Defender 90 - 6.0l LS V8 and 6l80 conversion.

Discussion

Bit more done.

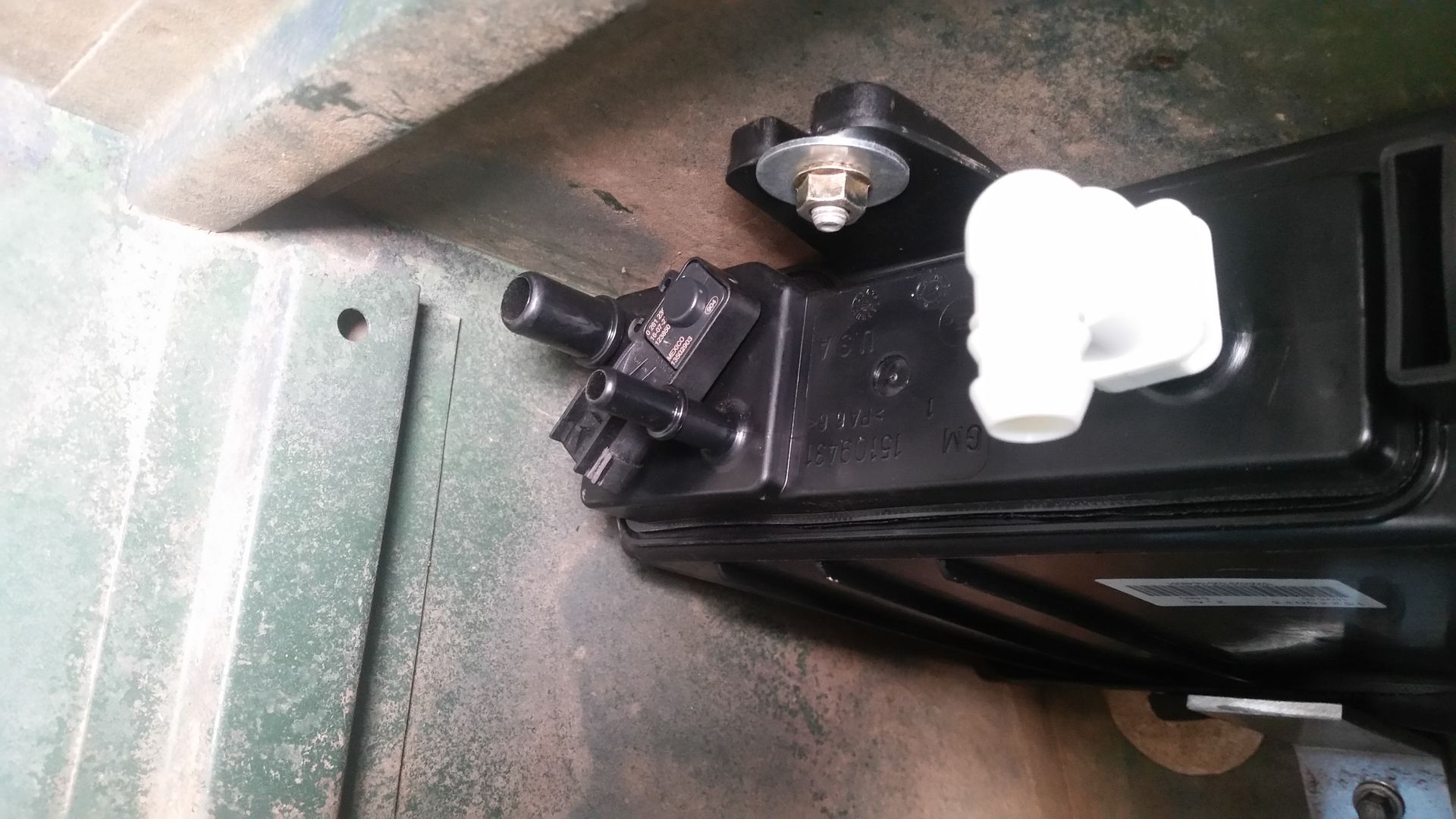

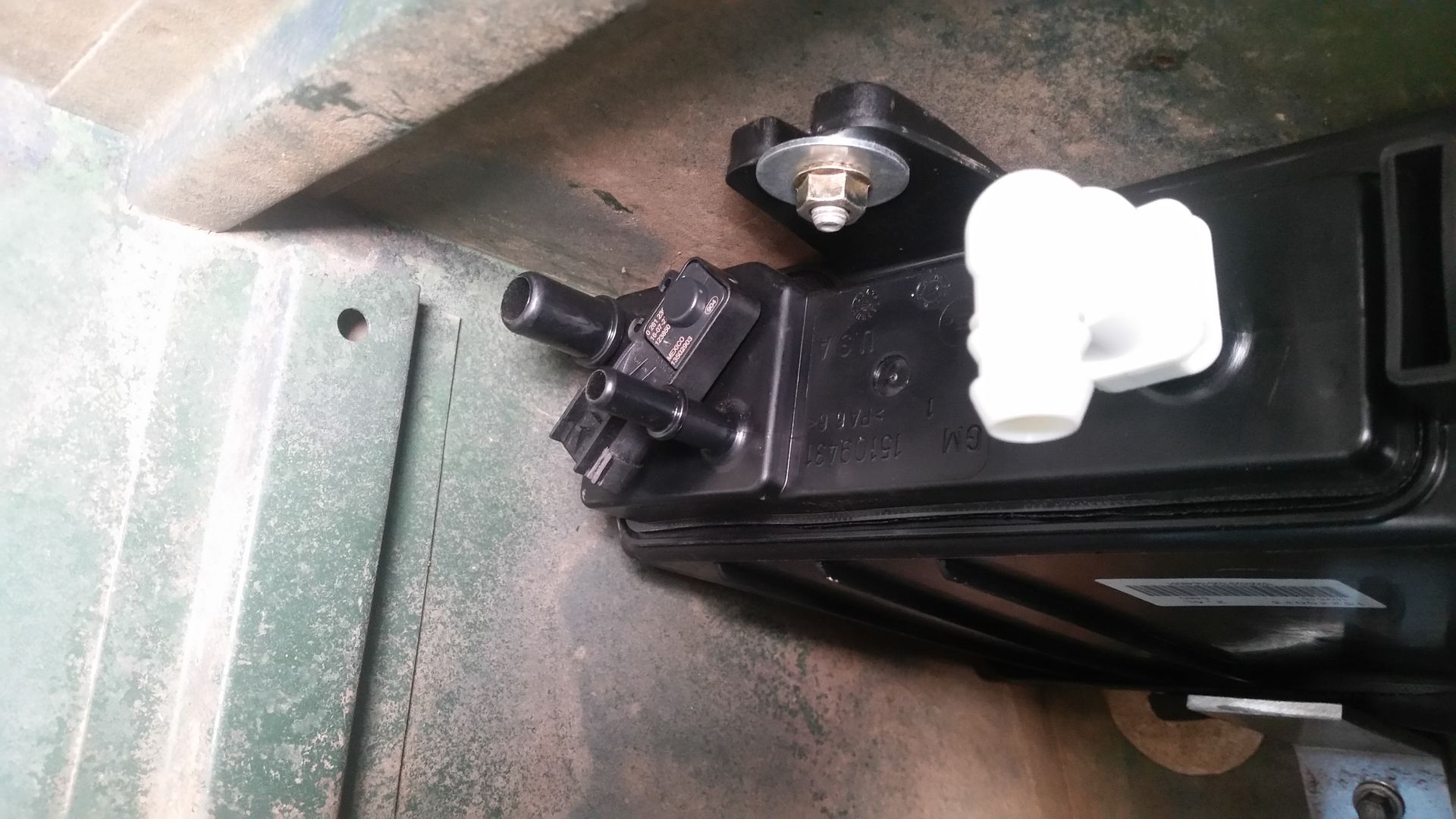

Fitted the fuel tank pressure sensor in the EVAP canister. Hoses for the 2 ports there will just be hose clamped on so there should be plenty of space.

Fitted the vent valve by the filler neck. The filter on the end is up behind the mud shield that attempts to protect the back of the rear lights.

I have also now removed a metre or so of wire from the loom for them as it was too long and routed the wiring as much out of the way as I can.

Fitted the fuel tank pressure sensor in the EVAP canister. Hoses for the 2 ports there will just be hose clamped on so there should be plenty of space.

Fitted the vent valve by the filler neck. The filter on the end is up behind the mud shield that attempts to protect the back of the rear lights.

I have also now removed a metre or so of wire from the loom for them as it was too long and routed the wiring as much out of the way as I can.

Pretty happy with how this looks so far.

I have a voltmeter still to fit and also the original clock to go back somewhere. I don't really want a heap of random gauges and switches inside the cab. At the moment I think at first glance looking through the window you would have to look twice to tell it wasn't fairly basic and standard.

I even think people will still think its a manual.

I have a voltmeter still to fit and also the original clock to go back somewhere. I don't really want a heap of random gauges and switches inside the cab. At the moment I think at first glance looking through the window you would have to look twice to tell it wasn't fairly basic and standard.

I even think people will still think its a manual.

Thanks all. Bit more done..

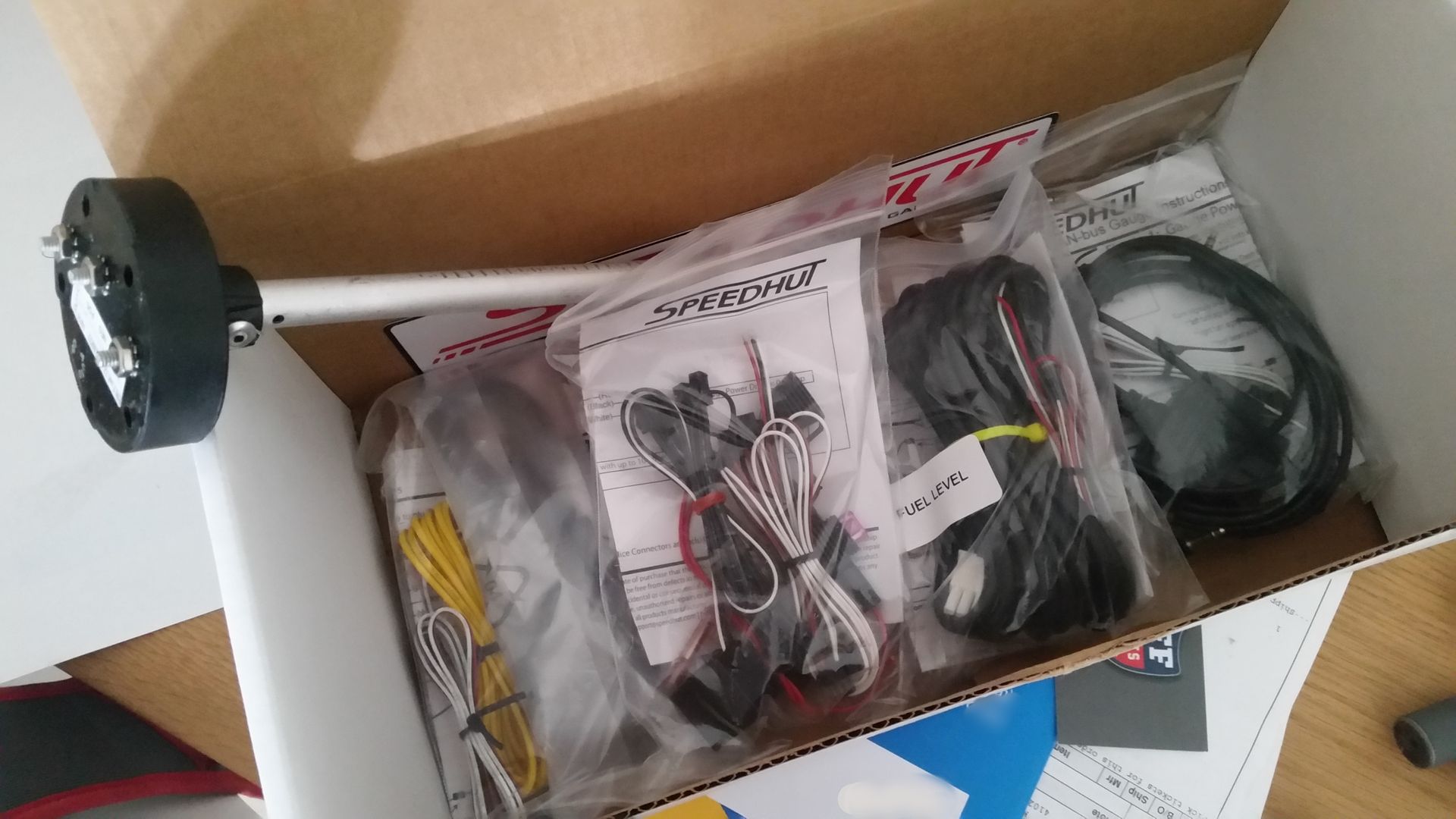

GPS Sensor for the speedo:

putting the dash back together...

Instruments connected up and go through the test sequence when ignition is on. GPS got a location within a minute or so. Dimmer for the lighting also works nicely.

I managed to strip out the unnecessary pins from the multi pin plugs for the instrument panel and reuse the required ones for the feeds, earths and lighting.

One step backwards tho..... The indicators have stopped working. Hazards are fine however. I assume I have removed something I shouldn't have in the loom. I am now doubting myself as to whether I actually tested them when I put the loom back in or if I just tested the hazards as it was quicker...

GPS Sensor for the speedo:

putting the dash back together...

Instruments connected up and go through the test sequence when ignition is on. GPS got a location within a minute or so. Dimmer for the lighting also works nicely.

I managed to strip out the unnecessary pins from the multi pin plugs for the instrument panel and reuse the required ones for the feeds, earths and lighting.

One step backwards tho..... The indicators have stopped working. Hazards are fine however. I assume I have removed something I shouldn't have in the loom. I am now doubting myself as to whether I actually tested them when I put the loom back in or if I just tested the hazards as it was quicker...

Another bit done

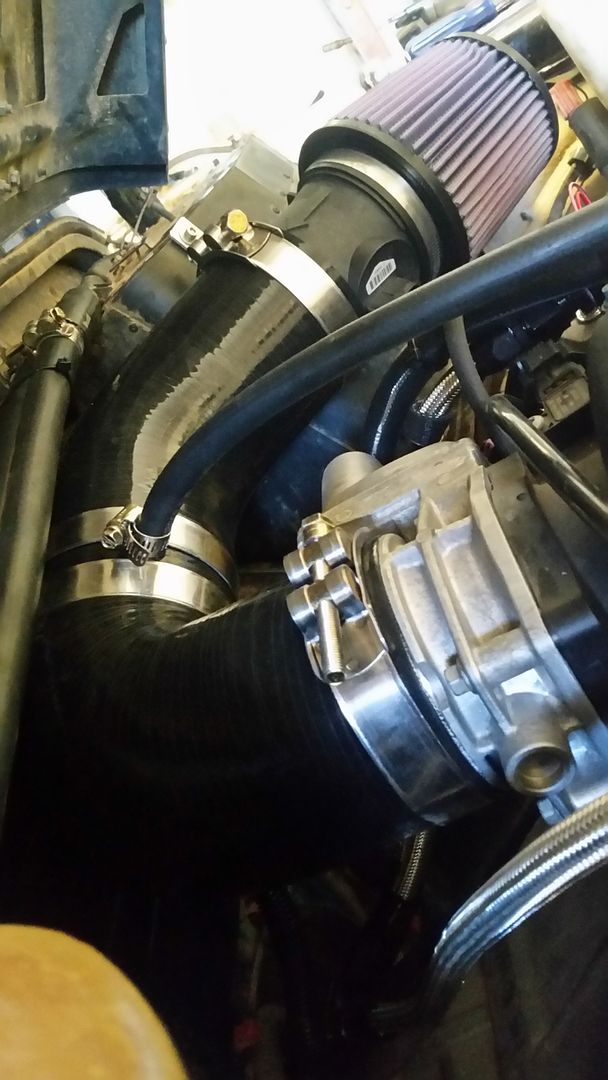

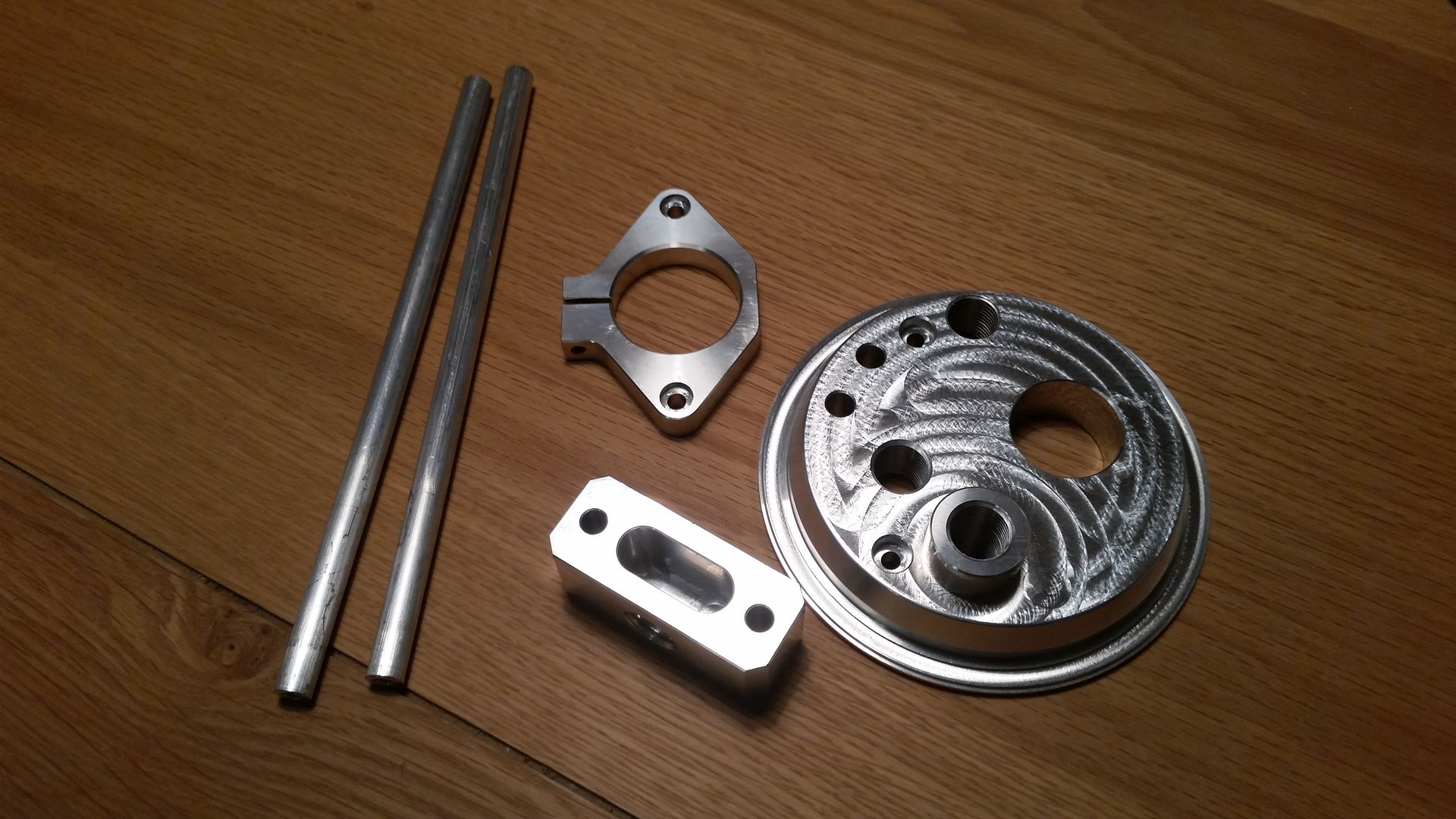

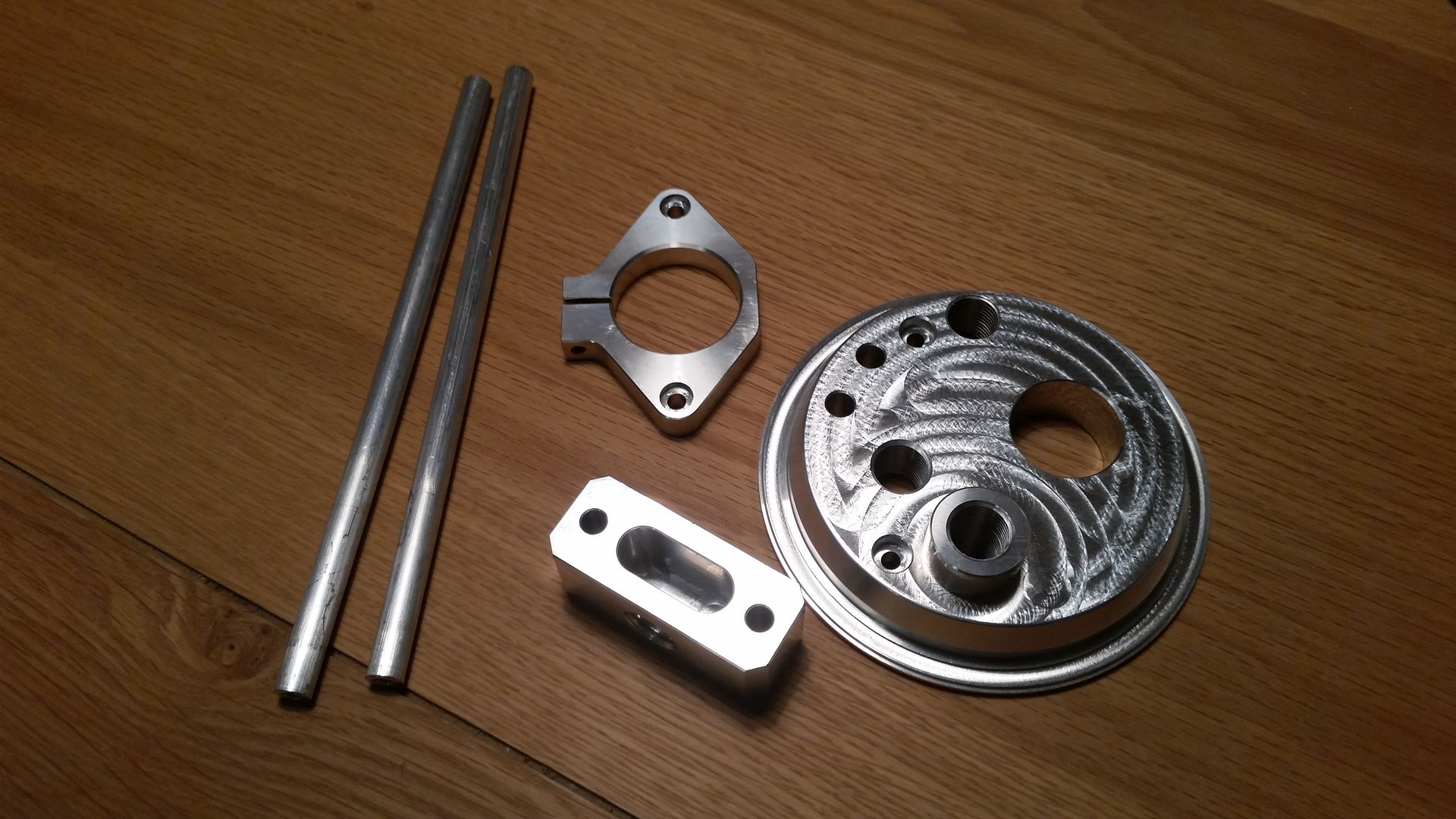

Oil pressure switch adaptor for the engine which I have been waiting on a while. Interestingly this was made on a friends CNC lathe as he had his CNC VMC in bits.

I also managed to pick up a Puma 90 headlining out of a 2012 puma for $50 as the owner fitted a new one due to a couple of minor marks.

It's far better than mine was. I have already fitted the front half, but the rear will take some adjustments due to the roll cage

Oil pressure switch adaptor for the engine which I have been waiting on a while. Interestingly this was made on a friends CNC lathe as he had his CNC VMC in bits.

I also managed to pick up a Puma 90 headlining out of a 2012 puma for $50 as the owner fitted a new one due to a couple of minor marks.

It's far better than mine was. I have already fitted the front half, but the rear will take some adjustments due to the roll cage

This has been a bit delayed as I spent 2 weeks in Queenstown Mountain biking which got in the way of progress along with also being in the middle of fairly major house renovations but I have an update...!

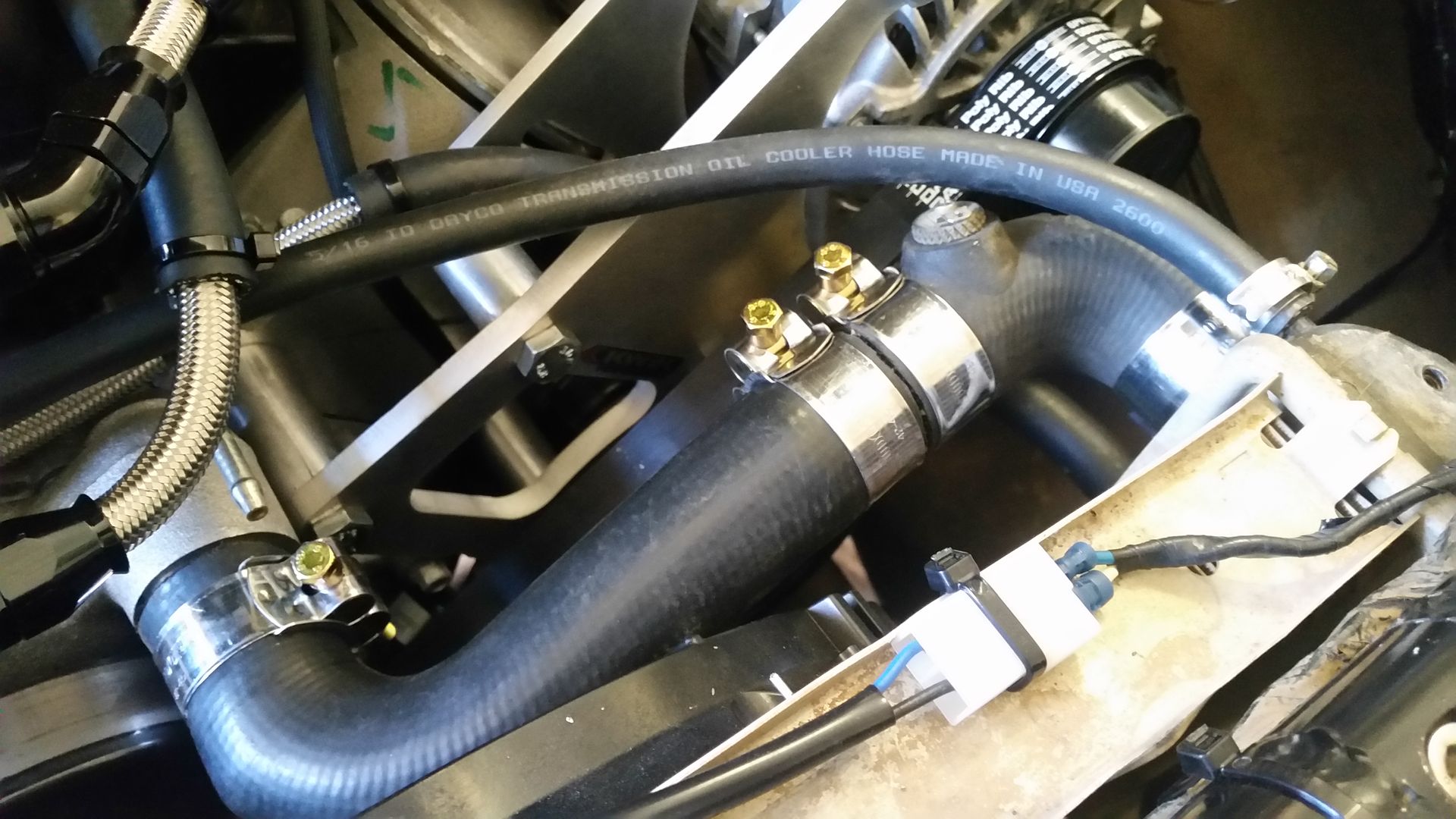

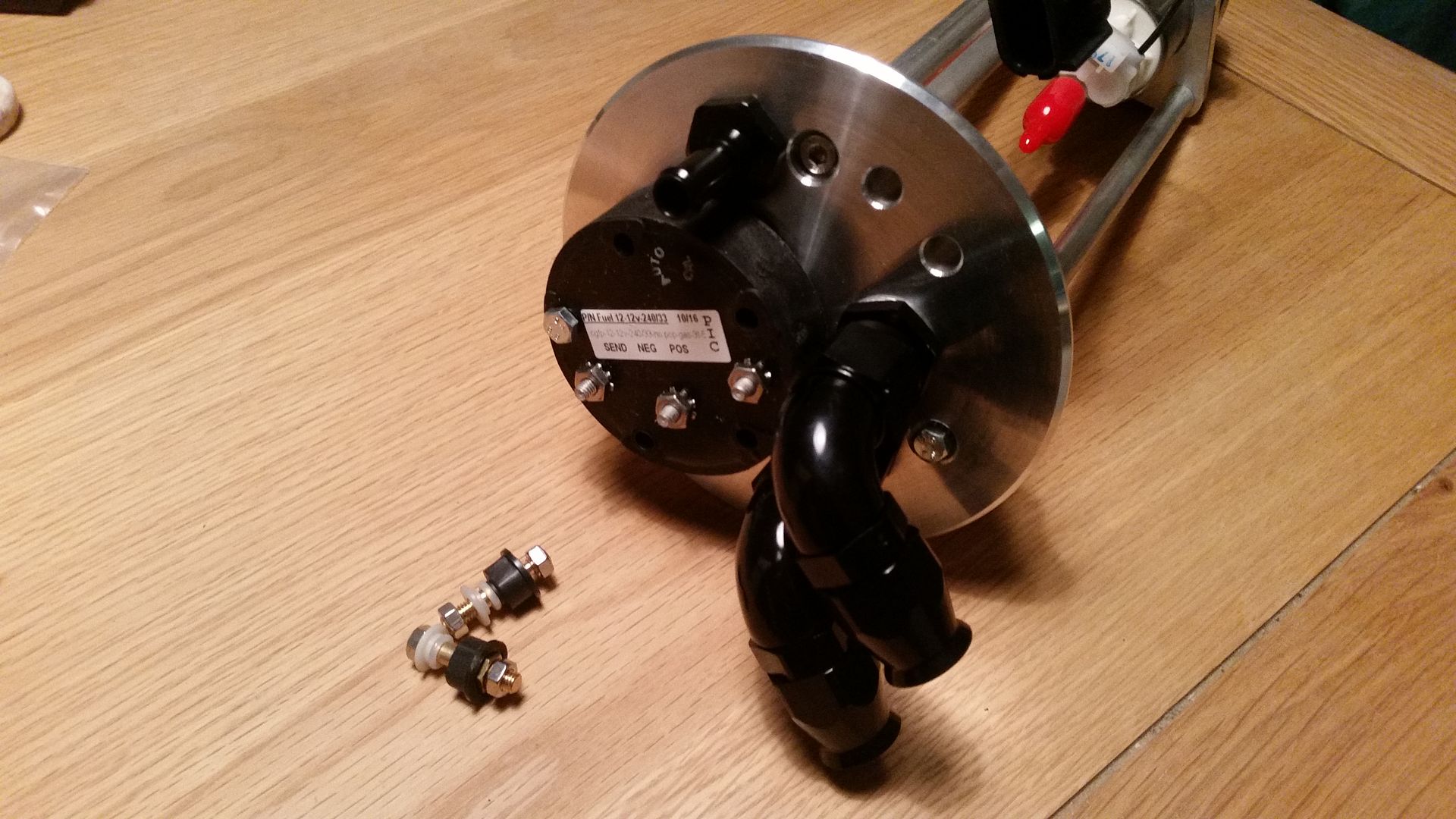

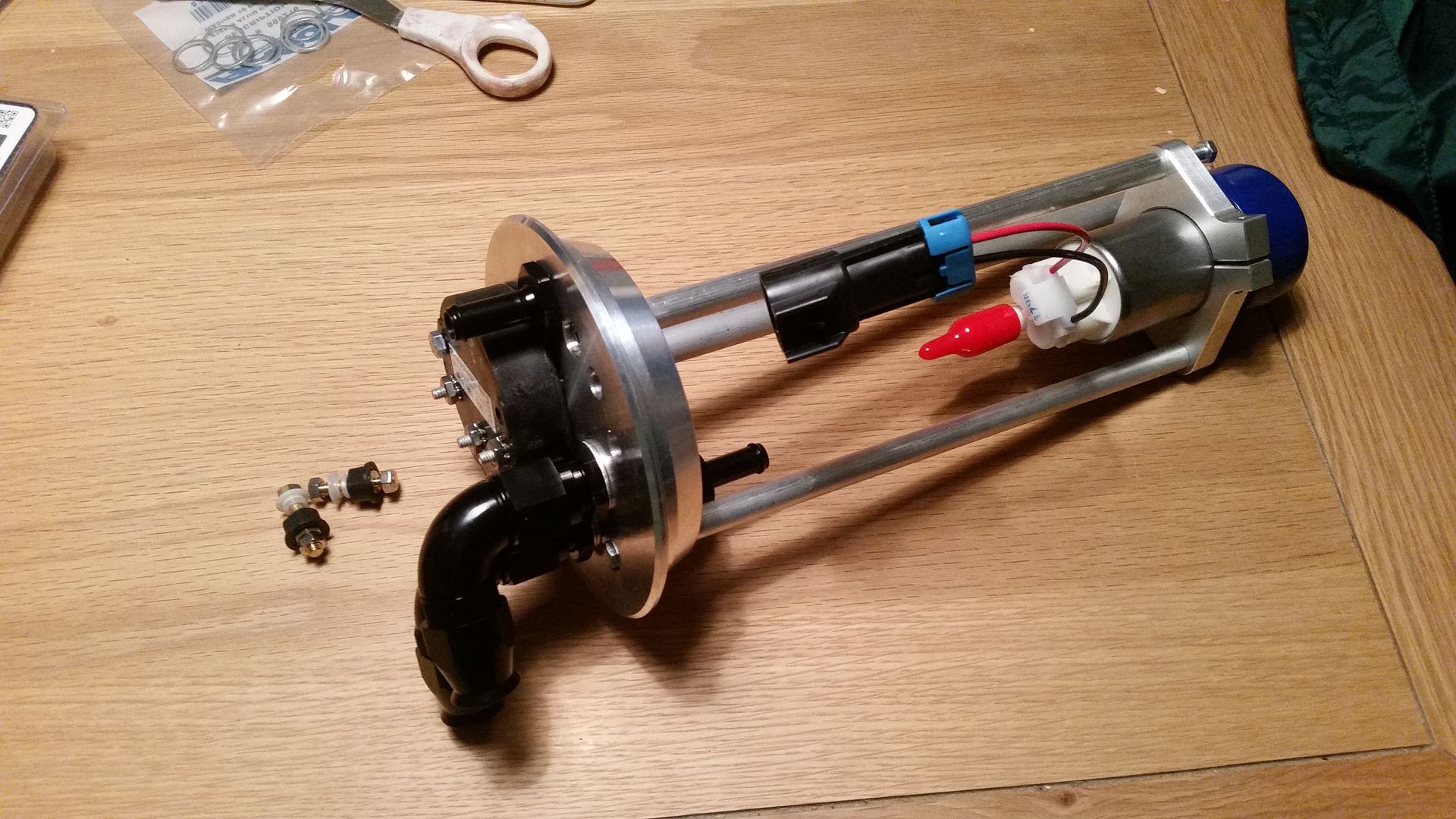

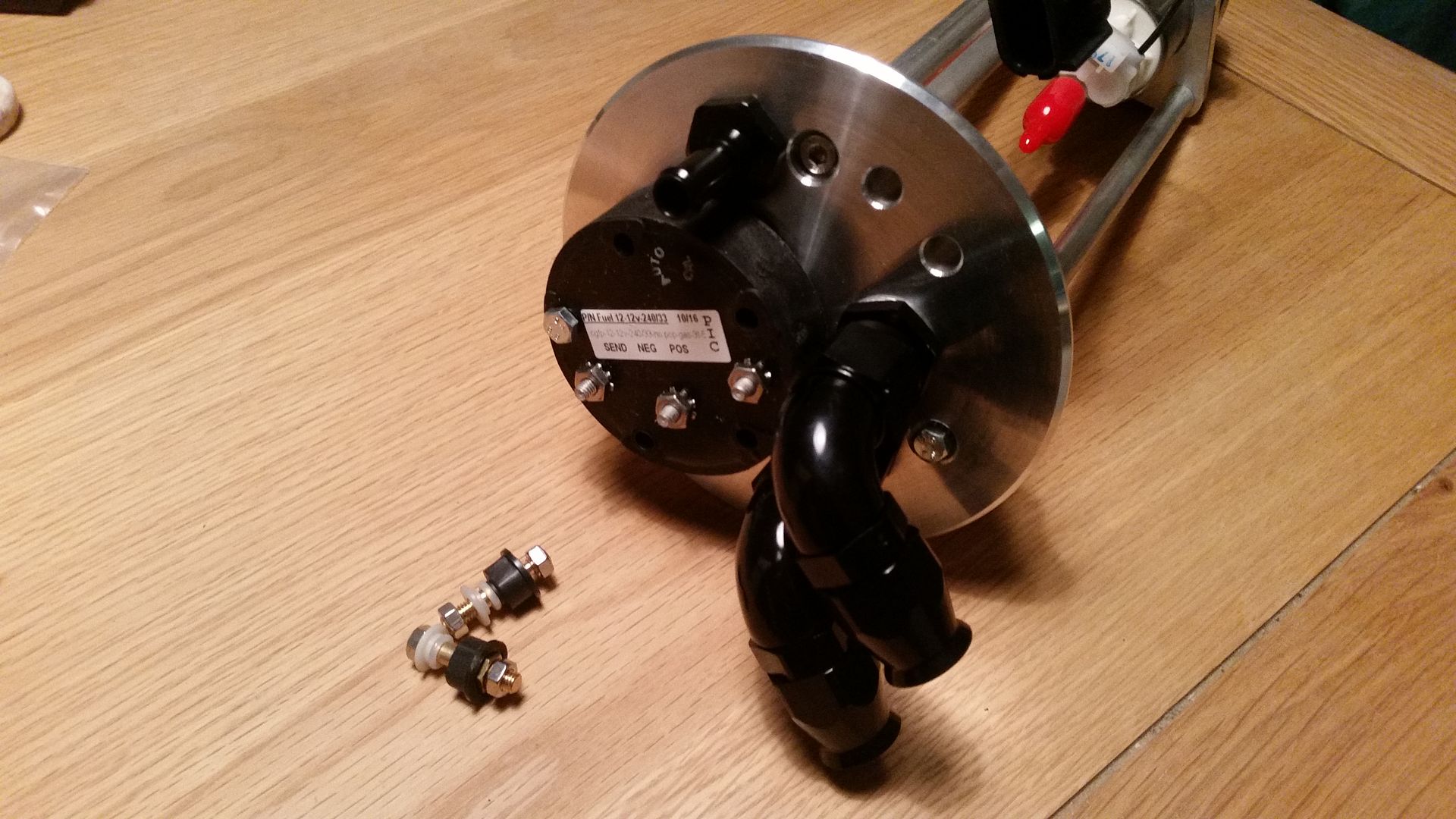

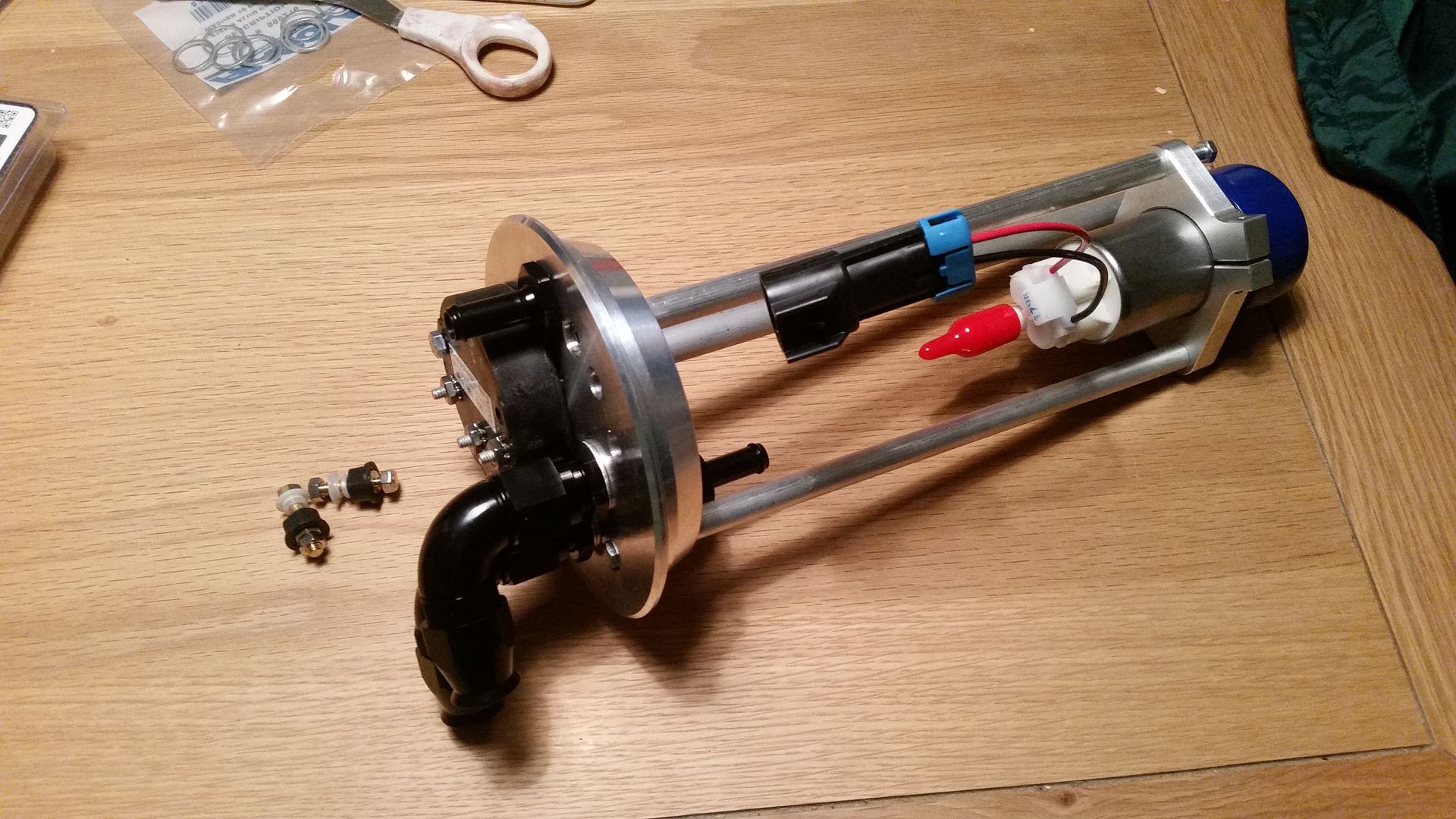

I picked up the oil pressure sensor adaptor and the fuel system parts and did a quick test assemble on the table.

I have also ordered some of the exhaust parts including the cats and silencer. With a bit of luck I may have it running by this weekend. (without an exhaust)

I picked up the oil pressure sensor adaptor and the fuel system parts and did a quick test assemble on the table.

I have also ordered some of the exhaust parts including the cats and silencer. With a bit of luck I may have it running by this weekend. (without an exhaust)

The Marks one requires the transfer to move which wasn't an option for me

This adapter is made by Nick Markiw at Rover-works.com

Easiest contact is probably via his profile here:

http://www.defendersource.com/forum/f6/gm-gen-4-co...

This adapter is made by Nick Markiw at Rover-works.com

Easiest contact is probably via his profile here:

http://www.defendersource.com/forum/f6/gm-gen-4-co...

Bit more of an update.

I have sorted the electrical issue I had. I had accidentally connected the IGN power feed for the loom/ecu etc to the accessories terminal on the key.

When the ignition was turned on power got to the pump to prime etc (as both IGN and ACC are live) but it dropped as soon as it was turned to start as the accessories power is killed during starting so it turned over but had no fuel supply or spark

Swapping the feed to the IGN terminal on the key as opposed to the ACC terminal has resolved that and the fact that the start inhibit didn't seem to work.

That now all works perfectly.

I have all the gauges working correctly, including the canbus water temp (tested it by heating the sensor in hot water aswell) and canbus oil pressure gauges. Had about 50psi on start up from memory.

I haven't got the canbus voltmeter connected yet (mainly as I am not sure where to put it!), but it is charging correctly when i multimetered the battery terminals

I have an issue with the throttle where it doesn't work.

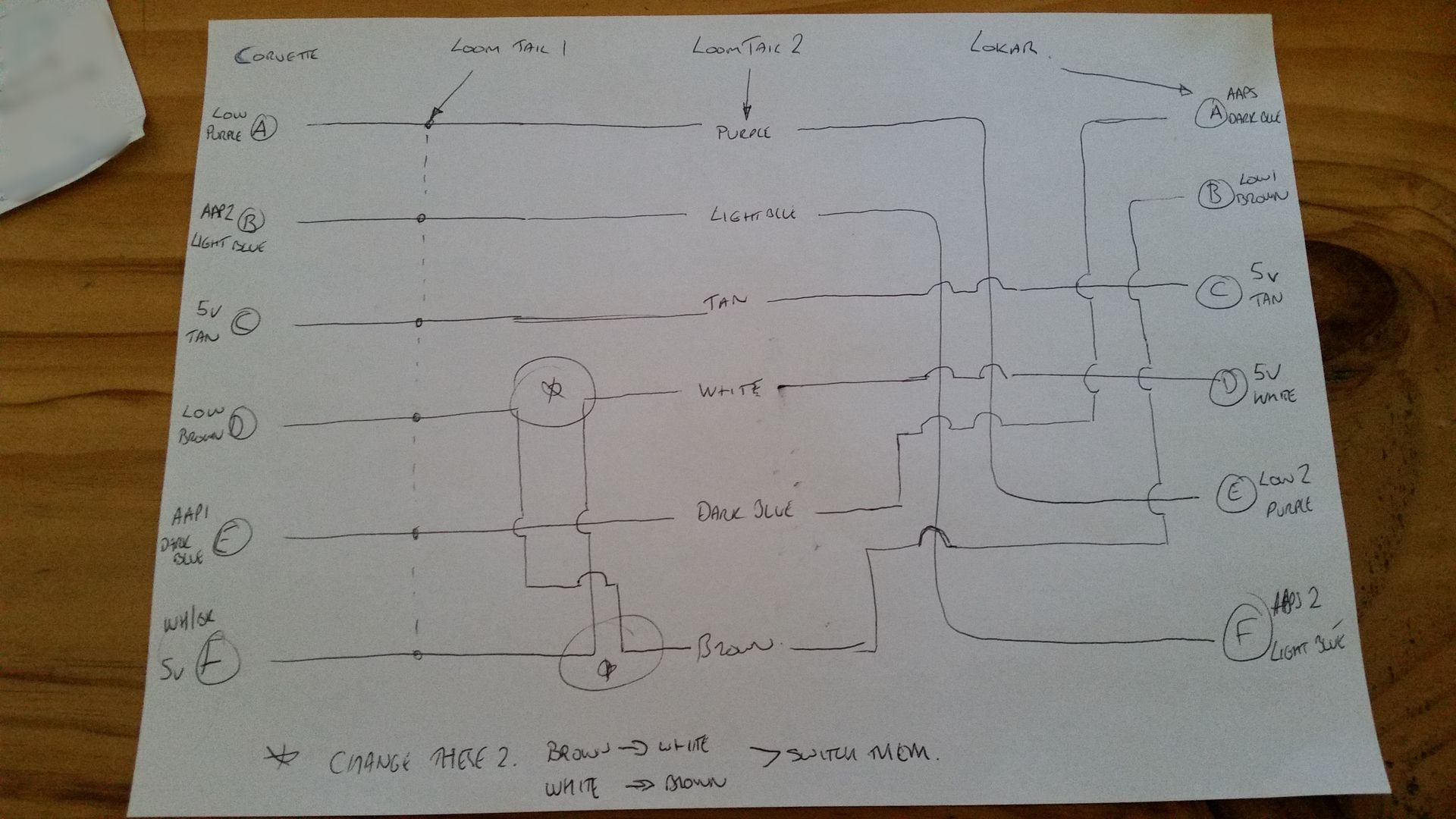

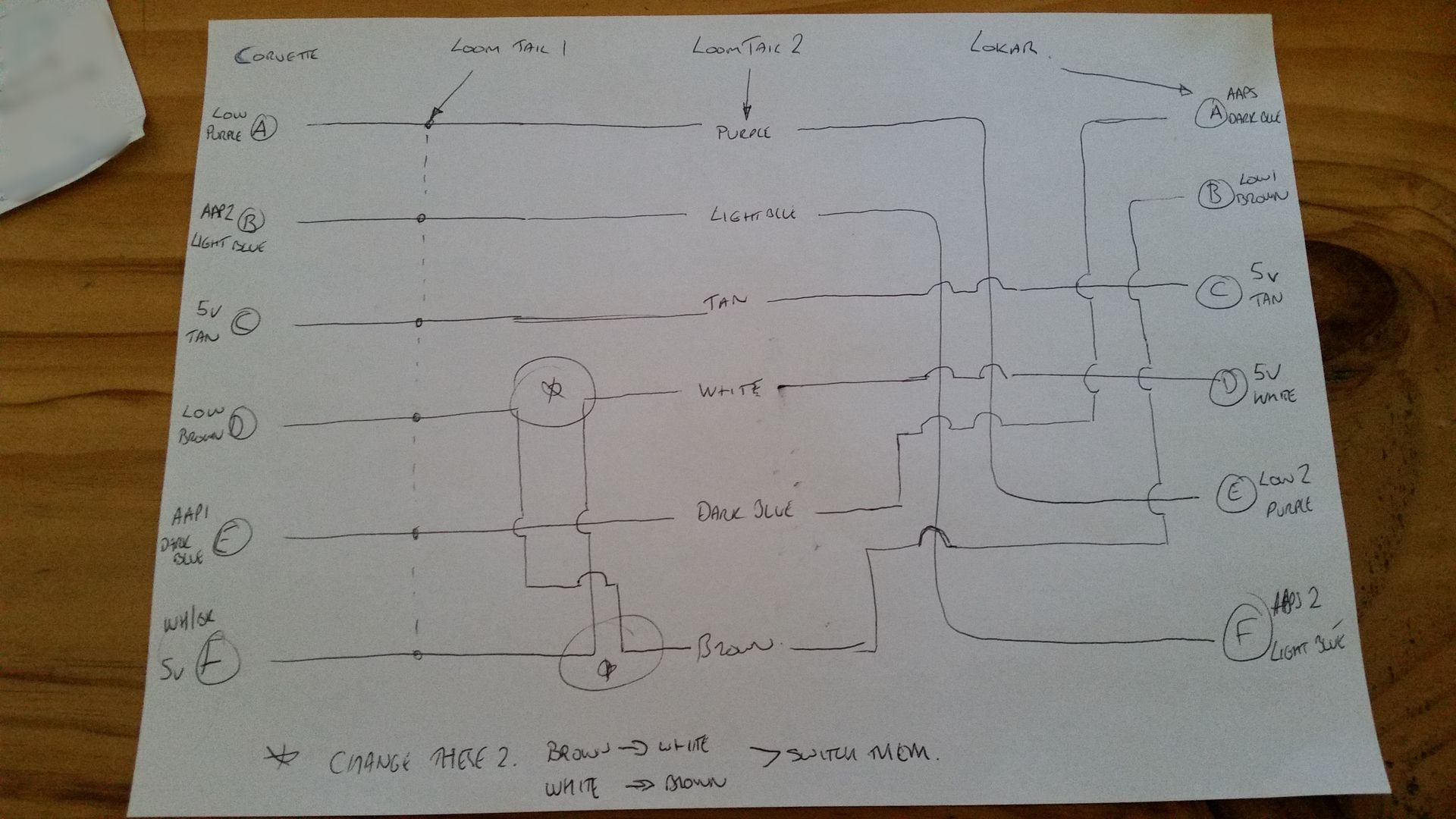

The loom is set for the corvette pinout in the connector but the Lokar pedal and loom tail/connector appears to be either camaro or truck configuration.

It looks like one of the 5v supplies and I assume corresponding low is switched around.

I have removed the short loom between the pedal and the main loom and will switch those 2 terminal pins.

I have a couple of pics I will upload when my Photobucket starts working again....

I have sorted the electrical issue I had. I had accidentally connected the IGN power feed for the loom/ecu etc to the accessories terminal on the key.

When the ignition was turned on power got to the pump to prime etc (as both IGN and ACC are live) but it dropped as soon as it was turned to start as the accessories power is killed during starting so it turned over but had no fuel supply or spark

Swapping the feed to the IGN terminal on the key as opposed to the ACC terminal has resolved that and the fact that the start inhibit didn't seem to work.

That now all works perfectly.

I have all the gauges working correctly, including the canbus water temp (tested it by heating the sensor in hot water aswell) and canbus oil pressure gauges. Had about 50psi on start up from memory.

I haven't got the canbus voltmeter connected yet (mainly as I am not sure where to put it!), but it is charging correctly when i multimetered the battery terminals

I have an issue with the throttle where it doesn't work.

The loom is set for the corvette pinout in the connector but the Lokar pedal and loom tail/connector appears to be either camaro or truck configuration.

It looks like one of the 5v supplies and I assume corresponding low is switched around.

I have removed the short loom between the pedal and the main loom and will switch those 2 terminal pins.

I have a couple of pics I will upload when my Photobucket starts working again....

Just a small update,

My rewired throttle works perfectly

This was my wiring diagram!

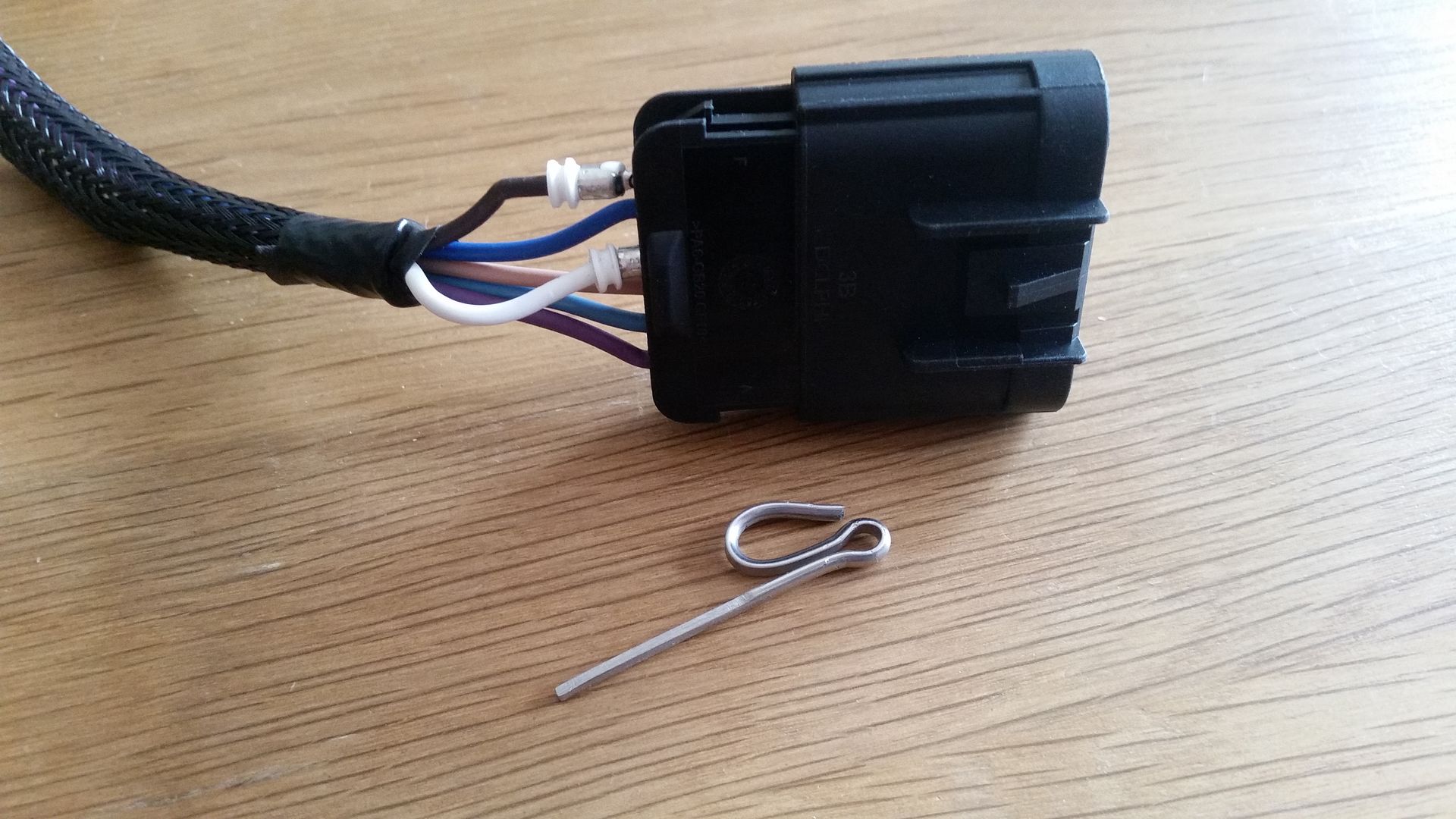

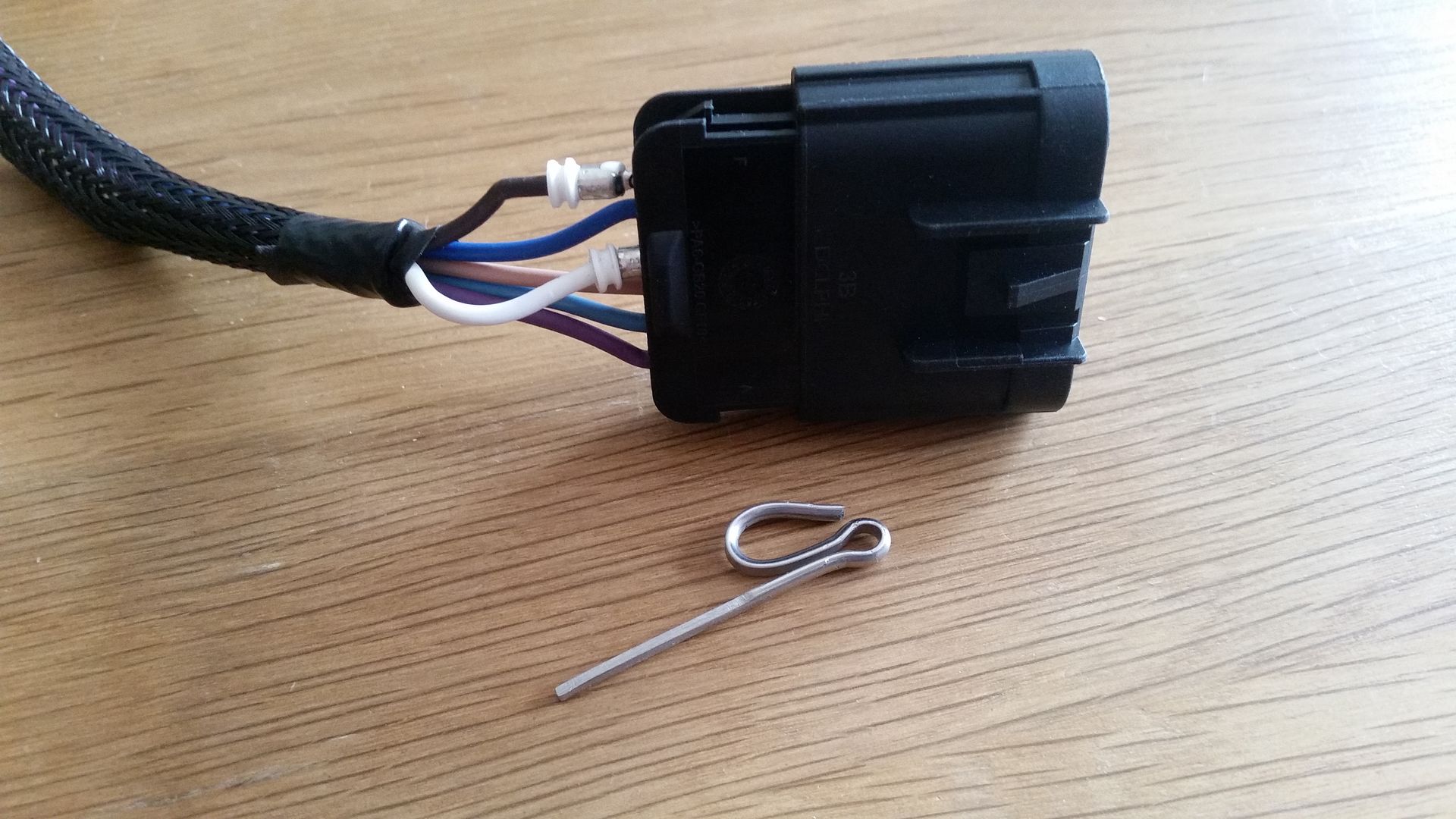

I ended up having to make a special tool out of a split pin and had to hold the tool in a bench vice to be able to push the pins out.

I also quickly tested the auto functions. All seem to work perfectly along with the gear indicator. In manual mode I can shift it from 1st-6th with the corresponding correct display on the indicator.

Only thing left is the exhaust. I have spoken to a couple of places and will try and get the car down to one asap

My rewired throttle works perfectly

This was my wiring diagram!

I ended up having to make a special tool out of a split pin and had to hold the tool in a bench vice to be able to push the pins out.

I also quickly tested the auto functions. All seem to work perfectly along with the gear indicator. In manual mode I can shift it from 1st-6th with the corresponding correct display on the indicator.

Only thing left is the exhaust. I have spoken to a couple of places and will try and get the car down to one asap

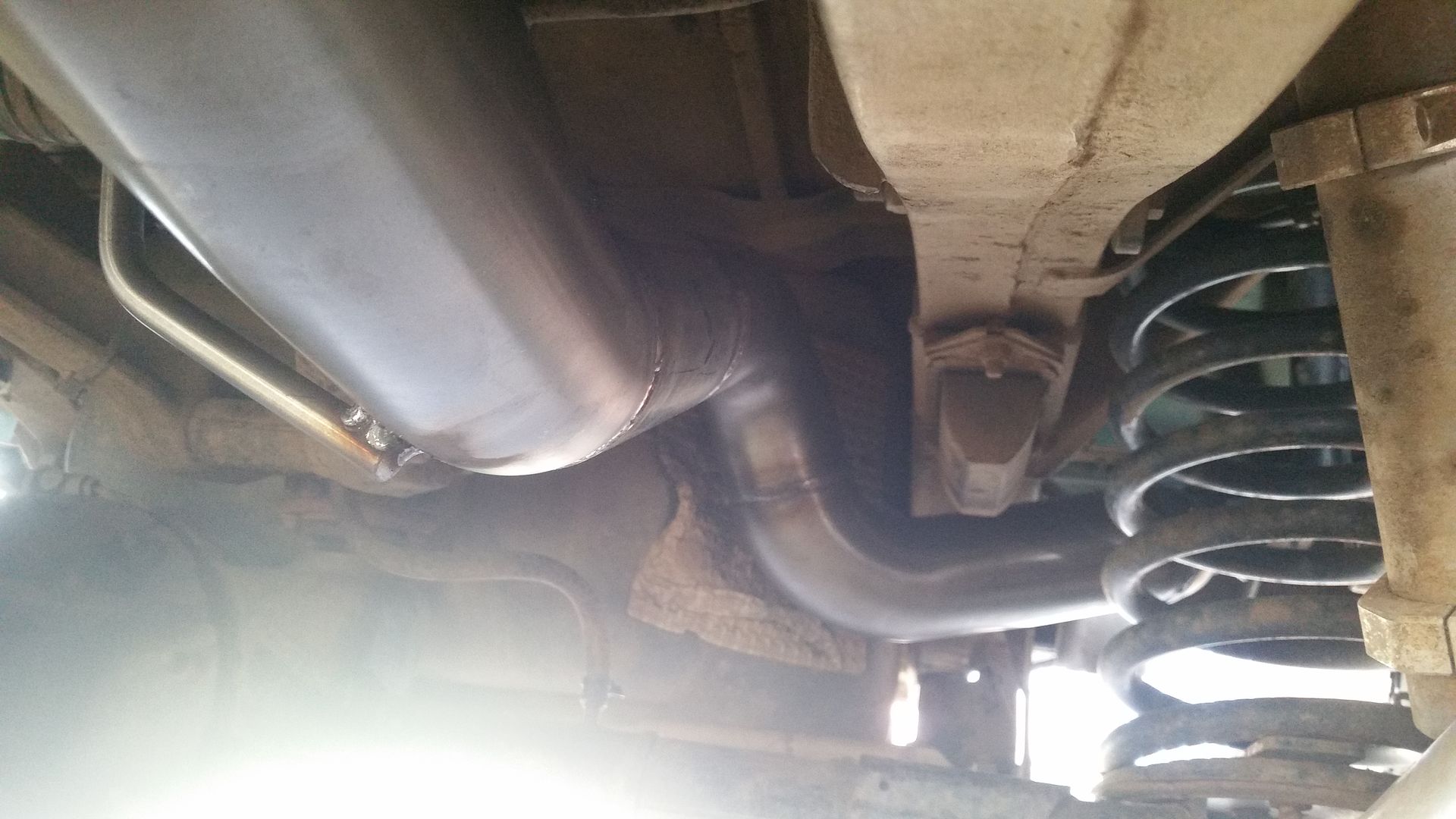

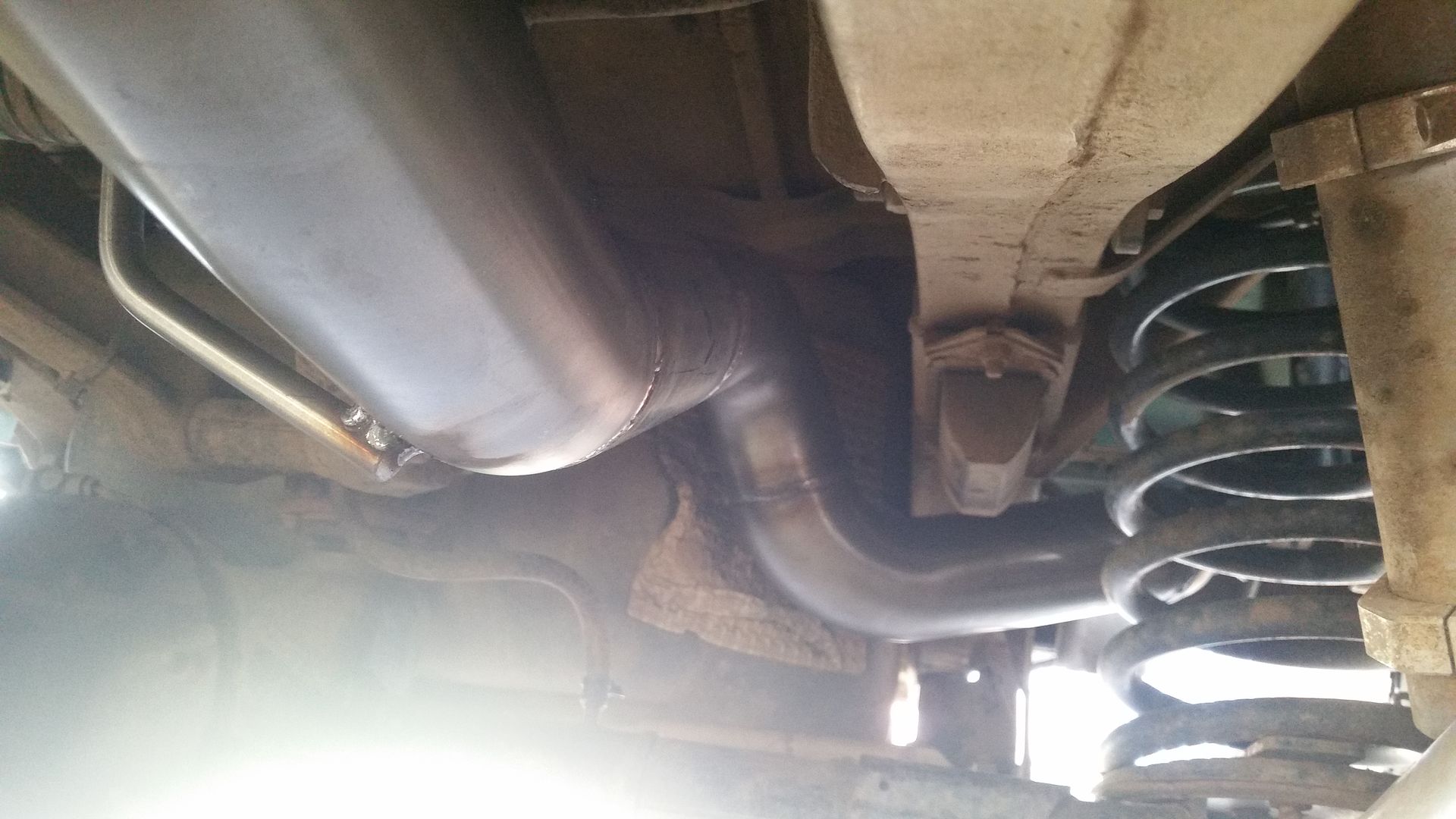

Exhaust is done. I had it collected by a truck to get it home but have since done a couple of k's in it.

I've also done the fluid level in the 6l80 now I can get it warm. All up I think it has taken 11.5litres

Will try and get a video of it once I have done a few short trips, and checked over everything that could possibly leak!

Few pics of the Exhaust below.

I've also done the fluid level in the 6l80 now I can get it warm. All up I think it has taken 11.5litres

Will try and get a video of it once I have done a few short trips, and checked over everything that could possibly leak!

Few pics of the Exhaust below.

Quick video from the drive. Will get some proper clips over the weekend. I have done a few more K's in it now, and I can say it is comedy fast.

I tried my phone and SLR to get a decent recording of the sound but neither were very good really. This is from my phone.

https://www.youtube.com/watch?v=BDiFtRGvDog

Need to fix my mud flap too!

It has a built in 0-60 and 1/4 mile timer in the speedo... I may see what it will do for the 0-60 at some stage.

I tried my phone and SLR to get a decent recording of the sound but neither were very good really. This is from my phone.

https://www.youtube.com/watch?v=BDiFtRGvDog

Need to fix my mud flap too!

It has a built in 0-60 and 1/4 mile timer in the speedo... I may see what it will do for the 0-60 at some stage.

Done a few more K's in this and sorted a couple of minor issues.

Had a slight leak from the rear of the sump. Re-torquing the bolts sorted that.

Slight squeak from one of the pulleys on the front of the engine, which appears to be the belt on the water pump. Spraying a little water on it stopped it. I will clean up and lightly sand the pulley to see if it sorts it.

It is incredibly tractable to drive. It shifts into 6th by 50kmh and will happily pull from there on a light throttle. (about 1500rpm) Its so smooth compared to the TD5/manual it had previously, and even when compared to our 2014 Defender. Mind you the TD5 was actually smoother than that in all honesty. If you just want to bumble about its totally happy doing so. It feels really lazy if you let it.

However, for what it is, its ferociously quick on anymore than half throttle, especially past about 4000rpm. It feels well into the sub 6 second range to 60mph.

Had a slight leak from the rear of the sump. Re-torquing the bolts sorted that.

Slight squeak from one of the pulleys on the front of the engine, which appears to be the belt on the water pump. Spraying a little water on it stopped it. I will clean up and lightly sand the pulley to see if it sorts it.

It is incredibly tractable to drive. It shifts into 6th by 50kmh and will happily pull from there on a light throttle. (about 1500rpm) Its so smooth compared to the TD5/manual it had previously, and even when compared to our 2014 Defender. Mind you the TD5 was actually smoother than that in all honesty. If you just want to bumble about its totally happy doing so. It feels really lazy if you let it.

However, for what it is, its ferociously quick on anymore than half throttle, especially past about 4000rpm. It feels well into the sub 6 second range to 60mph.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff