Exhaust Baffles

Discussion

I'm having a bit of a problem with noise on my Dax Rush.

It's a v6 with two side exhausts. Each has a cat and straight through silencer (perforated tube surrounded by wadding).

As is, noise is about 104 dB on the static test. I got it down to 99.2 for my IVA test (failed by 0.2dB!) by putting large penny washers in the ends:

It was still a bit loud if I'm honest though, so I wouldn't mind getting it down a bit more. Rather than just make the hole in the washer a bit smaller, I'm wondering about these things as a more permanent reduction:

I'm going to try putting one up inside the perforated section (as it's the only straight bit of pipe I have). Now I understand that this will cause some restriction and hence lower power, a bit. But what I don't know is, are there any other effects? Can it affect fueling for example, or require any changes to my engine map?

Or does anyone have a better idea of how to reduce the noise? A perforated cone with pointy end into the exhaust is the idea which keeps comming into my mind, but it'd be hard to make, and I've no idea if it would actually be any better than the one above.

It's a v6 with two side exhausts. Each has a cat and straight through silencer (perforated tube surrounded by wadding).

As is, noise is about 104 dB on the static test. I got it down to 99.2 for my IVA test (failed by 0.2dB!) by putting large penny washers in the ends:

It was still a bit loud if I'm honest though, so I wouldn't mind getting it down a bit more. Rather than just make the hole in the washer a bit smaller, I'm wondering about these things as a more permanent reduction:

I'm going to try putting one up inside the perforated section (as it's the only straight bit of pipe I have). Now I understand that this will cause some restriction and hence lower power, a bit. But what I don't know is, are there any other effects? Can it affect fueling for example, or require any changes to my engine map?

Or does anyone have a better idea of how to reduce the noise? A perforated cone with pointy end into the exhaust is the idea which keeps comming into my mind, but it'd be hard to make, and I've no idea if it would actually be any better than the one above.

Call these guys:

http://www.helical-technology.com/en/exhaust-valve...

It's a 12v actuated butterfly valve that can divert or restrict flow when you need to keep the noise down. The company is an OEM supplier; you'll have to come up with the solution yourself, but they talked about selling it to retail.

The website is a bit OEM-focused, but I handled the unit at Autosport and could see how it wouldn't be too hard to incorporate into a kit or racecar, and they weren't talking mega-bucks. The valve is welded into the pipe and the black part is a 12v input driving a solenoid. The guys were very approachable too. I will find a name if you need it, just don't have the card on me now.

http://www.helical-technology.com/en/exhaust-valve...

It's a 12v actuated butterfly valve that can divert or restrict flow when you need to keep the noise down. The company is an OEM supplier; you'll have to come up with the solution yourself, but they talked about selling it to retail.

The website is a bit OEM-focused, but I handled the unit at Autosport and could see how it wouldn't be too hard to incorporate into a kit or racecar, and they weren't talking mega-bucks. The valve is welded into the pipe and the black part is a 12v input driving a solenoid. The guys were very approachable too. I will find a name if you need it, just don't have the card on me now.

Edited by nsa on Wednesday 15th January 11:54

Are you looking for a permanent solution or just a quick fix to pass an IVA?

When I used to help out with some rallying lads we had a temp. fix if scrutineering failed for being too noisy.

A small hold was drilled into the tailpipe and a ball of steel wool shoved into end of tailpipe to act as a temporary baffle. A large split pin or length of welding wire poked through the drilled hole secured the steel wool in place.

A bit of a Bob the Builder bodge-up but surprisingly effective to get the required DB readings.

When I used to help out with some rallying lads we had a temp. fix if scrutineering failed for being too noisy.

A small hold was drilled into the tailpipe and a ball of steel wool shoved into end of tailpipe to act as a temporary baffle. A large split pin or length of welding wire poked through the drilled hole secured the steel wool in place.

A bit of a Bob the Builder bodge-up but surprisingly effective to get the required DB readings.

Obviously any restriction will depend how much power you actually have...and you say it's a n/a V6 with a silencer for each side ?

Shouldnt imagine it needs huge amounts of flow to start with.

For IVA purposes, what about finding two basic OEM silencers and using them ?

They're usually very good at keeping noise down. They might look ugly, but it will give you time to find something more appropriate

How well packed at the current silencers, what material, what does the inner perforated tube actually look like ?

All of those things can play a role too and may just need some tweeking.

Shouldnt imagine it needs huge amounts of flow to start with.

For IVA purposes, what about finding two basic OEM silencers and using them ?

They're usually very good at keeping noise down. They might look ugly, but it will give you time to find something more appropriate

How well packed at the current silencers, what material, what does the inner perforated tube actually look like ?

All of those things can play a role too and may just need some tweeking.

Well first goal is to get through IVA, but I want to track it as well and don't really want to be adding/removing baffles all the time. So I'd rather have something permanent if possible. The curved end pipes make it a bit more of a faff as I have to dismantle them to get at a straight bit. I guess for track work I could make something to go in the curved section, but for IVA they need to be able to stick the emissions probe in there. I just got away with the previous washers but the hole was only just big enough.

I've no doubt I can get the sound down, it's the knock on effects I'm worried about.

In answer to Steve's question, yes, n/a 3.0 V6, one exhaust per side. It's a 47mm perforated tube, wrapped with stainless steel wire, then acoustic padding around that. Quite tightly packed, I don't think you could squeeze much more in. I'm afraid I don't know what sort it is:

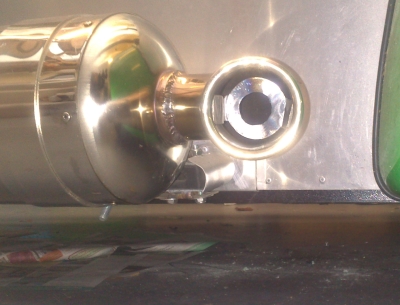

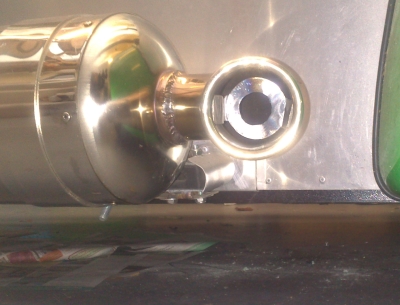

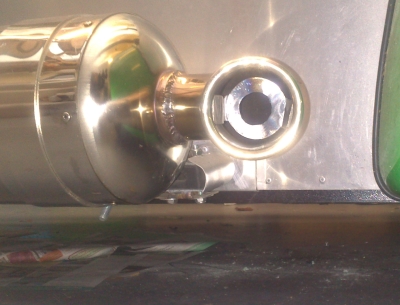

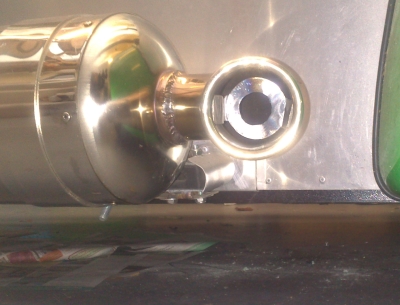

Pipe with steel wool, also shows how short it is:

Naked pipe (I'm trial fitting the baffle here)

The wadding - it's kind of stringy stuff, a bit like wool.

View down into the Cat

I've no doubt I can get the sound down, it's the knock on effects I'm worried about.

In answer to Steve's question, yes, n/a 3.0 V6, one exhaust per side. It's a 47mm perforated tube, wrapped with stainless steel wire, then acoustic padding around that. Quite tightly packed, I don't think you could squeeze much more in. I'm afraid I don't know what sort it is:

Pipe with steel wool, also shows how short it is:

Naked pipe (I'm trial fitting the baffle here)

The wadding - it's kind of stringy stuff, a bit like wool.

View down into the Cat

Packing silencers to tight can actualy make them too noisy ,I was suprised how loose mine was packed [ had to repack after holing a piston and filling the box with engine oil ! ] ,if you pack to tightly it acts as a solid pipe I had two goes at it to get it reasonable , but I'm registered 69% deaf !

The wire wool is stopping the noise from filtering into the wadding IMO, try removing the wire wool and see what it's like.

Too tightly packed silencers will make the car sound like it doesn't have a silencer at all! And gains zero power.

If my v6 with its short single straight through exhaust with a single can on can get well under what you have now then you should be able to get under 95db with a pair of straight through silencers.

Too tightly packed silencers will make the car sound like it doesn't have a silencer at all! And gains zero power.

If my v6 with its short single straight through exhaust with a single can on can get well under what you have now then you should be able to get under 95db with a pair of straight through silencers.

You want the gas to be able to expand into the silencer, the wire wool looks far too dense to allow that.

The wire wool is really only there to help prevent loss of the wadding, remove some and loosen it up a bit.

Next loosen up the wadding, and repack. The end result should be like pressing on a pile of towels.

It may take a couple of goes to get the optimum.

Also make sure the engine is fully up to temperature before doing a test, I have seen up to 12dB(a) difference between a cold and hot engine and 2-5dB(a) is not uncommon.

The wire wool is really only there to help prevent loss of the wadding, remove some and loosen it up a bit.

Next loosen up the wadding, and repack. The end result should be like pressing on a pile of towels.

It may take a couple of goes to get the optimum.

Also make sure the engine is fully up to temperature before doing a test, I have seen up to 12dB(a) difference between a cold and hot engine and 2-5dB(a) is not uncommon.

Hmmm ok I can try and repack them differently. I'd be surprised if I can lose 6 or 7 dB just by playing with the wadding though?

The wire wool is to prevent the wadding burning through isn't it?

I have stuck the baffles in and will be testing how much reduction they make as well.

Pain in the arse, this car building lark!

The wire wool is to prevent the wadding burning through isn't it?

I have stuck the baffles in and will be testing how much reduction they make as well.

Pain in the arse, this car building lark!

CrutyRammers said:

Hmmm ok I can try and repack them differently. I'd be surprised if I can lose 6 or 7 dB just by playing with the wadding though?

The wire wool is to prevent the wadding burning through isn't it?

I have stuck the baffles in and will be testing how much reduction they make as well.

Pain in the arse, this car building lark!

you would be surprised, a badly packed silencer could well increase noise 10db.... yest the wire wool is there to prevent wadding being burnt/blown out the back... but its all pointless if the silencer doesnt do it job lol.... the guy who does my silencers uses a finer mesh on the perf and it means teh wadding stays in the silencer and wire wool isnt required, slightly more expensive but cheaper in the long run.The wire wool is to prevent the wadding burning through isn't it?

I have stuck the baffles in and will be testing how much reduction they make as well.

Pain in the arse, this car building lark!

andygtt said:

the guy who does my silencers uses a finer mesh on the perf and it means teh wadding stays in the silencer and wire wool isnt required, slightly more expensive but cheaper in the long run.

The decent bike cans (e.g. Akrapovic) have a fine mesh installed over the perforated pipe as standard, much better than messing around with wire wool.Packing the wadding (or wire wool) too tightly can have a surprising impact on noise. We failed scrutineering at a tarmac rally because of this; we removed some wadding and 'fluffed' the remaining stuff up to take up the space and it dropped 5 dB.

Those cheap DB killers are horribly restrictive, they really should be sold as BHP killers. A much better solution is to make something like the baffles used in aftermarket bike cans, effectively just a narrower bore pipe about 6 inches or so long that have a shroud on the inside end and a larger diameter part on the outer end that's a snug fit into the tailpipe. Obviously a bike one won't fit as you have a much larger bend, but you could easily make one from e.g. 22mm copper pipe and some plumbing fittings to test the theory. You could then get something nicer fabricated in stainless if it works.

The longer and narrower you make the baffle the more restrictive it is and the more silencing it will provide.

Edited by Mr2Mike on Friday 17th January 17:02

CrutyRammers said:

I'm having a bit of a problem with noise on my Dax Rush.

It's a v6 with two side exhausts. Each has a cat and straight through silencer (perforated tube surrounded by wadding).

As is, noise is about 104 dB on the static test. I got it down to 99.2 for my IVA test (failed by 0.2dB!) by putting large penny washers in the ends:

It was still a bit loud if I'm honest though, so I wouldn't mind getting it down a bit more. Rather than just make the hole in the washer a bit smaller, I'm wondering about these things as a more permanent reduction:

I'm going to try putting one up inside the perforated section (as it's the only straight bit of pipe I have). Now I understand that this will cause some restriction and hence lower power, a bit. But what I don't know is, are there any other effects? Can it affect fueling for example, or require any changes to my engine map?

Or does anyone have a better idea of how to reduce the noise? A perforated cone with pointy end into the exhaust is the idea which keeps comming into my mind, but it'd be hard to make, and I've no idea if it would actually be any better than the one above.

Ive got these fitted in my side pipes on my 4ltr Ginetta. To start with they hissed as the gas went through them- sounded horrible- but then I drilled a series of large holes in the funnel shaped area to allow more gas out. This has worked well, and Ive not notaced an reduction in power. Its certainly a cheap and easy fix.It's a v6 with two side exhausts. Each has a cat and straight through silencer (perforated tube surrounded by wadding).

As is, noise is about 104 dB on the static test. I got it down to 99.2 for my IVA test (failed by 0.2dB!) by putting large penny washers in the ends:

It was still a bit loud if I'm honest though, so I wouldn't mind getting it down a bit more. Rather than just make the hole in the washer a bit smaller, I'm wondering about these things as a more permanent reduction:

I'm going to try putting one up inside the perforated section (as it's the only straight bit of pipe I have). Now I understand that this will cause some restriction and hence lower power, a bit. But what I don't know is, are there any other effects? Can it affect fueling for example, or require any changes to my engine map?

Or does anyone have a better idea of how to reduce the noise? A perforated cone with pointy end into the exhaust is the idea which keeps comming into my mind, but it'd be hard to make, and I've no idea if it would actually be any better than the one above.

Sorry, should have updated.

Well I've had it all apart and repacked - probably made it worse tbh as it was very neatly done before! It doesn't seem too tight from what people have said above, there's no spare space but it's not hard pressed in.

Anyway, I've stuck the baffles in the straight section for now, which has certainly reduced the noise. I'm going to get the emissions looked at as well, so it'll be interesting to see how much effect they have.

Plan then is to take the baffles out, and shorten them /open them up some so that they fit into the curved end; then I will have something neat and easily removable for trackdays etc.

Well I've had it all apart and repacked - probably made it worse tbh as it was very neatly done before! It doesn't seem too tight from what people have said above, there's no spare space but it's not hard pressed in.

Anyway, I've stuck the baffles in the straight section for now, which has certainly reduced the noise. I'm going to get the emissions looked at as well, so it'll be interesting to see how much effect they have.

Plan then is to take the baffles out, and shorten them /open them up some so that they fit into the curved end; then I will have something neat and easily removable for trackdays etc.

Mr2Mike said:

Those cheap DB killers are horribly restrictive, they really should be sold as BHP killers. A much better solution is to make something like the baffles used in aftermarket bike cans, effectively just a narrower bore pipe about 6 inches or so long that have a shroud on the inside end and a larger diameter part on the outer end that's a snug fit into the tailpipe. Obviously a bike one won't fit as you have a much larger bend, but you could easily make one from e.g. 22mm copper pipe and some plumbing fittings to test the theory. You could then get something nicer fabricated in stainless if it works.

This is the thing - I couldn't find any actual data to show if one type sapped power more than the other.I can actually easily modify the ones I've got to be like the one in your link if it's going to be better. But short of paying for a RR session I expect I'm never going to know for sure. If anyone's got any hard evidence one way or t'other I'd love to see it!

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff