BMW 330CI E46 Build thread

Discussion

Vladikar said:

Can you tell me more about the painting prep process in detail and how you got it to look like that inside, I have a megane engine Clio and would love the interior to look like that in black!

I’ve really enjoyed your thread!

Regarding the painting process any bare metal was primed with zinc primer before welding then primed again once all the welding was done and any welding has been wire wheeled. With all bare surfaced primed the whole of the inside of the car was rubbed down with wet/dry paper but mainly using scotch pads to rough up the surfaces to give a good key for the paint. When the car was first stripped all sound deadening was removed from the car with a heat gun and a scraped and I found that Jizer was really good at removing any residue from the sound deadening as well as the horrible sticky back foam from the roof. With it all scotched ready for paint it was thoroughly hoovered multiple times and then panel wiped to remove any contaminants. Paint used was a very simple 2K gloss black paint applied using a compressor and a spray gun. It's by no means perfect but I just wanted the whole inside of the car to be consistent colour and cover up all the areas that had been welded.I’ve really enjoyed your thread!

Update

So finally yesterday I decided to get the diff fitted. I had been putting this off mainly due to the weather but also the annoyance of having to undo the drive shaft and propshaft bolts.

When I actually built the car up it was built using my spare diff which meant I could actually build the Quaife using the diff housing and gear set which came on the car when I bought it. Here with the open diff removed on the right and the freshly built diff on the left. I had to swap over the output flanges from the open diff to the new one as I've using manual shafts in the auto diff (3.38)

Not too bad of a job with a second pair of hands who sat in the car for me taking the car in and out of gear and holding the brake pedal while I cracked off the drive shaft/prop bolts and then torqued them back up when fitting. Saves a lot of time rather than getting from under the car all the time to lock everything into position.

Nice freshly painted and assembled diff all bolted up into the rear sub frame

With that done I could refit the wheels and get the car back onto it's wheels. It's been on axle stands since the start of the December, I'm sure the neighbours in the street haven't been too pleased looking at this 'ratty old' BMW on axle stands on my drive way once again.

When you see it in photos like this one you realise how subtle it actually looks compared with what it is like inside and underneath.

I will come back with an update with how the car drives after the first track day. At the moment I have done a little drive around the estate just as a basic check. It will get a small road test before the next track day but I'm waiting for a nice day with bone dry roads. Want to keep the car salt and dirt free as much as possible if i can by not driving it on the road when it's wet.

tombate911 said:

I've drawn up the spare bush I had knocking around. When I measured my slider pins they where on average 11.8, I made a version with 11.9mm holes but when fitted there was too much binding on two bushes so settled at 12mm. Worth measuring your pins and calipers before making your own though as I've only measured my prototype bush and never had these fitted to anyone else's car other than my own. They're a push/press fit in to the calipers at that diameter too but also put a groove in them for a circlip just in case

Interesting to see someone finally put some numbers on their brass bushes. I made mine to 12mm H8 fit (re-reamed after pressing them into the calipers) and fitted brand new sliding pins as mine had mushroomed slightly (previously overtightened by an ape...). They didn't even last a week after a Donington track day before starting to bind (It was January and chucking it down to be fair). After that failure I binned them off and went back to the standard rubber and the bad pad taper wear that causes  They did feel great while they worked though! I have a suspicion they didn't press in true to the caliper carrier due to casting imperfections on the caliper - almost as if they needed machining in-situ, although I'm not sure how I'd achieve that!

They did feel great while they worked though! I have a suspicion they didn't press in true to the caliper carrier due to casting imperfections on the caliper - almost as if they needed machining in-situ, although I'm not sure how I'd achieve that! Incidentally I was at the first Oulton Park day you did, running in a silver 330Ti Compact (that'd be 3 of those cars owned by comenters on this thread!). It's a shame we were never out on track at the same time as I'd spotted your car in the pits and was intrigued to see how quick it was by comparison.

I'll be interested to see how this develops. As with yourself & '330Ti' an LSD was top of my wish list towards the end of last year too...

The LSD thing is interesting for me. I've never felt the need for one on either of my 330s, to be honest. But then they weren't track cars.

With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

C70R said:

The LSD thing is interesting for me. I've never felt the need for one on either of my 330s, to be honest. But then they weren't track cars.

With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

I didn’t think I needed one but on tight second gear corners the inside wheel will spin up and you have to wait to get the power on harder or you end up facing the wrong way ! That’s with 255 AD08r tyres in dry. With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

I’m still thinking between a 3j driveline plated diff or Quaife . Also Rally designs have started to sell Quaife reps made by blackline.

330ti said:

C70R said:

The LSD thing is interesting for me. I've never felt the need for one on either of my 330s, to be honest. But then they weren't track cars.

With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

I didn’t think I needed one but on tight second gear corners the inside wheel will spin up and you have to wait to get the power on harder or you end up facing the wrong way ! That’s with 255 AD08r tyres in dry. With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

I’m still thinking between a 3j driveline plated diff or Quaife . Also Rally designs have started to sell Quaife reps made by blackline.

mwggriffiths said:

Interesting to see someone finally put some numbers on their brass bushes. I made mine to 12mm H8 fit (re-reamed after pressing them into the calipers) and fitted brand new sliding pins as mine had mushroomed slightly (previously overtightened by an ape...).

Incidentally I was at the first Oulton Park day you did, running in a silver 330Ti Compact (that'd be 3 of those cars owned by comenters on this thread!). It's a shame we were never out on track at the same time as I'd spotted your car in the pits and was intrigued to see how quick it was by comparison.

I'll be interested to see how this develops. As with yourself & '330Ti' an LSD was top of my wish list towards the end of last year too...

Cheers. As you say shame I didn't see you on track. However I'm still getting used to driving the car and no were near the full potential of the car, You can see that from the videos I've posted on previous pages, Hopefully bump into you at another day, I'm there the first weekend in March. Incidentally I was at the first Oulton Park day you did, running in a silver 330Ti Compact (that'd be 3 of those cars owned by comenters on this thread!). It's a shame we were never out on track at the same time as I'd spotted your car in the pits and was intrigued to see how quick it was by comparison.

I'll be interested to see how this develops. As with yourself & '330Ti' an LSD was top of my wish list towards the end of last year too...

Interesting to hear your experiences of the brake bushes. At the moment I'm having no issues with mine, checked the fronts when I swapped over the wheel bearing after two track days. The only thing I did differently was the bush was made so that it was only just an interference fit into the caliper and could be tapped into the caliper and the circlip acting as a back up should the bush move in the caliper for any reason, None of the 8 bushes have moved so far after 3 track days so far. As you say the brass bushes should be ovaling slightly when pressed into the calipers and binding up on the pins.

C70R said:

The LSD thing is interesting for me. I've never felt the need for one on either of my 330s, to be honest. But then they weren't track cars.

With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

Yes I would never feel that one would ever need one for the road but on a track in a car like this it is very much needed in the wet and dry. In the wet it's so easy to spin up the inside tyre even with 255 wet tyres on and in turn makes the rear end more unpredictable with the open diff albeit easier to drive with then open diff. On dry days with a semi slick 2nd or 3rd gear corners the car easily spins the inside wheel and causes a loss of drive out of corners. I found this both at Anglesey and Oulton. The car is running 750F/400R springs so quite well springed and damped with coilover dampers. Looking forward to trying the car again at Oulton in March, quite nice to go back to the same circuit at the moment as I get used to the car and refine the set up of it and dial in some more base settings for wet and dry days. With a combination of 255-section rear tyres and 150bhp/ton, I can't ever remember breaking traction in anything other than monsoon conditions. Gut-feel is that you'll probably be fine for traction out of slow corners with decent tyres, but YMMV.

Been a few weeks since I had anything new to add to the build thread so here's a few photos and little updates to keep things ticking over.

Made a few bits for friends, one of which was a custom steering wheel switch panel to do exactly what he wanted it to with push buttons as well as locations for some rotary switches, cut from a piece of 3mm acrylic using a laser cutter

Rewelded the inline temp sensor. The previous version ended up with a M12x1.75 boss welded on not a M12x1.5 which was required for the temp sensor. Milled off the old boss on the milling machine at work and got a new boss welded on there ready to go on.

Mounted it up in place on the top of the oil cooler and ran the temp sensor wiring down to the oil cooler which feeds back to the gauge which is mounted just in front of the steering wheel nicely in the drivers eye line. Final job to do in the next week is to machine some upper mounts for the top of the oil cooler to hold it in it's final position. May even go down the route of 3D printing these angle brackets... Watch this space...

Little bit of a side note but at the beginning of last month I popped down the Autosport and while I was there managed to do something I've been meaning to do for a long time which was get my ears moulded for a proper set of ear plugs designed for motorsport use. The Clio used to have some horrific resonance at certain RPM on track but it was a job that was always put on the back burner, silly of me really but noticing a slight drop in how good my earing is over the past couple of years I decided it was silly not to get some made which could be used for work as well as in the car, the BMW is a totally different level of noise inside so certainly going to be needed for track days this year.

Edited by tombate911 on Saturday 2nd February 07:09

Prep for Oulton 2nd March 2019

Time for a little update, It's only a week now till the next Oulton Park track day so I've been working through some jobs trying to make sure everything is done in time and fix a couple of issues along the way.

I documented earlier on after the last track day that I was getting vibration through the wheel under braking and found the NSF wheel bearing had play in it after only 3 days on track. That was replaced and when I took the car out on a test drive I expected the vibration to have gone but it was weirdly still there. Obviously there must be something else causing it. I got the DTI onto the front discs and found there was a small amount of run out and waviness to the surface of the discs. I've now replaced both front discs and while I was there checked the condition of the brass slider pin bushes I made to check there was no binding after a few days use. I should add I'm using the CLRC5+ pads. But have always been a big advocate of DS1.11. I hope this is a one off problem with the brakes which can be prevented in the future

I'd forgotten to take any decent photos through this process so this will have to do.

With the brake issue arising after only 3 days on track I've decided to improve on the standard BMW cooling and run some proper ducts to the inside of the disc on the front.

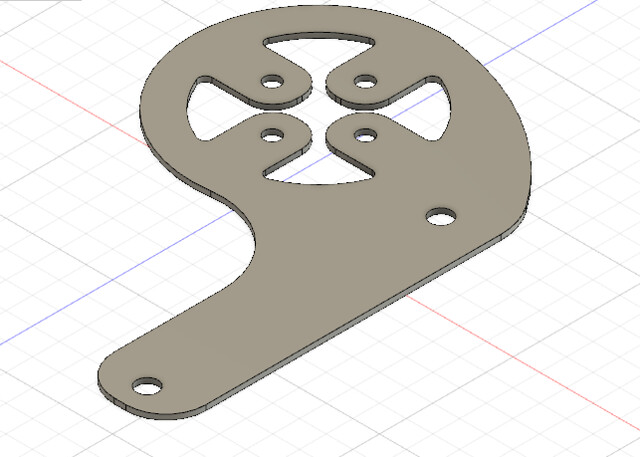

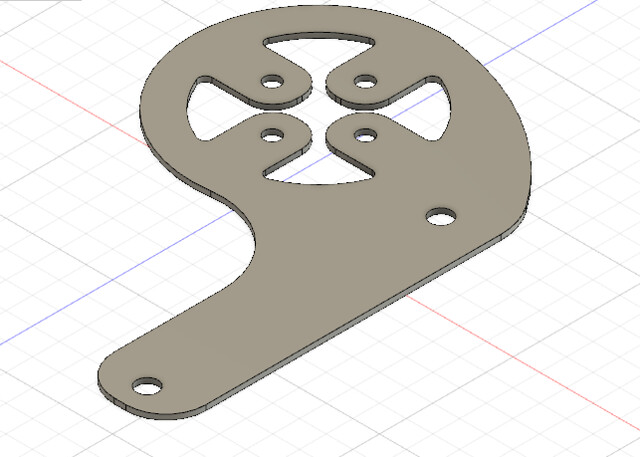

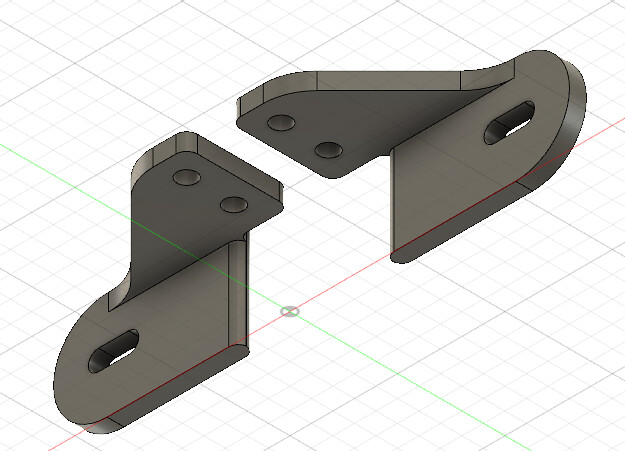

Using the two bolt holes in the front hubs which are normally used the mount the standard backing plates I've made up a quick paper template to make a bracket to hold the cooling duct in place.

Ducting will run directly into the back of this plate into the centre of the disc evacuating the heat outwards through the disc.

Quick mock up of where the ducts will run before making the plates up. Wanted to make sure there is clearance with the front wheel on full lock but also enough movement and slack in the ducting for it not to get ripped off or in the way.

Working from the card template I have drawn up the brackets in CAD and will have them laser cut this week ready for fitting before the weekend. Just a case of popping the discs off, bolting them to the hubs and attaching the ducts which have already been ran through to the existing BMW cooling ducts.

The centre sections will be bent outwards to mount the ducting to.

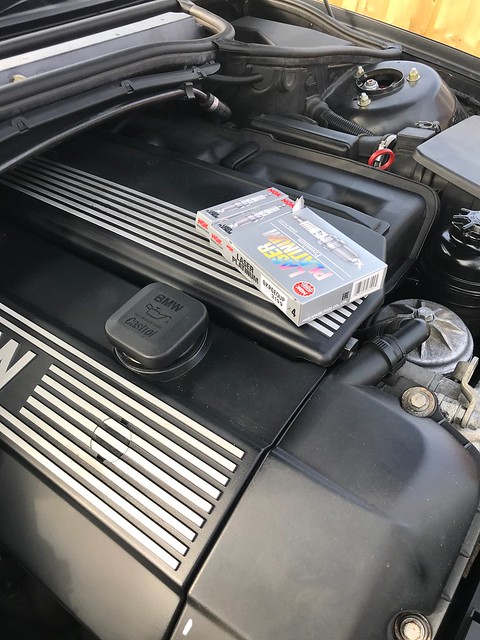

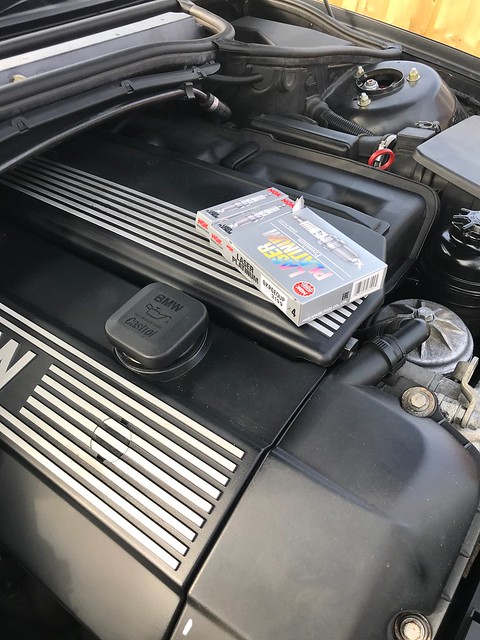

Little bit of prep. A job i should have done when I first serviced everything else on the car but didn't have them at the time which was swapping over the spark plugs. I didn't know what the previous owner had fitted for spark plugs or even how long they had been in there.

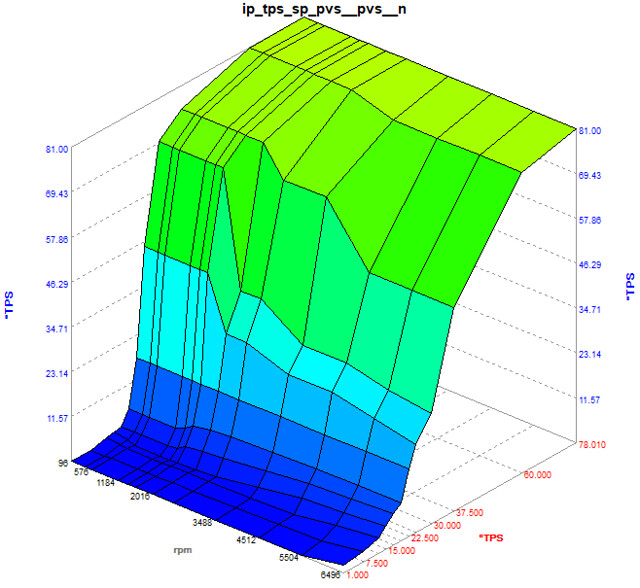

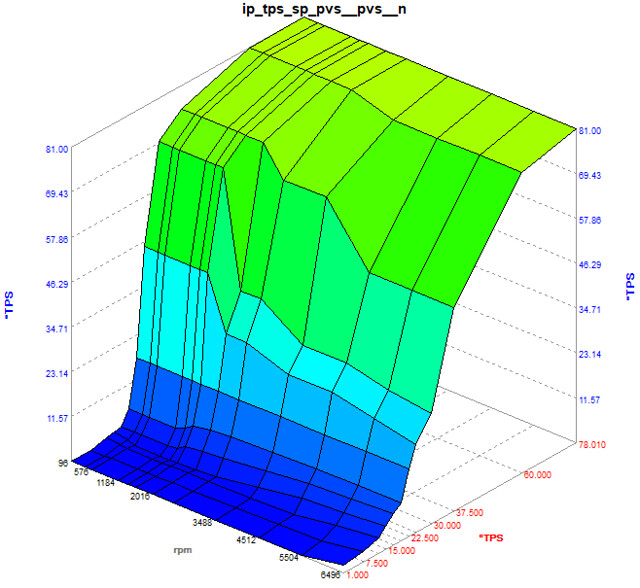

One of the final jobs I've been working on today is the throttle/ECU map. I noticed when driving on the last few track days how horrible the throttle felt, when applying the throttle it didn't do a great deal and then suddenly you got a hit of power. Not what I was looking for when trying to drive smoothly or even trying to balance the car through the corners or when it starts to slide. I can't help but notice this watching back over the track day footage. With a bit of help from a friend sorting out my laptop with the correct software for reading and writing to the MS43 ECU, I've been able to pull off the current map on the car and have a looking at the graph for the TPS

Here you can see the extent of how sharply the throttle changes. Feels great on the road and makes the car feel fast. But certainly not what I wanted.

With a little bit of experimenting with different throttle map Ideas I have settled with the following which I can test next weekend. I've ran this on the road today and it feels so much more smoother and easier to balance without the harsh increase in throttle. The eagle eyed people may notice how flat the bottom of the graph looks below 15% TPS. This is due to the fact that everything below 12% TPS and 4500RPM is controlled by the Idle Control valve until it reaches it's max duty cycle and then the throttle body starts to open at this point so I have had to adjust the table for the TPS accordingly.

Final car related job for today was to replace some of the grip tape on the floor and also wipe down the interior of the car after a wet track day and a slight off into the mud the underside of the car had to be jet washed, inevitably dirty water found it way into the car through a couple of tiny holes so I've spent a bit of time this evening tidying up inside the car. Will continue with the exterior tomorrow.

While I was at it I took a little interior photo...

Time for a little update, It's only a week now till the next Oulton Park track day so I've been working through some jobs trying to make sure everything is done in time and fix a couple of issues along the way.

I documented earlier on after the last track day that I was getting vibration through the wheel under braking and found the NSF wheel bearing had play in it after only 3 days on track. That was replaced and when I took the car out on a test drive I expected the vibration to have gone but it was weirdly still there. Obviously there must be something else causing it. I got the DTI onto the front discs and found there was a small amount of run out and waviness to the surface of the discs. I've now replaced both front discs and while I was there checked the condition of the brass slider pin bushes I made to check there was no binding after a few days use. I should add I'm using the CLRC5+ pads. But have always been a big advocate of DS1.11. I hope this is a one off problem with the brakes which can be prevented in the future

I'd forgotten to take any decent photos through this process so this will have to do.

With the brake issue arising after only 3 days on track I've decided to improve on the standard BMW cooling and run some proper ducts to the inside of the disc on the front.

Using the two bolt holes in the front hubs which are normally used the mount the standard backing plates I've made up a quick paper template to make a bracket to hold the cooling duct in place.

Ducting will run directly into the back of this plate into the centre of the disc evacuating the heat outwards through the disc.

Quick mock up of where the ducts will run before making the plates up. Wanted to make sure there is clearance with the front wheel on full lock but also enough movement and slack in the ducting for it not to get ripped off or in the way.

Working from the card template I have drawn up the brackets in CAD and will have them laser cut this week ready for fitting before the weekend. Just a case of popping the discs off, bolting them to the hubs and attaching the ducts which have already been ran through to the existing BMW cooling ducts.

The centre sections will be bent outwards to mount the ducting to.

Little bit of prep. A job i should have done when I first serviced everything else on the car but didn't have them at the time which was swapping over the spark plugs. I didn't know what the previous owner had fitted for spark plugs or even how long they had been in there.

One of the final jobs I've been working on today is the throttle/ECU map. I noticed when driving on the last few track days how horrible the throttle felt, when applying the throttle it didn't do a great deal and then suddenly you got a hit of power. Not what I was looking for when trying to drive smoothly or even trying to balance the car through the corners or when it starts to slide. I can't help but notice this watching back over the track day footage. With a bit of help from a friend sorting out my laptop with the correct software for reading and writing to the MS43 ECU, I've been able to pull off the current map on the car and have a looking at the graph for the TPS

Here you can see the extent of how sharply the throttle changes. Feels great on the road and makes the car feel fast. But certainly not what I wanted.

With a little bit of experimenting with different throttle map Ideas I have settled with the following which I can test next weekend. I've ran this on the road today and it feels so much more smoother and easier to balance without the harsh increase in throttle. The eagle eyed people may notice how flat the bottom of the graph looks below 15% TPS. This is due to the fact that everything below 12% TPS and 4500RPM is controlled by the Idle Control valve until it reaches it's max duty cycle and then the throttle body starts to open at this point so I have had to adjust the table for the TPS accordingly.

Final car related job for today was to replace some of the grip tape on the floor and also wipe down the interior of the car after a wet track day and a slight off into the mud the underside of the car had to be jet washed, inevitably dirty water found it way into the car through a couple of tiny holes so I've spent a bit of time this evening tidying up inside the car. Will continue with the exterior tomorrow.

While I was at it I took a little interior photo...

Darryl H said:

Great project thread. I've just read start to finish, some really good work in there

Thanks, as long as people are interested in it that's the main thing. One of the main reasons for coming over to PH was to have more conversations about the car and document it for people to see.

Sunday Progress

The paint work on this car has always been a little flat especially on the rear quarter where it's had some paint in the past. Wanted to give the car a bit of a clean up ready for next weekend. Couple of hours with the DA on a couple of panels, decontaminated the paint and added a coat of wax and taken some more detailed photos for this thread.

This angle shows off the interior of the car a lot more than usual photos.

Spent a little while with some detailing products tiding up the engine bay and bringing the plastics back to life

Also spent the afternoon doing a few maintenance jobs on the Brian James trailer I use for moving the car around. Paint added to the tyre rack, rebuilt the jockey wheel washed and painted a couple of bits of rust that had appeared on the wheels.

One final job I needed to do this weekend was to draw up some oil cooler top brackets. I could make these out of some piece of bent steel but i'd much rather design and make something a little more fancy. Designed these little brackets to support the top of the oil cooler. Will get these 3D printed in plastic this week and fitted to the car.

Designed to bolt to the standard cross brace that runs in front of the radiator. I have used the bottom posts to support the weight of it, the top ones will be there just to support the top from swaying, should keep everything in place nicely.

Progress before Oulton continues...

First one started out with a little bit of maintenance. Washer pump stopped working last week, little bit of testing pointed towards it being the pump. For 30 seconds I thought about removing it and making more space in the engine bay but I do like the functionality of being able to clear the windscreen of the car on track New pump ordered and fitted

Carrying on with the oil cooler mounting from the previous posts. I've printed off the two top cooler mounts in black plastics

Test fitted the top brackets and went together first time. The top bolts need replacing for some shorter ones but the bolt box is a little depleted after building this car, nice and simple design that's functional for the cooler mounting, much easier than making brackets from metal

Brake cooling duct brackets came back from water jet cutting

Bent the centre sections backwards to fit inside the ducting

Bolted to the hubs making sure the duct isn't going anywhere when cornering putting force onto the ducting and pointing the air nicely in the centre of the disc.

All done and clamped up. Enough clearance on the inside of the tyre too.

With those last few jobs done, time to get it loaded onto the trailer. Note, I never fitted these little blue side lights but couldn't resist taking a photo from that angle when loading it onto the trailer

Finally.... Before I post the update about yesterdays track day I've picked these up as a little treat to myself.

Team Dynamics 1.2 18"x9J ET35. Weighing in nicely at 9kg. They're going to be a big saving over the MV1's which I estimate to weigh in the region of 12-13kg.

First one started out with a little bit of maintenance. Washer pump stopped working last week, little bit of testing pointed towards it being the pump. For 30 seconds I thought about removing it and making more space in the engine bay but I do like the functionality of being able to clear the windscreen of the car on track New pump ordered and fitted

Carrying on with the oil cooler mounting from the previous posts. I've printed off the two top cooler mounts in black plastics

Test fitted the top brackets and went together first time. The top bolts need replacing for some shorter ones but the bolt box is a little depleted after building this car, nice and simple design that's functional for the cooler mounting, much easier than making brackets from metal

Brake cooling duct brackets came back from water jet cutting

Bent the centre sections backwards to fit inside the ducting

Bolted to the hubs making sure the duct isn't going anywhere when cornering putting force onto the ducting and pointing the air nicely in the centre of the disc.

All done and clamped up. Enough clearance on the inside of the tyre too.

With those last few jobs done, time to get it loaded onto the trailer. Note, I never fitted these little blue side lights but couldn't resist taking a photo from that angle when loading it onto the trailer

Finally.... Before I post the update about yesterdays track day I've picked these up as a little treat to myself.

Team Dynamics 1.2 18"x9J ET35. Weighing in nicely at 9kg. They're going to be a big saving over the MV1's which I estimate to weigh in the region of 12-13kg.

Oulton Park 2nd March 2018

Early start to the morning started when I woke up at 5:30 ready to head down to Oulton Park which is only a 40 minute drive for me. I was awake so decided to hit the road about 6am and have a relaxed start to the morning getting everything unloaded without rushing around, giving more time for catching up with friends. Within our track group we had 10 cars booked on with another additional 8-10 other friends and relatives with us who had come down for the day to take it all in and share the fun as a passenger.

Conditions for the morning were wet, overcast skies so it was sighting laps and the first session on wet tyres.

Some of the family come down to see what was going on on circuit, for some of them it was the first time at a track day, I persuaded my sister into getting a passenger wrist band and coming out with me for a few laps. Obviously for this I had to have the passenger reaction cam running.

Full video link - https://www.youtube.com/watch?v=KnPODPlVTMQ&fe...

Here's a little highlights video including a couple of moments I had on track during the day.

Youtube Link - https://www.youtube.com/watch?v=QzvXRZbAQ20

LSD

The day was going really well, the car running flawlessly, the additional control and grip from the diff was really noticeable, no longer was the car searching for grip coming out of the chicanes and spinning the inside wheel, I was able to get onto the throttle a earlier, this was also made possible too with the changes to the driver request map for the throttle making it much easier to feed in the power coming out of corners, as well as that being able to balance the car a lot easier with much smoother throttle response. The diff actually made the car more predictable to drive but as you can imagine it also makes the car that bit easier the slide. At the moment the Quaife seems pretty good, I know how I can make the Quaife spin one wheel by hopping kerbs and unweighting one of the wheels but that isn't my driving style. Will be able to give a better report on it in the future after a bit more testing in wet conditions. I only got to run to the car in the wet for one 15 minute session before a dry line started to appear and it was time to get the semi slicks on.

Oil Cooler

With the oil cooler fitted the car was much better at being able to do extended periodsof time out on track. Previously 4 hard laps was enough to send the oil temps climbing up into the mid 120's. Yesterday I had the ability to run the car for over 40 minute stints with the oil temps sitting around 110 degrees after that period. They climb up to that after around 5 laps and seem to settle there. I did at one point manage to run them up towards the 120 degree mark on one session in the middle of the day weirdly, which I did anticipate as where I have fitted the cooler some of the main section of the core is actually covered by the bumper. I will probably do the usual hack of drilling 3-4 holes in the front of the bumper behind were the reg plate mounts which will give some more air flow as the ambient temps increase through to summer.

Coolant temps didn't climb above 110 degrees over a 40 minute stint but I think I will replace the radiator before the next track day just for piece of mind.

Finally I did have a little bit of breathing from the power steering res but I think this will be the next temperature issue I come across on track. Especially with my plan to move to 9J front wheels I will be fitting a 10 Row cooler in the power steering return line to make sure it doesn't become a problem on track in the future as the car starts to get driven harder as I get used to driving RWD. At this point I'm still learning.

Brakes

I've since starting to track this car I've never been wowed over by the brake set up. I've doe all the usual things like new lines, discs, CL RC5+ Pads, also fitting cooling ducts to the front brakes for this track day to try and keep everything running perfectly. I had a little bit of an experiment with the brakes over the course of Saturday. Firstly starting off with my usual set up which is with ABS plugged in and working and traction control completely unplugged and disabled. This set up is fine if you're very smooth on the brakes but the power i'm able to put through the brakes feels to be constantly being limited by the ABS, in the past I've removed the RC5+ pads from the rear and gone back to standard brembo pads to ensure that the rear wheels aren't locking slightly causing the ABS to kick in anymore than it needs to. I often feel like I get a very firm pedal and pushing as hard as I want for more braking doesn't apply anymore force.

For the afternoon session I went out with the ABS controlled unplugged. Driving it that was a great, I was able to put more force through the brake pedal and brake a little later and never locked up except for one occasion as I was trail braking into Shell. I was much preferring the feel of driving the car without ABS however and this a very strange with the ABS unplugged the car started detecting a miss fire on the long uphill straights. I Initially thought it was a miss fire, swapping oils over, swapped spark plugs, thought it could have been fuel surge from the chicane before the straight so added an additional 40L of fuel to brim the tank, kept getting the engine light and miss fire detection repeatedly in the afternoon. In the second to last session I buzzed through the pits, jumped out, plugged in the ABS Controller and set off again. Ran for 45 minutes till to chequered flag without any issues what to ever. It appears there is something going on due to the fact the Engine ECU isn't getting a wheel speed signal from the ABS controller because it is unplugged. I know the ECU relies on this for a number of things due to the fact I have had to raise the RPM limiter in the ECU which is put in place in case it doesn't get a wheel speed sensor a lower RPM limit if around 4k is applied. However something else deeper is going on. I've got some things I'm going to change and experiment with inside the ECU as yesterday without the wheel speed sensor it wasn't cutting fuel on over run and sounded like a machine gun when I let off. I have already corrected that in the ECU just need to flash that file to it and test however the miss fire was detected at full load up hill just before the limiter around 6500RPM. So I know changing the overrun wont be the solution. At the moment I think i'm looking towards improving the front brake set up and continuing to run with the ABS. I don't really have a plan for this, possible Porsche 996 calipers, or after market calipers with a slightly bigger rotor to improve the braking performance of the front brakes then experiment with the same rear pads or refitting RC5+'s to the rear to increase the braking from the rear if the front was improved. My final thought is to go back to DS1.11 brake pads which I always ran on the Clio and the were fantastic and compare a different pad to the RC5+s.

Would be really interested to hear peoples thoughts and opinions on all the points above. I know there are some very knowledgeable and experienced people on here.

Early start to the morning started when I woke up at 5:30 ready to head down to Oulton Park which is only a 40 minute drive for me. I was awake so decided to hit the road about 6am and have a relaxed start to the morning getting everything unloaded without rushing around, giving more time for catching up with friends. Within our track group we had 10 cars booked on with another additional 8-10 other friends and relatives with us who had come down for the day to take it all in and share the fun as a passenger.

Conditions for the morning were wet, overcast skies so it was sighting laps and the first session on wet tyres.

Some of the family come down to see what was going on on circuit, for some of them it was the first time at a track day, I persuaded my sister into getting a passenger wrist band and coming out with me for a few laps. Obviously for this I had to have the passenger reaction cam running.

Full video link - https://www.youtube.com/watch?v=KnPODPlVTMQ&fe...

Here's a little highlights video including a couple of moments I had on track during the day.

Youtube Link - https://www.youtube.com/watch?v=QzvXRZbAQ20

LSD

The day was going really well, the car running flawlessly, the additional control and grip from the diff was really noticeable, no longer was the car searching for grip coming out of the chicanes and spinning the inside wheel, I was able to get onto the throttle a earlier, this was also made possible too with the changes to the driver request map for the throttle making it much easier to feed in the power coming out of corners, as well as that being able to balance the car a lot easier with much smoother throttle response. The diff actually made the car more predictable to drive but as you can imagine it also makes the car that bit easier the slide. At the moment the Quaife seems pretty good, I know how I can make the Quaife spin one wheel by hopping kerbs and unweighting one of the wheels but that isn't my driving style. Will be able to give a better report on it in the future after a bit more testing in wet conditions. I only got to run to the car in the wet for one 15 minute session before a dry line started to appear and it was time to get the semi slicks on.

Oil Cooler

With the oil cooler fitted the car was much better at being able to do extended periodsof time out on track. Previously 4 hard laps was enough to send the oil temps climbing up into the mid 120's. Yesterday I had the ability to run the car for over 40 minute stints with the oil temps sitting around 110 degrees after that period. They climb up to that after around 5 laps and seem to settle there. I did at one point manage to run them up towards the 120 degree mark on one session in the middle of the day weirdly, which I did anticipate as where I have fitted the cooler some of the main section of the core is actually covered by the bumper. I will probably do the usual hack of drilling 3-4 holes in the front of the bumper behind were the reg plate mounts which will give some more air flow as the ambient temps increase through to summer.

Coolant temps didn't climb above 110 degrees over a 40 minute stint but I think I will replace the radiator before the next track day just for piece of mind.

Finally I did have a little bit of breathing from the power steering res but I think this will be the next temperature issue I come across on track. Especially with my plan to move to 9J front wheels I will be fitting a 10 Row cooler in the power steering return line to make sure it doesn't become a problem on track in the future as the car starts to get driven harder as I get used to driving RWD. At this point I'm still learning.

Brakes

I've since starting to track this car I've never been wowed over by the brake set up. I've doe all the usual things like new lines, discs, CL RC5+ Pads, also fitting cooling ducts to the front brakes for this track day to try and keep everything running perfectly. I had a little bit of an experiment with the brakes over the course of Saturday. Firstly starting off with my usual set up which is with ABS plugged in and working and traction control completely unplugged and disabled. This set up is fine if you're very smooth on the brakes but the power i'm able to put through the brakes feels to be constantly being limited by the ABS, in the past I've removed the RC5+ pads from the rear and gone back to standard brembo pads to ensure that the rear wheels aren't locking slightly causing the ABS to kick in anymore than it needs to. I often feel like I get a very firm pedal and pushing as hard as I want for more braking doesn't apply anymore force.

For the afternoon session I went out with the ABS controlled unplugged. Driving it that was a great, I was able to put more force through the brake pedal and brake a little later and never locked up except for one occasion as I was trail braking into Shell. I was much preferring the feel of driving the car without ABS however and this a very strange with the ABS unplugged the car started detecting a miss fire on the long uphill straights. I Initially thought it was a miss fire, swapping oils over, swapped spark plugs, thought it could have been fuel surge from the chicane before the straight so added an additional 40L of fuel to brim the tank, kept getting the engine light and miss fire detection repeatedly in the afternoon. In the second to last session I buzzed through the pits, jumped out, plugged in the ABS Controller and set off again. Ran for 45 minutes till to chequered flag without any issues what to ever. It appears there is something going on due to the fact the Engine ECU isn't getting a wheel speed signal from the ABS controller because it is unplugged. I know the ECU relies on this for a number of things due to the fact I have had to raise the RPM limiter in the ECU which is put in place in case it doesn't get a wheel speed sensor a lower RPM limit if around 4k is applied. However something else deeper is going on. I've got some things I'm going to change and experiment with inside the ECU as yesterday without the wheel speed sensor it wasn't cutting fuel on over run and sounded like a machine gun when I let off. I have already corrected that in the ECU just need to flash that file to it and test however the miss fire was detected at full load up hill just before the limiter around 6500RPM. So I know changing the overrun wont be the solution. At the moment I think i'm looking towards improving the front brake set up and continuing to run with the ABS. I don't really have a plan for this, possible Porsche 996 calipers, or after market calipers with a slightly bigger rotor to improve the braking performance of the front brakes then experiment with the same rear pads or refitting RC5+'s to the rear to increase the braking from the rear if the front was improved. My final thought is to go back to DS1.11 brake pads which I always ran on the Clio and the were fantastic and compare a different pad to the RC5+s.

Would be really interested to hear peoples thoughts and opinions on all the points above. I know there are some very knowledgeable and experienced people on here.

Edited by tombate911 on Sunday 3rd March 20:11

Edited by tombate911 on Sunday 3rd March 21:58

Love the thread and love the car, in regards to the braking have you looked at the ABS pump/ECU from the e46 m3 or it might be from a CSL, they have a programmable ECU on them, one of the driftworks E30 build videos they discuss it. I will try and find the video and send you a link to it.

Found the link

https://youtu.be/Mlk3_P5Af50

Found the link

https://youtu.be/Mlk3_P5Af50

Edited by Joshsl on Tuesday 5th March 14:35

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff