Experience with pull type clutch slave cylinders

Discussion

Kitchski said:

Hi all,

Has anyone tried retrofitting a 'pull' type slave cylinder before (in installations where space doesn't allow a standard push type), and what kind of success did you have (or not have)?

Thanks

Any details ?Has anyone tried retrofitting a 'pull' type slave cylinder before (in installations where space doesn't allow a standard push type), and what kind of success did you have (or not have)?

Thanks

I have never seen any car with a pull type slave cylinder.

Or what is the problem you're trying to fix ?

Hillman Imp. Using an Imp transaxle, but a different engine. Normally the Imp engine lays on its side, and the clutch slave cylinder (conventional type) is bolted on top of it, and operates the clutch by pushing against the release arm, the head of which sticks out from the top of the box.

Because I have a different engine bolted to the transaxle, I can't fit the standard slave cylinder as there is an engine in the way. I was told that pull-type slave cylinders are a thing, so was wondering if anyone had experience as I was thinking of fitting a pull cylinder to the reverse side of the release arm.

I currently have a concentric cylinder fitted, but it's s te and I'm planning to ditch it.

te and I'm planning to ditch it.

Because I have a different engine bolted to the transaxle, I can't fit the standard slave cylinder as there is an engine in the way. I was told that pull-type slave cylinders are a thing, so was wondering if anyone had experience as I was thinking of fitting a pull cylinder to the reverse side of the release arm.

I currently have a concentric cylinder fitted, but it's s

te and I'm planning to ditch it.

te and I'm planning to ditch it.In my experience external slave cylinders on pull type clutches still push, they are just turned around so that they push the bearing away from the cover, not towards it.

If you are stuck for space at the release arm could you not convert to a cable?

I would have thought a concentric pull type slave would be ideal. What don't you like about the system you have?

If you are stuck for space at the release arm could you not convert to a cable?

I would have thought a concentric pull type slave would be ideal. What don't you like about the system you have?

stevieturbo said:

Not something I've ever seen or heard of.

All slave cylinders push....I imagine designing a hydraulic system that pulls would be unusual, at least certainly within a car environment.

A quick bit of hunting around found this:All slave cylinders push....I imagine designing a hydraulic system that pulls would be unusual, at least certainly within a car environment.

http://www.rallydesign.co.uk/product_info.php?prod...

Was just wondering if anyone had experience of fitting or operating one.

Little Pete said:

In my experience external slave cylinders on pull type clutches still push, they are just turned around so that they push the bearing away from the cover, not towards it.

Haven't seen one in front of me, but the link above seems to suggest otherwise, though I agree it's a bit oddball.Little Pete said:

If you are stuck for space at the release arm could you not convert to a cable?

Possibly, yes. Converting to cable would be better at the clutch end, but more hard work at the pedal end. Definitely a valid option though.Little Pete said:

I would have thought a concentric pull type slave would be ideal. What don't you like about the system you have?

So did I originally, but it's cack! The gearbox isn't ideally suited to housing it anyway, and if you get any leaks (which I do.....a lot) then it's engine out again to try and rectify it. It works well in operation, but seems to keep failing around the seals (on the unions and on the cylinder bore itself), and it's not like it's being asked to shift too much weight, or even overthrowing etc.I might give it one more chance yet, as it's the quickest way of sorting the problem, it's just that if it fails again it becomes a royal PITA.......again.

I like the idea of having the hydraulics easily accessible. I've sourced the correct release arm so just need to find a way of operating it.

Sounds like this installation has already had a lot of work put into it. Would you consider mounting the 'push' slave t'other way round and fabricating a pull rod attached to the far end? I'm envisaging chopping off the end of a clutch release arm where the slave pushrod normally seats, attaching a pair of straps that run down either side of the slave and a cross bar at the far end that hooks over the clutch release arm.

GreenV8S said:

Sounds like this installation has already had a lot of work put into it.

Just a bit!

GreenV8S said:

Would you consider mounting the 'push' slave t'other way round and fabricating a pull rod attached to the far end? I'm envisaging chopping off the end of a clutch release arm where the slave pushrod normally seats, attaching a pair of straps that run down either side of the slave and a cross bar at the far end that hooks over the clutch release arm.

Not quite sure I follow you there, but I've possibly had a similar idea already where I mount the convention slave to one side of the head of the release arm (which points upwards vertically) and then fashion a crossbar horizontally across the top of it. Then I'd have the slave on one side, and the other end either anchored in a rose-joint, along with a rosejoint on the top of the release arm for the crossbar to pass through.I've not seen that rally design thingy before but that could be your answer if you have enough room. Looking at how it operates I imagine it is quite a bit longer than a conventional slave.

You will probably have to experiment with release arm travel/pedal travel ratios but it sounds like you'll be up for that given what you've already achieved!

What type of vehicle is this in?

Sorry just re read your previous post

You will probably have to experiment with release arm travel/pedal travel ratios but it sounds like you'll be up for that given what you've already achieved!

What type of vehicle is this in?

Sorry just re read your previous post

Edited by Little Pete on Thursday 10th November 20:10

Little Pete said:

I've not seen that rally design thingy before but that could be your answer if you have enough room. Looking at how it operates I imagine it is quite a bit longer than a conventional slave.

You will probably have to experiment with release arm travel/pedal travel ratios but it sounds like you'll be up for that given what you've already achieved!

What type of vehicle is this in?

Sorry just re read your previous post

I think I'll have enough room there, but would need to measure up first. I should imagine it'll be a case of limiting the pedal travel, which I've already made an adjuster for to prevent over-throwing the existing slave.You will probably have to experiment with release arm travel/pedal travel ratios but it sounds like you'll be up for that given what you've already achieved!

What type of vehicle is this in?

Sorry just re read your previous post

Edited by Little Pete on Thursday 10th November 20:10

And yes, Hillman Imp running a Saxo TU5 engine.

227bhp said:

I'd be finding out why it leaks so often and going from there.

They're in daily use in millions of cars so you need to address that.

I think it's just a poor quality product. The unions don't seal properly and they're standard Goodridge hoses. The seals inside have been replaced already and keep leaking. And even if I managed to prevent it leaking, I don't like not being able to see what's going on in an area where I'm constantly having design issues. It could be the way that everything is set up is stressing it out somewhere. All looks true and can't see any issues, but doesn't mean there aren't any. I just think I'm done with this particular design.They're in daily use in millions of cars so you need to address that.

Appreciate millions of cars use concentric slaves as a design, but they're not all the same slave. That's like saying there's no reason why your gearbox should fail, as millions of cars use them.

Kitchski said:

Not quite sure I follow you there, but I've possibly had a similar idea already where I mount the convention slave to one side of the head of the release arm (which points upwards vertically) and then fashion a crossbar horizontally across the top of it. Then I'd have the slave on one side, and the other end either anchored in a rose-joint, along with a rosejoint on the top of the release arm for the crossbar to pass through.

I'm not sure I can explain it any better without a picture, but I'll try. Position a conventional 'push' type slave cylinder where you would have put your 'pull' style one i.e. so that it is in the right place but pushing where you want it to pull. Swap it end for end so that now it is pushing the right direction, but the body of the slave cylinder is in the way and prevents you connecting the pushrod directly to the clutch release arm. Now put a rectangular frame around the slave with the slave's pushrod pushing on one end, two sides carrying the force round the outside of the slave, and the far end connecting that force to the clutch release arm. The cage would be easy to make and has no moving parts - you just need to arrange a pivot for the slave cylinder pushrod to connect to it at one end, and the end of the clutch release arm to connect at the other end. I'd imagine it being welded up from a few pieces of bar and a salvaged pivot from a clutch release arm.GreenV8S said:

I'm not sure I can explain it any better without a picture, but I'll try. Position a conventional 'push' type slave cylinder where you would have put your 'pull' style one i.e. so that it is in the right place but pushing where you want it to pull. Swap it end for end so that now it is pushing the right direction, but the body of the slave cylinder is in the way and prevents you connecting the pushrod directly to the clutch release arm. Now put a rectangular frame around the slave with the slave's pushrod pushing on one end, two sides carrying the force round the outside of the slave, and the far end connecting that force to the clutch release arm. The cage would be easy to make and has no moving parts - you just need to arrange a pivot for the slave cylinder pushrod to connect to it at one end, and the end of the clutch release arm to connect at the other end. I'd imagine it being welded up from a few pieces of bar and a salvaged pivot from a clutch release arm.

Ahh, I'm with you now. Yes that's a good shout - a more effective version of what I was thinking of, cheers

Saxo 1.4 flywheel & clutch cover, Sierra 1.6 Pinto plate. Bearing is part of the concentric setup, but would be transferring it to a boss I'll get turned up that can be operated by the release arm. I can't use the standard setup as there is a 20mm adapter plate between engine (Saxo VTR 1600) and the Imp transaxle, so I need to make up the difference by fitting the release bearing to a boss that is operated by the release arm, rather than directly off the arm itself.

This is my reader's car thread if anyone's intrigued:

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

http://www.pistonheads.com/gassing/topic.asp?h=0&a...

Kitchski said:

227bhp said:

I'd be finding out why it leaks so often and going from there.

They're in daily use in millions of cars so you need to address that.

I think it's just a poor quality product. The unions don't seal properly and they're standard Goodridge hoses. The seals inside have been replaced already and keep leaking. And even if I managed to prevent it leaking, I don't like not being able to see what's going on in an area where I'm constantly having design issues. It could be the way that everything is set up is stressing it out somewhere. All looks true and can't see any issues, but doesn't mean there aren't any. I just think I'm done with this particular design.They're in daily use in millions of cars so you need to address that.

Appreciate millions of cars use concentric slaves as a design, but they're not all the same slave. That's like saying there's no reason why your gearbox should fail, as millions of cars use them.

The last time I did a conversion from pull type to push I got an old broken 'box and cut a huge window in the bell housing, I was then able to see what was going on rather than measure and hope. Some other points, sorry if they're equally as obvious:

Is the cylinder bearing clearing when retracted?

Is the stroke correct, not going too far or too little?

Some engines only have a pair of half moon thrust washers to stop longitudinal crank movement, is there any implication there? I have seen these effectively pounded to death along with the crank by different types of non OE designed clutches so it's something to consider.

You will have noticed that you can buy Motorsport off-the-shelf slave cylinders? AP do a range, as do others. I found AP to be helpful in this respect as they supplied me with very detailed working drawings of their product.

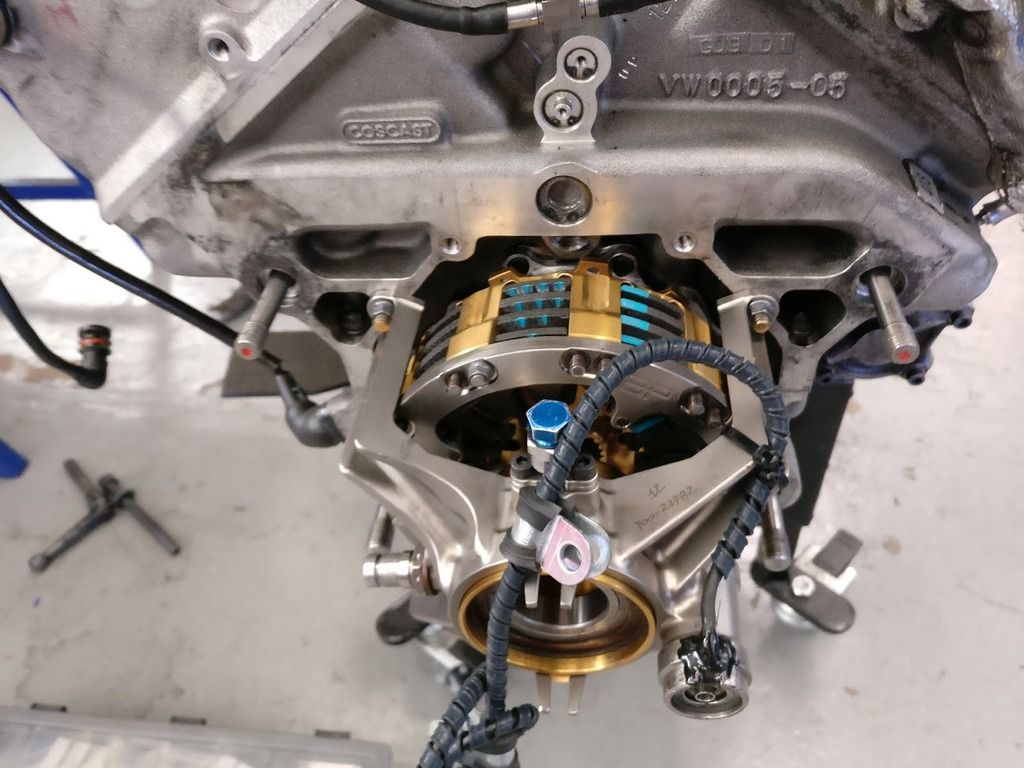

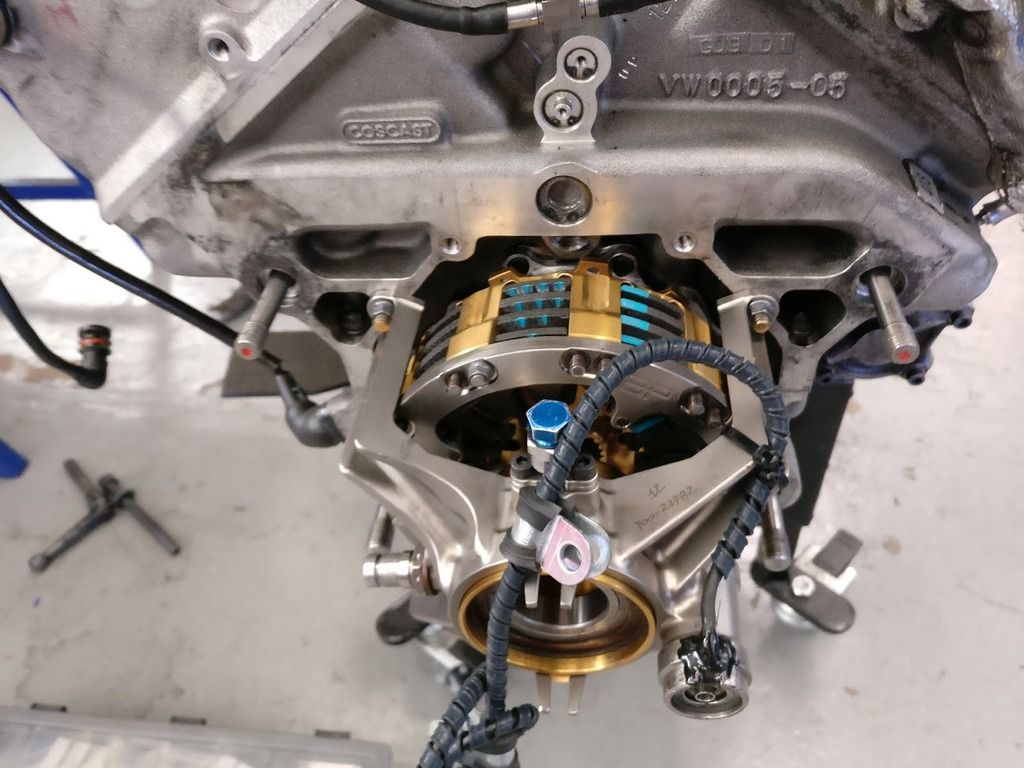

Concentric would be a better option to be honest with you, at the end of the day it's just hyds so if your issue is it leaks then there are many options for a robust concentric slave. From a packaging and performance point of view it's a better option. You could go pull type concentric if you are really tight on space in the bell housing either engine mounted like this:

or gearbox mounted like this:

Pull type linear slaves like the one posted above on RalDes are always a pain in the arse as finding a mounting on the opposite side of the clutch fork arm that's stiff enough and in the right position is never a simple task.

Having looked at your readers cars thread and seeing the issue you had with the load of the push type slave cracking the gearbox casing I would look at a pull type mounted on the engine, it looks like there is loads of room in the bell housing to do that and it completely removes any load on the gearbox. You will need to rebuild the pressure plate to be a true pull type pressure plate though but that is above the only complicated bit. It's likely there are plenty of flat bits of block you can tap threads into to support a three or four leg clutch spider. Failing that a push type on the gearbox will also reduce the load it is seeing in this area although your current leaking slave could just be because the casing is flexing and the slave is not running true leading to it nipping the bearing up (depending on what type is used) and therefore rotating the whole assembly and eating the seals.

Few pics below showing general pull type slave/spyder construction, there isn't a lot to it and it's a very simple design to scale up/down as required.

or gearbox mounted like this:

Pull type linear slaves like the one posted above on RalDes are always a pain in the arse as finding a mounting on the opposite side of the clutch fork arm that's stiff enough and in the right position is never a simple task.

Having looked at your readers cars thread and seeing the issue you had with the load of the push type slave cracking the gearbox casing I would look at a pull type mounted on the engine, it looks like there is loads of room in the bell housing to do that and it completely removes any load on the gearbox. You will need to rebuild the pressure plate to be a true pull type pressure plate though but that is above the only complicated bit. It's likely there are plenty of flat bits of block you can tap threads into to support a three or four leg clutch spider. Failing that a push type on the gearbox will also reduce the load it is seeing in this area although your current leaking slave could just be because the casing is flexing and the slave is not running true leading to it nipping the bearing up (depending on what type is used) and therefore rotating the whole assembly and eating the seals.

Few pics below showing general pull type slave/spyder construction, there isn't a lot to it and it's a very simple design to scale up/down as required.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff