500+bhp Mk3 Fiesta Project

Discussion

Cheers

Fuel tank - part 8

Next was to modify the tank to facilitate a new exhaust route underneath it. I will use a single 3" pipe for the new exhaust - standard Fiesta is 2.25" or 2.5" depending on model - and so I chose to use a 4" pipe to create a recess on the bottom edge of the tank. 4" will give sufficient clearance for the exhaust and a heat shield too.

I worked out the new route and ordered a 4" mild steel 60 degree bend to suit. Jetex were the only UK supplier I could find who stock 4" mandrel bends in mild steel, and with rarity comes cost!

Here's the 4" pipe next to the standard exhaust from the Ka I'm working with.

I cut the 4" bend in half lengthways and used each piece to work out the route and draw an outline on the bottom of the tank. I trimmed the pieces at a matching angle and welded them together.

New tank extensions seam welded and exhaust recess in place. I need to sink it into the tank another 20mm yet to provide the necessary exhaust to ground clearance, but it's looking good so far.

Fuel tank - part 8

Next was to modify the tank to facilitate a new exhaust route underneath it. I will use a single 3" pipe for the new exhaust - standard Fiesta is 2.25" or 2.5" depending on model - and so I chose to use a 4" pipe to create a recess on the bottom edge of the tank. 4" will give sufficient clearance for the exhaust and a heat shield too.

I worked out the new route and ordered a 4" mild steel 60 degree bend to suit. Jetex were the only UK supplier I could find who stock 4" mandrel bends in mild steel, and with rarity comes cost!

Here's the 4" pipe next to the standard exhaust from the Ka I'm working with.

I cut the 4" bend in half lengthways and used each piece to work out the route and draw an outline on the bottom of the tank. I trimmed the pieces at a matching angle and welded them together.

New tank extensions seam welded and exhaust recess in place. I need to sink it into the tank another 20mm yet to provide the necessary exhaust to ground clearance, but it's looking good so far.

jds32 said:

ezakimak said:

will be interesting to see how you get fuel out of both sides of the tank, unless im looking at the top?

I thought the same thing.The exhaust will be insulated around the tank area, probably with Heatshield Armor™ which has a ceramic lining. Routing an exhaust under a fuel tank is very commonplace as there really isn't a lot of choice given the available space.

E92 M3 as an example (fuel tank is above the two resonators to the right of the '65' annotations):

E92 M3 as an example (fuel tank is above the two resonators to the right of the '65' annotations):

mwstewart said:

Cheers

Fuel tank - part 8

Next was to modify the tank to facilitate a new exhaust route underneath it. I will use a single 3" pipe for the new exhaust - standard Fiesta is 2.25" or 2.5" depending on model - and so I chose to use a 4" pipe to create a recess on the bottom edge of the tank. 4" will give sufficient clearance for the exhaust and a heat shield too.

I worked out the new route and ordered a 4" mild steel 60 degree bend to suit. Jetex were the only UK supplier I could find who stock 4" mandrel bends in mild steel, and with rarity comes cost!

Here's the 4" pipe next to the standard exhaust from the Ka I'm working with.

I cut the 4" bend in half lengthways and used each piece to work out the route and draw an outline on the bottom of the tank. I trimmed the pieces at a matching angle and welded them together.

New tank extensions seam welded and exhaust recess in place. I need to sink it into the tank another 20mm yet to provide the necessary exhaust to ground clearance, but it's looking good so far.

Use plenty of heat wrap. Turbo engines hate hot/warm fuel.

Fuel tank - part 8

Next was to modify the tank to facilitate a new exhaust route underneath it. I will use a single 3" pipe for the new exhaust - standard Fiesta is 2.25" or 2.5" depending on model - and so I chose to use a 4" pipe to create a recess on the bottom edge of the tank. 4" will give sufficient clearance for the exhaust and a heat shield too.

I worked out the new route and ordered a 4" mild steel 60 degree bend to suit. Jetex were the only UK supplier I could find who stock 4" mandrel bends in mild steel, and with rarity comes cost!

Here's the 4" pipe next to the standard exhaust from the Ka I'm working with.

I cut the 4" bend in half lengthways and used each piece to work out the route and draw an outline on the bottom of the tank. I trimmed the pieces at a matching angle and welded them together.

New tank extensions seam welded and exhaust recess in place. I need to sink it into the tank another 20mm yet to provide the necessary exhaust to ground clearance, but it's looking good so far.

I'd consider having the underside of the fuel tank coated by Zircotec.

One thing I've noticed though is that with the half pipe section welded in, you'll end up unable to empty the tank entirely from the side furthest from the pump.

That is unless, you have a lift pump to pickup the fuel from the furthest side from the pump or a secondary pickup.

One thing I've noticed though is that with the half pipe section welded in, you'll end up unable to empty the tank entirely from the side furthest from the pump.

That is unless, you have a lift pump to pickup the fuel from the furthest side from the pump or a secondary pickup.

Once again I am captivated with what you are doing, I kind of don't want to see this build ever end its so good. I know there will be several pages to be added to the thread to satisfy subscribers so I am very much looking forward to watching this progress.

Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

H100S said:

Once again I am captivated with what you are doing, I kind of don't want to see this build ever end its so good. I know there will be several pages to be added to the thread to satisfy subscribers so I am very much looking forward to watching this progress.

Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

Thank you! In the morning I'm going to collect the front end of this rolled Clio RS 200Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

I will use its arms and 'PerfoHub' .

I plan to make a T45 subframe to mount the Clio parts to the standard Fiesta mounting points. If I want to change the suspension later on down the line, I just need to make another subframe.

mwstewart said:

H100S said:

Once again I am captivated with what you are doing, I kind of don't want to see this build ever end its so good. I know there will be several pages to be added to the thread to satisfy subscribers so I am very much looking forward to watching this progress.

Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

Thank you! In the morning I'm going to collect the front end of this rolled Clio RS 200Once completed I will come to a Ford show to see this car, I need to see it in the flesh.

Everything you have done so far has been outstanding although as many have said the headlamp wash solution I am on the fence with. On one hand I agree with your choice of components however aesthetically there must be a better option.

Did you ever look at the Astra GTC / Insignia VXR option for the front suspension?

PS keep up the good work on the E46 M3 too!

I will use its arms and 'PerfoHub' .

I plan to make a T45 subframe to mount the Clio parts to the standard Fiesta mounting points. If I want to change the suspension later on down the line, I just need to make another subframe.

Edited by H100S on Friday 28th February 19:47

H100S said:

Nice one, the Clio set up looks great. Will you be able to use a combination of the Ford steering rack and Renault ends with bespoke Tie rods to link up the steering with the steering knuckles?

That's the plan. The uprights are a quality forging by Brembo that have pressed in steel inserts to suit the Renault track rod ends. I will have those pressed out and replaced with inserts machined to suit the Fiesta track rod end diameter & taper.

The hub flange/wheel bearing comes in cartridge form on the Clio so it's easy enough for me to replace it with a custom machined part. I require a Mk1 Focus bearing to run my ABS system (ABS sensor pickup is from magnetic inserts in the Ford bearing), and the Focus front bearings come as a kit with a new hub flange.

A custom cartridge will be machined from billet that suits a suit the Mk1 Focus wheel bearing and hub flange on one side, and the clio upright on the other.

I need to add at this point the conversion is purely at the ideas stage. I'll have a better idea of feasibility tomorrow or Sunday once the Clio parts are in front of me, and I can start to make measurements to determine if it'll work with the Fiesta chassis/dimensions/suspension layout.

Fuel tank - part 9

I made some reinforcing tabs and welded them around the mounting hole positions. These will help spread the weight of the increased fuel load.

To finish off the exhaust recess I welded a 25mm extension to it to provide necessary ground clearance for a 3" exhaust.

I then seam welded the recess into place.

This shot shows how much clearance I have. Just a small infill piece to do next where I joined the two tank sections together.

Front Suspension

I decided on Clio RS 197/200 front suspension. I would have liked to use a Ford offering to keep to the same manufacturer - and parts counter! - but the RevoKnuckle in the Mk2 Focus RS weighs more than a boat anchor. This lot came from Norwich...My girlfriend is now used to jaunts across the country visiting dirty scrap yards followed by a pub lunch - how spoilt she is

The first step was a strip down to learn how it's built and put together.

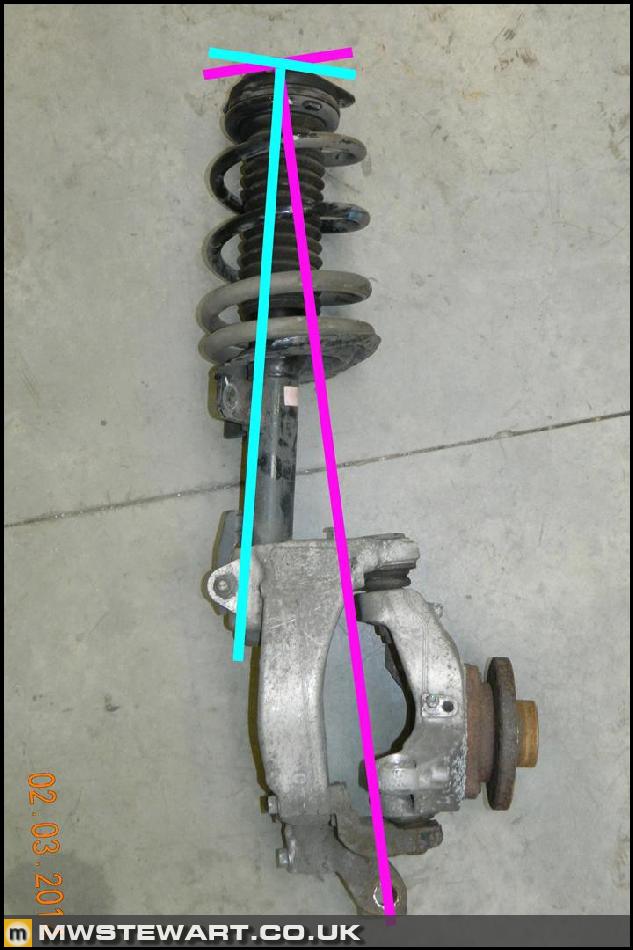

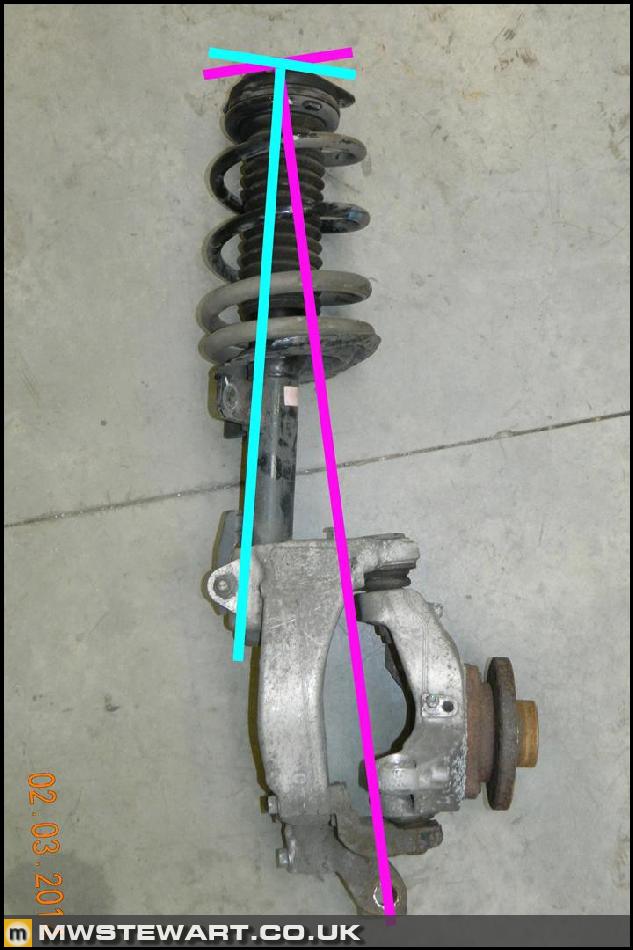

Here's the strut layout with Renault's PerfoHub; this arrangement means that the base of the McPherson strut is further inboard than with a traditional hub, and in order to keep the required Steering Axis Inclination (SAI) - purple line- acceptable, the strut is angled outboard at the top rather than the usual inboard inclination - light blue line.

To negate the requirement for a different suspension turret in the 197/200 models Renault use a canted top mount to adapt the outboard tilted strut to the standard inboard tilted suspension turrets.

Clio strut - 47mm base (left), Fiesta Mk5 KW V3 strut - 45mm base (right). The Clio weighs 176Kg more than the Fiesta.

As it happens the M12 locking bolt tab is in an identical position on each strut, so the Fiesta strut can be mounted and tightened, however the 2mm difference in diameter means the Clio strut must clamp further than designed which places undue stress on the hub. This is obviously an absolute no-no. The solution will be a machined shim, or potentially a complete remake of this part of the hub in billet 7075 aluminium.

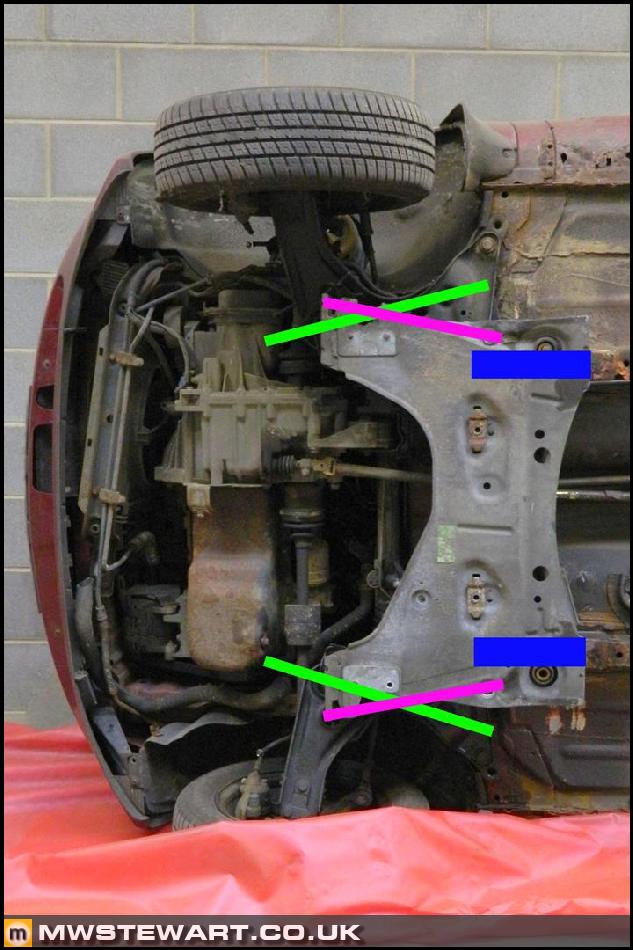

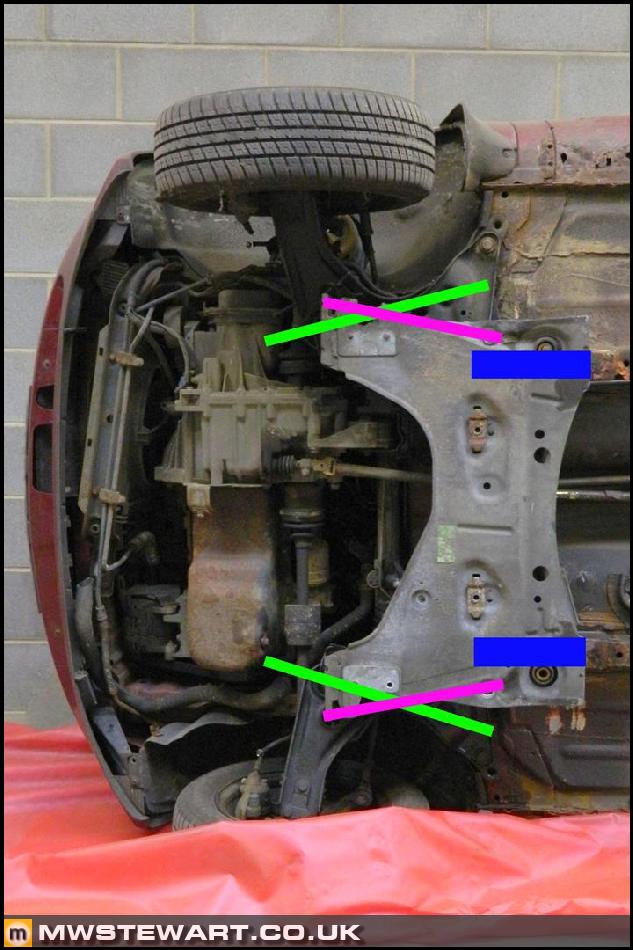

The purple lines in the photo below show the angle that the Clio lower arms are mounted; it will not be possible to mount them this way on the Fiesta due to the route of the chassis rails ([u]blue rectangles[/u]). Based on this it's looking like the approach I'll take is to retain the Fiesta lower arm mounting ([u]green lines[/u]) and modify the arms to suit the Renault PerfoHub. I'll possibly end up with billet arms.

As an observation: going from pictures on the internet I thought the Clio RS subframe to be pressed Aluminium, but it isn't, it's just galvanised steel. It is really heavy and in fact it and the one piece discs add a significant amount of weight to the suspension assembly.

I made some reinforcing tabs and welded them around the mounting hole positions. These will help spread the weight of the increased fuel load.

To finish off the exhaust recess I welded a 25mm extension to it to provide necessary ground clearance for a 3" exhaust.

I then seam welded the recess into place.

This shot shows how much clearance I have. Just a small infill piece to do next where I joined the two tank sections together.

Front Suspension

I decided on Clio RS 197/200 front suspension. I would have liked to use a Ford offering to keep to the same manufacturer - and parts counter! - but the RevoKnuckle in the Mk2 Focus RS weighs more than a boat anchor. This lot came from Norwich...My girlfriend is now used to jaunts across the country visiting dirty scrap yards followed by a pub lunch - how spoilt she is

The first step was a strip down to learn how it's built and put together.

Here's the strut layout with Renault's PerfoHub; this arrangement means that the base of the McPherson strut is further inboard than with a traditional hub, and in order to keep the required Steering Axis Inclination (SAI) - purple line- acceptable, the strut is angled outboard at the top rather than the usual inboard inclination - light blue line.

To negate the requirement for a different suspension turret in the 197/200 models Renault use a canted top mount to adapt the outboard tilted strut to the standard inboard tilted suspension turrets.

Clio strut - 47mm base (left), Fiesta Mk5 KW V3 strut - 45mm base (right). The Clio weighs 176Kg more than the Fiesta.

As it happens the M12 locking bolt tab is in an identical position on each strut, so the Fiesta strut can be mounted and tightened, however the 2mm difference in diameter means the Clio strut must clamp further than designed which places undue stress on the hub. This is obviously an absolute no-no. The solution will be a machined shim, or potentially a complete remake of this part of the hub in billet 7075 aluminium.

The purple lines in the photo below show the angle that the Clio lower arms are mounted; it will not be possible to mount them this way on the Fiesta due to the route of the chassis rails ([u]blue rectangles[/u]). Based on this it's looking like the approach I'll take is to retain the Fiesta lower arm mounting ([u]green lines[/u]) and modify the arms to suit the Renault PerfoHub. I'll possibly end up with billet arms.

As an observation: going from pictures on the internet I thought the Clio RS subframe to be pressed Aluminium, but it isn't, it's just galvanised steel. It is really heavy and in fact it and the one piece discs add a significant amount of weight to the suspension assembly.

Couple of thoughts:

1) the clio subframe almost certainly is a "shear" plate to enable the car to meet the offset frontal crash test (which didn't exist when your fiesta was made!) This means it probably has to be steel!

2) The angled struts on the clio are offset by the heavily angled/offset lower spring platforms that act to limit strut bending loads by directing the spring loads through the centre of the contact patch.

1) the clio subframe almost certainly is a "shear" plate to enable the car to meet the offset frontal crash test (which didn't exist when your fiesta was made!) This means it probably has to be steel!

2) The angled struts on the clio are offset by the heavily angled/offset lower spring platforms that act to limit strut bending loads by directing the spring loads through the centre of the contact patch.

Max_Torque said:

Couple of thoughts:

1) the clio subframe almost certainly is a "shear" plate to enable the car to meet the offset frontal crash test (which didn't exist when your fiesta was made!) This means it probably has to be steel!

2) The angled struts on the clio are offset by the heavily angled/offset lower spring platforms that act to limit strut bending loads by directing the spring loads through the centre of the contact patch.

Thanks - very interesting! I now see the offset platforms 1) the clio subframe almost certainly is a "shear" plate to enable the car to meet the offset frontal crash test (which didn't exist when your fiesta was made!) This means it probably has to be steel!

2) The angled struts on the clio are offset by the heavily angled/offset lower spring platforms that act to limit strut bending loads by directing the spring loads through the centre of the contact patch.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff