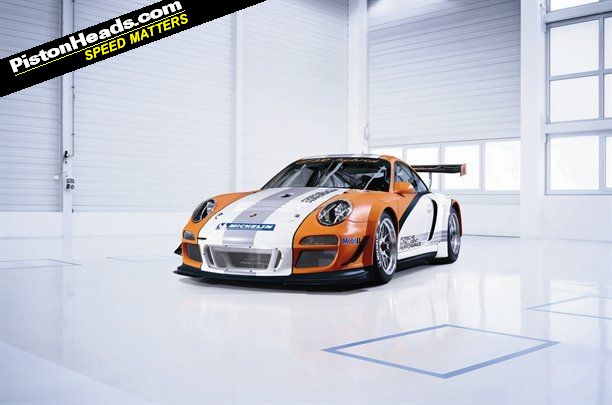

911 GT3 R Hybrid

Discussion

Hmmmmm...

Small low mass flywheel spinning really fast.

Looks like it's mounted near the centre of inertia of the car, and low down, and flat, so it's only really going to impact roll performance and dive performance, not yawing as much...

I can't believe though, that more energy is wasted in braking, than is used in accelerating all that extra mass each time, and making the components in the first place, added tyre wear due to weight reducing life of those etc etc...

Dust to dust is it really that good?

I still think the 'keep it simple stupid' philosophy has been lost in all this green s te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.

If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

Small low mass flywheel spinning really fast.

Looks like it's mounted near the centre of inertia of the car, and low down, and flat, so it's only really going to impact roll performance and dive performance, not yawing as much...

I can't believe though, that more energy is wasted in braking, than is used in accelerating all that extra mass each time, and making the components in the first place, added tyre wear due to weight reducing life of those etc etc...

Dust to dust is it really that good?

I still think the 'keep it simple stupid' philosophy has been lost in all this green s

te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

The system is basically the same as the Chrysler Patriot back in the early 90's for Le Mans and Williams' abandoned flywheel KERS.

IIRC the Chrysler was banned by the organisers because they didn't like the thought of what would happen if it was in an accident and the flywheel got loose so I don't think they'll be putting this in road cars somehow...

I wonder how the weight of the flywheel and motors compares with the transaxle, front diff etc. of the Carerra 4?

IIRC the Chrysler was banned by the organisers because they didn't like the thought of what would happen if it was in an accident and the flywheel got loose so I don't think they'll be putting this in road cars somehow...

I wonder how the weight of the flywheel and motors compares with the transaxle, front diff etc. of the Carerra 4?

Mr Whippy said:

I still think the 'keep it simple stupid' philosophy has been lost in all this green s te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.

If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

Wrong! If keeping it simple was best, why bother with a 6-cylinder, overhead cam engine, a turbo, or other performance niceties? A hybrid system is just another power adder that gets it's energy from stuff that is normally wasted. What's not to like? te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

I agree that in certain applications (i.e. uninterrupted motorway cruising) simple is best, but lots of slowing down and speeding up means lots of wasted energy unless you have some way of re-cycling it.

Shabs said:

Sitting next to a flywheel going 40,000rpm would make me a) deaf and b) scared. Interesting to see what ends up in the road cars

Me too!It's an interesting idea - much more so than the battery 'blind alley' - but all that kinetic energy in a little box at the side of the driver! What happens when one of those goes into to the wall or another car.

Mind you I think the out come of a couple of Teslars running into one another could be interesting!

TB

kingb said:

Im not totally sure i want a heavy fly wheel spinning at 40,000rpm sitting next to me instead of a passenger seat. Sounds scary. Im sure ive seen pictures of where someone has attempted t0 lighten there flywheel which has just resulted in it coming loose and shooting straight through the bonnet.

nice to try something new but sounds scary to me

For F1 the plan was to mount it behind the drivers head !nice to try something new but sounds scary to me

It has a carbon fibre containment structure in case of failure according to Williams. I'm sure I've seen a video of a failure test somewhere but google is failing me at the moment.

donteatpeople said:

alexpa said:

Nice wheels!

Cars are becoming more like toys. The tech brings to mind the pull back and let go toy cars.

They really are, I even had a Tonka Porsche that worked in a very similar way when I was a child. You pushed it along which turned a flywheel that sat there spinning until you pressed a button on the roof that engaged the drive gear. It was actually a pretty nice toy, the gear ratios were different for input and output to the flywheel so it really went (made a great whirring noise to annoy my mother too).Cars are becoming more like toys. The tech brings to mind the pull back and let go toy cars.

What's next - full-scale pull back and go cars for the road...!

Awesome.

esudfu said:

The system is basically the same as the Chrysler Patriot back in the early 90's for Le Mans and Williams' abandoned flywheel KERS.

More than "basically"...Gary C said:

This system was developed by Williams F1 for their 09 F1 car, but I don't think they used it

Interesting that the press release and the PH story doesn't mention it.Source here: http://www.f1fanatic.co.uk/2010/02/11/williams-sup...

I've seen one of these kinetic KERS units in the flesh and it wasn't much bigger than a front diff. Anout the size of a washing machine electric motor.

The version I saw had been tested to destruction a few times - the issue being fragamentation of the flywheel and the case was designed to easily cope with this up to 40,000 rpm hence that limit.

This version was designed to sit on the end of the gearbox out of harms way.

They've sold the concept to various train and truck companies for whom it is said to decrease running costs by 30% a year.

The version I saw had been tested to destruction a few times - the issue being fragamentation of the flywheel and the case was designed to easily cope with this up to 40,000 rpm hence that limit.

This version was designed to sit on the end of the gearbox out of harms way.

They've sold the concept to various train and truck companies for whom it is said to decrease running costs by 30% a year.

Edited by guards red on Thursday 11th February 14:23

ThirdShift said:

Id be expecting a road going homologation special out pretty soon, there are rumours of it racing in next year at the 2011 Le Mans 24hrs so it would need homologting before then. With the next generation GT-R possibly being a Hybrid driving the Front wheels electrically it should make for an interesting head to head circa 2013! Cant wait to see the times from the 'ring!

I think the rumors that you are referring to are related to a LMP1 hybrid car to race in Le Mans 2012.Don't expect a road going homologation special anytime soon as this car is being used a "racing laboratory" and as you know, LMP's do not require homologation.

Flywheels do not have to be particularly heavy - the "circumferential speed" is far more significant. Remember E=mc² - the energy stored increases with the square of the velocity but only linearly with mass. So a light flywheel can store energy given a high RPM (and 40K is forty times faster than a washing machine on spin).

The other advantage of a light flywheel is that it can be made from composites. These, unlike metal flywheels in car engines, tend to shred themselves into a fibrous mess when they fail so can have a light housing and still be safe. (Although a power-station generator rotor can take a day to spool down when unloaded, or rip itself out of the moorings and ricochet all round the turbine room if shorted. It's heavy, solid iron & copper and generally unhealthy when used as a frisbee.)

The housing holds the flywheel in a vacuum and uses magnetic bearings, both of which help reduce noise levels while avoiding drag.

The other advantage of flywheels is the repeated efficient charge/discharge cycling at high currents that a regen brake system needs.

So Porsche selecting flywheel technology with a composite material and high RPM is no surprise on a endurance car. I'd be interested to know if the gyrodynamics effect the handling, or if it be mounted in such a way as to create downforce.

For comparison, McLaren's KERS system, uses Li-ion battery and is reported as 23.5 kg including motor, battery and cooling radiator. The Flybrid KERS system was 25kg.

The other advantage of a light flywheel is that it can be made from composites. These, unlike metal flywheels in car engines, tend to shred themselves into a fibrous mess when they fail so can have a light housing and still be safe. (Although a power-station generator rotor can take a day to spool down when unloaded, or rip itself out of the moorings and ricochet all round the turbine room if shorted. It's heavy, solid iron & copper and generally unhealthy when used as a frisbee.)

The housing holds the flywheel in a vacuum and uses magnetic bearings, both of which help reduce noise levels while avoiding drag.

The other advantage of flywheels is the repeated efficient charge/discharge cycling at high currents that a regen brake system needs.

So Porsche selecting flywheel technology with a composite material and high RPM is no surprise on a endurance car. I'd be interested to know if the gyrodynamics effect the handling, or if it be mounted in such a way as to create downforce.

For comparison, McLaren's KERS system, uses Li-ion battery and is reported as 23.5 kg including motor, battery and cooling radiator. The Flybrid KERS system was 25kg.

lusopiston said:

Can we consider the BBS wheels the modern borrani wire wheels? They look awesome in all racing cars! I like hybrids, they keep the thundering flat-six noise while adding a dash of eco stuff in it to please everyone... :-)

The wheels for the GT3-R are actually made by Rays rather than BBS, I assume this has the same wheels as the standard GT3-R.What I find interesting is that the current 2011 ACO regulations for Hybrid engined LMP1 car's appears not to allow for this type of hybrid system:

Energy recovery systems will be free, provided they respect the following rules:

* Recovery of energy from the brakes on the 4 wheels or from the heat of the exhaust.

* Only the rear wheels can be used to drive the vehicle.

* Electric systems are allowed only to recover energy from the brakes.

* Energy can only be stocked in the form of electricity.

* The car’s minimum weight will be identical to that of the other LM P1s using conventional engine technology (petrol or diesel): 900 kgs.

* The internal combustion engine and the electric motor must be controlled by the driver using the accelerator pedal (push to pass buttons forbidden).

* The quantity of usable energy stocked on board the vehicle must not exceed 1 MJ.

* Installation of systems enabling the power to be controlled at the entry and exit of engines/generators and the energy dissipated on a lap of the circuit at the exit of the motor/generator.

* The ACO will impose its own safety regulations.

Energy recovery systems will be free, provided they respect the following rules:

* Recovery of energy from the brakes on the 4 wheels or from the heat of the exhaust.

* Only the rear wheels can be used to drive the vehicle.

* Electric systems are allowed only to recover energy from the brakes.

* Energy can only be stocked in the form of electricity.

* The car’s minimum weight will be identical to that of the other LM P1s using conventional engine technology (petrol or diesel): 900 kgs.

* The internal combustion engine and the electric motor must be controlled by the driver using the accelerator pedal (push to pass buttons forbidden).

* The quantity of usable energy stocked on board the vehicle must not exceed 1 MJ.

* Installation of systems enabling the power to be controlled at the entry and exit of engines/generators and the energy dissipated on a lap of the circuit at the exit of the motor/generator.

* The ACO will impose its own safety regulations.

Edited by slivka on Thursday 11th February 15:15

Edited by slivka on Thursday 11th February 15:15

Mr Gear said:

Mr Whippy said:

I still think the 'keep it simple stupid' philosophy has been lost in all this green s te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.

If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

Wrong! If keeping it simple was best, why bother with a 6-cylinder, overhead cam engine, a turbo, or other performance niceties? A hybrid system is just another power adder that gets it's energy from stuff that is normally wasted. What's not to like? te. Meeting 'targets' often means engineering to meet badly set targets.

te. Meeting 'targets' often means engineering to meet badly set targets.If the target was simply to be as efficient as possible, then a small diesel in a light car still seems to do the trick better than any level of expensive hybridisation and lugging batteries/flywheels around + higher cost, complexity, reliability issues etc...

Bah.

Dave

I agree that in certain applications (i.e. uninterrupted motorway cruising) simple is best, but lots of slowing down and speeding up means lots of wasted energy unless you have some way of re-cycling it.

6 cylinder engine because if you need more power, you need more cfm, and you might want more cylinders to achieve that. Cripes, 6 pot is simpler than any other engine config from a simplicity pov!

A hybrid makes sense, but it costs energy to save it. Weight in the car during acceleration. The more useful it is when it's saving energy being wasted, the more is used accelerating it's mass each time too! Then more wear on tyres having to carry it around, more heavy duty suspension makes car weigh more. Making all these components costs energy before they even get put in cars.

Better driving can negate the need for much of this regen braking if you use good acceleration sense.

The circular loop of negative feedback from adding weight to cars. It's not good. They cost more, are more complex to service and maintain, weigh more, reward bad acceleration sense in some fashion...

Fine if you want them, but to me it seems a waste of materials. People would be better learning to crash their cars less often, save a chunk of weight there, and then drive better so as to negate the worry of so much energy loss from braking, which would now be less nasty because cars are lighter too!

Adding to the negative feedback loop with more complexity/weight/bad driving practice isn't ideal.

Cripes, all these regen systems so far tested are on race cars to meet benefits generated by man-made rules.

Wow, diesels won at Lemans, because the rules made them able to win.

Wow, regen inertial braking systems won in GT3 class racing cars, because the rules made them the natural winner.

They must be the ideal choice if they win (nothing to do with rules/targets/testing procedures making them appear to be ideal)

Dave

Mr Whippy said:

Wrong? As clear as that?

6 cylinder engine because if you need more power, you need more cfm, and you might want more cylinders to achieve that. Cripes, 6 pot is simpler than any other engine config from a simplicity pov!

A hybrid makes sense, but it costs energy to save it. Weight in the car during acceleration. The more useful it is when it's saving energy being wasted, the more is used accelerating it's mass each time too! Then more wear on tyres having to carry it around, more heavy duty suspension makes car weigh more. Making all these components costs energy before they even get put in cars.

Better driving can negate the need for much of this regen braking if you use good acceleration sense.

The circular loop of negative feedback from adding weight to cars. It's not good. They cost more, are more complex to service and maintain, weigh more, reward bad acceleration sense in some fashion...

Fine if you want them, but to me it seems a waste of materials. People would be better learning to crash their cars less often, save a chunk of weight there, and then drive better so as to negate the worry of so much energy loss from braking, which would now be less nasty because cars are lighter too!

Adding to the negative feedback loop with more complexity/weight/bad driving practice isn't ideal.

Cripes, all these regen systems so far tested are on race cars to meet benefits generated by man-made rules.

Wow, diesels won at Lemans, because the rules made them able to win.

Wow, regen inertial braking systems won in GT3 class racing cars, because the rules made them the natural winner.

They must be the ideal choice if they win (nothing to do with rules/targets/testing procedures making them appear to be ideal)

Dave

You might be surprised to read that I don't disagree with any of that. As with any car, it will perform best within its given sphere. 6 cylinder engine because if you need more power, you need more cfm, and you might want more cylinders to achieve that. Cripes, 6 pot is simpler than any other engine config from a simplicity pov!

A hybrid makes sense, but it costs energy to save it. Weight in the car during acceleration. The more useful it is when it's saving energy being wasted, the more is used accelerating it's mass each time too! Then more wear on tyres having to carry it around, more heavy duty suspension makes car weigh more. Making all these components costs energy before they even get put in cars.

Better driving can negate the need for much of this regen braking if you use good acceleration sense.

The circular loop of negative feedback from adding weight to cars. It's not good. They cost more, are more complex to service and maintain, weigh more, reward bad acceleration sense in some fashion...

Fine if you want them, but to me it seems a waste of materials. People would be better learning to crash their cars less often, save a chunk of weight there, and then drive better so as to negate the worry of so much energy loss from braking, which would now be less nasty because cars are lighter too!

Adding to the negative feedback loop with more complexity/weight/bad driving practice isn't ideal.

Cripes, all these regen systems so far tested are on race cars to meet benefits generated by man-made rules.

Wow, diesels won at Lemans, because the rules made them able to win.

Wow, regen inertial braking systems won in GT3 class racing cars, because the rules made them the natural winner.

They must be the ideal choice if they win (nothing to do with rules/targets/testing procedures making them appear to be ideal)

Dave

That means a hybrid could be better or worse than a non-hybrid vehicle at performance or efficiency, depending on what you ask of it.

What is "wrong" is is the blanket statement that simple is best. You should see the way my girlfriend drives (or rather you'll be glad you don't). She can't get more than 31mpg out of her TT as a rolling average, but I can get 41mpg out of it over a 100 mile distance. This isn't because she's some sort of racing driver, it's because she doesn't know what gear to use, doesn't anticipate things she will have to brake for up ahead, and mashes the throttle when she wants to go a bit faster.

Someone with her skills (or lack of them) would benefit greatly from having a fully-automated hybrid system to do the thinking for her! ...If, the name of the game was making the car go for a given distance using the minimum amount of fuel.

ian964 said:

lusopiston said:

Can we consider the BBS wheels the modern borrani wire wheels? They look awesome in all racing cars! I like hybrids, they keep the thundering flat-six noise while adding a dash of eco stuff in it to please everyone... :-)

The wheels for the GT3-R are actually made by Rays rather than BBS, I assume this has the same wheels as the standard GT3-R.According to Williams F1 they have worked to produce this solution for Porsche-so not all Porsche brains more like British aka Williams-see below Press Release

WILLIAMS HYBRID POWER CONTRACTS

WITH PORSCHE AG FOR 911 GT3 R HYBRID

Oxford, UK, February 11, 2010. Williams Hybrid Power Limited is pleased to confirm that

the energy storage system as part of the new Porsche 911 GT3 R Hybrid, which was

announced today by Dr. Ing. h.c. F. Porsche AG, Stuttgart, has been developed and supplied

by Williams Hybrid Power. The 911 GT3 R Hybrid with innovative hybrid drive will make its

debut at the Geneva Motor Show. Further details from Porsche follow in the attached press

release.

The energy storage system was originally developed for use in Formula One by the AT&T

Williams team but Williams Hybrid Power is now focused on applications in road vehicles.

The technology will also be developed for larger, infrastructure applications by Williams F1 at

its new research facility in the Qatar Science and Technology Park.

Ian Foley, Managing Director of Williams Hybrid Power said, "We are delighted to see our

technology being adopted by one of the world's leading engineering companies and most

prestigious automotive manufacturers in one of their racing cars. Partnering with Porsche on

this project has been a very positive experience and we are grateful to them for choosing to

work with us."

Alex Burns, Chairman of Williams Hybrid Power and Chief Operating Officer of Williams F1

said, "This is a milestone for both Williams Hybrid Power and Williams F1. Together we have

worked to bring this technology forward to the point where it can be tested in a racing car and

deployed in a road car. We hope that this will be just the start of the evolution of hybrid

systems developed for Formula One moving across to applications where they can

contribute to cleaner and more powerful vehicles."

- Ends -

NOTES TO EDITORS

Williams Hybrid Power Ltd (WHP) has developed a novel, patented electromechanical composite flywheel system that

provides a high-power, cost-effective and environmentally friendly solution for mobile or stationary energy storage and recovery,

originally developed for Formula One. Through development of a flywheel for Williams F1’s Kinetic Energy Recovery System,

WHP has proved its world-class engineering capabilities in the composite flywheel field as well as radically improving aspects of

the technology in the process. WHP is today making the technology available to meet the high-power energy storage needs in a

variety of applications including hybrid passenger vehicles, hybrid buses, electric trains, diesel-electric ships and wind power

generation. In November 2009, the company announced its involvement in a mild hybrid road car programme with Ricardo,

CTG, JCB, Jaguar Land Rover, SKF and Torotrak. The project aims to demonstrate the potential of flywheel-based hybrid

systems with the potential for 30 per cent fuel savings (and equivalent reductions in CO2 emissions) at an on-cost of less than

£1000, to enable mass-market uptake of hybrid vehicles in price sensitive vehicle applications. www.williamshybridpower.com

For more information, please contact Liam Clogger, Head of Communications, Williams F1

e liam.clogger@williamsf1.com. t +44 (0)1235 777706, m +44 (0)7977 275756

Press Release February 11, 2010

No 13/10

Dr. Ing. h.c. F. Porsche Aktiengesellschaft 1 of 2 International Press

Porscheplatz 1 Michael Baumann

70435 Stuttgart Telephone +49 (0) 711/911 – 27904

michael.baumann@porsche.de

Porsche Intelligent Performance makes Racing Cars even More Efficient

911 GT3 R Hybrid Celebrates World Debut in Geneva

Stuttgart. Exactly 110 years after Ferdinand Porsche developed the world’s first car

with hybrid drive, the Lohner Porsche Semper Vivus, Dr. Ing. h.c. F. Porsche AG,

Stuttgart, is once again taking up this visionary drive concept in production-based GT

racing: During the Geneva Motor Show, a Porsche 911 GT3 R with innovative hybrid

drive is making its debut, opening up a new chapter in the history of Porsche with

more than 20,000 wins in 45 years scored by the extremely successful Porsche 911

in racing trim.

The innovative hybrid technology featured in the car has been developed especially

for racing, standing out significantly in its configuration and components from conventional

hybrid systems. In this case, electrical front axle drive with two electric motors

developing 60 kW each supplements the 480-bhp four-litre flat-six at the rear of the

911 GT3 R Hybrid. A further significant point is that instead of the usual batteries in a

hybrid road car, an electrical flywheel power generator fitted in the interior next to the

driver delivers energy to the electric motors.

The flywheel generator itself is an electric motor with its rotor spinning at speeds of

up to 40,000 rpm, storing energy mechanically as rotation energy. The flywheel generator

is charged whenever the driver applies the brakes, with the two electric motors

reversing their function on the front axle and acting themselves as generators. Then,

whenever necessary, that is when accelerating out of a bend or when overtaking, the

driver is able to call up extra energy from the charged flywheel generator, the flywheel

being slowed down electromagnetically in the generator mode and thus supPress

Release February 11, 2010

No 13/10

Dr. Ing. h.c. F. Porsche Aktiengesellschaft 2 of 2 International Press

Porscheplatz 1 Michael Baumann

70435 Stuttgart Telephone +49 (0) 711/911 – 27904

michael.baumann@porsche.de

plying up to 120 kW to the two electric motors at the front from its kinetic energy. This

additional power is available to the driver after each charge process for approximately

6 - 8 seconds.

Energy formerly converted – and thus wasted – into heat upon every application of

the brakes, is now highly efficiently converted into additional drive power.

Depending on racing conditions, hybrid drive is used in this case not only for extra

power, but also to save fuel. This again increases the efficiency and, accordingly, the

performance of the 911 GT3 R Hybrid, for example by reducing the weight of the tank

or making pitstops less frequent.

After its debut in Geneva the 911 GT3 R Hybrid will be tested in long-distance races

on the Nürburgring. The highlight of this test programme will be the 24 Hours on the

Nordschleife of Nürburgring on May 15th and 16th. The focus is not on the 911 GT3 R

Hybrid winning the race, but rather serving as a spearhead in technology and a

“racing laboratory” providing know-how on the subsequent use of hybrid technology

in road-going sports cars.

The 911 GT3 R Hybrid is a perfect example of the Porsche Intelligent Performance

philosophy, a principle to be found in every Porsche: More power on less fuel, more

efficiency and lower CO2 emissions – on the track and on the road.

GO

Note: Images of the new Porsche 911 GT3 R Hybrid are available to accredited journalists in the Porsche

Press Database at https://presse.porsche.de. Footage is available to registered users at

http://thenewsmarket.com/porsche.

WILLIAMS HYBRID POWER CONTRACTS

WITH PORSCHE AG FOR 911 GT3 R HYBRID

Oxford, UK, February 11, 2010. Williams Hybrid Power Limited is pleased to confirm that

the energy storage system as part of the new Porsche 911 GT3 R Hybrid, which was

announced today by Dr. Ing. h.c. F. Porsche AG, Stuttgart, has been developed and supplied

by Williams Hybrid Power. The 911 GT3 R Hybrid with innovative hybrid drive will make its

debut at the Geneva Motor Show. Further details from Porsche follow in the attached press

release.

The energy storage system was originally developed for use in Formula One by the AT&T

Williams team but Williams Hybrid Power is now focused on applications in road vehicles.

The technology will also be developed for larger, infrastructure applications by Williams F1 at

its new research facility in the Qatar Science and Technology Park.

Ian Foley, Managing Director of Williams Hybrid Power said, "We are delighted to see our

technology being adopted by one of the world's leading engineering companies and most

prestigious automotive manufacturers in one of their racing cars. Partnering with Porsche on

this project has been a very positive experience and we are grateful to them for choosing to

work with us."

Alex Burns, Chairman of Williams Hybrid Power and Chief Operating Officer of Williams F1

said, "This is a milestone for both Williams Hybrid Power and Williams F1. Together we have

worked to bring this technology forward to the point where it can be tested in a racing car and

deployed in a road car. We hope that this will be just the start of the evolution of hybrid

systems developed for Formula One moving across to applications where they can

contribute to cleaner and more powerful vehicles."

- Ends -

NOTES TO EDITORS

Williams Hybrid Power Ltd (WHP) has developed a novel, patented electromechanical composite flywheel system that

provides a high-power, cost-effective and environmentally friendly solution for mobile or stationary energy storage and recovery,

originally developed for Formula One. Through development of a flywheel for Williams F1’s Kinetic Energy Recovery System,

WHP has proved its world-class engineering capabilities in the composite flywheel field as well as radically improving aspects of

the technology in the process. WHP is today making the technology available to meet the high-power energy storage needs in a

variety of applications including hybrid passenger vehicles, hybrid buses, electric trains, diesel-electric ships and wind power

generation. In November 2009, the company announced its involvement in a mild hybrid road car programme with Ricardo,

CTG, JCB, Jaguar Land Rover, SKF and Torotrak. The project aims to demonstrate the potential of flywheel-based hybrid

systems with the potential for 30 per cent fuel savings (and equivalent reductions in CO2 emissions) at an on-cost of less than

£1000, to enable mass-market uptake of hybrid vehicles in price sensitive vehicle applications. www.williamshybridpower.com

For more information, please contact Liam Clogger, Head of Communications, Williams F1

e liam.clogger@williamsf1.com. t +44 (0)1235 777706, m +44 (0)7977 275756

Press Release February 11, 2010

No 13/10

Dr. Ing. h.c. F. Porsche Aktiengesellschaft 1 of 2 International Press

Porscheplatz 1 Michael Baumann

70435 Stuttgart Telephone +49 (0) 711/911 – 27904

michael.baumann@porsche.de

Porsche Intelligent Performance makes Racing Cars even More Efficient

911 GT3 R Hybrid Celebrates World Debut in Geneva

Stuttgart. Exactly 110 years after Ferdinand Porsche developed the world’s first car

with hybrid drive, the Lohner Porsche Semper Vivus, Dr. Ing. h.c. F. Porsche AG,

Stuttgart, is once again taking up this visionary drive concept in production-based GT

racing: During the Geneva Motor Show, a Porsche 911 GT3 R with innovative hybrid

drive is making its debut, opening up a new chapter in the history of Porsche with

more than 20,000 wins in 45 years scored by the extremely successful Porsche 911

in racing trim.

The innovative hybrid technology featured in the car has been developed especially

for racing, standing out significantly in its configuration and components from conventional

hybrid systems. In this case, electrical front axle drive with two electric motors

developing 60 kW each supplements the 480-bhp four-litre flat-six at the rear of the

911 GT3 R Hybrid. A further significant point is that instead of the usual batteries in a

hybrid road car, an electrical flywheel power generator fitted in the interior next to the

driver delivers energy to the electric motors.

The flywheel generator itself is an electric motor with its rotor spinning at speeds of

up to 40,000 rpm, storing energy mechanically as rotation energy. The flywheel generator

is charged whenever the driver applies the brakes, with the two electric motors

reversing their function on the front axle and acting themselves as generators. Then,

whenever necessary, that is when accelerating out of a bend or when overtaking, the

driver is able to call up extra energy from the charged flywheel generator, the flywheel

being slowed down electromagnetically in the generator mode and thus supPress

Release February 11, 2010

No 13/10

Dr. Ing. h.c. F. Porsche Aktiengesellschaft 2 of 2 International Press

Porscheplatz 1 Michael Baumann

70435 Stuttgart Telephone +49 (0) 711/911 – 27904

michael.baumann@porsche.de

plying up to 120 kW to the two electric motors at the front from its kinetic energy. This

additional power is available to the driver after each charge process for approximately

6 - 8 seconds.

Energy formerly converted – and thus wasted – into heat upon every application of

the brakes, is now highly efficiently converted into additional drive power.

Depending on racing conditions, hybrid drive is used in this case not only for extra

power, but also to save fuel. This again increases the efficiency and, accordingly, the

performance of the 911 GT3 R Hybrid, for example by reducing the weight of the tank

or making pitstops less frequent.

After its debut in Geneva the 911 GT3 R Hybrid will be tested in long-distance races

on the Nürburgring. The highlight of this test programme will be the 24 Hours on the

Nordschleife of Nürburgring on May 15th and 16th. The focus is not on the 911 GT3 R

Hybrid winning the race, but rather serving as a spearhead in technology and a

“racing laboratory” providing know-how on the subsequent use of hybrid technology

in road-going sports cars.

The 911 GT3 R Hybrid is a perfect example of the Porsche Intelligent Performance

philosophy, a principle to be found in every Porsche: More power on less fuel, more

efficiency and lower CO2 emissions – on the track and on the road.

GO

Note: Images of the new Porsche 911 GT3 R Hybrid are available to accredited journalists in the Porsche

Press Database at https://presse.porsche.de. Footage is available to registered users at

http://thenewsmarket.com/porsche.

Gassing Station | Porsche General | Top of Page | What's New | My Stuff