500+bhp Mk3 Fiesta Project

Discussion

Can i suggest a "halfway house"?

Take you steel tank, and "wrap it" in kevlar. Easy to do, adds massive strength, and will look good. If you then finished it with a black "gel coat" (or similar) it would look just like a plastic tank, pretty much be as strong as a plastic tank. Other than a slight weight penalty it's be great, and much better than an ally tank, which tbh, i wouldn't use "unprotected" under a car for fear of piercing type impacts etc etc

Take you steel tank, and "wrap it" in kevlar. Easy to do, adds massive strength, and will look good. If you then finished it with a black "gel coat" (or similar) it would look just like a plastic tank, pretty much be as strong as a plastic tank. Other than a slight weight penalty it's be great, and much better than an ally tank, which tbh, i wouldn't use "unprotected" under a car for fear of piercing type impacts etc etc

This morning Ian sent through some engine progress photos.

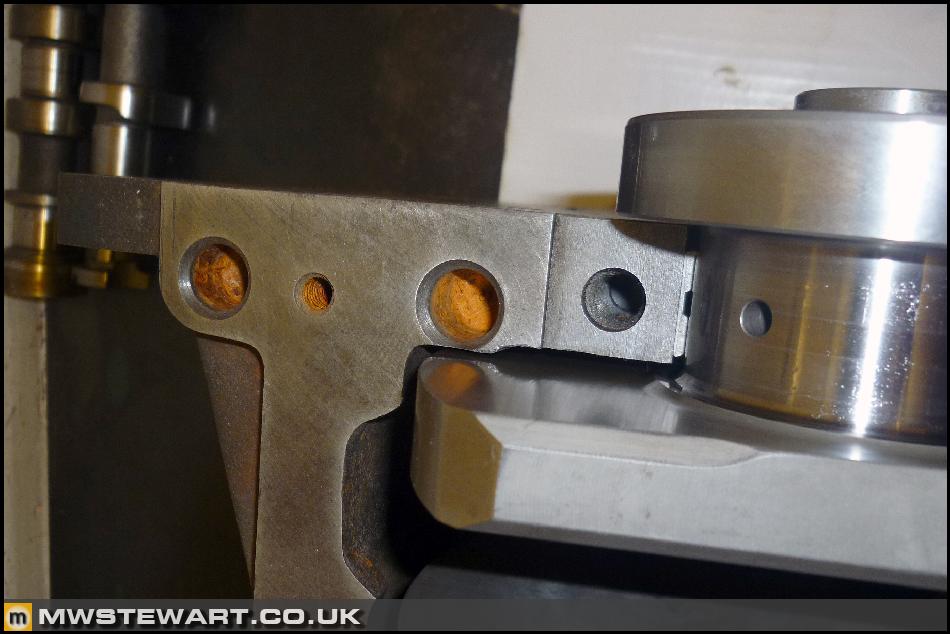

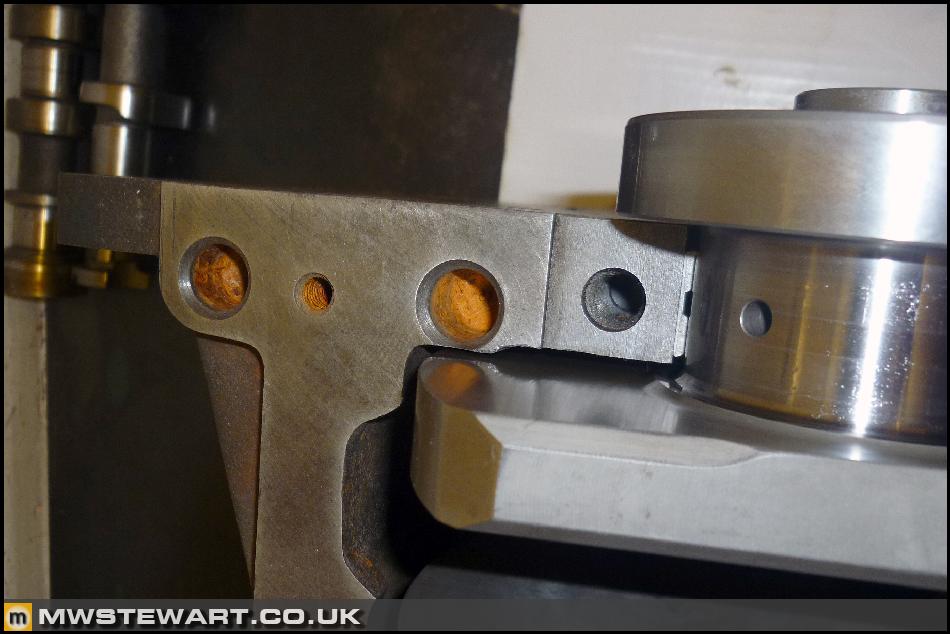

Here are the custom rods:

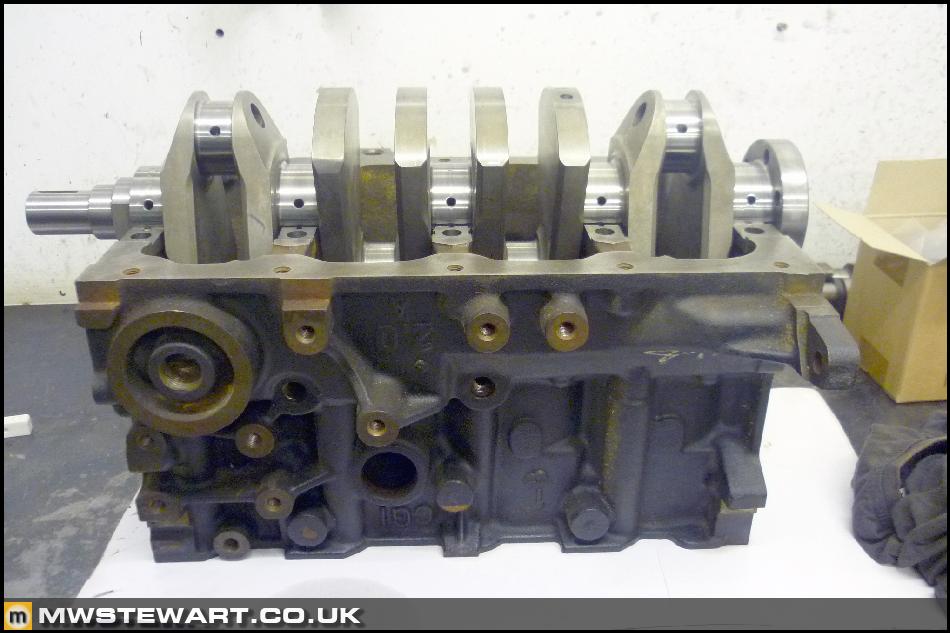

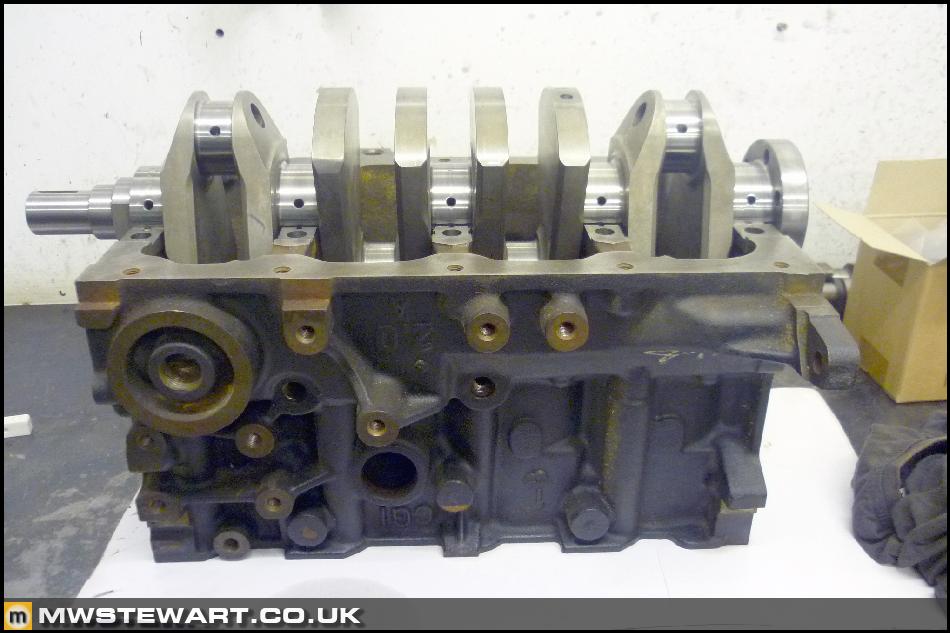

The block required various clearance pockets for the billet crank

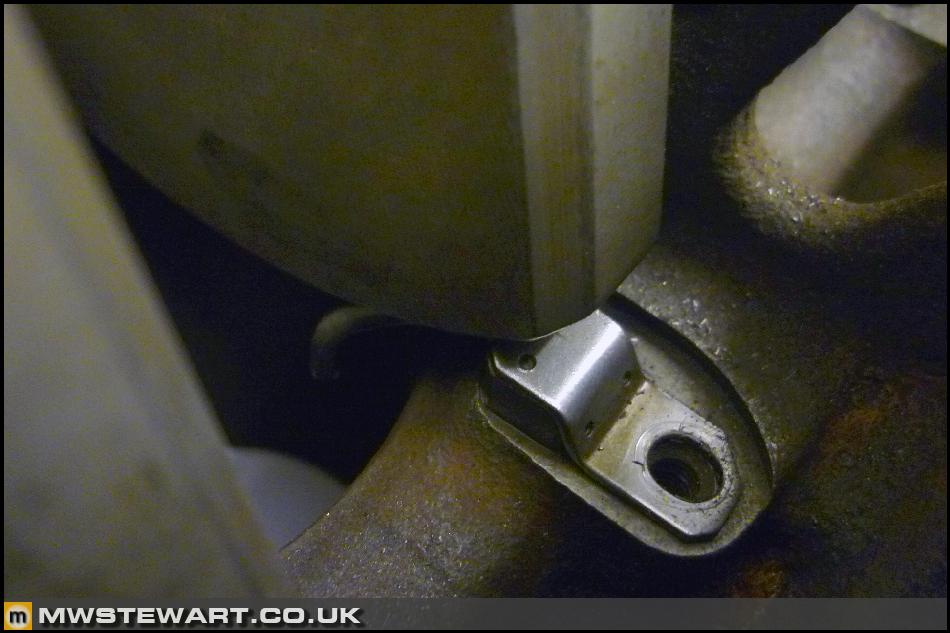

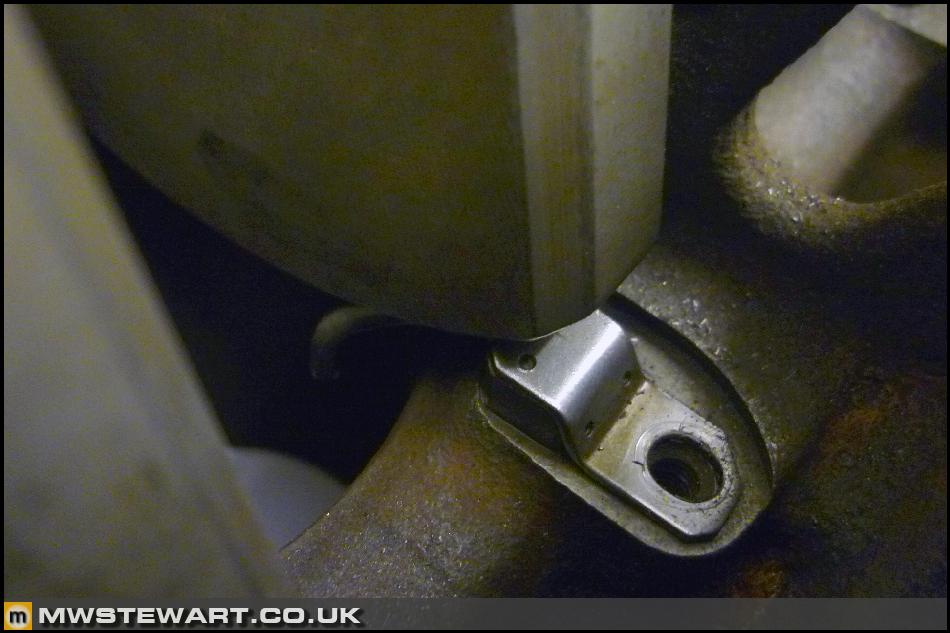

The standard Ford oil jets were fouled by the new crank, so Ian has worked out another solution.

Here's the crank fitted.

The next step on the engine is to finalise the piston design and then order a set. The car itself is going away in two weeks time to have the front suspension designed and machined. The estimate for that work is 4-6 weeks.

Here are the custom rods:

The block required various clearance pockets for the billet crank

The standard Ford oil jets were fouled by the new crank, so Ian has worked out another solution.

Here's the crank fitted.

The next step on the engine is to finalise the piston design and then order a set. The car itself is going away in two weeks time to have the front suspension designed and machined. The estimate for that work is 4-6 weeks.

dom9 said:

Quick question...

Does this need to seal?

Apologies for my poor IT skills!

Keep up the good work!

Will be interested in the suspension updates over the next few weeks!

No, it doesn't. There's an allot endplate not attached in that photo, which is the sealing surface for the sump.Does this need to seal?

Apologies for my poor IT skills!

Keep up the good work!

Will be interested in the suspension updates over the next few weeks!

I've annotated the following photo to help illustate:

Green line represents the gasket.

Because I'm doing something weird with the coilovers - keeping them near maximum ride height - the helper springs are redundant and when compressed under load rob me of a good 50mm of further adjustment. The standard rear configuration was 20-60-80 helpers with a 30-200 main spring, which is KW parlance for the following:

20-60-80 = 20 N/mm spring rate (114.20 lb/in), 60mm dia, 80mm length

30-200 = 30 N/mm spring rate (171.30 lb/in), 200 length. Not shown: KW part number 60110069 (10mm wire diameter, 124mm spring travel)

I've got rid of the helpers and ordered a pair of rear springs that are the same length as the uncompressed original springs and helpers - ~300mm. Original configuration on the left, modified on the right.

The new springs are 50-300, so 285.50 lb/in. They are KW 60110057 (12mm wire diameter, 135mm spring travel). This is a 60% increase in spring rate, which is my estimate at the new baseline that takes into account the additional weight of the rear suspension & larger fuel tank, and also the way I want the car to respond. Further tuning will obviously take place once the car is ready for corner weighting.

For reference here is a KW motorsport spring brochure http://www.kw-suspensions.co.uk/pdf/KW-racingsprin... It took me a while to find that.

20-60-80 = 20 N/mm spring rate (114.20 lb/in), 60mm dia, 80mm length

30-200 = 30 N/mm spring rate (171.30 lb/in), 200 length. Not shown: KW part number 60110069 (10mm wire diameter, 124mm spring travel)

I've got rid of the helpers and ordered a pair of rear springs that are the same length as the uncompressed original springs and helpers - ~300mm. Original configuration on the left, modified on the right.

The new springs are 50-300, so 285.50 lb/in. They are KW 60110057 (12mm wire diameter, 135mm spring travel). This is a 60% increase in spring rate, which is my estimate at the new baseline that takes into account the additional weight of the rear suspension & larger fuel tank, and also the way I want the car to respond. Further tuning will obviously take place once the car is ready for corner weighting.

For reference here is a KW motorsport spring brochure http://www.kw-suspensions.co.uk/pdf/KW-racingsprin... It took me a while to find that.

I had arranged to drop off the car to http://mkmotorsport.co.uk/ on Sat April 5th, but Mark still has too many cars in his workshop so I'm waiting for him to finish a few projects, hopefully any time soon.

Mark needs the Fiesta for between four and six weeks.

Mark needs the Fiesta for between four and six weeks.

mwstewart said:

I had arranged to drop off the car to http://mkmotorsport.co.uk/ on Sat April 5th, but Mark still has too many cars in his workshop so I'm waiting for him to finish a few projects, hopefully any time soon.

Mark needs the Fiesta for between four and six weeks.

What are you having done there?Mark needs the Fiesta for between four and six weeks.

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff