Craig's 328i Sport - e36 Track Car Build Thread

Discussion

I know what you mean Craig about not wanting to get carried away with an older car. Similarly I've been thinking of what will happen to my 328 (left for 6 weeks in Germany and still fired up first turn of the key!). I'm getting a JK next year and aiming to do around 200 odd laps, without the road mileage I reckon the car should just about last. Then next winter I'll pillage it for the decent bits, and scrap the rusty shell. I've got a nice clean M3 EVO shell ready to build my next E36 track car out of, will be prepped and caged properly unlike my silver one which was just intended to be a fairly disposable car. Not sure weather to go for M52 or S50 power in the next one though.

Your shell does seem fairly clean from the times I've seen it, if it were mine I'd go for a bolt in cage from Safety devices or whoever. You seem handy enough that you could probably fit it yourself. If the engine ever let go (not that it should as it seemed very healthy for a car with the standard manifold) you could just put in another M52 or even an S50 as you have the rest of the M3 transmission ready for it.

Your shell does seem fairly clean from the times I've seen it, if it were mine I'd go for a bolt in cage from Safety devices or whoever. You seem handy enough that you could probably fit it yourself. If the engine ever let go (not that it should as it seemed very healthy for a car with the standard manifold) you could just put in another M52 or even an S50 as you have the rest of the M3 transmission ready for it.

Think I'm slowly coming round to the idea of keeping it, I'll be in touch Rich about a few things as may need some parts and advice if I do keep it. You just leaving the silver 328i as it is for next year then?

In a bid to motivate myself into finishing off the car properly I decided to give it a good winter once over to remove any of the salt that might have been sat feeding the tin worm. Not much of an update, just any excuse to post a picture I guess... ohh and my brother was dying to try out his new fish eye lens.

Cleaning the car also gave me the chance to see how the shell is standing up to the winter conditions, to be honest its fairing up well if I was to be fussy there’s two small chips on the doors that are slightly starting to bubble, and one of the rear arches looks like it’s getting a trace of bubbling on the inside edge. Driver wing is shot, but I knew about that as this was the only flaw with the car when I first bought it.

I think if I go ahead and finish the car off I’ll have to seriously consider either leaving the bodywork be (after all, it’s a track car!) or going the whole hog and getting it all sorted at once!

In a bid to motivate myself into finishing off the car properly I decided to give it a good winter once over to remove any of the salt that might have been sat feeding the tin worm. Not much of an update, just any excuse to post a picture I guess... ohh and my brother was dying to try out his new fish eye lens.

Cleaning the car also gave me the chance to see how the shell is standing up to the winter conditions, to be honest its fairing up well if I was to be fussy there’s two small chips on the doors that are slightly starting to bubble, and one of the rear arches looks like it’s getting a trace of bubbling on the inside edge. Driver wing is shot, but I knew about that as this was the only flaw with the car when I first bought it.

I think if I go ahead and finish the car off I’ll have to seriously consider either leaving the bodywork be (after all, it’s a track car!) or going the whole hog and getting it all sorted at once!

Well I guess it’s time for another update;

Got bored the other week, decided to go into the garage for a play... I’ve always hated the faded purple rear parcel shelf so decided I would remove it to re-black it, easier said than done with fixed bucket seats and harnesses as the only way to get in was to remove these first. Anyway, got the cabin clear and made my way into the back all that was needed to do was pop the lights out the C-Pillar, remove the covers from either side then the parcel shelf simply lifted (well, more jiggled) out.

It was at this point I noticed a load of fibre sound deadening as well as the usual stick on tar sound proofing, and decided to remove it whilst I had access to it.

Well, one thing lead to another and I decided since I had the heat gun out I should finally get round to removing all the tar sound deadening underneath the main carpet, after all I’ve been bleating on about doing it since April!!

First off was the centre console, shortly followed by the sill covers and front speaker covers. Then the driver’s side lower dash cover was removed along with the glove box and lower cowling, next came the on-board-computer and finally the centre of the lower dash. Once all this was removed the carpet could finally be lifted up, I was not going to take the heater matrix out to removed the front carpet so got some new Stanley and cut as closely and neatly round the heater as possible, this would make re-fitting the carpet easier too, and the centre console completely covers the cut / join lines.

Next up was removing the under floor heating channels, then it was onto the tar. With the promise of beer and pizza I had managed to lure in a few friends to help with the removal, this really did make life a lot less stressful it only took three people and hour or two to complete including larking around. All that was used was a heat gun and some plastic ice scrapers, I chose to use plastic scrapers so that the paint didn’t get damaged underneath.

With the tar itself removed, all that was left was to get rid of the sticky residue. After trying all sorts of different techniques over the years, I have found using petrol soaked flannel (Sorry Mam!!) in a well ventilated area the best, a cut towel will suffice too. It would appear that flannel / towels work better than old t-shirts and rags due to the larger surface area caused by the plush bobbly bits, yes that is the correct scientific term for them too, ha!

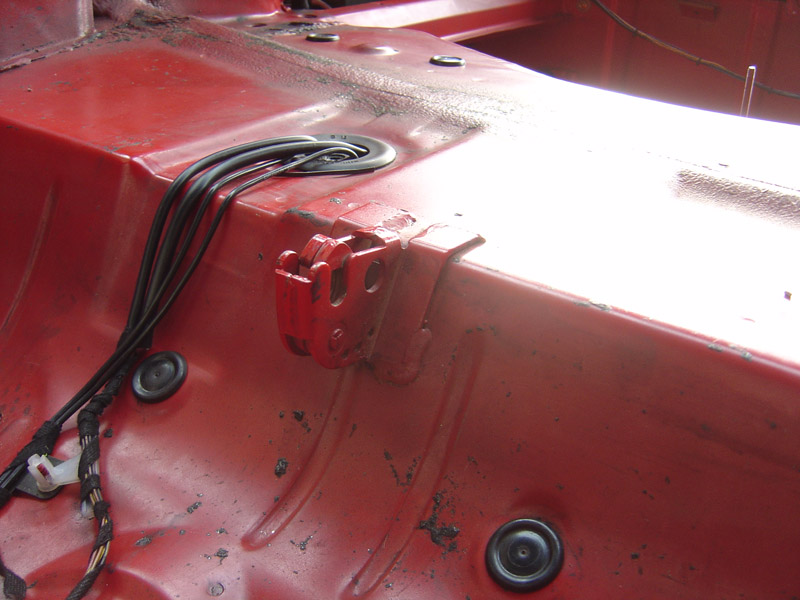

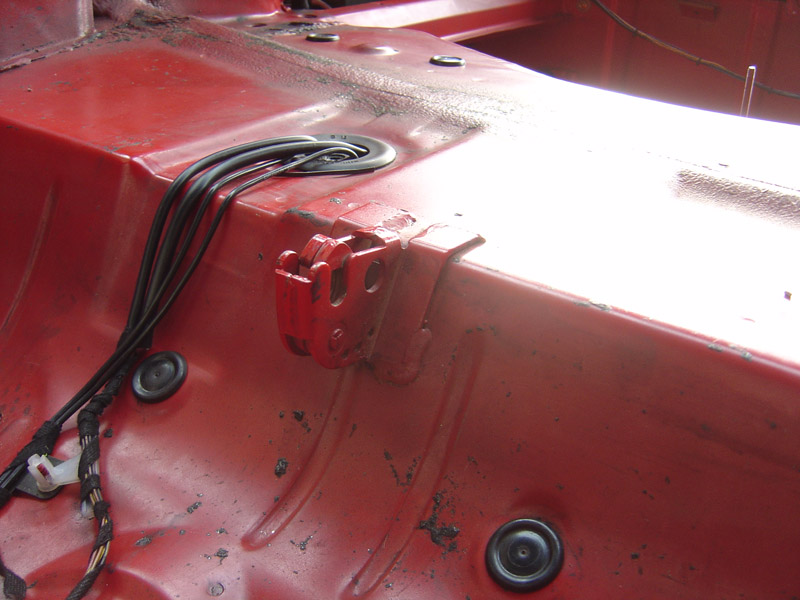

As you can see in the last picture I have pulled back all the un-needed rear wiring, I will eventually removed this, along with the air bag wiring at a later date. The aim is to just have the bare minimum amount of wiring, which is the rear lights, central locking filler cap and boot locking mechanism even the third brake light has been removed due to the spoiler that will eventually be fitted.

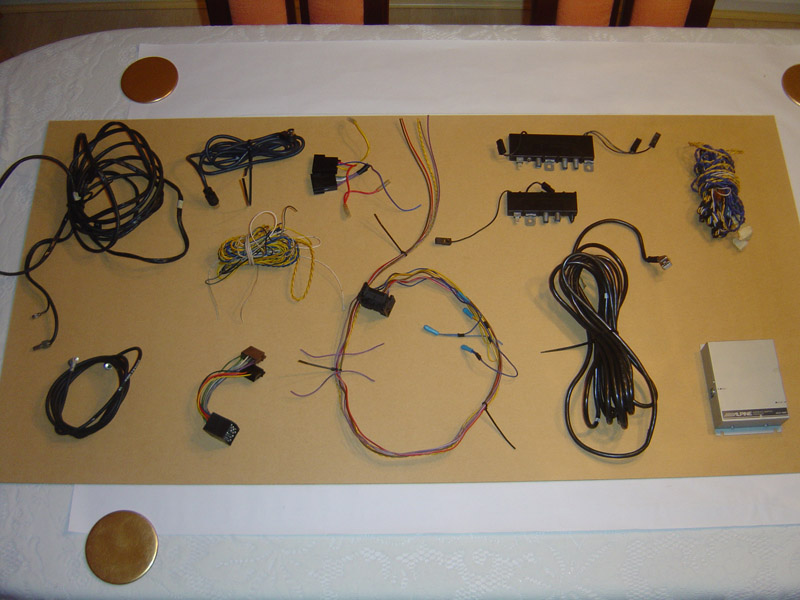

Not content with just removing the rear aerial wire, CD changer lead, rear speaker wiring and other optional extra wires that weren’t needed I decided the stereo loom was too cluttered too. So below as you can see is the standard stereo loom, now going the Club Sport route I decided that I would keep the main front speakers and door tweeters for those long road trips where a little music was required, so most of the wiring in the below loom could be hacked out.

I didn’t like how the OEM loom went into an ISO lead, then into the Alpine power lead so decided to make a loom from scratch using all existing OEM/Alpine connectors. Below is all the wiring that has been removed from just the sound system in the car alone;

Now my new loom consists of the following;

- Live (Fused)

- Switched Live

- Neutral

- Front Right Speaker (+/-)

- Front Left Speaker (+/-)

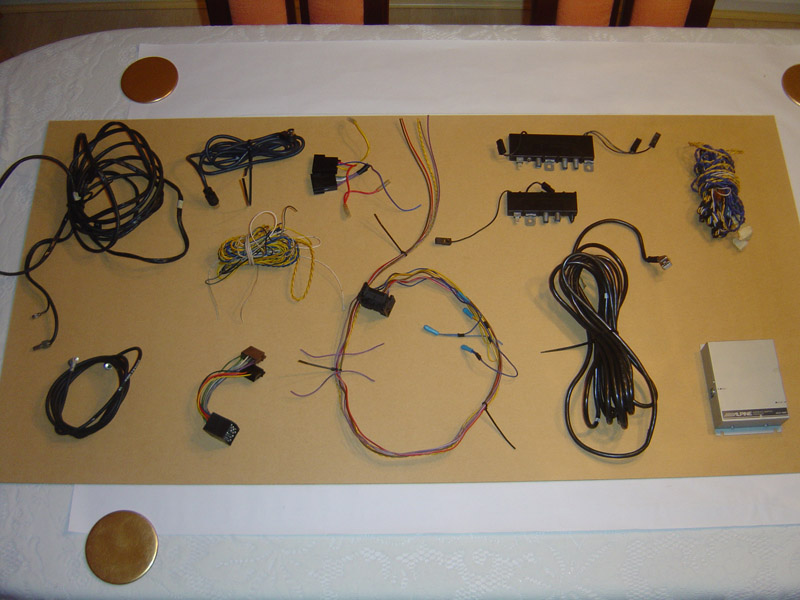

I have utilised the OEM BMW power plug which connects under the carpet in the passenger’s side foot well and the Alpine head unit connector plug. The speaker leads run into some existing aftermarket cross over boxes which power both the door speaker and tweeters, after re-fitting and testing everything worked flawlessly. Here is my new lightweight no-frills loom;

As Porky Pig would say... “That’s all folks!” well for now!

Got bored the other week, decided to go into the garage for a play... I’ve always hated the faded purple rear parcel shelf so decided I would remove it to re-black it, easier said than done with fixed bucket seats and harnesses as the only way to get in was to remove these first. Anyway, got the cabin clear and made my way into the back all that was needed to do was pop the lights out the C-Pillar, remove the covers from either side then the parcel shelf simply lifted (well, more jiggled) out.

It was at this point I noticed a load of fibre sound deadening as well as the usual stick on tar sound proofing, and decided to remove it whilst I had access to it.

Well, one thing lead to another and I decided since I had the heat gun out I should finally get round to removing all the tar sound deadening underneath the main carpet, after all I’ve been bleating on about doing it since April!!

First off was the centre console, shortly followed by the sill covers and front speaker covers. Then the driver’s side lower dash cover was removed along with the glove box and lower cowling, next came the on-board-computer and finally the centre of the lower dash. Once all this was removed the carpet could finally be lifted up, I was not going to take the heater matrix out to removed the front carpet so got some new Stanley and cut as closely and neatly round the heater as possible, this would make re-fitting the carpet easier too, and the centre console completely covers the cut / join lines.

Next up was removing the under floor heating channels, then it was onto the tar. With the promise of beer and pizza I had managed to lure in a few friends to help with the removal, this really did make life a lot less stressful it only took three people and hour or two to complete including larking around. All that was used was a heat gun and some plastic ice scrapers, I chose to use plastic scrapers so that the paint didn’t get damaged underneath.

With the tar itself removed, all that was left was to get rid of the sticky residue. After trying all sorts of different techniques over the years, I have found using petrol soaked flannel (Sorry Mam!!) in a well ventilated area the best, a cut towel will suffice too. It would appear that flannel / towels work better than old t-shirts and rags due to the larger surface area caused by the plush bobbly bits, yes that is the correct scientific term for them too, ha!

As you can see in the last picture I have pulled back all the un-needed rear wiring, I will eventually removed this, along with the air bag wiring at a later date. The aim is to just have the bare minimum amount of wiring, which is the rear lights, central locking filler cap and boot locking mechanism even the third brake light has been removed due to the spoiler that will eventually be fitted.

Not content with just removing the rear aerial wire, CD changer lead, rear speaker wiring and other optional extra wires that weren’t needed I decided the stereo loom was too cluttered too. So below as you can see is the standard stereo loom, now going the Club Sport route I decided that I would keep the main front speakers and door tweeters for those long road trips where a little music was required, so most of the wiring in the below loom could be hacked out.

I didn’t like how the OEM loom went into an ISO lead, then into the Alpine power lead so decided to make a loom from scratch using all existing OEM/Alpine connectors. Below is all the wiring that has been removed from just the sound system in the car alone;

Now my new loom consists of the following;

- Live (Fused)

- Switched Live

- Neutral

- Front Right Speaker (+/-)

- Front Left Speaker (+/-)

I have utilised the OEM BMW power plug which connects under the carpet in the passenger’s side foot well and the Alpine head unit connector plug. The speaker leads run into some existing aftermarket cross over boxes which power both the door speaker and tweeters, after re-fitting and testing everything worked flawlessly. Here is my new lightweight no-frills loom;

As Porky Pig would say... “That’s all folks!” well for now!

Sorry not read the whole thread, but noticed you were after some more power.

i used to own a 328i Msport which had some engine upgrades. a BBTB and manifold kit, decat, custom air filter and schnitzer exhaust which up'd the power to around 240bhp, and with the lighter weight of the 2.8 compared to the M3 it was very similar in perfomance. I had a play with a few and a regular play with an E46 M3 although he was faster on every occassion it was closer than you would expect, which surprised the other owner, as his was brand new circa £50k but he couldn't shake off a £4.5k 10 year old motor.

Anyway the forum i used to go on is e36coupe have a search it should give you all the answers to the questions you may or may not ask!!

i used to own a 328i Msport which had some engine upgrades. a BBTB and manifold kit, decat, custom air filter and schnitzer exhaust which up'd the power to around 240bhp, and with the lighter weight of the 2.8 compared to the M3 it was very similar in perfomance. I had a play with a few and a regular play with an E46 M3 although he was faster on every occassion it was closer than you would expect, which surprised the other owner, as his was brand new circa £50k but he couldn't shake off a £4.5k 10 year old motor.

Anyway the forum i used to go on is e36coupe have a search it should give you all the answers to the questions you may or may not ask!!

Here you go a link to the thread for the upgrade . . .

http://www.bmwowner.com/forum/viewtopic.php?f=17&a...

Apologies if this isn't allowed, MODS feel free to remove if required and i'll PM

http://www.bmwowner.com/forum/viewtopic.php?f=17&a...

Apologies if this isn't allowed, MODS feel free to remove if required and i'll PM

Hoping luck isn't required, put my money into the Safety Devices cage due to their impressive build quality and usually ease of fitment. I love full weld in FIA approved cages but really didn't want to start hacking the dash and going through bulk heads, especially since the car isn't a competition car.

I didn't do the wheel myself I'm afraid, I have done so in the past but find the stress and longetivity of a DIY job far outweighs the cost of paying a specialist to do it. You often find that home painted wheels only last a few months before they start looking like there due another refurb, I can pay someone £200.00 and the wheels will last 3 years, or I can do it myself at £40.00 odd a time but to keep them looking good they'll need doing another 4 times over those three few years.

I didn't do the wheel myself I'm afraid, I have done so in the past but find the stress and longetivity of a DIY job far outweighs the cost of paying a specialist to do it. You often find that home painted wheels only last a few months before they start looking like there due another refurb, I can pay someone £200.00 and the wheels will last 3 years, or I can do it myself at £40.00 odd a time but to keep them looking good they'll need doing another 4 times over those three few years.

Well it’s been a few weeks without an update, but here’s a big one so you’ll need a fast internet connection at the ready, several cups of coffee and a few pro-plus caffeine pills to keep your tiredness at bay!

First up came a bit more wiring removal, mainly taking out the airbag wiring, several un-used connections and generally anything that wasn’t of great importance such as the vacuum line for the exhaust valve. All in all there was a fair bit more un-needed wiring removed since the last update.

Car now sporting a light weight, no-frills interior wiring loom.

Now came a tiny bit of weight loss, since the car didn’t have any airbag electrics I figured I’d no longer need the airbag controller mounting plate and whilst the grinder was out decided the rear seats would never be re-fitted so that fixture could also be removed.

Now for the important bit; roll cage floor mount fitting. I hope people will understand the reasons there’s so few pictures, it’s a bad enough task for two people to undertake without having to stop every two minutes to take a photo.

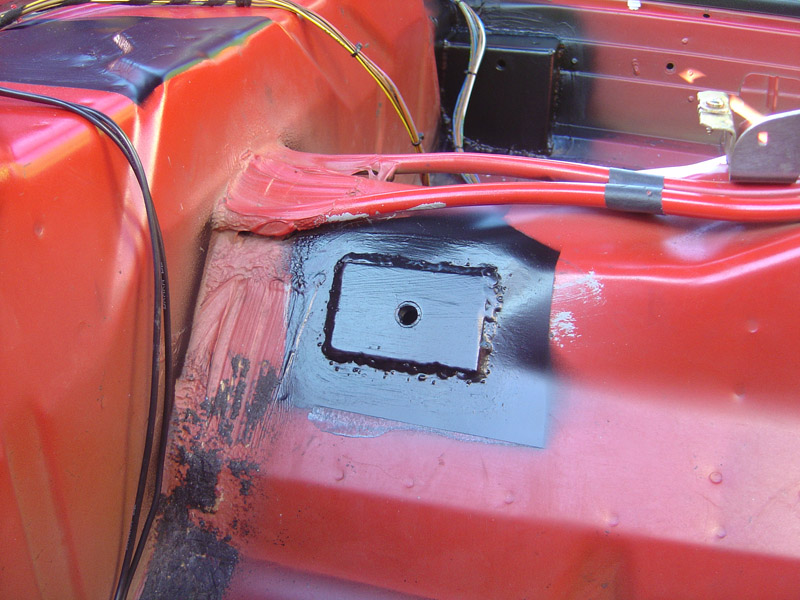

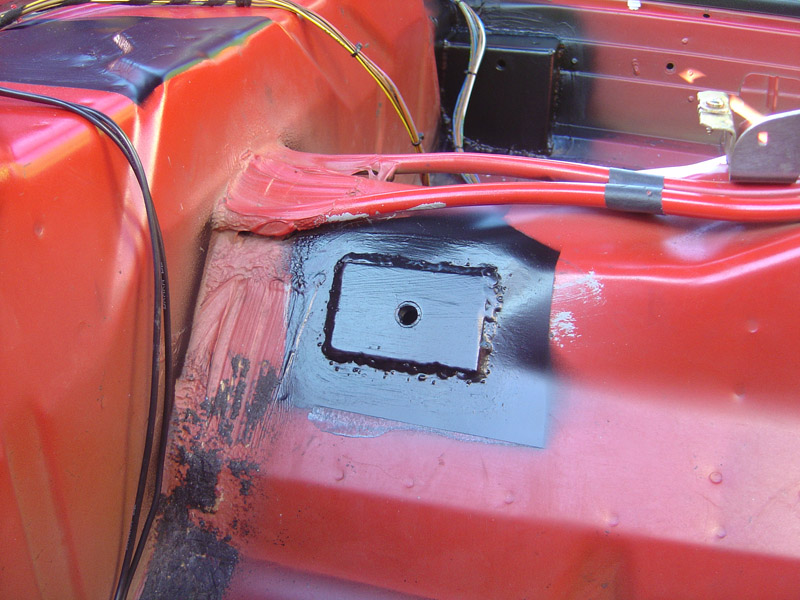

First up the car was parked on flat level ground and the floor pan was marked where the floor plates were to be welded in, next the grinder and sanding disc was used to prepare the surface for welding.

Then with the floor plates loosely placed in position the cage was fitted into the car and tightened up to ensure the correct positioning of the plates. This all sounds easy, but trust me the cage was in and out of the car several times before this process was complete.

Next the floor plates were tacked into place and the cage, once again, removed. Now came the main welding, this needs to be done in a well ventilated area with one man on designated fire watch. The under body sealer will burn and it’s advisable to remove it before welding, or have someone scraping the warm sealer as the welding takes place.

Again, I must stress I’m making this all sound very easy but I enlisted the help of a friend who is very talented when it comes to building special conversion cars with cages, his current project is a Mk2 Escort with an LS1 V8 engine. I recommend either taking your car to a specialist for a job like this, or having someone with a similar set of skills help out, you don’t want to ruin your shell.

Now with the floor plates painted, they were coated with Galva-Zinc, a Zinc rich anti-corrosion paint. I applied three coats to both the floor plates and the underside of the car, allow several days for this paint to fully cure before painting on top of.

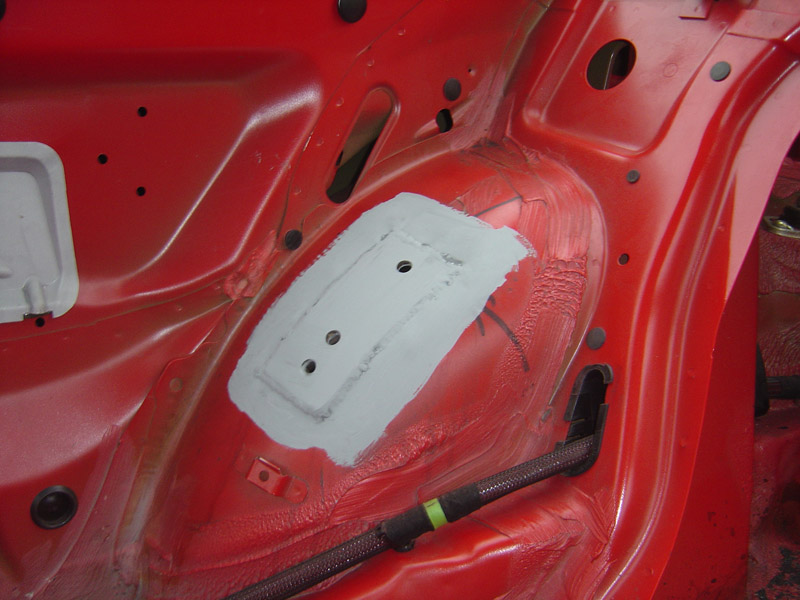

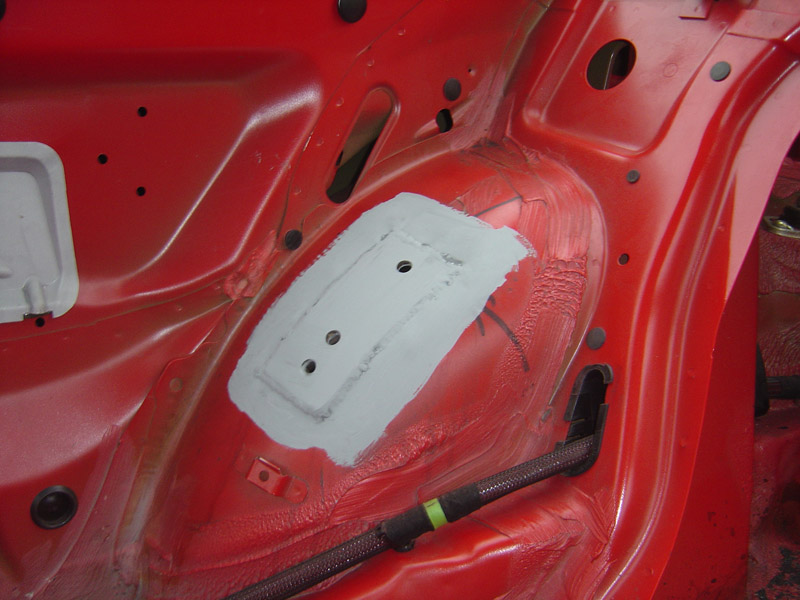

Again, killing two birds with one stone whilst the welder was out I decided to fit some harness spreader plates to the exhaust tunnel. I didn’t want to remove the exhaust, prop shaft and heat shields for this job so decided to get some FIA approved plates that could be fitted internally. As you can see from the picture the threaded lug is staggered so it cannot be easily broken away or pulled through the plate in the event of an accident.

Again more anti-corrosion paint was used.

Now as mentioned several times before, the carpet in this car is to be re-fitted so I needed to paint the floor plates black so that they wouldn’t look out of place when they protruded through the carpet. I simply used some satin black paint for this job, and used the anti-corrosion paint as a primer.

With the carpet going in the under floor heaving vents and wiring tracks were trimmed around the cage floor plates and re-fitted.

Next came the trimming of the carpet, this was a task I was dreading as I didn’t want to keep dragging the carpet in and out of the car, but at the same time wanted to get it right first time. I worked off the sill measurements and managed to get it relatively perfect, there was one mistake but using an off cut of the trimmed carpet this area could be patched and blended back into plate.

For cutting the carpet I’d suggest investing in some fresh Stanley knife blades, you’d be surprised how many you go through too.

Finally the carpet was re-fitted, along with the dash and all the other interior trim that was to go back into the car.

Now the rear of the car looked pretty bare, the red rear bench where the seats once were was exposed as well as a few wires. At first I thought I would just paint the rear bench black in hope to draw the attention away from it all but then decided to trim it, and make a proper job of it!

First things first, I needed a rear fire wall... for months I’ve had a CAD file that someone was kind enough to send me from when they did the job, after a bit of digging around I struck lucky and found a company who would cut it at reasonable cost. So the following week I picked up one alloy rear fire wall, added a few bands in it to match the curves of the car and I was left with this;

To fit, I simply used a drill and some pop rivets.

Finally, came the last stage of the interior; making a rear carpet, another task which I was dreading but been honest it went a lot better than planned.

After looking at several carpeting options I settled on using a thick acoustic carpet, this gave a good match to the existing carpet and was also quiet flexible and followed the contours of the rear bench nicely. The carpet was made in 4 parts; base, back and two arch sides, to affix the carpet I used the ‘hooked’ side of some heavy duty 45mm thick Velcro this seemed to work a treat!

Once the carpet was in the rear door cards were re-fitted too.

Here’s a few shoddy pictures of the job, I’ll try and get some better quality pictures up shortly. The camera flash makes the carpet look a total miss match but in natural light it’s as good as a match as I could find.

Two other interior touches were the rear parcel shelf was re-blacked using Autoglym Black Dye, in all honesty I’m not too happy with the job as its not totally black, but instead of been light sun-faded purple it’s now a deep shade of navy and the third brake light was removed and the space where the light would be was blacked off using black vinyl.

That’s all for this instalment of project infinity, more to come over the next week or two...

First up came a bit more wiring removal, mainly taking out the airbag wiring, several un-used connections and generally anything that wasn’t of great importance such as the vacuum line for the exhaust valve. All in all there was a fair bit more un-needed wiring removed since the last update.

Car now sporting a light weight, no-frills interior wiring loom.

Now came a tiny bit of weight loss, since the car didn’t have any airbag electrics I figured I’d no longer need the airbag controller mounting plate and whilst the grinder was out decided the rear seats would never be re-fitted so that fixture could also be removed.

Now for the important bit; roll cage floor mount fitting. I hope people will understand the reasons there’s so few pictures, it’s a bad enough task for two people to undertake without having to stop every two minutes to take a photo.

First up the car was parked on flat level ground and the floor pan was marked where the floor plates were to be welded in, next the grinder and sanding disc was used to prepare the surface for welding.

Then with the floor plates loosely placed in position the cage was fitted into the car and tightened up to ensure the correct positioning of the plates. This all sounds easy, but trust me the cage was in and out of the car several times before this process was complete.

Next the floor plates were tacked into place and the cage, once again, removed. Now came the main welding, this needs to be done in a well ventilated area with one man on designated fire watch. The under body sealer will burn and it’s advisable to remove it before welding, or have someone scraping the warm sealer as the welding takes place.

Again, I must stress I’m making this all sound very easy but I enlisted the help of a friend who is very talented when it comes to building special conversion cars with cages, his current project is a Mk2 Escort with an LS1 V8 engine. I recommend either taking your car to a specialist for a job like this, or having someone with a similar set of skills help out, you don’t want to ruin your shell.

Now with the floor plates painted, they were coated with Galva-Zinc, a Zinc rich anti-corrosion paint. I applied three coats to both the floor plates and the underside of the car, allow several days for this paint to fully cure before painting on top of.

Again, killing two birds with one stone whilst the welder was out I decided to fit some harness spreader plates to the exhaust tunnel. I didn’t want to remove the exhaust, prop shaft and heat shields for this job so decided to get some FIA approved plates that could be fitted internally. As you can see from the picture the threaded lug is staggered so it cannot be easily broken away or pulled through the plate in the event of an accident.

Again more anti-corrosion paint was used.

Now as mentioned several times before, the carpet in this car is to be re-fitted so I needed to paint the floor plates black so that they wouldn’t look out of place when they protruded through the carpet. I simply used some satin black paint for this job, and used the anti-corrosion paint as a primer.

With the carpet going in the under floor heaving vents and wiring tracks were trimmed around the cage floor plates and re-fitted.

Next came the trimming of the carpet, this was a task I was dreading as I didn’t want to keep dragging the carpet in and out of the car, but at the same time wanted to get it right first time. I worked off the sill measurements and managed to get it relatively perfect, there was one mistake but using an off cut of the trimmed carpet this area could be patched and blended back into plate.

For cutting the carpet I’d suggest investing in some fresh Stanley knife blades, you’d be surprised how many you go through too.

Finally the carpet was re-fitted, along with the dash and all the other interior trim that was to go back into the car.

Now the rear of the car looked pretty bare, the red rear bench where the seats once were was exposed as well as a few wires. At first I thought I would just paint the rear bench black in hope to draw the attention away from it all but then decided to trim it, and make a proper job of it!

First things first, I needed a rear fire wall... for months I’ve had a CAD file that someone was kind enough to send me from when they did the job, after a bit of digging around I struck lucky and found a company who would cut it at reasonable cost. So the following week I picked up one alloy rear fire wall, added a few bands in it to match the curves of the car and I was left with this;

To fit, I simply used a drill and some pop rivets.

Finally, came the last stage of the interior; making a rear carpet, another task which I was dreading but been honest it went a lot better than planned.

After looking at several carpeting options I settled on using a thick acoustic carpet, this gave a good match to the existing carpet and was also quiet flexible and followed the contours of the rear bench nicely. The carpet was made in 4 parts; base, back and two arch sides, to affix the carpet I used the ‘hooked’ side of some heavy duty 45mm thick Velcro this seemed to work a treat!

Once the carpet was in the rear door cards were re-fitted too.

Here’s a few shoddy pictures of the job, I’ll try and get some better quality pictures up shortly. The camera flash makes the carpet look a total miss match but in natural light it’s as good as a match as I could find.

Two other interior touches were the rear parcel shelf was re-blacked using Autoglym Black Dye, in all honesty I’m not too happy with the job as its not totally black, but instead of been light sun-faded purple it’s now a deep shade of navy and the third brake light was removed and the space where the light would be was blacked off using black vinyl.

That’s all for this instalment of project infinity, more to come over the next week or two...

Sorry, forgot to answer your previous post... left the tank in place, used sheet metal to protect it and also had a spray bottle of water that was misted as the welding took place. Ideal world, remove the tank but I was using a friends garage in which I had 24 hours to get the job done.

Big fan of what you've done here, it's certainly how I would prep my 328 if a had one...it might very well be my next car.

I'm sure you're aware, but cages in cars where the passengers aren't secured but comprehensive harnesses can do more harm than good in terms of head injuries - make sure you get some good quality padding anywhere near your or your passenger's head.

I'm sure you're aware, but cages in cars where the passengers aren't secured but comprehensive harnesses can do more harm than good in terms of head injuries - make sure you get some good quality padding anywhere near your or your passenger's head.

Thanks for the comments guys... at first I didn't think I'd need padding as my seats sit that low, however after doing a few seat test fits today if you're my height (6ft4) you've still got a big gap between head and gape, but theres still a chance there could be contact, so for peace of mind there will be some Safety Devices FIA approved padding going on there.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff