Noble M12 heavily modified

Discussion

I made the inner door panels and drivers door... i want laquered carbon on the inside of the door visable so I spent some time ensuring the weave was nice around here.... also had the door pad re-trimmed in leather as well as a pressed leather that looks like carbon.

they fit perfectly and are extremelly strong... could have made them lighter but I wanted some extra crash protection over standard... still saved 3kgs a door though... moving on to doing the front clip in carbon in Feb

they fit perfectly and are extremelly strong... could have made them lighter but I wanted some extra crash protection over standard... still saved 3kgs a door though... moving on to doing the front clip in carbon in Feb

stevieturbo said:

andygtt said:

Ok well lets be clear I had no experience with carbon until 2 months ago, so this is me teaching myself... get the right products and advice and its achievable by anyone.... break down each stage of what I did and it doesnt seem hard.. polish a part... then apply wax... paint some gel coat on.. etc etc

Also remember Im actually just a bean counter, if I can do it, anyone can lol

Only just seeing this thread now...awesome work !Also remember Im actually just a bean counter, if I can do it, anyone can lol

So what would it take from a cost point of view to get started making say a door ? Ive no experience whatsoever with any sort of composites. Cost wise..would fibreglass or Kevlar be vastly different than carbon ? I see you've a vacuum pump setup, is this required for all composites ?

I'd like to make doors for mine, but it'd be a huge undertaking I think. Plus mine have frames for the windows...does that make it easier or harder ?

quite a bit of that is the materials to make the moulds so further doors will cost approx £5-600... each door takes probably 3days of my time to make (8hrs assumed)... so you can start to see why carbon is so expensive.

You can wet lay the final part, but this is significantly heavier and the weave wont be as nice... vacume forming means you only use the resin required to wet the part out so you get a greater strength to weight ratio... I use whats called resin infusion, this is effectively as strong and good as autoclaving but is MUCH more labour intensive.

Fact is I would use autoclave if I could... I just don't have the spare 2-300k (guess) to buy the equipment of the room to house it!... however its easier and much quicker to make parts this way.

You can use carbon, kevlar or fibreglass with resin infusion... carbon is stronger but not impact resistant, kevlar is much less strong but has high impact strength, fibreglass is cheap lol.... given the time taken is the largest cost it wouldnt be worth doing your parts in anything but carbon or kevlar.

However if I was to buy a full door in carbon to the same strength and quality of mine, I would be paying over £2k... seeing as I have the moulds and 2 doors for a lot less than a single door Id say it was well worth it.... plus know-one makes carbon doors for a noble but me

IMO a granada door will be no more difficult than my door... the frame just means more material thats all... it would weigh similar to mine

Im glad people like it

car was originally my company car so stayed stock and did lots of miles, now its is more of a test mule to 'learn' new skills so I can apply them to my more serious GTT supercar I have designed. Almost all of the things I have done to the car is all new to me, Id never designed a turbo package before and I have never worked with carbon, its all self taught

the V weave is actually very hard and Im personally amazed I managed to get it close to perfect... i'm fairly critical and even Im going to be happy with it being pure laquer... its by no means perfect though, there are some areas were the carbon is slightly pulled, but then without doing it in pre-preg it would almost imposible to get it flawless.

BTW this is vacume formed so bagged in similar way to pre-preg, its just that the resin cures at a lower temperature and the cloth is impregnated with resin when its in the bag, so the material goes in dry and resin is sucked in... its called vacume infusion.

car was originally my company car so stayed stock and did lots of miles, now its is more of a test mule to 'learn' new skills so I can apply them to my more serious GTT supercar I have designed. Almost all of the things I have done to the car is all new to me, Id never designed a turbo package before and I have never worked with carbon, its all self taught

the V weave is actually very hard and Im personally amazed I managed to get it close to perfect... i'm fairly critical and even Im going to be happy with it being pure laquer... its by no means perfect though, there are some areas were the carbon is slightly pulled, but then without doing it in pre-preg it would almost imposible to get it flawless.

BTW this is vacume formed so bagged in similar way to pre-preg, its just that the resin cures at a lower temperature and the cloth is impregnated with resin when its in the bag, so the material goes in dry and resin is sucked in... its called vacume infusion.

TobyLaRohne said:

I've just seen this, wow! I am in awe of your dedication and work.

I think this is the best project I've ever seen on pistonheads!

What is the purpose/the aim of this project? I seem to of missed it despite reading the thread..

Is it a "fun" project to teach yourself things, or do you want the ultimate road car or ultimate track car or a bit of a mix?..or is it just a "because I can" project?

How do the brakes and suspension set up deal with the mods? Will you be doing something like fitting Ceramic brakes and some kind of trick racing suspension?

Keep up the amazing work, you're living MY dream! haha

In truth the car is a road/track car, I don't have any real goals in mind (other than I want to achieve 700bhp per ton), i'm just making it the best 'I' can... Im getting a little carried away, but im enjoying the challenges and its a hobby so thats all that matters.... brakes have coped well, they are 4 pot AP's all round as standard and whilst some 'issues' exist I personaly have never had and problems... reducing the weight of the car helps the brakes a lot as well.I think this is the best project I've ever seen on pistonheads!

What is the purpose/the aim of this project? I seem to of missed it despite reading the thread..

Is it a "fun" project to teach yourself things, or do you want the ultimate road car or ultimate track car or a bit of a mix?..or is it just a "because I can" project?

How do the brakes and suspension set up deal with the mods? Will you be doing something like fitting Ceramic brakes and some kind of trick racing suspension?

Keep up the amazing work, you're living MY dream! haha

I have looked at ceramic brakes and yes I will definately be looking at these on the GTT, if they come up for good price I will probably use them on this as well.

I upgraded the Suspension to Protec and is more than up to the job, this is an area were the noble is rightly thought very highly, so other than the camber changes I don't need to do anything else

To be clear... this is a scratch made carbon panel NOT a wrapped original, I made a mould then vac formed an entire new front clip (clam  ) it is actually a composite panel as it is also lined with kevlar within the wheelarches to give some abrasion resistance to stone impacts.

) it is actually a composite panel as it is also lined with kevlar within the wheelarches to give some abrasion resistance to stone impacts.

My clip weighs under 8kgs compared to nearly 20kgs for the standard one and is actually stronger!

So 10kgs weigh saving for this panel

) it is actually a composite panel as it is also lined with kevlar within the wheelarches to give some abrasion resistance to stone impacts.

) it is actually a composite panel as it is also lined with kevlar within the wheelarches to give some abrasion resistance to stone impacts.My clip weighs under 8kgs compared to nearly 20kgs for the standard one and is actually stronger!

So 10kgs weigh saving for this panel

bishbash said:

andygtt said:

now its is more of a test mule to 'learn' new skills so I can apply them to my more serious GTT supercar I have designed.

This is looking fantastic. Great to hear the other project is still going, I thought you might have canned it to concentrate on this one.When you make your molds do you need the existing parts as templates, if so how are you going to make the new parts on the GTT?

Also, will it need more downforce (aero) to compensate for the weight loss, (excuse my ignorance here if this is a daft question) or will it not matter?

Edited by bishbash on Friday 26th April 16:59

For the GTT I make the buck to the shape I want, then I again take moulds.... Basically I end up making the part 3 times hence it's a stupid amount of work

Regarding aero, I have done quite a bit on the rear, at the front it's mostly going to be hidden as its underside and splitter.... The weight saving has an impact as it changes the weight distribution and centre of gravity, but in truth these changes are minimal... Most of the aero is to address issues with the original design or to improve it.

dom9 said:

Tiger Tim said:

So Andy, no dodging.. What's happening with the GTT?

Don't get me wrong I love the Noble but the GTT was really progressing and then stalled due to working away? Where are you with it now? Can we have some updates?

Cheers

Paul

+1,000,000

Don't get me wrong I love the Noble but the GTT was really progressing and then stalled due to working away? Where are you with it now? Can we have some updates?

Cheers

Paul

I won't be restarting it till I have finished the noble and I'm currently really enjoying it.

M159V8 said:

andygtt said:

I'm planning to get rid of the old BMW V12 and fit a M5 V10 instead

Will you be using SMG? Or perhaps you could import a manual transmission from the States?  Should really be manual IMO

Should really be manual IMO

be good for cruising though lol

chuntington101 said:

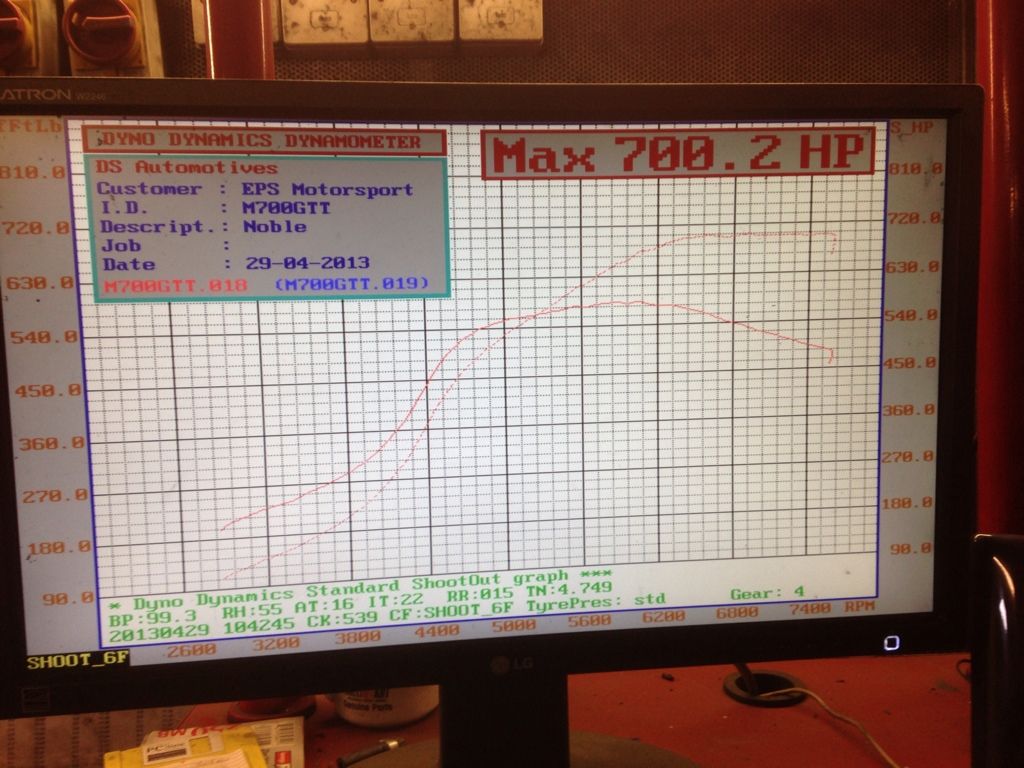

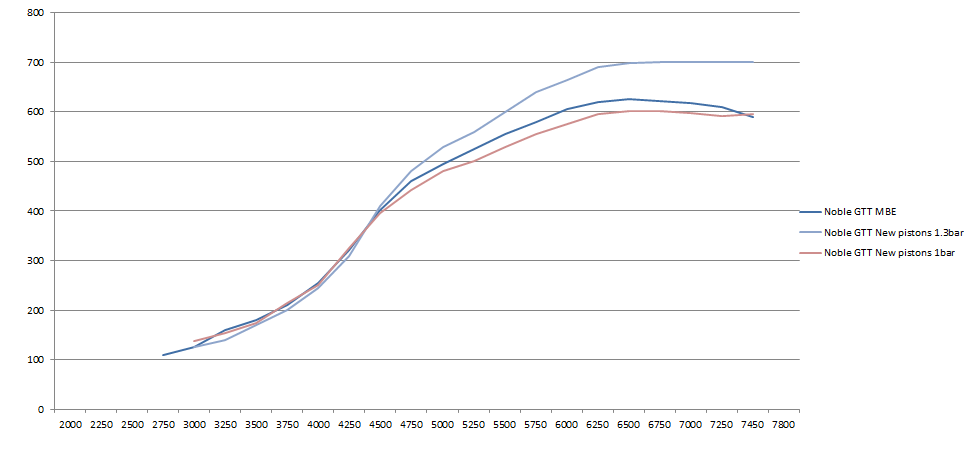

Cracking graph there andy! Are you still capping the torque to save the box? Looks like there is still room for a little more boost up top if you wanted to hold that torque curve a little longer. That's assuming the engine can take a little more.

Dose that mean you are the most powerful Noble in the uk?

must admit im pretty pleased with it... usable power over a wide rev range

Dose that mean you are the most powerful Noble in the uk?

yes power and torque is still capped, i ran 1.6 bar previously at 7500rpm, the extra power has been found with new piston design... the ecu has also changed but that wont add power just much better control and safety/logging.

this chart shows the old engine running full boost vs the new engine... done on a different dyno but surprisingly similar low down curvs which suggest the dynos read similar.

Greg_D said:

I'll bet that 'wrapping' comment was like a dagger to the heart, wasn't it andy!!!

Just out of interest, are the quarter panels going to get any sort of carbon treatment or are you going to leave them as is by way of a juxtaposition?

must say i've never seen wrap that looked like real carbon so was a little confused lol... to be fair the pics were not that great as it was a raw unlacquered panel and many dont appreciate that real carbon isnt glossy as it starts as a matt cloth and is usually gel coated or lacquered to give the finish people know and love.Just out of interest, are the quarter panels going to get any sort of carbon treatment or are you going to leave them as is by way of a juxtaposition?

I might make a carbon tub which inlcudes the side quarter panels... this is the only panel I have not made moulds of yet and made in carbon.... It will be a huge amount of work even by my standards so it will depend if i need the extra weight saving to meet my 1000kgs weight goal

FWDRacer said:

Sorry naysayers, but having put my hard work into the Carbon, I'd be inclined to show it off

If a full Carbon tub isn't required to meet your weight target, paint the W-anky blue bit in Hi gloss black as a match to the finished Hi-gloss carbon...

Then it'll look 'Proper' stealth bomber.

I kinda have the same opinion, I've seen carbon supercars and thought 'nah preffer it painted'... but having worked so hard to get the weave good enough to just lacquer I feel it looks cool in raw carbon.... plus there isnt and is unlikelly to be another lacquered carbon Noble M12 so it makes it unique.

If a full Carbon tub isn't required to meet your weight target, paint the W-anky blue bit in Hi gloss black as a match to the finished Hi-gloss carbon...

Then it'll look 'Proper' stealth bomber.

Incidentally the weave isnt perfect everywere, there is a few flaws so there is room for improvement... but i'm a fussy bugger and its still good enough for me.

I had thought about painting the tub black... however a large number of people have said it looks good as is, so I think I will paint the white parts a colour and leave rest lacquered carbon for the summer

CobraChris said:

Hi Andy.

Saw your Noble in the flesh at Stoneleigh today.

Great job!

Cheers, tbh the car was very rough around the edges with its cobbled in temporary lights and I didn't even have time to wipe the polish out of the pinholes in the front clip lacquer... But I wanted to use the car rather than leaving it in the garage... And it was a good show worth going to... Even managed to buy my new lights while I was there :-)Saw your Noble in the flesh at Stoneleigh today.

Great job!

Did We meet?

so I finally got a local paint shop (phil did it ferg!) to slap a few coats of paint on... it ISNT finished as I lack the cash and time (as i'm going to monaco etc in it friday) so it will have further flatting and laquer later on in the year.

its still a long way from being finished, but it now feels like its getting there

its still a long way from being finished, but it now feels like its getting there

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff