Craig's 328i Sport - e36 Track Car Build Thread

Discussion

Forward thinking was needed if everything was going to get done in such a small space of time!

Regarding traction, its a throttle cut system (very crude!) so it doesnt have any control over the braking of the wheels. I personally don't like the system, I mean harsh cutting the power mid slide can never be a good thing.

Regarding traction, its a throttle cut system (very crude!) so it doesnt have any control over the braking of the wheels. I personally don't like the system, I mean harsh cutting the power mid slide can never be a good thing.

Craig! said:

Forward thinking was needed if everything was going to get done in such a small space of time!

Regarding traction, its a throttle cut system (very crude!) so it doesnt have any control over the braking of the wheels. I personally don't like the system, I mean harsh cutting the power mid slide can never be a good thing.

The rear wheel braking only happens at low speeds on the E36 Craig - you've probably not noticed it for that reason.Regarding traction, its a throttle cut system (very crude!) so it doesnt have any control over the braking of the wheels. I personally don't like the system, I mean harsh cutting the power mid slide can never be a good thing.

Nice project anyway!

Just a small update, the weather put a stop to play Monday / Tuesday as did a little hiccup. At the moment the old beam is blocking access to my garage and I really didn’t fancy working out in the rain, so I decided to do something about the beam in case this rain stays for the next few weeks!

Here’s the beam in all its former glory;

Now it has been reduced down to parts, to be moved to a more appropriate places before I get round to selling it on, speaking of which by the time the front end is done I’ll have the following kicking about; Rear Axel, Drive Shafts, Open Diff, Prop-Shaft, Rear Brake Set-Up, Front Wishbones, Front Brake Set-Up, Front Hubs and some Bilstein Suspension w/ Eibach Springs.

Cleaned and prepared some of the front end parts in my free time, below we have pictured the 3.2 Master Cylinder + Servo, 3.2 Floating Front Discs and of course the 3.2 Front Hubs.

I also got round to painting the front callipers and re-assembling them with copper grease in all the right areas. Please note I did paint every inch of metal, then once dry I proceeded to remove the paint from surfaces that made contact with the pads of front hubs as I didn’t want the paint to cause sticking of the pads.

I also got round to fitting the front Powerflex bushes into the ‘lollipops’ and placing them on the wishbones. Also the little hiccup mentioned above can be spotted in the below pictures too, guessed what it is yet?

That’s right, spotted the ball joint rubber boot had a crack in it, no problem I’ll press out the old ball joint and order another one. Ball joint came out without any issues, but hey most things would come out without issue with the size of the press I used. Ordered a replacement Lemforder (OEM Spec) ball joint from ECP, only to find out it’s the wrong size and will not fit my wishbone!?!

Anyway, to cut a long story short it turns out the M3 wishbone ball joints are not replaceable and BMW want £150.00 for a new arm... HOWEVER all is not lost, I may have come up with a solution to the problem. After measuring an old E30 ball joint it seems its identical to the E36 M3 one, so I have ordered one in (due tomorrow!) and will press that into the E36 M3 wishbone. The quality of the E30 one may not be as long lasting as the standard E36 ones, but after all it’s a car that will be kept on top of maintenance wise.

Next up is just a few shots of the BBS RC041’s split down ready for paint, I’m going to keep them track friendly by painting them black, however there’s a little twist. I’m going to do the centres matt black and the outer rims gloss giving them the effect of a polished rim with a painted centre like OEM finish just black.

I just need to find a company willing to powder coat or paint the pieces at a reasonable cost, a local places wanted £40.00 + VAT per item that would bring the total to £640.00 + VAT, sod that!!! If I get time I might look into firing up ye ‘ole spray gun and going for a bit of DIY paint action too.

Also to keep with the red and black theme I have also picked up a second hand set of face lift kidney grills and a 328i badge, these are both going gloss black too. More details on these bits when I get round to painting them, at the moment the front end is going to take priority!!!

Here’s the beam in all its former glory;

Now it has been reduced down to parts, to be moved to a more appropriate places before I get round to selling it on, speaking of which by the time the front end is done I’ll have the following kicking about; Rear Axel, Drive Shafts, Open Diff, Prop-Shaft, Rear Brake Set-Up, Front Wishbones, Front Brake Set-Up, Front Hubs and some Bilstein Suspension w/ Eibach Springs.

Cleaned and prepared some of the front end parts in my free time, below we have pictured the 3.2 Master Cylinder + Servo, 3.2 Floating Front Discs and of course the 3.2 Front Hubs.

I also got round to painting the front callipers and re-assembling them with copper grease in all the right areas. Please note I did paint every inch of metal, then once dry I proceeded to remove the paint from surfaces that made contact with the pads of front hubs as I didn’t want the paint to cause sticking of the pads.

I also got round to fitting the front Powerflex bushes into the ‘lollipops’ and placing them on the wishbones. Also the little hiccup mentioned above can be spotted in the below pictures too, guessed what it is yet?

That’s right, spotted the ball joint rubber boot had a crack in it, no problem I’ll press out the old ball joint and order another one. Ball joint came out without any issues, but hey most things would come out without issue with the size of the press I used. Ordered a replacement Lemforder (OEM Spec) ball joint from ECP, only to find out it’s the wrong size and will not fit my wishbone!?!

Anyway, to cut a long story short it turns out the M3 wishbone ball joints are not replaceable and BMW want £150.00 for a new arm... HOWEVER all is not lost, I may have come up with a solution to the problem. After measuring an old E30 ball joint it seems its identical to the E36 M3 one, so I have ordered one in (due tomorrow!) and will press that into the E36 M3 wishbone. The quality of the E30 one may not be as long lasting as the standard E36 ones, but after all it’s a car that will be kept on top of maintenance wise.

Next up is just a few shots of the BBS RC041’s split down ready for paint, I’m going to keep them track friendly by painting them black, however there’s a little twist. I’m going to do the centres matt black and the outer rims gloss giving them the effect of a polished rim with a painted centre like OEM finish just black.

I just need to find a company willing to powder coat or paint the pieces at a reasonable cost, a local places wanted £40.00 + VAT per item that would bring the total to £640.00 + VAT, sod that!!! If I get time I might look into firing up ye ‘ole spray gun and going for a bit of DIY paint action too.

Also to keep with the red and black theme I have also picked up a second hand set of face lift kidney grills and a 328i badge, these are both going gloss black too. More details on these bits when I get round to painting them, at the moment the front end is going to take priority!!!

Very small update;

Ball joint idea worked a treat, first two pictures show the E30 ball joint lined up in the wishbone ready to be pressed in and the last two show the ball joint all pressed in and functional. Sat side by side with a normal un-craigified wishbone the height and thread length all match up perfectly, job well done if I do say so myself.

Also had an hour spare yesterday so checked everything would come apart, all seems fine but the inner ball joint looks like it’s going to need a gentle bit of persuasion and a normal ball joint splitter won’t suffice. So picked up this little beauty, a ball joint fork it should do the trick!

Hopefully I’ll be posting here on Wednesday saying how the front end work is complete and the car’s all set for Germany on the 16th of April.

Ball joint idea worked a treat, first two pictures show the E30 ball joint lined up in the wishbone ready to be pressed in and the last two show the ball joint all pressed in and functional. Sat side by side with a normal un-craigified wishbone the height and thread length all match up perfectly, job well done if I do say so myself.

Also had an hour spare yesterday so checked everything would come apart, all seems fine but the inner ball joint looks like it’s going to need a gentle bit of persuasion and a normal ball joint splitter won’t suffice. So picked up this little beauty, a ball joint fork it should do the trick!

Hopefully I’ll be posting here on Wednesday saying how the front end work is complete and the car’s all set for Germany on the 16th of April.

Woohoo, as planned today was the day and all the front end work has been carried out. Of course it wouldn’t be modifying without the dramas of incorrect fitting parts and having to use your noggin to overcome small problems.

First started by getting the car up in the air and making it secure, then sprayed everything that needed to be freed off with WD40. Everything came apart with ease, brake unions cracked straight away and the ball joint fork was a god send and made splitting the inner ball joint a doddle. Normal ball joint splitter on the tie rod end ball joint, and a range of sockets and all the parts were off within an hour.

Here’s everything fitted and working as it should be;

Powerflex front anti-roll bar bushes in place, the 328i Sport requires a 25mm bush and it only took a few minutes to fit, much easier than fitting the rear’s as they were a really tight fit, in fact a little too tight.

Concentric Powerflex rear wishbone bushes to suit the M3 3.2 Evo wishbones... again really easy to fit, fits nice and tight however no presses were required and it all lined up fit without any adjustments needed anywhere.

M3 3.2 Evo front brakes with floating discs, also 10mm hub-centric spacers. This is where the problems arose, the spacers although nicely machined were not perfect, the inner bore that sits onto the hub lug had been machined 2mm too short causing a gap between the spacer and hub face. A trip to Halfords to get some emergency 9mm spacers (needed to clear the coilovers) paid off as they had some 3mm spacers on the shelf which fit fine behind the spacers causing a tight fit and also still retaining the use of the hub-centric lug.

Not ideal but it’ll have to do, next I’ll look into getting some 12mm spacers. I also found out I need even longer bolts, I ordered 35mm thread length but due to the extra 3mm spacer I’m going to have to find some 38~40mm bolts tomorrow.

Goodridge braided front brake lines in place, I used the existing rubber brake line bung to secure the brake line to the strut like OEM fitment. Also a big thanks to my friend James for helping me bleed the brakes and also provide emergency transport to get to Halfords for the spacers.

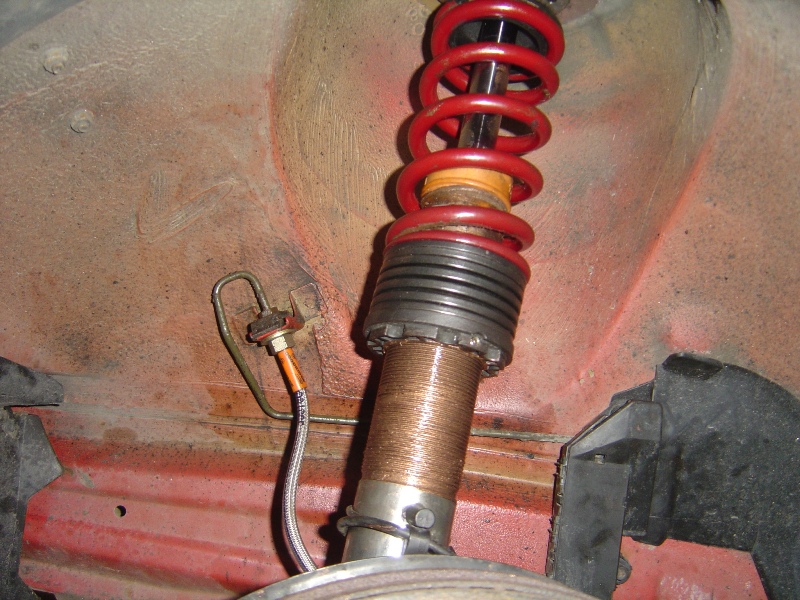

Eibach Pro-Street coilovers in place, let’s hope there up to the job.

Camber adjustable top mounts in position I still have to set the geometry up.

Now coming from a M3 CSL something was lacking from the 6 pots engine tone, it needed a bit of induction noise and the DaveF filter did the trick. OK it’s not as aggressive sounding as the CSL, but it gives a great tone and brings out the true induction noise of the M52B28 engine.

After spending hours staring at the car in the works car park I decided it needed something, I just couldn’t put my finger on what it was then it hit me, the front lights are very dark inside however the clear indicators although much better than tango units just stuck out a little too much. I decided it needed some smoked corner indicators so tracked down some Auto-Lamp lenses.

The fit is good, it’s not OEM perfect but as far as aftermarket indicators go there fine and will tie in nicely with the red and black theme going on.

Next up is to set the geometry, I’m going to just set it up roughly for the moment but hopefully on Saturday will be able to spend some time setting the camber and toe up ready to hit the track.

First started by getting the car up in the air and making it secure, then sprayed everything that needed to be freed off with WD40. Everything came apart with ease, brake unions cracked straight away and the ball joint fork was a god send and made splitting the inner ball joint a doddle. Normal ball joint splitter on the tie rod end ball joint, and a range of sockets and all the parts were off within an hour.

Here’s everything fitted and working as it should be;

Powerflex front anti-roll bar bushes in place, the 328i Sport requires a 25mm bush and it only took a few minutes to fit, much easier than fitting the rear’s as they were a really tight fit, in fact a little too tight.

Concentric Powerflex rear wishbone bushes to suit the M3 3.2 Evo wishbones... again really easy to fit, fits nice and tight however no presses were required and it all lined up fit without any adjustments needed anywhere.

M3 3.2 Evo front brakes with floating discs, also 10mm hub-centric spacers. This is where the problems arose, the spacers although nicely machined were not perfect, the inner bore that sits onto the hub lug had been machined 2mm too short causing a gap between the spacer and hub face. A trip to Halfords to get some emergency 9mm spacers (needed to clear the coilovers) paid off as they had some 3mm spacers on the shelf which fit fine behind the spacers causing a tight fit and also still retaining the use of the hub-centric lug.

Not ideal but it’ll have to do, next I’ll look into getting some 12mm spacers. I also found out I need even longer bolts, I ordered 35mm thread length but due to the extra 3mm spacer I’m going to have to find some 38~40mm bolts tomorrow.

Goodridge braided front brake lines in place, I used the existing rubber brake line bung to secure the brake line to the strut like OEM fitment. Also a big thanks to my friend James for helping me bleed the brakes and also provide emergency transport to get to Halfords for the spacers.

Eibach Pro-Street coilovers in place, let’s hope there up to the job.

Camber adjustable top mounts in position I still have to set the geometry up.

Now coming from a M3 CSL something was lacking from the 6 pots engine tone, it needed a bit of induction noise and the DaveF filter did the trick. OK it’s not as aggressive sounding as the CSL, but it gives a great tone and brings out the true induction noise of the M52B28 engine.

After spending hours staring at the car in the works car park I decided it needed something, I just couldn’t put my finger on what it was then it hit me, the front lights are very dark inside however the clear indicators although much better than tango units just stuck out a little too much. I decided it needed some smoked corner indicators so tracked down some Auto-Lamp lenses.

The fit is good, it’s not OEM perfect but as far as aftermarket indicators go there fine and will tie in nicely with the red and black theme going on.

Next up is to set the geometry, I’m going to just set it up roughly for the moment but hopefully on Saturday will be able to spend some time setting the camber and toe up ready to hit the track.

Cheer guys, its nice to be heavily tweeking again, I mean I did a fair few things to the Exige S but never to the extream as I am with the e36.... roughly set the geometry up today aswell, going to do some fine tuning at the weekend then its just about ready to go. Going to add a few small cosmetic tweeks ready for next weekend but don't think I'll be able to pull off a wheel colour change in time, but who knows.

Well I managed to spend a few days playing about on the car doing some finishing touches and generally giving it a good once over. First off came the painting of the grills and rear badges, I like to try things different so instead of the usual satin black I thought I would give gloss black ago, the idea behind it is everything that was chrome will now be gloss black. Excuse the bug splatter haven’t got round to cleaning the car this week.

If I’m honest, I’m not convinced on the look however I’ll leave it for the time being and see if it grows on me, the kidney’s look OK however the rear badge just doesn’t look right at times, maybe black on a darker colour might have gave the effect I was looking for, I also think it clashes with the silver chrome details on the rear BMW roundel.

Next up was to tidy the garage and gather up the old front end parts, needed to make room for the possibilities of doing the geometry in the garage if the weather didn’t hold out.

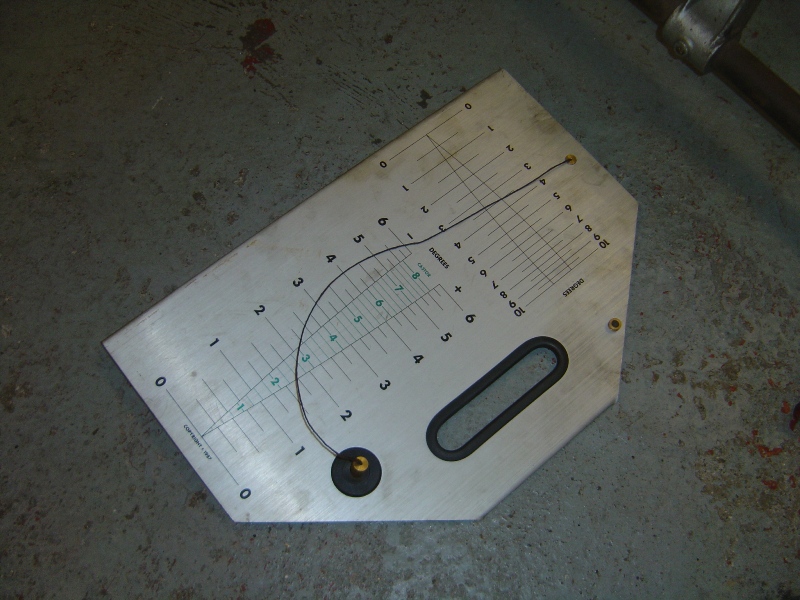

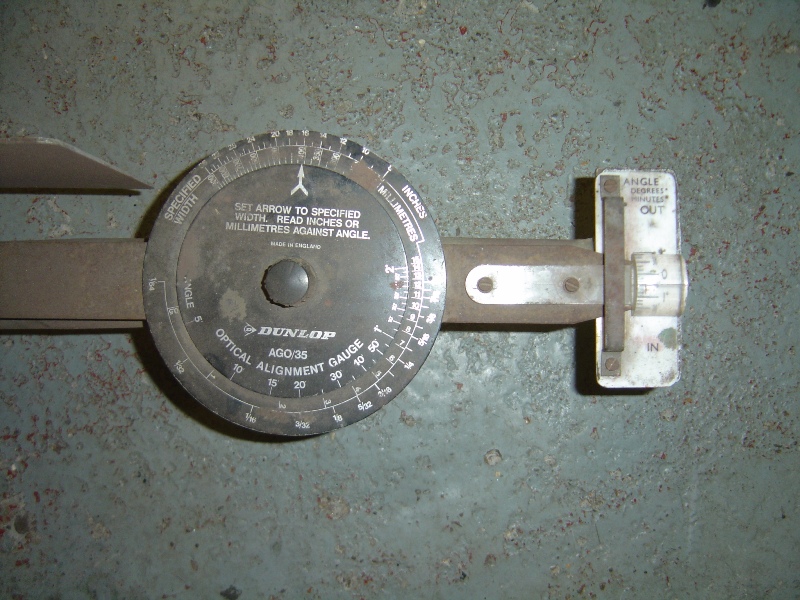

Fortunately for me if I don’t have the equipment my friends do, and they were ever so kind to lend me these alignment gauges. First been a Dunlop optical alignment gauge for setting the toe, the other a camber gauge.

I didn’t get any pictures of the process, but to start with I balanced up the suspension height all round, setting it at 305mm wheel centre to arch at the rear, and 320mm wheel centre to arch at the front. Once the height was set I took it for a test drive to let the suspension settle itself and then double checked the measurements.

Next up was the camber, at the rear this was set to -1.5 degrees and at the front -2.5 was dialled in, the adjustable top mounts really did make it easy to set the camber. Once the camber was set we could then move onto the toe; remember to set camber before toe.

The rear toe was pretty much spot on, a small bit of toe in which would be fine. Next was the front, at first this was toe’ing out heavily, once I’d managed to free off the track rod ends I then set about balancing both sides up by eye to give 0.0 toe. A quick test drive and the car really has been transformed over these last few weeks, but there was a little dead spot in the steering suggesting toe out was still present. Got back and set the toe properly using the optical alignment gauge, ended up setting it at 0.5 degree of toe in.

Final test drive and the car is now perfect, I’m really happy with how it drives and for the first time in weeks am looking forward to getting it out on track. Between now and this Friday there maybe a little update with the latest tyre choice and maybe one of two other track enhancements but until then it’s all set for next weekend, the deadline I keep going on, and on about.

Once back from Germany I’ll then start to plan the interior and get to work on that, more on that subject at a later date.....

If I’m honest, I’m not convinced on the look however I’ll leave it for the time being and see if it grows on me, the kidney’s look OK however the rear badge just doesn’t look right at times, maybe black on a darker colour might have gave the effect I was looking for, I also think it clashes with the silver chrome details on the rear BMW roundel.

Next up was to tidy the garage and gather up the old front end parts, needed to make room for the possibilities of doing the geometry in the garage if the weather didn’t hold out.

Fortunately for me if I don’t have the equipment my friends do, and they were ever so kind to lend me these alignment gauges. First been a Dunlop optical alignment gauge for setting the toe, the other a camber gauge.

I didn’t get any pictures of the process, but to start with I balanced up the suspension height all round, setting it at 305mm wheel centre to arch at the rear, and 320mm wheel centre to arch at the front. Once the height was set I took it for a test drive to let the suspension settle itself and then double checked the measurements.

Next up was the camber, at the rear this was set to -1.5 degrees and at the front -2.5 was dialled in, the adjustable top mounts really did make it easy to set the camber. Once the camber was set we could then move onto the toe; remember to set camber before toe.

The rear toe was pretty much spot on, a small bit of toe in which would be fine. Next was the front, at first this was toe’ing out heavily, once I’d managed to free off the track rod ends I then set about balancing both sides up by eye to give 0.0 toe. A quick test drive and the car really has been transformed over these last few weeks, but there was a little dead spot in the steering suggesting toe out was still present. Got back and set the toe properly using the optical alignment gauge, ended up setting it at 0.5 degree of toe in.

Final test drive and the car is now perfect, I’m really happy with how it drives and for the first time in weeks am looking forward to getting it out on track. Between now and this Friday there maybe a little update with the latest tyre choice and maybe one of two other track enhancements but until then it’s all set for next weekend, the deadline I keep going on, and on about.

Once back from Germany I’ll then start to plan the interior and get to work on that, more on that subject at a later date.....

Well I made the deadline, only just mind and with quite a few minor incidents along the way. However there is a few shock instalments to this update that I bet no one (me included) was expecting.

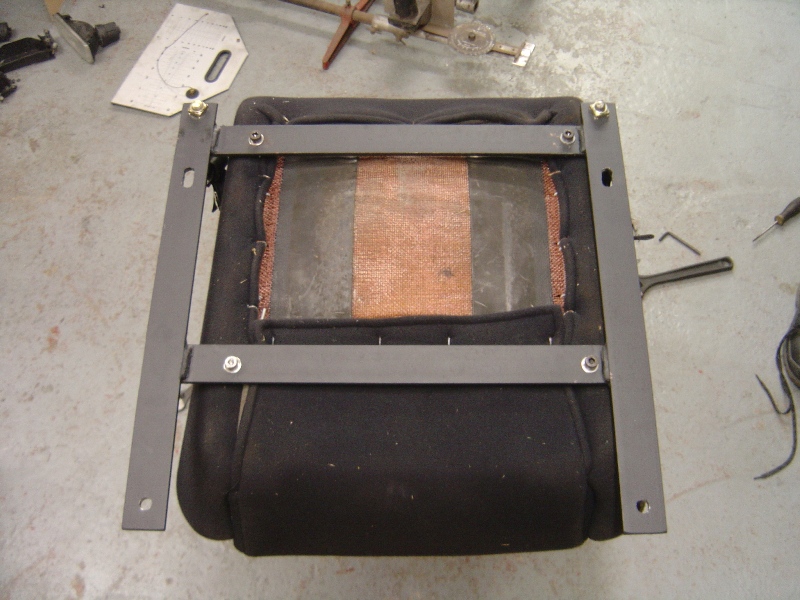

First shock update is the interior, although this is a temporary measure I really didn’t expect to have the time to make the seat sub-frames let alone get it all fitted and functional. It started a few days before departure for Rotterdam, a friend and I were sat staring at his current project; a Pegueot 306 Rally track car, which he’d just bought some new seats for. So surplus to his requirements were these seats;

They are Sparco Sprint seats, not the world’s most elusive set of sports seats but they’d certainly do a better job of holding me in than the current OEM 328i Sport seats. One thing that was noted is that they have a strung base and are not hard backed. This actually made them really comfortable for long journeys and was a huge relief from the normal pain and discomfort endured for hundreds of miles.

First up once the standard seats was removed was to work out how we were going to make the seat sub-frames. We decided to stick to a basic 5mm flat bar steel square frame which would incorporate the factory mounting points, and we would later space the seat to the correct height.

Once the frame shape was made and welded up the holes were drilled and the frames painted satin black. The above frame as you can see is not quiet finished, there was four holes drilled from the frame to floor mounting, and a further four for the frame to seat mounting points.

It’s worth noting that the seats are off set and should sit as near to the centre tunnel as physically possible, with the passengers frame (above) this wasn’t too essential however on the drivers frame due to the centre position of the steering wheel it is. On the drivers frame (not pictured) the near side seat holes were actually drilled into the flat bar that run from the front to back of the car, due to the lack of space between the frame and carpet to fit nuts and bolts underneath, the welded bar that was now 10mm thick was threaded with an M8 thread.

The drivers seat has a sliding runner fitted which was 12mm thick, and it also required a further 25mm of spacing to get the correct height. The passengers seat sits really low, I need to raise this at a later date.

Here is the two seats mounted in situ complete with some Schroth Profi-II ASM 4-Point harnesses.

Next up was the tyres, the current Hankook RS2’s were running a little low so decided to fit a fresh set of rubber all round, I couldn’t quite decide what to run but eventually settled on a set of Kumho V70a semi-slick tyres, they are in the same league as R888’s however I had never tried them before so didn’t know what to expect.

I went for the usually 225/45/17 and 245/40/17 staggered fitment sizes.

This is where the problems started it was 36 hours before I was due to leave for Germany and I only had 2 front tyres, the rears still hadn’t arrived. I also decided that if I was paying for the tyres to be fitted, I might as well offset the cost and get the wheels re-furbished at the same time, a risky chance that would hopefully pay off.

Thursday morning arrived and the rear’s were no where to be seen so I dropped off all 4 wheels and tyres at a local refurb company that is just in the process of setting themselves up. They said they would refurb the wheels and fit and balance my new tyres all within the previously set price, which was great if I had 4 tyres to fit!!!!

Stress levels went through the roof during the course of the day, however a phone call at 16:15 to say the rear tyres have arrived brought them back to normal. At 17:30 the car was ready to be collected, I was at work so a friend offered to collect it and bring it home. Looking good if I do say so myself...

Got home from work and was really happy with how the car had transformed in the space of a month, give the car the final once over ready for the morning, I say morning, I was giving the car the once over at 3am so it already was morning.

All was fine until I checked the front wheels, one spacer had been fitted arse over tit (refer to above spacer problems) they has fitted the 10mm first and then the 2mm spacer and proceeded to tighten it right down to the point the hub-centric lug sheared off the spacer. Balls, I had all but a few hours to get this problem sorted, it wasn’t going to happen, or was it....

I placed an urgent plea out for anyone who may know of a set of hub-centric spacers kicking about either in the UK or Germany, or anywhere on route. Fortunately for me Darren Langeveld who was organising the Nurburgring track day (www.destination-nurburgring.com) knew of a place in Coventry who would have some on the shelf, he offered to pick them up on route to the ferry and give them to me on board, so I would have them in time for the track day. Perfect, this was the news that I was waiting for and I could finally relax and enjoy the holiday.

Finally boarded the ferry Friday and was on the continent by the morning, stopped by Spa in Belgium to have a nosey round the Porsche Club Francorchamps track day on the Saturday morning and was in Nurburg by later afternoon. I won’t turn this topic into a trip report, there will be a separate topic for this another day.

Monday came and the weather was perfect, the car was ready and so was I. The track day was on the full Nordschleife + GP Circuit so it was going to be a good day, here’s a few select pictures from the trip, I do apologise for the quality of some pictures my brothers laptop broke after the trip so all pictures had to be downloaded off the likes of Facebook & Photobucket.

Really am impressed with the car and its set up, after 15 laps at 17.5 miles a lap all was still running fine. The tyres I can really say are worth considering over the R888’s especially with the price difference these days, and the brakes pads which are Mintex 1155 at the front and 1144 at the rear really do work well with the M3 Evo callipers and discs.

Since getting back I’ve give the car a once over and the only problem to report is one of the lower rear trailing arm ball joints has a small bit of play in it, this is the same joint I was suspected of it having a minute bit of play before I left for Germany anyway, so there’s no shocks there. I’m going to replace the ball joint and use the car for the next few months as it is, will concentrate on taking a bit of weight out of the car and also decide what the final plans will be.

Hope you’re still awake after reading all the above! :P

First shock update is the interior, although this is a temporary measure I really didn’t expect to have the time to make the seat sub-frames let alone get it all fitted and functional. It started a few days before departure for Rotterdam, a friend and I were sat staring at his current project; a Pegueot 306 Rally track car, which he’d just bought some new seats for. So surplus to his requirements were these seats;

They are Sparco Sprint seats, not the world’s most elusive set of sports seats but they’d certainly do a better job of holding me in than the current OEM 328i Sport seats. One thing that was noted is that they have a strung base and are not hard backed. This actually made them really comfortable for long journeys and was a huge relief from the normal pain and discomfort endured for hundreds of miles.

First up once the standard seats was removed was to work out how we were going to make the seat sub-frames. We decided to stick to a basic 5mm flat bar steel square frame which would incorporate the factory mounting points, and we would later space the seat to the correct height.

Once the frame shape was made and welded up the holes were drilled and the frames painted satin black. The above frame as you can see is not quiet finished, there was four holes drilled from the frame to floor mounting, and a further four for the frame to seat mounting points.

It’s worth noting that the seats are off set and should sit as near to the centre tunnel as physically possible, with the passengers frame (above) this wasn’t too essential however on the drivers frame due to the centre position of the steering wheel it is. On the drivers frame (not pictured) the near side seat holes were actually drilled into the flat bar that run from the front to back of the car, due to the lack of space between the frame and carpet to fit nuts and bolts underneath, the welded bar that was now 10mm thick was threaded with an M8 thread.

The drivers seat has a sliding runner fitted which was 12mm thick, and it also required a further 25mm of spacing to get the correct height. The passengers seat sits really low, I need to raise this at a later date.

Here is the two seats mounted in situ complete with some Schroth Profi-II ASM 4-Point harnesses.

Next up was the tyres, the current Hankook RS2’s were running a little low so decided to fit a fresh set of rubber all round, I couldn’t quite decide what to run but eventually settled on a set of Kumho V70a semi-slick tyres, they are in the same league as R888’s however I had never tried them before so didn’t know what to expect.

I went for the usually 225/45/17 and 245/40/17 staggered fitment sizes.

This is where the problems started it was 36 hours before I was due to leave for Germany and I only had 2 front tyres, the rears still hadn’t arrived. I also decided that if I was paying for the tyres to be fitted, I might as well offset the cost and get the wheels re-furbished at the same time, a risky chance that would hopefully pay off.

Thursday morning arrived and the rear’s were no where to be seen so I dropped off all 4 wheels and tyres at a local refurb company that is just in the process of setting themselves up. They said they would refurb the wheels and fit and balance my new tyres all within the previously set price, which was great if I had 4 tyres to fit!!!!

Stress levels went through the roof during the course of the day, however a phone call at 16:15 to say the rear tyres have arrived brought them back to normal. At 17:30 the car was ready to be collected, I was at work so a friend offered to collect it and bring it home. Looking good if I do say so myself...

Got home from work and was really happy with how the car had transformed in the space of a month, give the car the final once over ready for the morning, I say morning, I was giving the car the once over at 3am so it already was morning.

All was fine until I checked the front wheels, one spacer had been fitted arse over tit (refer to above spacer problems) they has fitted the 10mm first and then the 2mm spacer and proceeded to tighten it right down to the point the hub-centric lug sheared off the spacer. Balls, I had all but a few hours to get this problem sorted, it wasn’t going to happen, or was it....

I placed an urgent plea out for anyone who may know of a set of hub-centric spacers kicking about either in the UK or Germany, or anywhere on route. Fortunately for me Darren Langeveld who was organising the Nurburgring track day (www.destination-nurburgring.com) knew of a place in Coventry who would have some on the shelf, he offered to pick them up on route to the ferry and give them to me on board, so I would have them in time for the track day. Perfect, this was the news that I was waiting for and I could finally relax and enjoy the holiday.

Finally boarded the ferry Friday and was on the continent by the morning, stopped by Spa in Belgium to have a nosey round the Porsche Club Francorchamps track day on the Saturday morning and was in Nurburg by later afternoon. I won’t turn this topic into a trip report, there will be a separate topic for this another day.

Monday came and the weather was perfect, the car was ready and so was I. The track day was on the full Nordschleife + GP Circuit so it was going to be a good day, here’s a few select pictures from the trip, I do apologise for the quality of some pictures my brothers laptop broke after the trip so all pictures had to be downloaded off the likes of Facebook & Photobucket.

Really am impressed with the car and its set up, after 15 laps at 17.5 miles a lap all was still running fine. The tyres I can really say are worth considering over the R888’s especially with the price difference these days, and the brakes pads which are Mintex 1155 at the front and 1144 at the rear really do work well with the M3 Evo callipers and discs.

Since getting back I’ve give the car a once over and the only problem to report is one of the lower rear trailing arm ball joints has a small bit of play in it, this is the same joint I was suspected of it having a minute bit of play before I left for Germany anyway, so there’s no shocks there. I’m going to replace the ball joint and use the car for the next few months as it is, will concentrate on taking a bit of weight out of the car and also decide what the final plans will be.

Hope you’re still awake after reading all the above! :P

Great write up! Roughly how long labour would you say it would take to install a M3 Evo diff carrier/3.23 LSD to a 328is? I have had one sitting in my garage for over a year now and think its about time it got installed. I also have a prop shaft so I believe I have everything I need.

Was it much of an improvement over the standard 2.93 diff both in Grip and acceleration?

Was it much of an improvement over the standard 2.93 diff both in Grip and acceleration?

Edited by crimbo on Wednesday 5th May 14:37

Thanks for the kind words guys, it really is worth considering a 328i as a track car you don't need M3 power although it is nice. Budget wise well it's certainly gone over what was first planned but then I did expect that, I do have a cost break down of every penny spent on the car to date and its just over £6k at the moment including tyres, tax, test and insurance.

Labour on the diff would vary depending on if you're fitting all the rear trailing arms and other associated parts. I'd reccomend going 3.2 trailing arms and hollow drive shafts whilst you've got the car in bits. Also note that you need a 3.0 prop shaft NOT a 3.2 Evo one, the Evo one is too short due to the 6 speed box that the 3.2 comes supplied with. I'd say its a worthy upgrade for track use, however it will increase fuel amounts due to the gear ratio been changed.

I have only had the one piece M3 Saloon wheels re-furbished so far, going to have the splits done shortly thought so will post an update about that at a later date.

Labour on the diff would vary depending on if you're fitting all the rear trailing arms and other associated parts. I'd reccomend going 3.2 trailing arms and hollow drive shafts whilst you've got the car in bits. Also note that you need a 3.0 prop shaft NOT a 3.2 Evo one, the Evo one is too short due to the 6 speed box that the 3.2 comes supplied with. I'd say its a worthy upgrade for track use, however it will increase fuel amounts due to the gear ratio been changed.

I have only had the one piece M3 Saloon wheels re-furbished so far, going to have the splits done shortly thought so will post an update about that at a later date.

just got a quote for the bolts... £180!!!! i think ill just paint mine black or something! I'm tempted to whip the ones out of the spare and refurb those, then do a wheel at a time. Do you think i'd be ok swapping a bolt a time? also... have you any idea of the proper torque figure?

Just a quick one also, i need a new rear trailing arm, do you think the M3 one will be a direct swap?

Just a quick one also, i need a new rear trailing arm, do you think the M3 one will be a direct swap?

Edited by S3_Graham on Thursday 6th May 14:57

Craig! said:

Thanks for the kind words guys, it really is worth considering a 328i as a track car you don't need M3 power although it is nice. Budget wise well it's certainly gone over what was first planned but then I did expect that, I do have a cost break down of every penny spent on the car to date and its just over £6k at the moment including tyres, tax, test and insurance.

Labour on the diff would vary depending on if you're fitting all the rear trailing arms and other associated parts. I'd reccomend going 3.2 trailing arms and hollow drive shafts whilst you've got the car in bits. Also note that you need a 3.0 prop shaft NOT a 3.2 Evo one, the Evo one is too short due to the 6 speed box that the 3.2 comes supplied with. I'd say its a worthy upgrade for track use, however it will increase fuel amounts due to the gear ratio been changed.

I have only had the one piece M3 Saloon wheels re-furbished so far, going to have the splits done shortly thought so will post an update about that at a later date.

Thanks for the reply, the prop shaft I have is a custom one a guy had made for his 323 rally car when he put the 3.23lsd in. Apparantly it will fit a 328 too. I was just planning on the diff carrier/LSD and prop as I just want it installed so I have LSD for a low friction drift day at Oulton. Won't be going on a track day for awhile yet I'd need new suspension and brakes first.Labour on the diff would vary depending on if you're fitting all the rear trailing arms and other associated parts. I'd reccomend going 3.2 trailing arms and hollow drive shafts whilst you've got the car in bits. Also note that you need a 3.0 prop shaft NOT a 3.2 Evo one, the Evo one is too short due to the 6 speed box that the 3.2 comes supplied with. I'd say its a worthy upgrade for track use, however it will increase fuel amounts due to the gear ratio been changed.

I have only had the one piece M3 Saloon wheels re-furbished so far, going to have the splits done shortly thought so will post an update about that at a later date.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff