Dodge Viper GTS on the rollers

Discussion

stevieturbo said:

Fully agree, and it is odd that many in the UK seem to insist on the guesstimated flywheel figures.

But I guess in the US they sort of do too by using a Dynojet which seems to read as high as these flywheel figures anyway lol

As you mentioned the US, I've noticed they usually quote whp, yet the figures are often comparable with UK flywheel figures?But I guess in the US they sort of do too by using a Dynojet which seems to read as high as these flywheel figures anyway lol

Does the US use a different metric behind their HP? or this DynoJet you mention - are they just full of B.S?

stevieturbo said:

Fully agree, and it is odd that many in the UK seem to insist on the guesstimated flywheel figures.

But I guess in the US they sort of do too by using a Dynojet which seems to read as high as these flywheel figures anyway lol

I reverse-engineered some Dynojet corrections once.....But I guess in the US they sort of do too by using a Dynojet which seems to read as high as these flywheel figures anyway lol

I could tell you, but then I'd have to

you.

you. The other thing is that manufacturer power figures are more realistic than they used to be.

To quote from the SAE :

Document SAE J2723 specifies the procedure to be used for a manufacturer to certify the net power and torque rating of a production engine according to SAE J1349 or the gross engine power of a production engine according to SAE J1995.

This means they have to run in as close to in-vehicle trim as possible.

In the bad old days, some manufacturers quoted power figures for engines with no alternator, water pump, air cleaner or standard exhaust, running any fuel they wanted. Others just made things up.

If you are correcting to 1970's quoted engine power, just think of a number and double it

Many years ago we contacted an engineer I knew at a major manufacturer, trying to find out why a stock test engine only made x kW, which was less than their quoted power.

The answer was approximitaly "x sounds about right, ignore the brochure figure"

The wheel power is not the only figure available with the inertia testing dynos.Using the coastdown test does give us a link to what is happening twixt engine and wheels, as I said, we can compare wheel power and losses from same make and model cars to ensure all is correct, and, if not, find out why transmission losses are higher than the norm. It also gives a modicum of satisfaction to those wanting a ball park engine figure. All in all a very useful tuning/testing tool and beats the pants off guessing the wheel or flywheel power or effects of tweaks to timing and or fuelling!

Peter

Peter

Here is another article which has the same engine on 3 different dynos. eddy current, inertia, and water brake, chart near end.

http://www.hotrod.com/how-to/additional-how-to/110...

Stan

http://www.hotrod.com/how-to/additional-how-to/110...

Stan

Stan Weiss said:

Here is another article which has the same engine on 3 different dynos. eddy current, inertia, and water brake, chart near end.

http://www.hotrod.com/how-to/additional-how-to/110...

Stan

Seems odd they make a big point about the state of the tyres on the Dyno Dynamics.http://www.hotrod.com/how-to/additional-how-to/110...

Stan

Surely they should all know, DD would never recommend such a tyre on the dyno ?

DD will even say the likes of a Toyo 888 tyre shouldnt even be used. Best are always perfectly normal road tyres.

Good point Stevie, all it takes is a tyre inflator to see if the tyre deformation was costly. No point in saying would be interesting to try higher tyre pressure another time....waste of time writing up, would have been more interesting to show effects of tyre pressure....we lost 6ish whp on a B dropping from 30ish to 19 psi!

No deformation like that on Carl's car. Ollie said he could visibly see tyre growth at 170+mph!

With something like Carl's car we just had a ball park snap shot with reasonable temps underbonnet/intercooler etc. Cooler would have shown more, hotter less, as you know very difficult if not impossible to maintain conditions for tuning turbo monsters. Power lines vs temp of intake charge look like physics class graphs with 1% change in whp for every 3 degrees centigrade change!

Accurate for whp and transmission losses or not, we have a whp, losses and a ball park flywheel figure for Carl's first stage 1000 hp tune, which is pretty close, without a dyno run folk are just guessing (usually very optimistic guessing/hoping!) what they have got under the foot Imagine what would have shown with the second stage predicted 1500 hp!

Imagine what would have shown with the second stage predicted 1500 hp!

Peter

No deformation like that on Carl's car. Ollie said he could visibly see tyre growth at 170+mph!

With something like Carl's car we just had a ball park snap shot with reasonable temps underbonnet/intercooler etc. Cooler would have shown more, hotter less, as you know very difficult if not impossible to maintain conditions for tuning turbo monsters. Power lines vs temp of intake charge look like physics class graphs with 1% change in whp for every 3 degrees centigrade change!

Accurate for whp and transmission losses or not, we have a whp, losses and a ball park flywheel figure for Carl's first stage 1000 hp tune, which is pretty close, without a dyno run folk are just guessing (usually very optimistic guessing/hoping!) what they have got under the foot

Imagine what would have shown with the second stage predicted 1500 hp!

Imagine what would have shown with the second stage predicted 1500 hp!Peter

Pondering a little more, I reckon the article Stan linked to is quite informative. For years folk have criticized inertia dynos for reading higher than power absorbing braked dynos. Maybe both dynos read correctly? Inertia obviously causes less transmission losses; look at the wrinkled tyre on the pic from the eddy braked dyno! So we may show less whp with eddy brake and higher transmission losses and conversely more whp with inertia and correspondingly less losses but end results are ball park same when whp and losses added together. For Carl's car I put a 2% eddy brake load on the rollers (100% load = 750 bhp) to spool up the turbos, with no load power curve was low and poor shape, same with 1% load. At 2% we had a good 'proper'turbo curve. The 15 hp load would not have upset the tyre shape to any extent! I find the repeatability of tests best with no load on non turbo below 400 bhp cars and just small min load on +400 cars and turbos.

Whilst engine dyno should be more definitive for flywheel power and purists, once we get the SF901 up and running I don't suppose many folk will take the engine out of the car and pay for a day's work to see if engine is still on song at end of season....easier and much more cost effective strapping it on rollers and see how it compares to last session!

Peter

Whilst engine dyno should be more definitive for flywheel power and purists, once we get the SF901 up and running I don't suppose many folk will take the engine out of the car and pay for a day's work to see if engine is still on song at end of season....easier and much more cost effective strapping it on rollers and see how it compares to last session!

Peter

The wrinkled tyres isnt the fault of the dyno.

Those tyres should never be used on such a dyno. They are either drag radials or wrinkle walls. The worst possible tyre you could ever use on a DD

The flip side is on the likes of a Dynojet such tyres are almost needed to get traction on their roller, whereas in almost all cases a normal road tyre will achieve perfect traction on the DD

Those tyres should never be used on such a dyno. They are either drag radials or wrinkle walls. The worst possible tyre you could ever use on a DD

The flip side is on the likes of a Dynojet such tyres are almost needed to get traction on their roller, whereas in almost all cases a normal road tyre will achieve perfect traction on the DD

No wrinkle on eddy brake pic with no load so would have shown more in inertia mode.

We have been ok with grip and minimal strapping, maybe the nurled roller helps us? We used to struggle on the Clayton as I only used wheel chocks and weight (people) in the boot! Clayton used to destroy soft tyres, Dynocom is very gentle on tyres , soft ones get hot if we hold load to check fuel supply/detonation etc.

Peter

We have been ok with grip and minimal strapping, maybe the nurled roller helps us? We used to struggle on the Clayton as I only used wheel chocks and weight (people) in the boot! Clayton used to destroy soft tyres, Dynocom is very gentle on tyres , soft ones get hot if we hold load to check fuel supply/detonation etc.

Peter

The difference is not so much eddy-current vs inertia, but large vs small roller diameter.

Both have advantages and disadvantages : small rollers generally give better traction, at the expense of more tyre distortion.

We have made eddy-current truck dynos with rollers up to 750mm diameter, and a one-off special with 2m diameter rollers, but you would be hard-pressed to fit either of those in a normal workshop

Regarding tyres, I visited a customer who had one of our bike dynos years ago, and they had a "dyno wheel" they fitted for dyno testing. It had the hardest compound tyre they could find, pumped up to something stupid like 90 psi.

Tuning 125 cc race bikes, they wanted to minimise variations in both friction and inertia as much as possible, and traction was never going to be a problem at those power levels.

We are building a hub dyno at the moment, and it will be interesting to do back-to-back testing of the same car(s) on it and a chassis dyno. Hub dynos are more expensive and less convenient to use, but they do bypass the whole tyre issue.

The most we have run on a standard chassis dyno is a shade over 2,000 hp, at which point the tyres get hot very fast indeed - to do serious tuning and developement at those power levels and above on a chassis dyno may require buying shares in a tyre company.

Both have advantages and disadvantages : small rollers generally give better traction, at the expense of more tyre distortion.

We have made eddy-current truck dynos with rollers up to 750mm diameter, and a one-off special with 2m diameter rollers, but you would be hard-pressed to fit either of those in a normal workshop

Regarding tyres, I visited a customer who had one of our bike dynos years ago, and they had a "dyno wheel" they fitted for dyno testing. It had the hardest compound tyre they could find, pumped up to something stupid like 90 psi.

Tuning 125 cc race bikes, they wanted to minimise variations in both friction and inertia as much as possible, and traction was never going to be a problem at those power levels.

We are building a hub dyno at the moment, and it will be interesting to do back-to-back testing of the same car(s) on it and a chassis dyno. Hub dynos are more expensive and less convenient to use, but they do bypass the whole tyre issue.

The most we have run on a standard chassis dyno is a shade over 2,000 hp, at which point the tyres get hot very fast indeed - to do serious tuning and developement at those power levels and above on a chassis dyno may require buying shares in a tyre company.

For those who might be interested I ran a full acceleration simulation of the drag car Stan linked to in my vehicle performance software. Detail given in the article was car weight 3501 lbs, final drive 3.73, 315/60/15 tyres, 8.67s 1/4 mile @ 158 mph with the turbos fitted.

I stuck it in the simulator with the engine dyno power curve, 4 speed auto box geared for 160 mph as this didn't appear to have been changed for the non-turbo test, 22 sq foot frontal area and a Cd of 0.45 (very non critical), 4500 rpm launch rpm and 7000 peak rpm, drag tyre grip coefficients from my database, 0.22 second gearchange time.

Must be the easiest simulation I've ever done. I didn't have to tinker with anything to agree the timed 1/8th mile performance. Article said 1.58 to 1.61 seconds at 60 feet, 6.64 seconds at 106.3 mph at 1/8th mile.

Simulator came straight out with 1.61s 60 ft time and 6.64s @ 106.6 mph 1/8th mile at 675 flywheel bhp and 554 wheel bhp. 18% total transmission and tyre losses which isn't unreasonable for an auto box setup.

Conclusion. The engine dyno flywheel figure and inertia dyno wheel figure were about spot on. The eddy current chassis dyno numbers were pure nonsense.

I stuck it in the simulator with the engine dyno power curve, 4 speed auto box geared for 160 mph as this didn't appear to have been changed for the non-turbo test, 22 sq foot frontal area and a Cd of 0.45 (very non critical), 4500 rpm launch rpm and 7000 peak rpm, drag tyre grip coefficients from my database, 0.22 second gearchange time.

Must be the easiest simulation I've ever done. I didn't have to tinker with anything to agree the timed 1/8th mile performance. Article said 1.58 to 1.61 seconds at 60 feet, 6.64 seconds at 106.3 mph at 1/8th mile.

Simulator came straight out with 1.61s 60 ft time and 6.64s @ 106.6 mph 1/8th mile at 675 flywheel bhp and 554 wheel bhp. 18% total transmission and tyre losses which isn't unreasonable for an auto box setup.

Conclusion. The engine dyno flywheel figure and inertia dyno wheel figure were about spot on. The eddy current chassis dyno numbers were pure nonsense.

Edited by Pumaracing on Friday 29th May 13:08

Pumaracing said:

For those who might be interested I ran a full acceleration simulation of the drag car Stan linked to in my vehicle performance software. Detail given in the article was car weight 3501 lbs, final drive 3.73, 315/60/15 tyres, 8.67s 1/4 mile @ 158 mph with the turbos fitted.

I stuck it in the simulator with the engine dyno power curve, 4 speed auto box geared for 160 mph as this didn't appear to have been changed for the non-turbo test, 22 sq foot frontal area and a Cd of 0.45 (very non critical), 4500 rpm launch rpm and 7000 peak rpm, drag tyre grip coefficients from my database, 0.22 second gearchange time.

Must be the easiest simulation I've ever done. I didn't have to tinker with anything to agree the timed 1/8th mile performance. Article said 1.58 to 1.61 seconds at 60 feet, 6.64 seconds at 106.3 mph at 1/8th mile.

Simulator came straight out with 1.61s 60 ft time and 6.64s @ 106.6 mph 1/8th mile at 675 flywheel bhp and 554 wheel bhp. 18% total transmission and tyre losses which isn't unreasonable for an auto box setup.

Conclusion. The engine dyno flywheel figure and inertia dyno wheel figure were about spot on. The eddy current chassis dyno numbers were pure nonsense.

But that's because the simulation software will have been built around results from the inertia dyno's ?I stuck it in the simulator with the engine dyno power curve, 4 speed auto box geared for 160 mph as this didn't appear to have been changed for the non-turbo test, 22 sq foot frontal area and a Cd of 0.45 (very non critical), 4500 rpm launch rpm and 7000 peak rpm, drag tyre grip coefficients from my database, 0.22 second gearchange time.

Must be the easiest simulation I've ever done. I didn't have to tinker with anything to agree the timed 1/8th mile performance. Article said 1.58 to 1.61 seconds at 60 feet, 6.64 seconds at 106.3 mph at 1/8th mile.

Simulator came straight out with 1.61s 60 ft time and 6.64s @ 106.6 mph 1/8th mile at 675 flywheel bhp and 554 wheel bhp. 18% total transmission and tyre losses which isn't unreasonable for an auto box setup.

Conclusion. The engine dyno flywheel figure and inertia dyno wheel figure were about spot on. The eddy current chassis dyno numbers were pure nonsense.

Edited by Pumaracing on Friday 29th May 13:08

If the software was built around millions of results from a DD Dyno as it's base, the results would be different.

Given the tyre deformation on the small-roller dyno, I wouldn't trust those figures at all either.

Drag tyres are designed to deform under load to maximise traction on the tarmac : not exactly ideal in these circumstances.

Anyway, I don't want to get into a "mine's better than yours" argument : I leave that to the sales guys.

All engineering is compromise : there is no such thing as the "best" dyno. Best means different things to different people, eg.

Cheapest

Most accurate

Most reliable

Easiest to use

Most portable

Most features

Longest service life

Lowest maintenance

Fastest payback

Fits in my workshop

I like the colour

and so on.

Would an OEM research engine dyno accurate to 0.01 Hp, complete with climate-controlled test cell and in-cylinder combustion monitoring be the best dyno for Bloggs' classic motors? Why not?

There is nothing built by humans that is best on every measure - the trick is to be aware of the compromises involved.

Drag tyres are designed to deform under load to maximise traction on the tarmac : not exactly ideal in these circumstances.

Anyway, I don't want to get into a "mine's better than yours" argument : I leave that to the sales guys.

All engineering is compromise : there is no such thing as the "best" dyno. Best means different things to different people, eg.

Cheapest

Most accurate

Most reliable

Easiest to use

Most portable

Most features

Longest service life

Lowest maintenance

Fastest payback

Fits in my workshop

I like the colour

and so on.

Would an OEM research engine dyno accurate to 0.01 Hp, complete with climate-controlled test cell and in-cylinder combustion monitoring be the best dyno for Bloggs' classic motors? Why not?

There is nothing built by humans that is best on every measure - the trick is to be aware of the compromises involved.

stevieturbo said:

But that's because the simulation software will have been built around results from the inertia dyno's ?

I'm trying to work out if you're actually being serious or silly. Irony, if such exists above, tends not to come across in posts. I wrote the software based on the findings of a gentleman called Sir Isaac Newton who discovered that F=Ma. The type of dyno doesn't enter into it. X number of actual ft lbs per second applied to Y number of actual lbs of vehicle mass = a certain rate of acceleration. Short of some unknown breakdown in the laws of physics, perhaps due to eddies in the space time continuum, the horsepower required to accelerate a given vehicle at a measured rate is very precisely calculable. In the above case the computer says 554 bhp +/- the odd percent or two delivered to the tyre contact patch.AW111 said:

We are building a hub dyno at the moment, and it will be interesting to do back-to-back testing of the same car(s) on it and a chassis dyno. Hub dynos are more expensive and less convenient to use, but they do bypass the whole tyre issue.

The most we have run on a standard chassis dyno is a shade over 2,000 hp, at which point the tyres get hot very fast indeed - to do serious tuning and developement at those power levels and above on a chassis dyno may require buying shares in a tyre company.

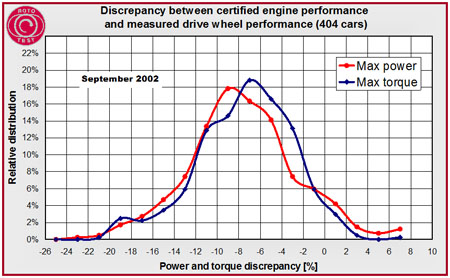

Rototest have produced and number of articles on the web site one of which contains the graph below.The most we have run on a standard chassis dyno is a shade over 2,000 hp, at which point the tyres get hot very fast indeed - to do serious tuning and developement at those power levels and above on a chassis dyno may require buying shares in a tyre company.

This shows the difference between claimed power and measured power at the hubs for 404 cars.

-9% for power and -8% for torque is the most common.

On the issue of FWHP and RWHP, RWHP is flawed as a means of comparing one car to another, even of the same make and model, but with different modification. There are so many things that effect the wheel/tyre interface that it is almost impossible to get exactly the same conditions. Gear used, tyre type, tyre pressure, toe, camber all effect the result.

Although a coast down loss is not representative of true transmission loss, it does give an indication of comparative losses and in that respect taking some of the above variables in to consideration. Better than a fixed added % IMO.

It mildly amuses me that every dyno operator I have met claims their dyno is accurate. It would be fun to take a car to several operators and get the results and challenge them on the accuracy. Let's see how confident they are in the defence of their dyno then.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff