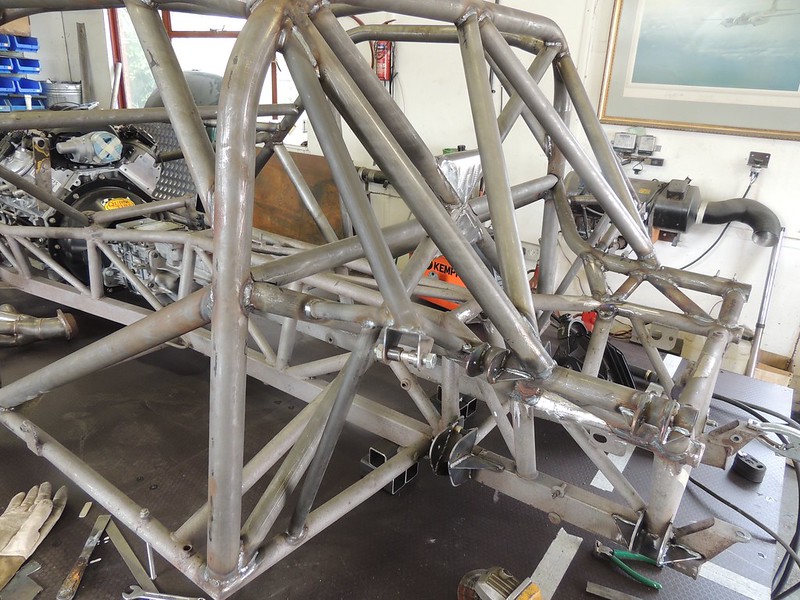

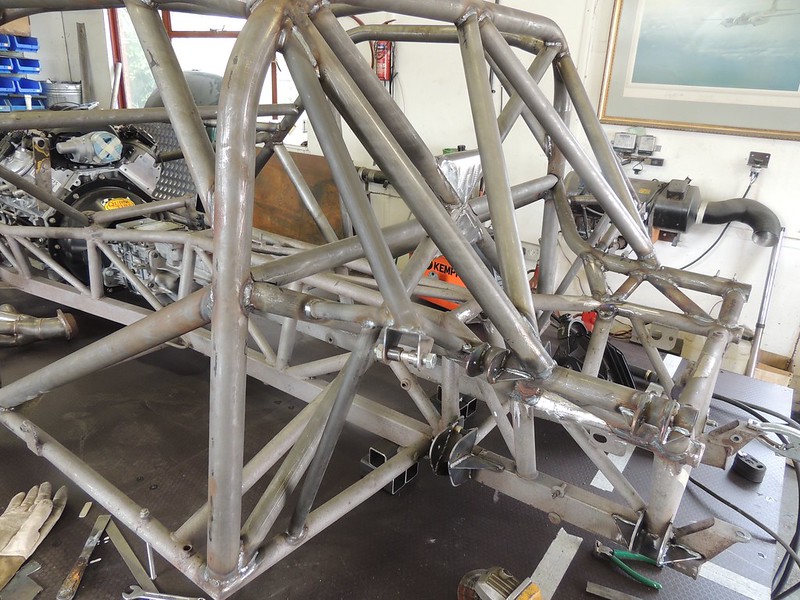

Johns cerbera rebuild and upgrade

Discussion

been at it again and got the glass out off the body ready for the mods although a little way in the future.

john

DSCN1823 by Brundall Motorsport, on Flickr

DSCN1823 by Brundall Motorsport, on Flickr

DSCN1822 by Brundall Motorsport, on Flickr

DSCN1822 by Brundall Motorsport, on Flickr

john

DSCN1823 by Brundall Motorsport, on Flickr

DSCN1823 by Brundall Motorsport, on Flickr DSCN1822 by Brundall Motorsport, on Flickr

DSCN1822 by Brundall Motorsport, on FlickrQuinny said:

julian64 said:

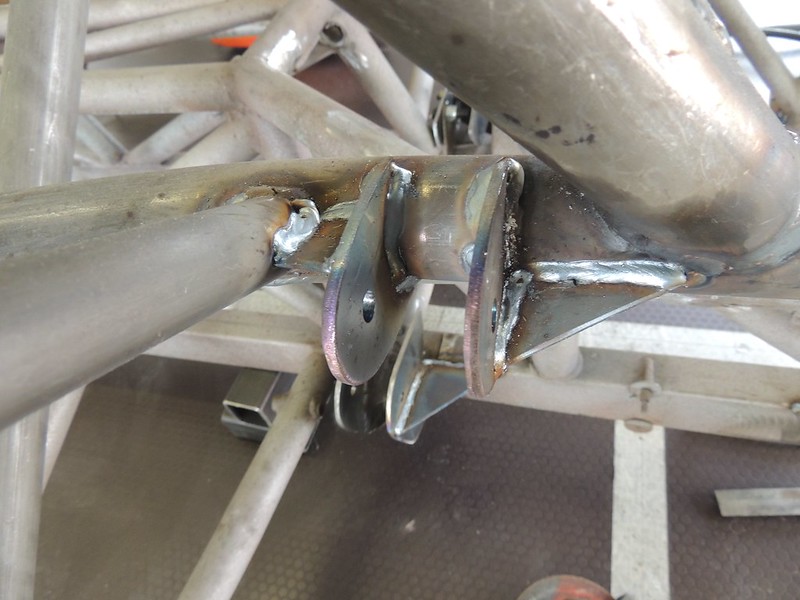

What sort of welder are you using on those joints.

You seem to avoid the splatter that comes with mig, and they look too beefy to be tig, are you stick welding?

You can avoid lots of spatter, by using the correct gas mix, and using anti spatter sprayYou seem to avoid the splatter that comes with mig, and they look too beefy to be tig, are you stick welding?

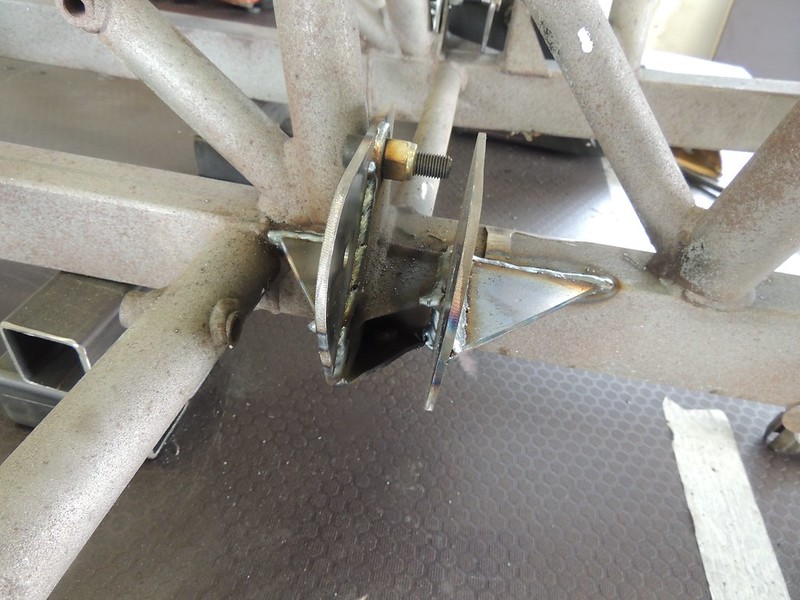

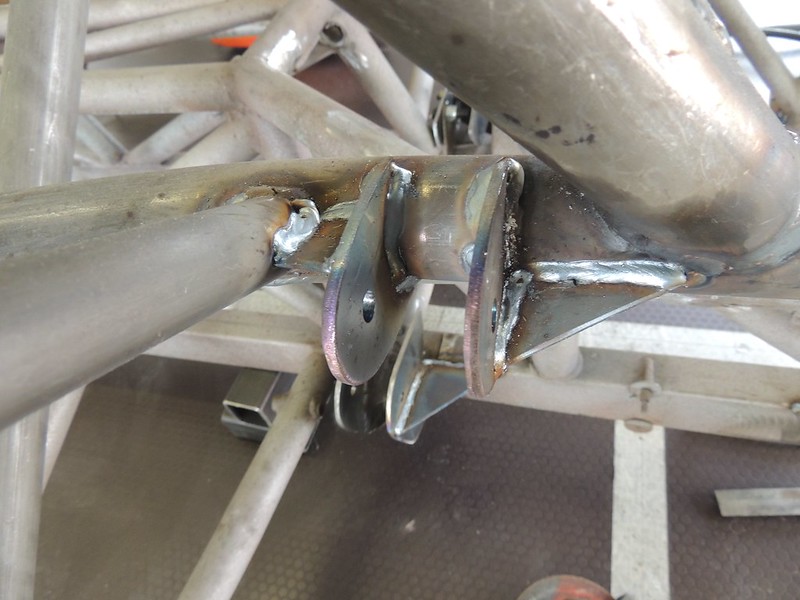

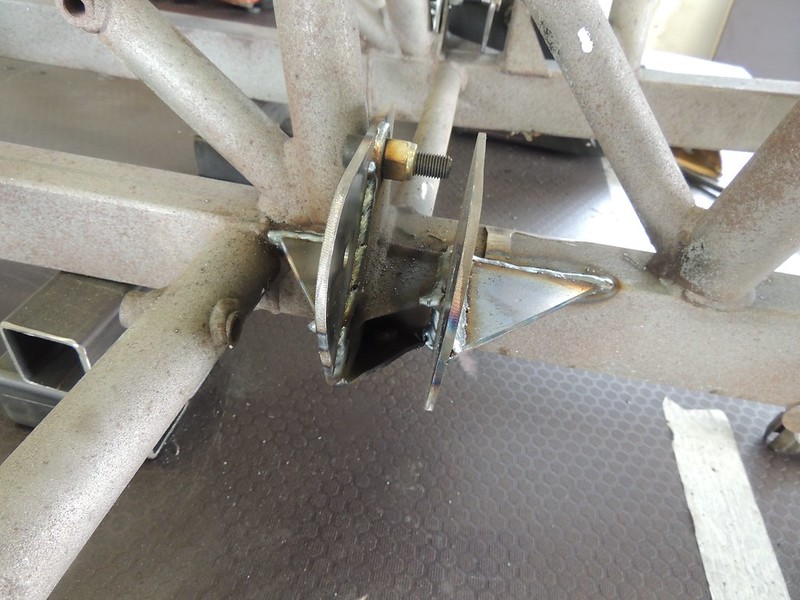

cerbera week this week started today on the remaining major job to the chassis the nearside rear shock mounting got it all fabricated and fully welded plus fully welded all the suspension mounts for that corner with all there gussets in place and welded also fully welded the nearside shock mounting do the same job on the suspension mounts etc. tomorrow.

john

DSCN1841 by Brundall Motorsport, on Flickr

DSCN1841 by Brundall Motorsport, on Flickr

DSCN1842 by Brundall Motorsport, on Flickr

DSCN1842 by Brundall Motorsport, on Flickr

DSCN1843 by Brundall Motorsport, on Flickr

DSCN1843 by Brundall Motorsport, on Flickr

DSCN1844 by Brundall Motorsport, on Flickr

DSCN1844 by Brundall Motorsport, on Flickr

DSCN1845 by Brundall Motorsport, on Flickr

DSCN1845 by Brundall Motorsport, on Flickr

DSCN1846 by Brundall Motorsport, on Flickr

DSCN1846 by Brundall Motorsport, on Flickr

john

DSCN1841 by Brundall Motorsport, on Flickr

DSCN1841 by Brundall Motorsport, on Flickr DSCN1842 by Brundall Motorsport, on Flickr

DSCN1842 by Brundall Motorsport, on Flickr DSCN1843 by Brundall Motorsport, on Flickr

DSCN1843 by Brundall Motorsport, on Flickr DSCN1844 by Brundall Motorsport, on Flickr

DSCN1844 by Brundall Motorsport, on Flickr DSCN1845 by Brundall Motorsport, on Flickr

DSCN1845 by Brundall Motorsport, on Flickr DSCN1846 by Brundall Motorsport, on Flickr

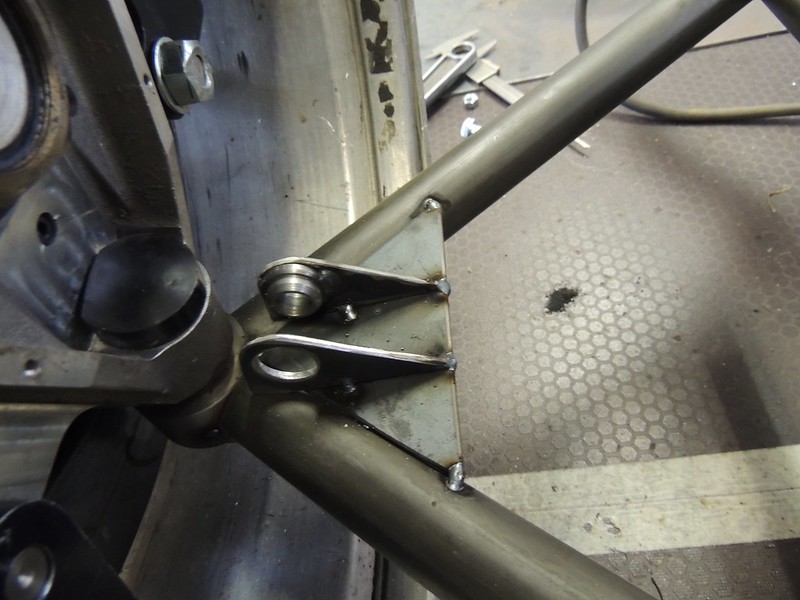

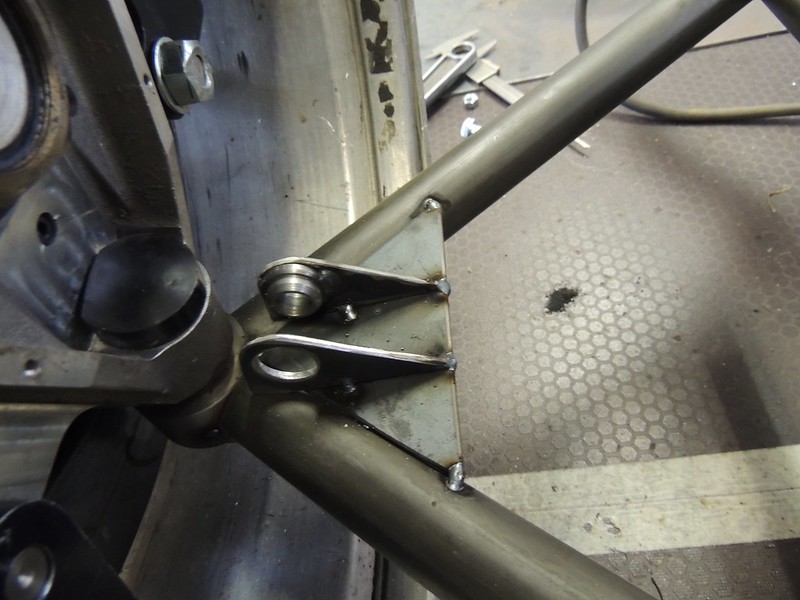

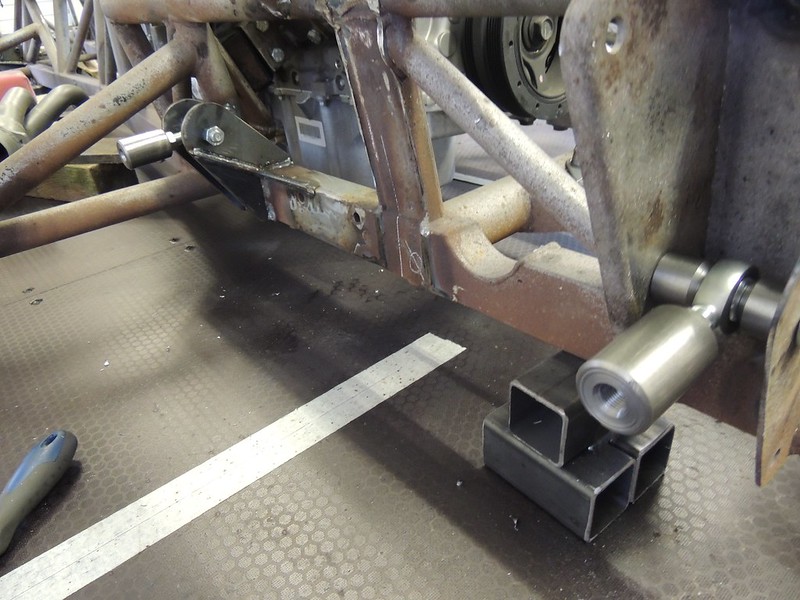

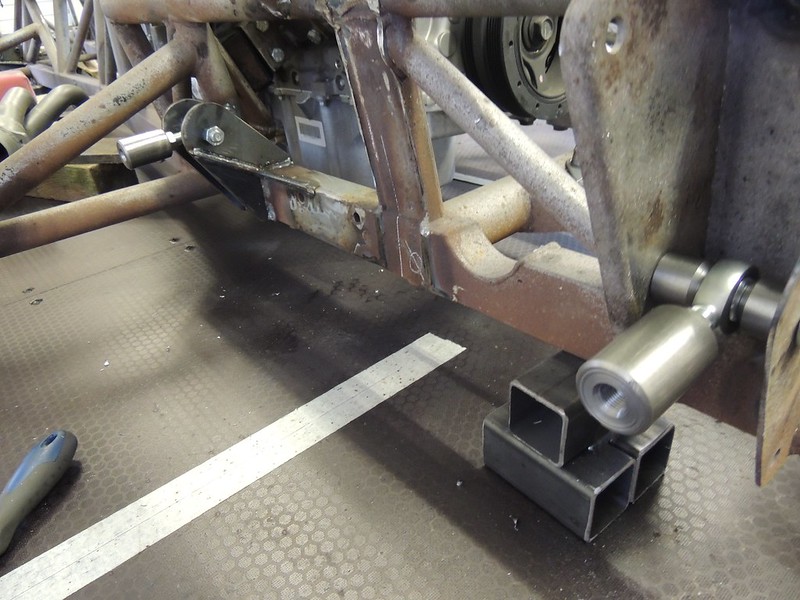

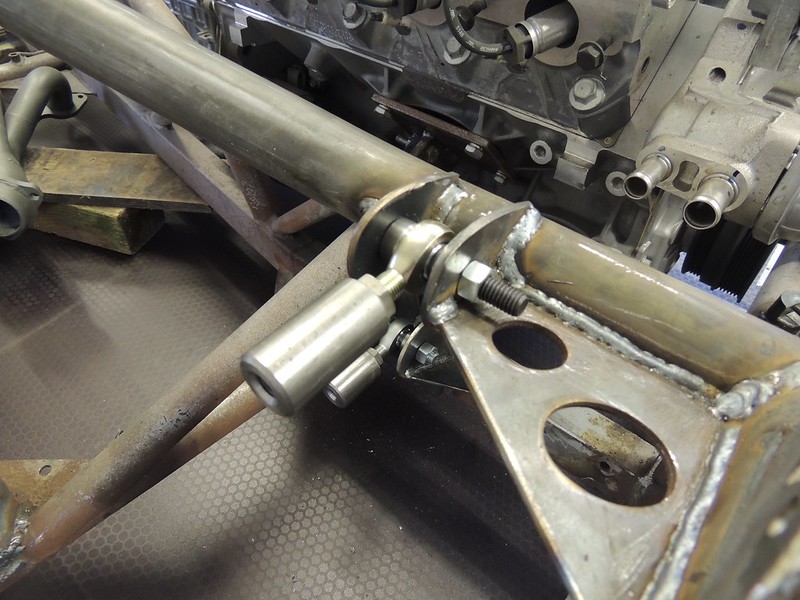

DSCN1846 by Brundall Motorsport, on Flickrback on the cerb this week tough day today sorting the start of the wishbone construction, lots of turning for spacers etc.plus working out angles for cutting the tube to match perfectly to the rod end bosses etc. so made some good progress, second side will be much easier now the leg work is nearly done.

john

IMG_0973 by Brundall Motorsport, on Flickr

IMG_0973 by Brundall Motorsport, on Flickr

IMG_0974 by Brundall Motorsport, on Flickr

IMG_0974 by Brundall Motorsport, on Flickr

IMG_0975 by Brundall Motorsport, on Flickr

IMG_0975 by Brundall Motorsport, on Flickr

IMG_0976 by Brundall Motorsport, on Flickr

IMG_0976 by Brundall Motorsport, on Flickr

john

IMG_0973 by Brundall Motorsport, on Flickr

IMG_0973 by Brundall Motorsport, on Flickr IMG_0974 by Brundall Motorsport, on Flickr

IMG_0974 by Brundall Motorsport, on Flickr IMG_0975 by Brundall Motorsport, on Flickr

IMG_0975 by Brundall Motorsport, on Flickr IMG_0976 by Brundall Motorsport, on Flickr

IMG_0976 by Brundall Motorsport, on FlickrEdited by Engineer1949 on Tuesday 6th October 20:22

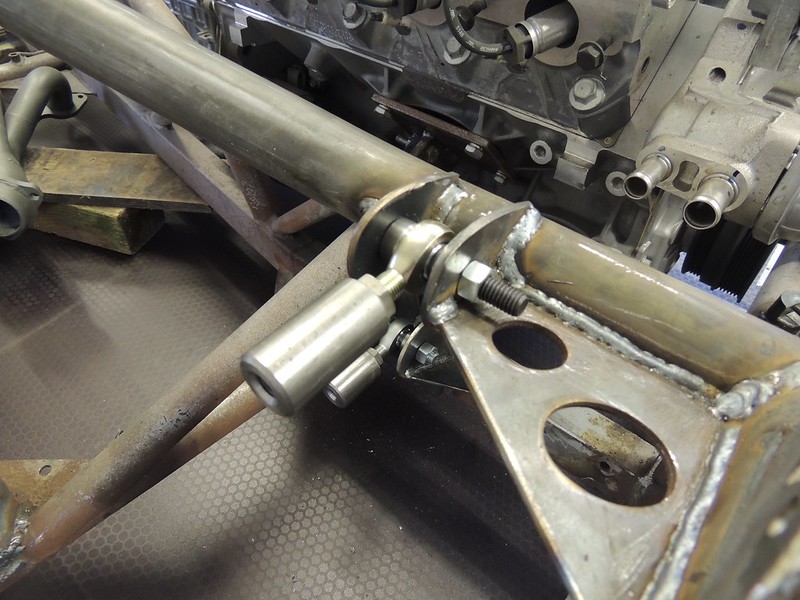

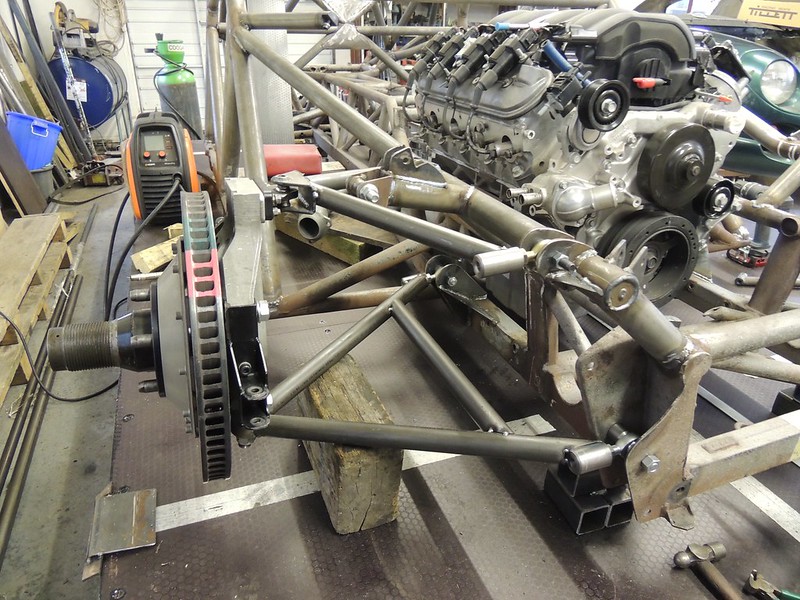

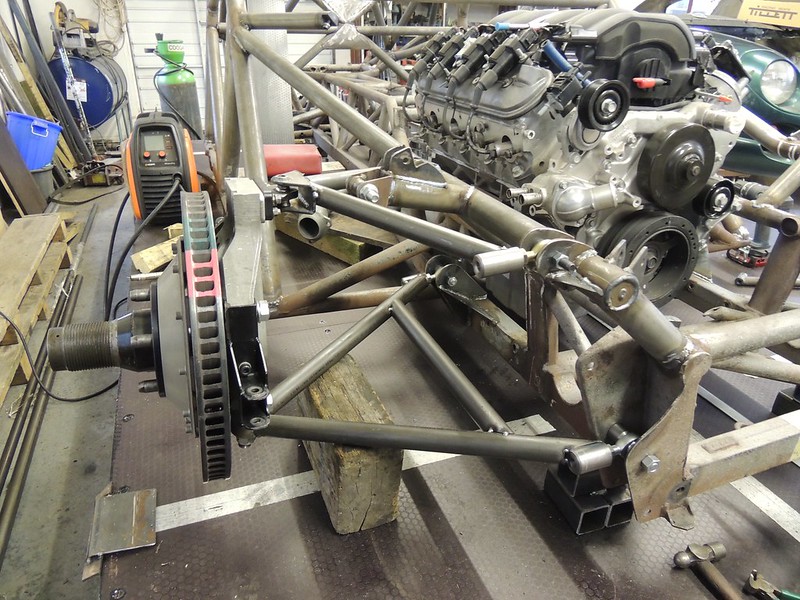

another day on the suspension mill, got the top a arm completed, fabricated the start of the bottom shock mount, lots of work on the lathe with fiddly bushes spacers etc. for the various mounts, made two of everything so offside should go quicker, stripped it all down for the full tig welding.just as an aside anyone in the district wants to have a look at the car as it proceeds just haul on by kettles always on.

john

DSCN1872 by Brundall Motorsport, on Flickr

DSCN1872 by Brundall Motorsport, on Flickr

DSCN1873 by Brundall Motorsport, on Flickr

DSCN1873 by Brundall Motorsport, on Flickr

DSCN1874 by Brundall Motorsport, on Flickr

DSCN1874 by Brundall Motorsport, on Flickr

DSCN1875 by Brundall Motorsport, on Flickr

DSCN1875 by Brundall Motorsport, on Flickr

DSCN1876 by Brundall Motorsport, on Flickr

DSCN1876 by Brundall Motorsport, on Flickr

DSCN1877 by Brundall Motorsport, on Flickr

DSCN1877 by Brundall Motorsport, on Flickr

DSCN1878 by Brundall Motorsport, on Flickr

DSCN1878 by Brundall Motorsport, on Flickr

john

DSCN1872 by Brundall Motorsport, on Flickr

DSCN1872 by Brundall Motorsport, on Flickr DSCN1873 by Brundall Motorsport, on Flickr

DSCN1873 by Brundall Motorsport, on Flickr DSCN1874 by Brundall Motorsport, on Flickr

DSCN1874 by Brundall Motorsport, on Flickr DSCN1875 by Brundall Motorsport, on Flickr

DSCN1875 by Brundall Motorsport, on Flickr DSCN1876 by Brundall Motorsport, on Flickr

DSCN1876 by Brundall Motorsport, on Flickr DSCN1877 by Brundall Motorsport, on Flickr

DSCN1877 by Brundall Motorsport, on Flickr DSCN1878 by Brundall Motorsport, on Flickr

DSCN1878 by Brundall Motorsport, on FlickrEdited by Engineer1949 on Wednesday 7th October 21:19

Edited by Engineer1949 on Wednesday 7th October 21:21

first set off a arms finished got the arb mount done today fully welded all the joints started making the jigs so they can be repeated also turned the bottom ball joint housing for the next set off side front.

john

DSCN1886 by Brundall Motorsport, on Flickr

DSCN1886 by Brundall Motorsport, on Flickr

DSCN1884 by Brundall Motorsport, on Flickr

DSCN1884 by Brundall Motorsport, on Flickr

DSCN1883 by Brundall Motorsport, on Flickr

DSCN1883 by Brundall Motorsport, on Flickr

DSCN1882 by Brundall Motorsport, on Flickr

DSCN1882 by Brundall Motorsport, on Flickr

DSCN1880 by Brundall Motorsport, on Flickr

DSCN1880 by Brundall Motorsport, on Flickr

DSCN1879 by Brundall Motorsport, on Flickr

DSCN1879 by Brundall Motorsport, on Flickr

john

DSCN1886 by Brundall Motorsport, on Flickr

DSCN1886 by Brundall Motorsport, on Flickr DSCN1884 by Brundall Motorsport, on Flickr

DSCN1884 by Brundall Motorsport, on Flickr DSCN1883 by Brundall Motorsport, on Flickr

DSCN1883 by Brundall Motorsport, on Flickr DSCN1882 by Brundall Motorsport, on Flickr

DSCN1882 by Brundall Motorsport, on Flickr DSCN1880 by Brundall Motorsport, on Flickr

DSCN1880 by Brundall Motorsport, on Flickr DSCN1879 by Brundall Motorsport, on Flickr

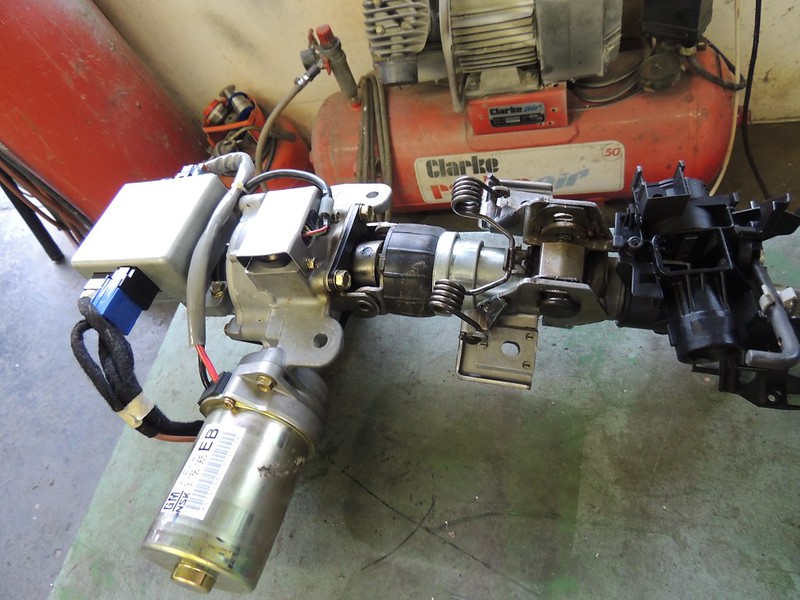

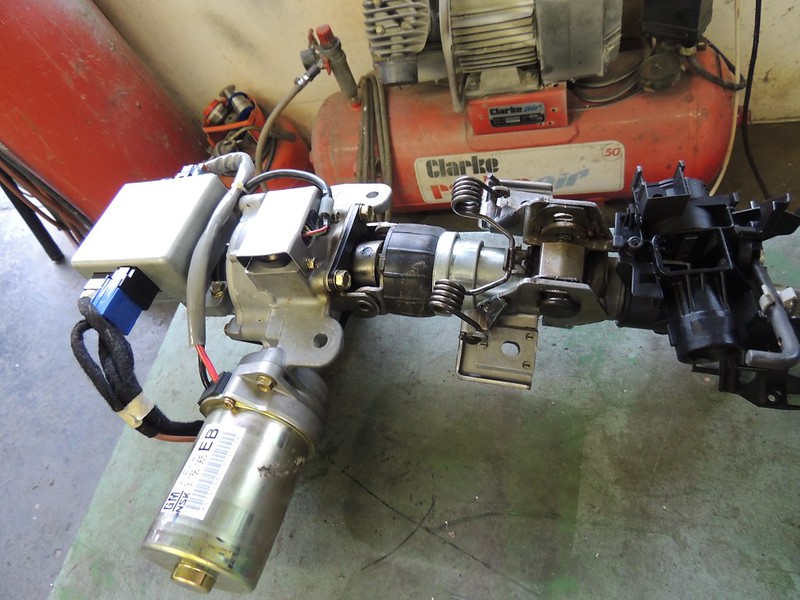

DSCN1879 by Brundall Motorsport, on Flickrgot some more done today after job on an old gottwald crane turned up the spacers for the rod ends just one to do then on with the tubes etc. plus motor for the power steering has turned up more to play with.

john

DSCN1889 by Brundall Motorsport, on Flickr

DSCN1889 by Brundall Motorsport, on Flickr

DSCN1890 by Brundall Motorsport, on Flickr

DSCN1890 by Brundall Motorsport, on Flickr

DSCN1891 by Brundall Motorsport, on Flickr

DSCN1891 by Brundall Motorsport, on Flickr

john

DSCN1889 by Brundall Motorsport, on Flickr

DSCN1889 by Brundall Motorsport, on Flickr DSCN1890 by Brundall Motorsport, on Flickr

DSCN1890 by Brundall Motorsport, on Flickr DSCN1891 by Brundall Motorsport, on Flickr

DSCN1891 by Brundall Motorsport, on Flickrnot quite so much accomplished this week had to fit another engine into my old 200 disco which i have upgraded to a 300 seems a lot better, so managed to complete the a arms for the off side front apart from welding in the shock mount but another milestone completed, also took delivery off the tillet carbon seat and mounts which is very nice so i can build the mounts into the chassis.

john

DSCN1892 by Brundall Motorsport, on Flickr

DSCN1892 by Brundall Motorsport, on Flickr

DSCN1893 by Brundall Motorsport, on Flickr

DSCN1893 by Brundall Motorsport, on Flickr

DSCN1894 by Brundall Motorsport, on Flickr

DSCN1894 by Brundall Motorsport, on Flickr

DSCN1895 by Brundall Motorsport, on Flickr

DSCN1895 by Brundall Motorsport, on Flickr

DSCN1896 by Brundall Motorsport, on Flickr

DSCN1896 by Brundall Motorsport, on Flickr

DSCN1897 by Brundall Motorsport, on Flickr

DSCN1897 by Brundall Motorsport, on Flickr

DSCN1898 by Brundall Motorsport, on Flickr

DSCN1898 by Brundall Motorsport, on Flickr

DSCN1900 by Brundall Motorsport, on Flickr

DSCN1900 by Brundall Motorsport, on Flickr

DSCN1899 by Brundall Motorsport, on Flickr

DSCN1899 by Brundall Motorsport, on Flickr

john

DSCN1892 by Brundall Motorsport, on Flickr

DSCN1892 by Brundall Motorsport, on Flickr DSCN1893 by Brundall Motorsport, on Flickr

DSCN1893 by Brundall Motorsport, on Flickr DSCN1894 by Brundall Motorsport, on Flickr

DSCN1894 by Brundall Motorsport, on Flickr DSCN1895 by Brundall Motorsport, on Flickr

DSCN1895 by Brundall Motorsport, on Flickr DSCN1896 by Brundall Motorsport, on Flickr

DSCN1896 by Brundall Motorsport, on Flickr DSCN1897 by Brundall Motorsport, on Flickr

DSCN1897 by Brundall Motorsport, on Flickr DSCN1898 by Brundall Motorsport, on Flickr

DSCN1898 by Brundall Motorsport, on Flickr DSCN1900 by Brundall Motorsport, on Flickr

DSCN1900 by Brundall Motorsport, on Flickr DSCN1899 by Brundall Motorsport, on Flickr

DSCN1899 by Brundall Motorsport, on FlickrGassing Station | Cerbera | Top of Page | What's New | My Stuff