

Sliced some off the front to make them look less heavy using a similar jig:

End result looks a lot better I think:

The full beam lights wouldn't stay on so I took the scuttle off, decided I really need to rewire the car from scratch. The bike harness is still in there mostly complete and has been modified over the years. Easiest way to get rid of the bike harness is to convert it to run on a megasquirt.

I built this one for an MX-5 so had to swap the rpm input circuit from optical to VR in, using the latest MSII V3.0 filter it works great. Few different parts using what I had to hand or could get easily.

VR sensor output in yellow, signal to microcontroller in orange:

I didn't want to pass a large current through the MS so rather than fit a coil driver/IGBT in the MS I bought a MX-5 1.6 ignition amplifier off ebay, it works well. After poking around a fair bit, measuring toothed wheels on my spare engine and a few backfires the engine is running:

I have now bought 954cc throttle bodies, air box, got an MX-5 fuel pump, lengths of new fuel hose, a load of sealed connectors for the harness and I'm converting it over to injection. At the moment I'm drawing up a system diagram and wiring harnesses. It looks like the harness will be split in to 3 or 4 parts for ease of maintenance. I have a Zeitronix wideband controller and need to order the sensor.

kev b said:

I am helping a mate with his unfinished project Fireblade engined Westfield Megablade.

We have had a great deal of good advice from Andy Bates of AB performance of Stowmarket.

He does a carb kit similar to Dynojet but tailored specifically to installation in a car where the fuelling requirements are different, the jets and custom made needles are the result of scores of dyno runs and no more costly than a Dynojet kit.

Cheers for the info, I was looking at Andy's kit but I'm going for injection now. Makes it easier to add the turbo.We have had a great deal of good advice from Andy Bates of AB performance of Stowmarket.

He does a carb kit similar to Dynojet but tailored specifically to installation in a car where the fuelling requirements are different, the jets and custom made needles are the result of scores of dyno runs and no more costly than a Dynojet kit.

Got a bit more work done.

Fitted the MX-5 fuel pump to the tank, the unit has a sender in too that I will wire up to the dash. The sender was at the wrong angle to fit in the tank but a blowtorch and adjustable spanner and it was the right way.

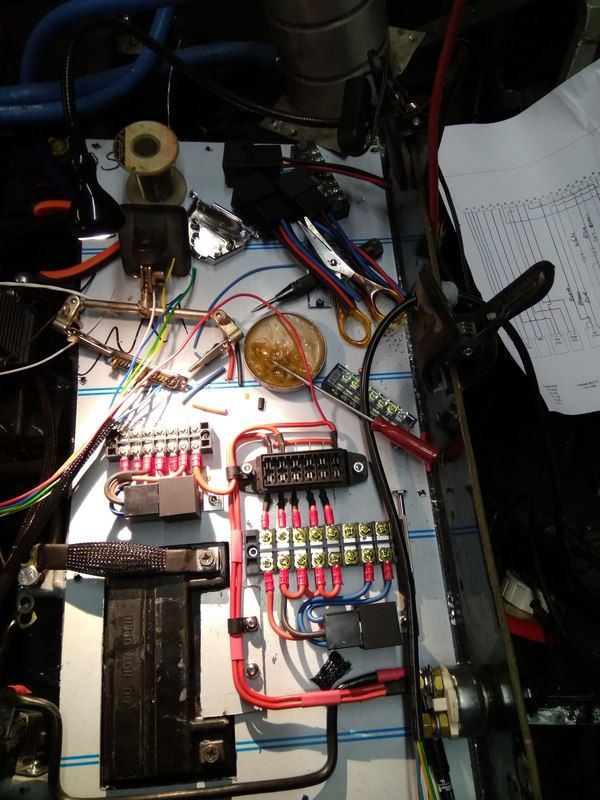

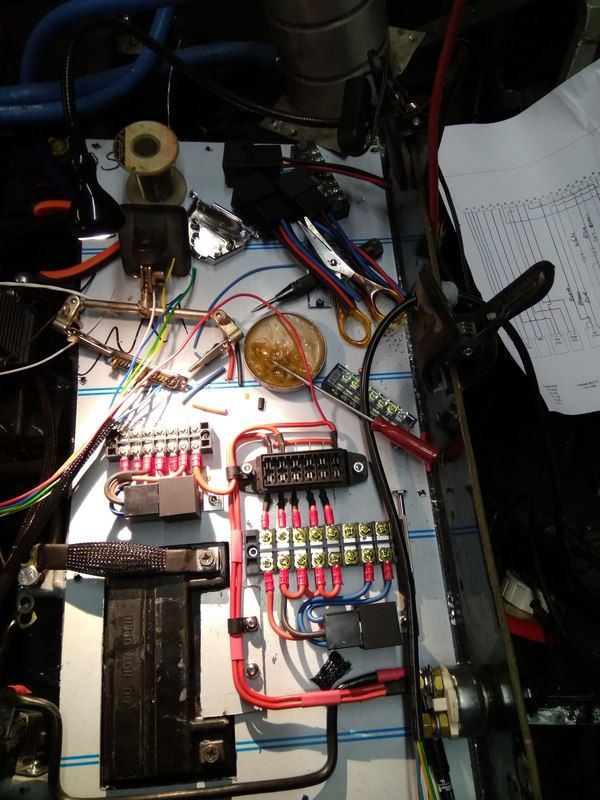

The existing wiring harness was in such a state I cut it out, it's full of bad crimps twisted wire and electrical tape.

Much better, although the car no longer runs

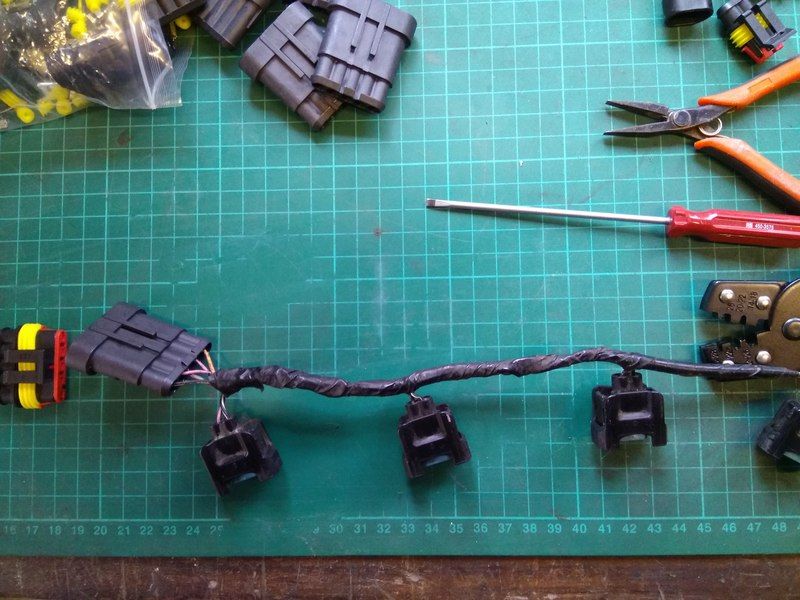

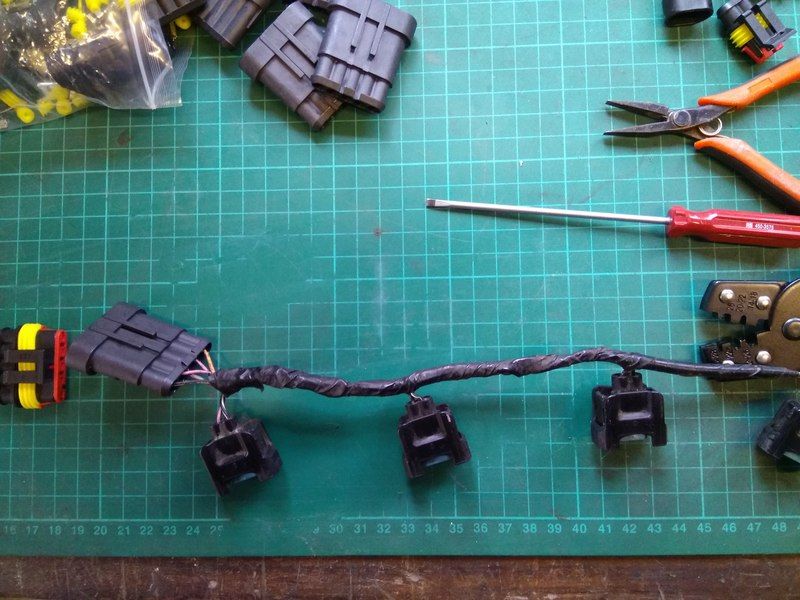

I have started to make parts for the harness, this is the injector harness swapped over to a superseal connector.

I'm going to attach the throttle bodies upside down compared to there position on the bike, this give the fuel a better shot in to the cylinders, I'm not sure why Honda did it any other way, perhaps packaging.

This meant the wax valve that controls the cold idle fouled on the cam cover so I had to drill and tap the throttle bodies to mount the wax valve between cylinders 1 and 2 instead of 3 and 4.

I'm waiting for some silicone hose to come in the post, then I can attach the TBs and work out the harness lengths.

Fitted the MX-5 fuel pump to the tank, the unit has a sender in too that I will wire up to the dash. The sender was at the wrong angle to fit in the tank but a blowtorch and adjustable spanner and it was the right way.

The existing wiring harness was in such a state I cut it out, it's full of bad crimps twisted wire and electrical tape.

Much better, although the car no longer runs

I have started to make parts for the harness, this is the injector harness swapped over to a superseal connector.

I'm going to attach the throttle bodies upside down compared to there position on the bike, this give the fuel a better shot in to the cylinders, I'm not sure why Honda did it any other way, perhaps packaging.

This meant the wax valve that controls the cold idle fouled on the cam cover so I had to drill and tap the throttle bodies to mount the wax valve between cylinders 1 and 2 instead of 3 and 4.

I'm waiting for some silicone hose to come in the post, then I can attach the TBs and work out the harness lengths.

Got the TBs mounted on the engine. The engine has 45mm ports and the TBs are 50mm OD using 48mm hose I managed to get a good seal on both and account for the different bore spacing.

The wax valve clears the cam cover.

I started to run the new fuel lines, I took the prop out for access to fit the P clips, the cable ties used previously weren't quite up to the job. Unfortunately the prop bolts to the diff weren't even finger tight, they loosely moved when I touched them. The bolts the other end err finger tight but not much more. It seems the prop departed the diff at some point and chewed out the chassis so I had to make up a new cross piece with a bit of added clearance.

Fuel lines run, clearance is a bit more than it appears in this picture, I have jumped around on the suspension and it doesn't come close.

Made a simple bracket to hold the fuel filter.

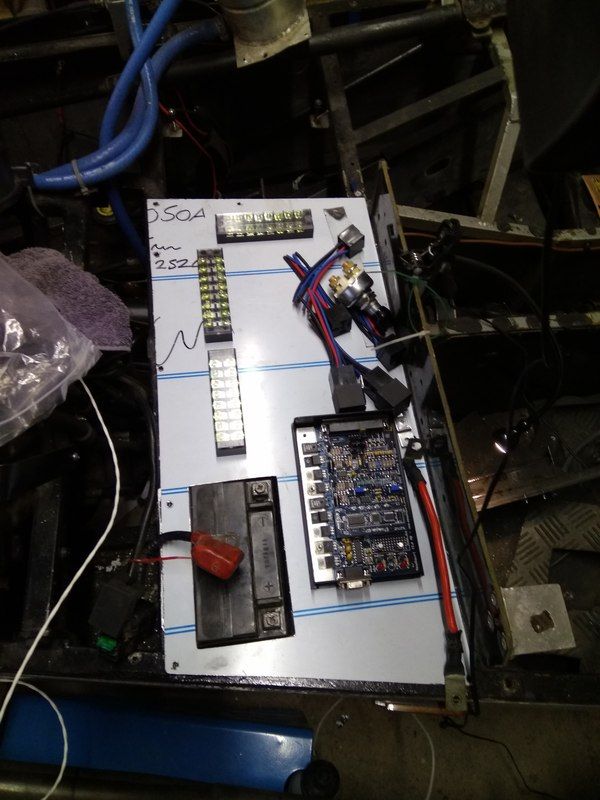

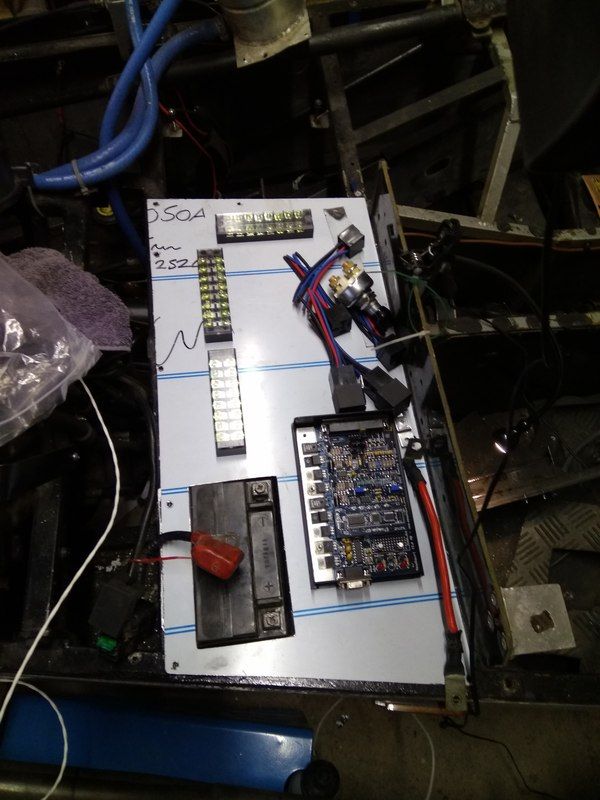

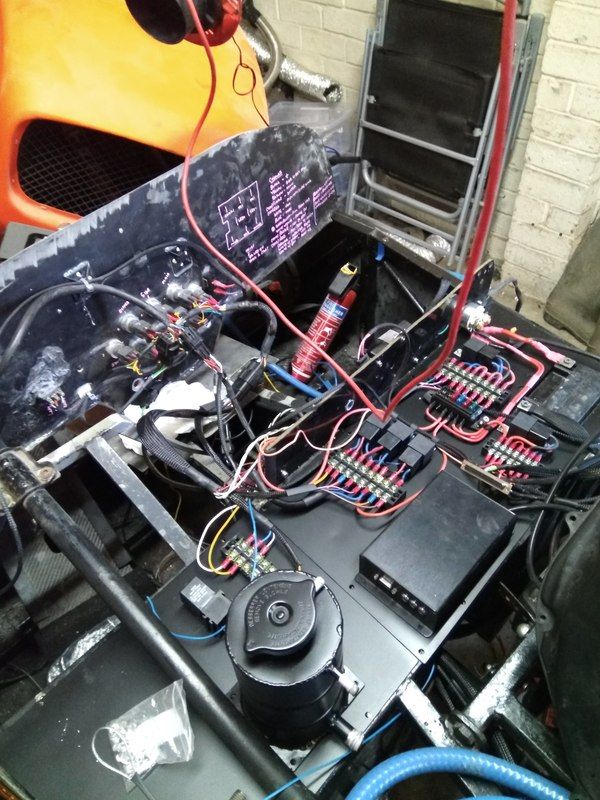

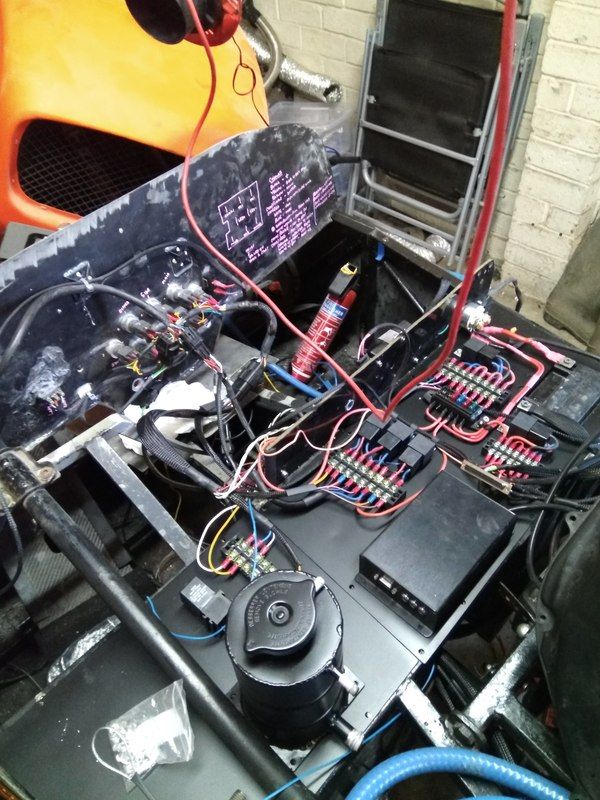

Made a new panel and battery holder and the other one looked like it had been shot at and started to test fit.

Fitted the ingitor on a piece of cut down aluminium I section and started wiring up.

Edit: I made a couple of youtube vids too:

https://www.youtube.com/watch?v=5_CSt1E1UrE

Very early on and running far too rich but lots of fun.

https://www.youtube.com/watch?v=ZljPGk5UZ0A

The wax valve clears the cam cover.

I started to run the new fuel lines, I took the prop out for access to fit the P clips, the cable ties used previously weren't quite up to the job. Unfortunately the prop bolts to the diff weren't even finger tight, they loosely moved when I touched them. The bolts the other end err finger tight but not much more. It seems the prop departed the diff at some point and chewed out the chassis so I had to make up a new cross piece with a bit of added clearance.

Fuel lines run, clearance is a bit more than it appears in this picture, I have jumped around on the suspension and it doesn't come close.

Made a simple bracket to hold the fuel filter.

Made a new panel and battery holder and the other one looked like it had been shot at and started to test fit.

Fitted the ingitor on a piece of cut down aluminium I section and started wiring up.

Edit: I made a couple of youtube vids too:

https://www.youtube.com/watch?v=5_CSt1E1UrE

Very early on and running far too rich but lots of fun.

https://www.youtube.com/watch?v=ZljPGk5UZ0A

Edited by Murdoc on Tuesday 7th March 20:49

Been a while updating this. I have taken fewer pictures but made more progress.

The car looked something like this, decorating supplies are not integral to the exhaust structure.

I continued wiring up the relays and fuses, the wiring harness for the engine, the front of the car, the rear and the dash are all separate so can be removed for rework. The wiring took a very long time with all the connector crimps, braid and heatshrink. I don't have any detailed pictures of the front and rear harnesses but you can see them in some pictures, it was many hours of cutting and stripping wire in the cold.

Regulator-Rectifier

Dashboard, used molex MX150 connectors for the dash, the digital dash part is an Acewell 6856.

Finished the wiring.

I had a close look at the roll cage, it turns out the welds holding the front part on were actually mostly filler. I scraped around the weld with a round file, it it a few times with a copper hammer and the joint popped open. I checked the back part and it's fine, the tube is also a different diameter so probably original. I cut the front cage out and left the roll hoop in.

Also, the bolts in the prop shaft weren't tight, the rear bolts weren't even finger tight. Not sure how I survived driving this thing. All loctited in now.

Put the car back together

I made a mistake after getting the engine harness complete but not having the radiator fan or front harness. I was tuning the car for idle and hadn't noticed the coolant temperature rising until it blew the expansion tank cap off. Boiling coolant showered down on the open topped megasquirt and wiring. It took a dose of brake cleaner and a bucket load of MEK and an oven to get the megasquirt back to life. The coolant got everywhere and wouldn't evaporate. I'm still mopping it up two months later, the amount of glycol meant it hasn't corroded anything but it's still a mess.

I have the car booked in for an MOT on Friday but not sure if I will make it, I can't get the idle stable as the wax valve idle arrangement is an air trap and unreliable, I have ordered a stepper motor so the idle can be controlled by the megasquirt.

Throttle response seems better than the carbs but I haven't driven the car yet, I have a lot of tuning to do before it is drivable, if I can find someone who is willing I may pay for it to go on a rolling road and tuner professionally. Any recommendations in the midlands?

The car looked something like this, decorating supplies are not integral to the exhaust structure.

I continued wiring up the relays and fuses, the wiring harness for the engine, the front of the car, the rear and the dash are all separate so can be removed for rework. The wiring took a very long time with all the connector crimps, braid and heatshrink. I don't have any detailed pictures of the front and rear harnesses but you can see them in some pictures, it was many hours of cutting and stripping wire in the cold.

Regulator-Rectifier

Dashboard, used molex MX150 connectors for the dash, the digital dash part is an Acewell 6856.

Finished the wiring.

I had a close look at the roll cage, it turns out the welds holding the front part on were actually mostly filler. I scraped around the weld with a round file, it it a few times with a copper hammer and the joint popped open. I checked the back part and it's fine, the tube is also a different diameter so probably original. I cut the front cage out and left the roll hoop in.

Also, the bolts in the prop shaft weren't tight, the rear bolts weren't even finger tight. Not sure how I survived driving this thing. All loctited in now.

Put the car back together

I made a mistake after getting the engine harness complete but not having the radiator fan or front harness. I was tuning the car for idle and hadn't noticed the coolant temperature rising until it blew the expansion tank cap off. Boiling coolant showered down on the open topped megasquirt and wiring. It took a dose of brake cleaner and a bucket load of MEK and an oven to get the megasquirt back to life. The coolant got everywhere and wouldn't evaporate. I'm still mopping it up two months later, the amount of glycol meant it hasn't corroded anything but it's still a mess.

I have the car booked in for an MOT on Friday but not sure if I will make it, I can't get the idle stable as the wax valve idle arrangement is an air trap and unreliable, I have ordered a stepper motor so the idle can be controlled by the megasquirt.

Throttle response seems better than the carbs but I haven't driven the car yet, I have a lot of tuning to do before it is drivable, if I can find someone who is willing I may pay for it to go on a rolling road and tuner professionally. Any recommendations in the midlands?

It has been over a year since I last posted. I've been quite busy in that time. The car is back on the road, I've resprayed pearlescent black which required a lot of (endless!) bodywork.

The turbo is complete, TD04 from an impreza, RX7 intercooler. It's around 10psi at the moment, the car had a few issues on the dyno which I wasn't there to fix but mostly a boost cut limit left on in the megasquirt, I need to head back for a power run. At 10psi it should be around 200bhp. The car weighs 460kg so it shifts OK.

The turbo:

Shiny paint:

The Car (needs a clean!):

The intercooler works very well, the intake air is so cold it is below the dew point:

The random wire cable tied on is temporary for my 'det cans'

And some terrible youtube videos I took while my brother had a drive:

https://www.youtube.com/watch?v=tc15EDrgoNE

https://www.youtube.com/watch?v=gW4Rj0hk5CE

The turbo is complete, TD04 from an impreza, RX7 intercooler. It's around 10psi at the moment, the car had a few issues on the dyno which I wasn't there to fix but mostly a boost cut limit left on in the megasquirt, I need to head back for a power run. At 10psi it should be around 200bhp. The car weighs 460kg so it shifts OK.

The turbo:

Shiny paint:

The Car (needs a clean!):

The intercooler works very well, the intake air is so cold it is below the dew point:

The random wire cable tied on is temporary for my 'det cans'

And some terrible youtube videos I took while my brother had a drive:

https://www.youtube.com/watch?v=tc15EDrgoNE

https://www.youtube.com/watch?v=gW4Rj0hk5CE

chuntington101 said:

Is it on carbs? If so that would explain the condensation in the intake. As the air mixes with the fuel in the carbs you get a temperature drop.

Still better than a hot intake!

Cracking car by the way. Nice to see something other than a bussa getting turboed!

It's injected, I'm using throttle bodies off a later Fireblade. The intercooler cools the intake temp just above ambient but well under the bonnet temperature is so the pipes are colder than the dew point.

Still better than a hot intake!

Cracking car by the way. Nice to see something other than a bussa getting turboed!

Cheers, I'm going to need a lockup clutch before pushing the boost much higher.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff