Knackered old Porsche with loads of natural light - Boxster!

Discussion

eltax91 said:

[Doubt]"Apparently it could be a ‘knock sensor’"

[/Doubt]

In all seriousness though that looks like a perfect base car! Sensible miles, roof is in good order, works enough to be confident in the rest of it but broken enough to be cheap! Well found

As it wasn't raining this evening I took the opportunity to take a few decent pictures of car, partly because I need a few for the kit website and partly because I felt like I owed you guys more than some grainy camera phone pics

It looks so very standard.... and I am absolutely over the moon with that!

It still polishes up very well considering most of the paint is 25 years old!

No MIL lights or similar, idles at 1000RPM, could be a stock car.

Even has a standard exhaust under the rear end!

As the charge cooler rad used to be an aircon heat exchanger it looks 99% stock in the rad duct. Only the lower 19mm hose fitting gives it away.

Interior looks pretty standard but the dash display and build plate give the game away a little bit...

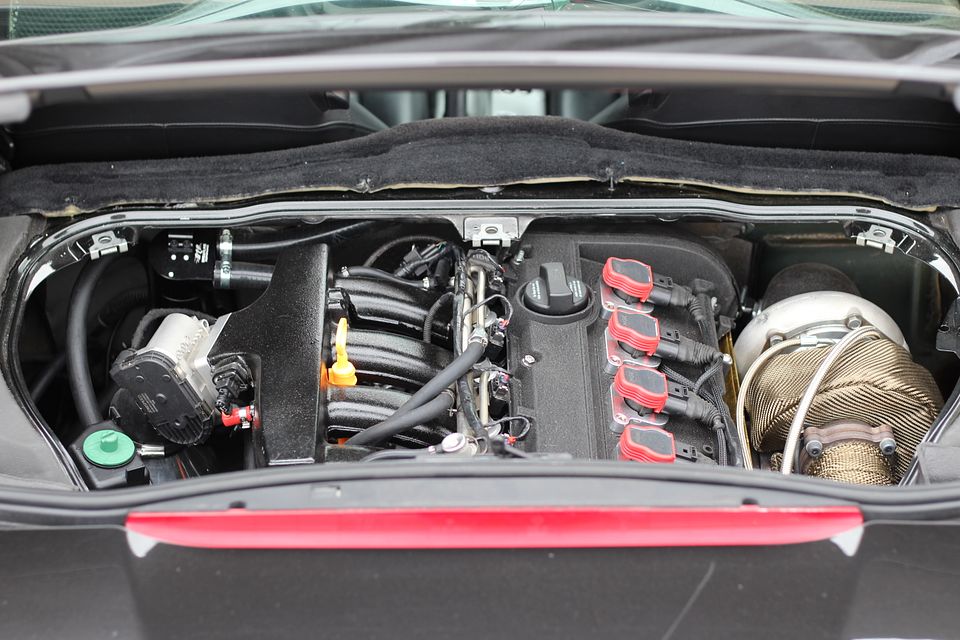

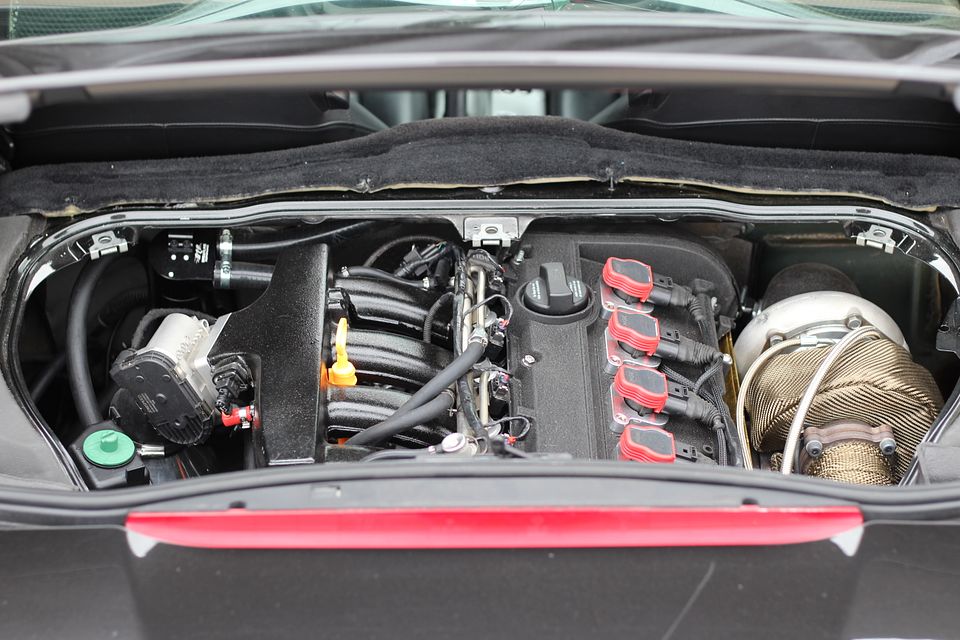

And when you take the engine cover off it becomes very clear how not standard it is!

It really does fit in there an absolute treat!

Even the high speed racing snail tucks into the corner of the bay with plenty of clerance.

Nothing else to report with regards running in, I've got an oil change to do in the next 50 miles and have about 300 miles left to cover. It's all behaving as it should and it drives like a standard road car.... just with boosty noises

I remain very, very, very pleased with how well this project has come together!

It looks so very standard.... and I am absolutely over the moon with that!

It still polishes up very well considering most of the paint is 25 years old!

No MIL lights or similar, idles at 1000RPM, could be a stock car.

Even has a standard exhaust under the rear end!

As the charge cooler rad used to be an aircon heat exchanger it looks 99% stock in the rad duct. Only the lower 19mm hose fitting gives it away.

Interior looks pretty standard but the dash display and build plate give the game away a little bit...

And when you take the engine cover off it becomes very clear how not standard it is!

It really does fit in there an absolute treat!

Even the high speed racing snail tucks into the corner of the bay with plenty of clerance.

Nothing else to report with regards running in, I've got an oil change to do in the next 50 miles and have about 300 miles left to cover. It's all behaving as it should and it drives like a standard road car.... just with boosty noises

I remain very, very, very pleased with how well this project has come together!

poppopbangbang said:

eltax91 said:

[Doubt]"Apparently it could be a ‘knock sensor’"

[/Doubt]

In all seriousness though that looks like a perfect base car! Sensible miles, roof is in good order, works enough to be confident in the rest of it but broken enough to be cheap! Well found

eltax91 said:

Wonder how long it will last if someone just bought it and drove the wheels off it around track.

I mean the law of sod would come into play where it would be absolutely fine being hammered off the rev limiter for endless track days in a row but would immediately throw the rattling bit out of the engine if you were ever in a situation that meant you needed to use it to get anywhere important and time critical in it  .

.braddo said:

Will the dyno session include having a couple of different power levels/maps and at what kind of hp (approx)?

300bhp on gate, 400bhp on road boost and 500bhp on push to pass boost is the expectation based on what the Formula 2 engines used to do. Reality is at this stage it will be calibrated for as much boost as the charge cooling allows and we'll work from there. Lower outputs are just a function of boost pressure and rev limit. Either way it'll end up being nippy!

Steve_W said:

"made in a shed by a bloke"

What's really amazing is how much "sheds" have progressed in terms of technology, the easy and relatively cheap availability now of parametric CAD, FEA, 3D Print, Laser Engraving/Cutting, 3D Scanning and a host of other technologies that were absolutely bleeding edge 20 years ago has mean it's possible to produce some absolutely amazing home builds... I can't quite take the glory under that title as after all automotive engineering / powertrain is my day job and whilst I did build this at home my office is perhaps better equiped than others.

I am constantly blown away by the quality of engineering people are achieving on hobby projects though, from those laminating their own drone bodies to casting their own cylinder heads and everything in between. It feels like engineering has had a bit of resurgance recently as a passtime!

Thank you for the great feedback, it's a pleasure to share and very rewarding to know that people enjoy reading it.

Harfi88 said:

Brilliant thread, unsurprisingly the workmanship and quality is off the chart. I’ve got a hard top for my 987, I think it’s been on for two weeks out of 5 years of ownership, I think they look great on the car but I couldn’t get mine to fit quite right so it let water in on the front drivers side, I don’t remember it creaking much and made the car feel like a cayman from the inside.

Bit late to the party and wanted to comment on hard tops. Feel free to ignore if you have no interest in hard top and leaks.Mine came with a hard top. I put it on last winter and had some leaks. This winter I left it off to rule out if the car is leaking without. A few others on the boxa forum have been asking questions recently about hardtops leaking. I suspect some and possibly mine were not leaking but collecting condensation from the car in general and then allowing this to collect in a different spot. I could be totally wrong of course but I have a suspicion that water can condense on the inside and then droplets will travel to where they want to go. The Boxster has a lot of breathing holes so condensation in these seems more problematic than any other car. I now have several dehumidifiers in mine and I have almost managed to dry out all damp spots from last winter. Then I can try again with the hard top. I even stripped mine down to double check the seal was seated properly. The main seal is all one piece and does the front edge and both sides. These are over 500 quid from Porsche new if yours has a problem - ouch. So I'm not convinced seals can really break and I did quite a bit of adjusting with mine but was never sure it was sealed up properly. Once I get the car completely dried out and driving I will make sure the soft top version of the car isnt leaking anywhere and then try the hard top again.

I think they look good with the hard top on. More so if the car is a colour. Not so much with Black unless you add some big thick stripes or details to it.

Copy Pasting here

Stripped down the hard top to see if I can understand how I might fix this leak. 1 screw is rusted up badly and didn't want to come out - pointed out. That's why the long black metal strip is still attached to the roof.

I found quite a bit of sticky gunk between the seal and the hardtop in the corners. Not sure how much of this is factory or been added later. I did find some metal tabs in the far corners of the seal which should clip into holes in the hardtop but these were not situated correctly so it is possible this is why my corners did not look right.

poppopbangbang said:

300bhp on gate, 400bhp on road boost and 500bhp on push to pass boost is the expectation based on what the Formula 2 engines used to do. Reality is at this stage it will be calibrated for as much boost as the charge cooling allows and we'll work from there. Lower outputs are just a function of boost pressure and rev limit.

Either way it'll end up being nippy!

What's "on gate"?Either way it'll end up being nippy!

I find it amazing that there can be so much control of the turbo and the output. As opposed to the old days when you strapped a big turbo on and got a huge spike in power when the turbo spools up.

Am very much looking forward to seeing what dyno graphs looks like.

braddo said:

What's "on gate"?

I find it amazing that there can be so much control of the turbo and the output. As opposed to the old days when you strapped a big turbo on and got a huge spike in power when the turbo spools up.

Am very much looking forward to seeing what dyno graphs looks like.

"On gate" refers to waste gate pressure i.e. the amount of boost the wastegate will allow with no external influence on it. The wastegate on this engine has a 0.9bar spring in it i.e. a spring that in this size of wastegate will provide somewhere close to 0.9bar of manifold pressure. I find it amazing that there can be so much control of the turbo and the output. As opposed to the old days when you strapped a big turbo on and got a huge spike in power when the turbo spools up.

Am very much looking forward to seeing what dyno graphs looks like.

For more than 0.9bar there is a MAC three way valve fitted inline between the turbo compressor housing and the wastegate can. This valve bleeds off pressure from the gate (to avoid it opening) and is driven by a PWM signal from the ECU. If the ECU wants 1.5bar of boost then it will drive the valve (via a PID loop) to bleed enough pressure from the gate to maintain 1.5bar manifold pressure.

This is about the simplest form of boost control going and is very common on production turbo engines, there are better ways to do it but this is simple and reliable. I do have a few more complex forms available to me, including some WRC bits, but if I can get the level of boost control required with what are basically better quality road car bits then that suits this project perfectly.

A lot of the improvements in big turbo driveability are down to modern electronics and engine control, for example many ECU's now use strategies which will reduce the throttle opening as the boost builds if the pedal position remains constant i.e. they aim to deliver a constant torque for pedal position and aim to maintain as much turbo speed as possible for this torque value so throttle response (from the drivers perspective) is more linear and less peaky.

Modern turbo chargers with roller bearing CHRA's etc. are also way more responsive than those of old, the GT3076R on this engine is a 20 year old design now and very much last gen when compared to modern G series stuff, but still makes positive manifold pressure at 2500RPM and a bar of boost by 3800RPM (and on a fairly big turbo like the 3076 that's a lot of air mass!).

Solid MOT pass today, I wanted to see just how early the Cat would light off considering it's a 200 cell metalic brick:

That's at 70 degrees coolant temp, 60 degrees oil temp and 2750RPM (with no cat warm up time). So engine just at a point one would consider off cold start and revs in the middle of the allowed range. Lambda control was as good as it'll get with 1000CC injectors and 4 bar base fuel pressure as even a tiny adjustment in the duty cycle is quite a bit of change in mass of fuel delivered, it flip flops a little within the allowed range but doesn't fall off either end so we'll take that.

With another hundred degrees of Cat temp and a bit of calibration clean up it'll scrub the CO considerably more than it is at the moment too as the Cat was only just into the lit off range.

Very pleased with that as it emits just as well as the M96 did and remains completely road legal (like actual road legal, not just MOT test legal). I'm still going to see if with a bit of effort we can't get it to Euro 4 levels, at least at an MOT emissions test level - it's already there on hydrocarbons.

That's at 70 degrees coolant temp, 60 degrees oil temp and 2750RPM (with no cat warm up time). So engine just at a point one would consider off cold start and revs in the middle of the allowed range. Lambda control was as good as it'll get with 1000CC injectors and 4 bar base fuel pressure as even a tiny adjustment in the duty cycle is quite a bit of change in mass of fuel delivered, it flip flops a little within the allowed range but doesn't fall off either end so we'll take that.

With another hundred degrees of Cat temp and a bit of calibration clean up it'll scrub the CO considerably more than it is at the moment too as the Cat was only just into the lit off range.

Very pleased with that as it emits just as well as the M96 did and remains completely road legal (like actual road legal, not just MOT test legal). I'm still going to see if with a bit of effort we can't get it to Euro 4 levels, at least at an MOT emissions test level - it's already there on hydrocarbons.

poppopbangbang said:

"On gate" refers to waste gate pressure i.e. the amount of boost the wastegate will allow with no external influence on it. The wastegate on this engine has a 0.9bar spring in it i.e. a spring that in this size of wastegate will provide somewhere close to 0.9bar of manifold pressure.

For more than 0.9bar there is a MAC three way valve fitted inline between the turbo compressor housing and the wastegate can. This valve bleeds off pressure from the gate (to avoid it opening) and is driven by a PWM signal from the ECU. If the ECU wants 1.5bar of boost then it will drive the valve (via a PID loop) to bleed enough pressure from the gate to maintain 1.5bar manifold pressure.

This is about the simplest form of boost control going and is very common on production turbo engines, there are better ways to do it but this is simple and reliable. I do have a few more complex forms available to me, including some WRC bits, but if I can get the level of boost control required with what are basically better quality road car bits then that suits this project perfectly.

A lot of the improvements in big turbo driveability are down to modern electronics and engine control, for example many ECU's now use strategies which will reduce the throttle opening as the boost builds if the pedal position remains constant i.e. they aim to deliver a constant torque for pedal position and aim to maintain as much turbo speed as possible for this torque value so throttle response (from the drivers perspective) is more linear and less peaky.

Modern turbo chargers with roller bearing CHRA's etc. are also way more responsive than those of old, the GT3076R on this engine is a 20 year old design now and very much last gen when compared to modern G series stuff, but still makes positive manifold pressure at 2500RPM and a bar of boost by 3800RPM (and on a fairly big turbo like the 3076 that's a lot of air mass!).

HI PPBB - as (mostly) a lurker on PH I wanted to post to say that I admire your work and thoroughly enjoy the way you write about it - the post above is a perfect example of the little snippets of tech info you add that I find fascinating. Keep up the good work!For more than 0.9bar there is a MAC three way valve fitted inline between the turbo compressor housing and the wastegate can. This valve bleeds off pressure from the gate (to avoid it opening) and is driven by a PWM signal from the ECU. If the ECU wants 1.5bar of boost then it will drive the valve (via a PID loop) to bleed enough pressure from the gate to maintain 1.5bar manifold pressure.

This is about the simplest form of boost control going and is very common on production turbo engines, there are better ways to do it but this is simple and reliable. I do have a few more complex forms available to me, including some WRC bits, but if I can get the level of boost control required with what are basically better quality road car bits then that suits this project perfectly.

A lot of the improvements in big turbo driveability are down to modern electronics and engine control, for example many ECU's now use strategies which will reduce the throttle opening as the boost builds if the pedal position remains constant i.e. they aim to deliver a constant torque for pedal position and aim to maintain as much turbo speed as possible for this torque value so throttle response (from the drivers perspective) is more linear and less peaky.

Modern turbo chargers with roller bearing CHRA's etc. are also way more responsive than those of old, the GT3076R on this engine is a 20 year old design now and very much last gen when compared to modern G series stuff, but still makes positive manifold pressure at 2500RPM and a bar of boost by 3800RPM (and on a fairly big turbo like the 3076 that's a lot of air mass!).

Dr.Hellno said:

Nice one man, congrats!

Are you looking to replicate a similar power delivery to the formula cars?

Did you say they ran relatively low torque figures?

Were there dyno graphs for their setups that you saw?

Yes very similar, although I am using a log type manifold for packaging and durability. The F2's ran fairly low torque but rev'd to 8250RPM so made plenty of power. Are you looking to replicate a similar power delivery to the formula cars?

Did you say they ran relatively low torque figures?

Were there dyno graphs for their setups that you saw?

I'm a bit nervous about how much torque the clutch will happily deal with and if it does how much torque the 5 speed will happily deal with. Circa 300ftlbls seems sensible and the car should be very linear at this, I may allow a bit more in higher gears as 350 ftlbs would allow me to make 500bhp at 7.5K which is better for engine life than needing another 750RPM to do it.

The thing is even at 400bhp it will be a quick car so I'm not stressing too much about the actual figure I end up running it at, a big part of this project is to bring some durability to the party hence the idea to run the big figure on push to pass.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff