S into 9 does go........

Discussion

woolders said:

What we do NOtT have is variable suspension which is more unpredictable as far as I am told .

I am sure that those in the know will comment

I had the CATS system on my old Jaaag... Really didn't like it as there was no switch. You never really knew what the car was doing as it made all the decisions and I never had faith in it. I am sure that those in the know will comment

I like to switch when I choose to

8Tech said:

Hopefully, I can get the Aston suspension system sorted properly. I did have some success with the BMW's?

What do you reckon?

What are you trying to do?What do you reckon?

There are several routes that have already been taken with great success; from the basics of replacing the springs with H&Rs lowering ones to the full magnetorheological damper (and spring) set up that I and a good few others have.

You may not have to reinvent the wheel here

8Tech said:

Cockernee said:

Nice work Gerry, good to see an experienced engineer looking at solutions and sharing with other owners.

How has the handling changed? Any noticeable under or oversteer or just reduced roll?

I have noticed significantly reduced roll but admit to never pushing it far enough to induce under/oversteer yet.How has the handling changed? Any noticeable under or oversteer or just reduced roll?

Given the correct conditions, and plenty of room, I will push harder and harder until one or the other raises its ugly head, or, confirm perfect balance as I hope.

I am now working with 2 of the worlds largest suspension manufacturers to produce springs and damper upgrades. Visiting the design and development sections this Friday actually to start on the designs.

Well Friday was a big success with some perfect results from some very expensive and accurate hardware.

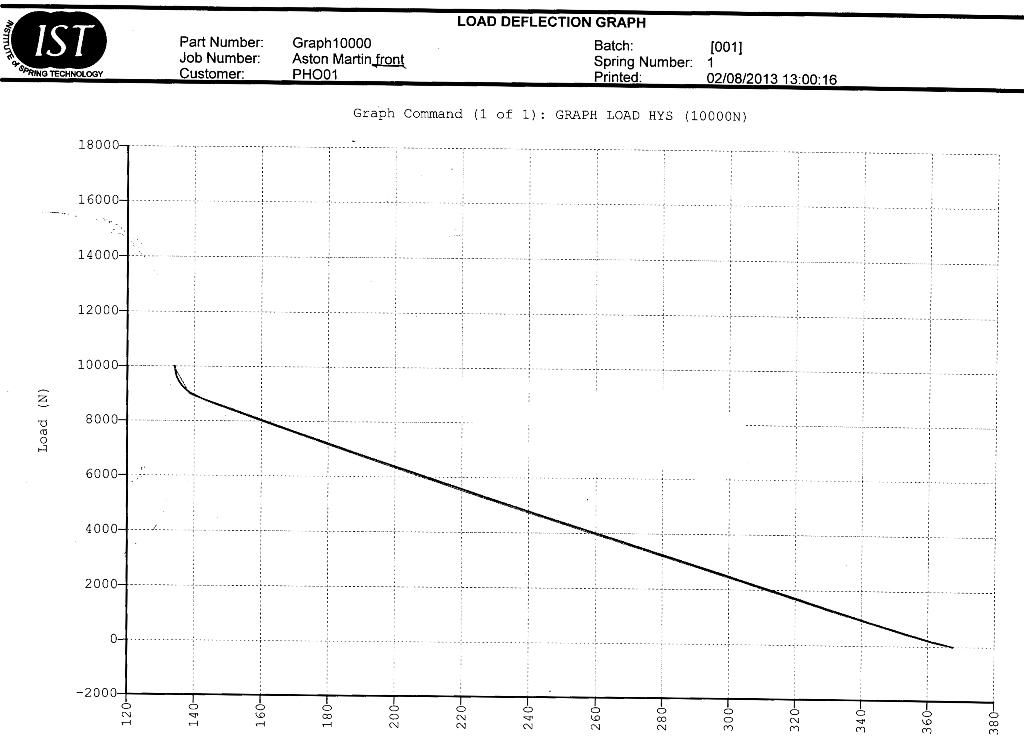

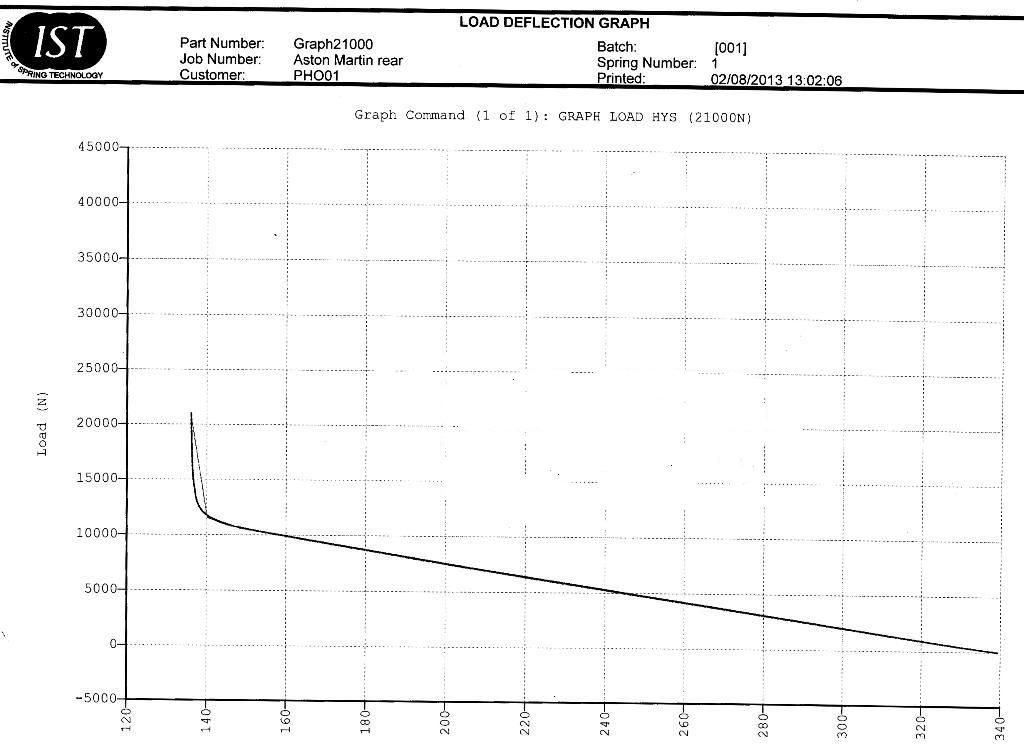

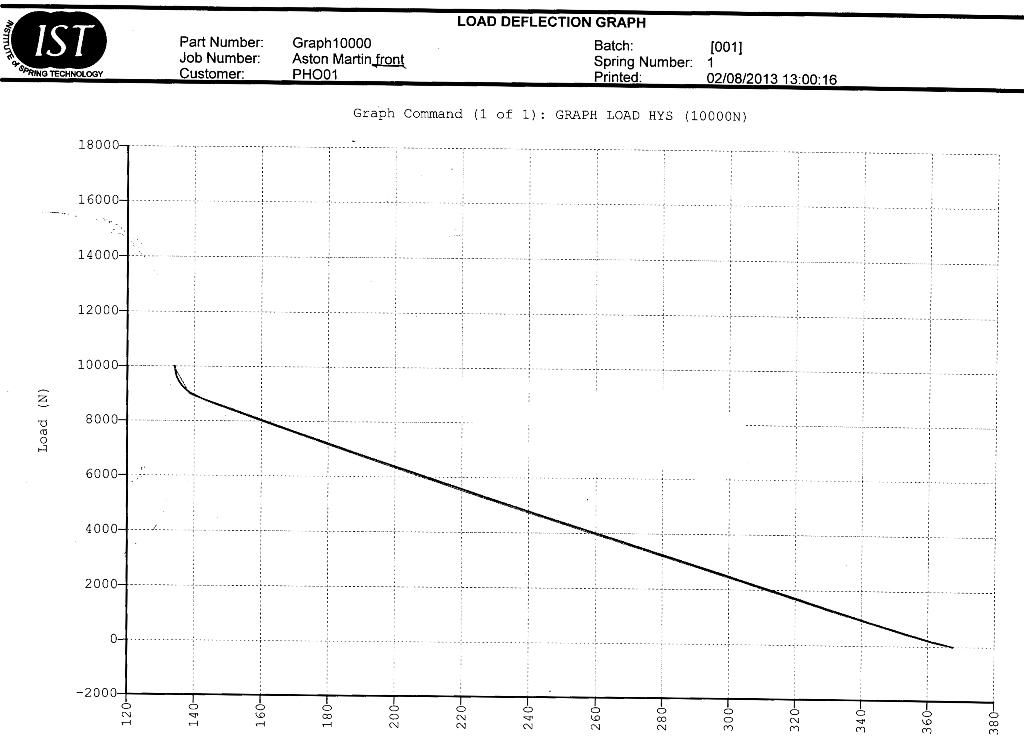

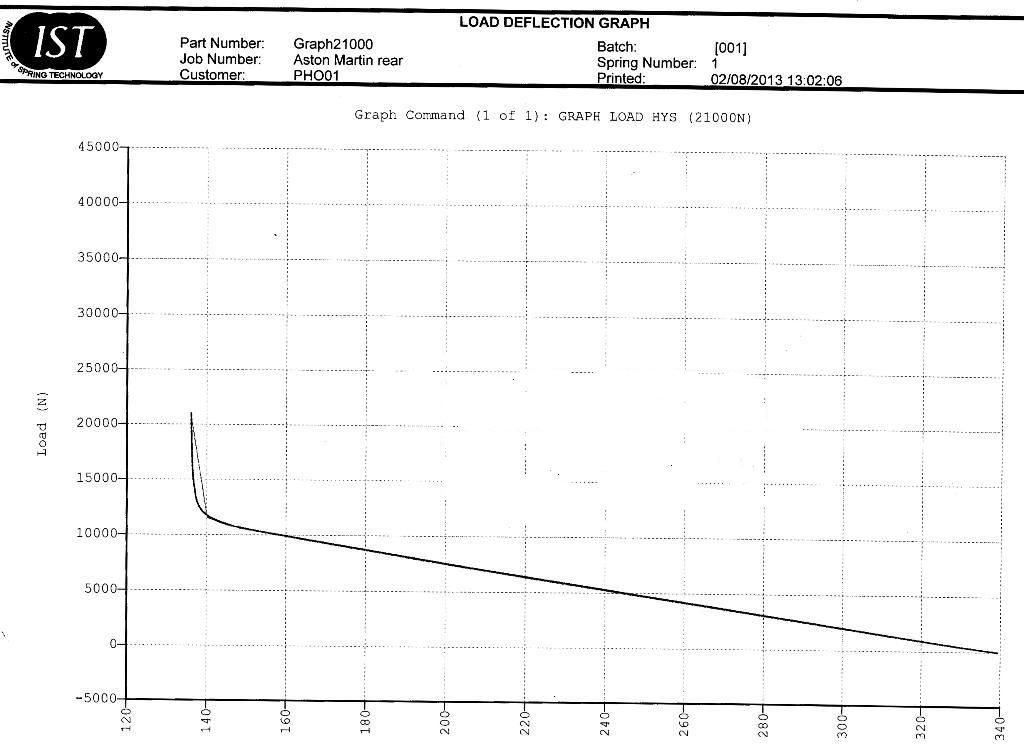

The first point of call was to find out what springs were installed on the DB9 Coupe. I used this as a starting point because that was where Aston based their rates for the Sport Pack springs. We know these were then uprated 63% and 68% for front and rear and extensive testing showed this to be a little too harsh.

However, 63%/68% of what? That was what I needed to find out.

So, removing a set of springs from a DB9 Coupe, I set about finding just what we were starting with.

The equipment used was an IST (Institute of Spring Technology) LT4-30000-3.

http://www.ist.org.uk/spring-load-testers-LT4.php

[pic] [/pic]

[/pic]

I loaded the springs into the computer controlled machine, rod through the middle of the spring is for safety, and the testing was fully automated from there. The spring is compressed to coil bind, and then unloaded until there is no load but the spring is in contact. This gives the machine the range of movement which it then divides into 100 to give a reading of load every 1% of the springs travel.

[poc] [/pic]

[/pic]

The machine then automatically compresses the spring again to coil bind, measuring the load every 1% of travel and then plots a graph of load against reflection.

We can then see both the spring rate at any point plus whether the spring is linear or progressive.

Below are the plots I got from the springs...........

FRONT.......

[pic] [/pic]

[/pic]

REAR.......

[pic] [/pic]

[/pic]

Both of these graphs show a very soft spring rate and I suspect this is designed for maximum comfort rather than performance and would explain partly the need for such large roll bars to control the body as there will be little help from the springs.

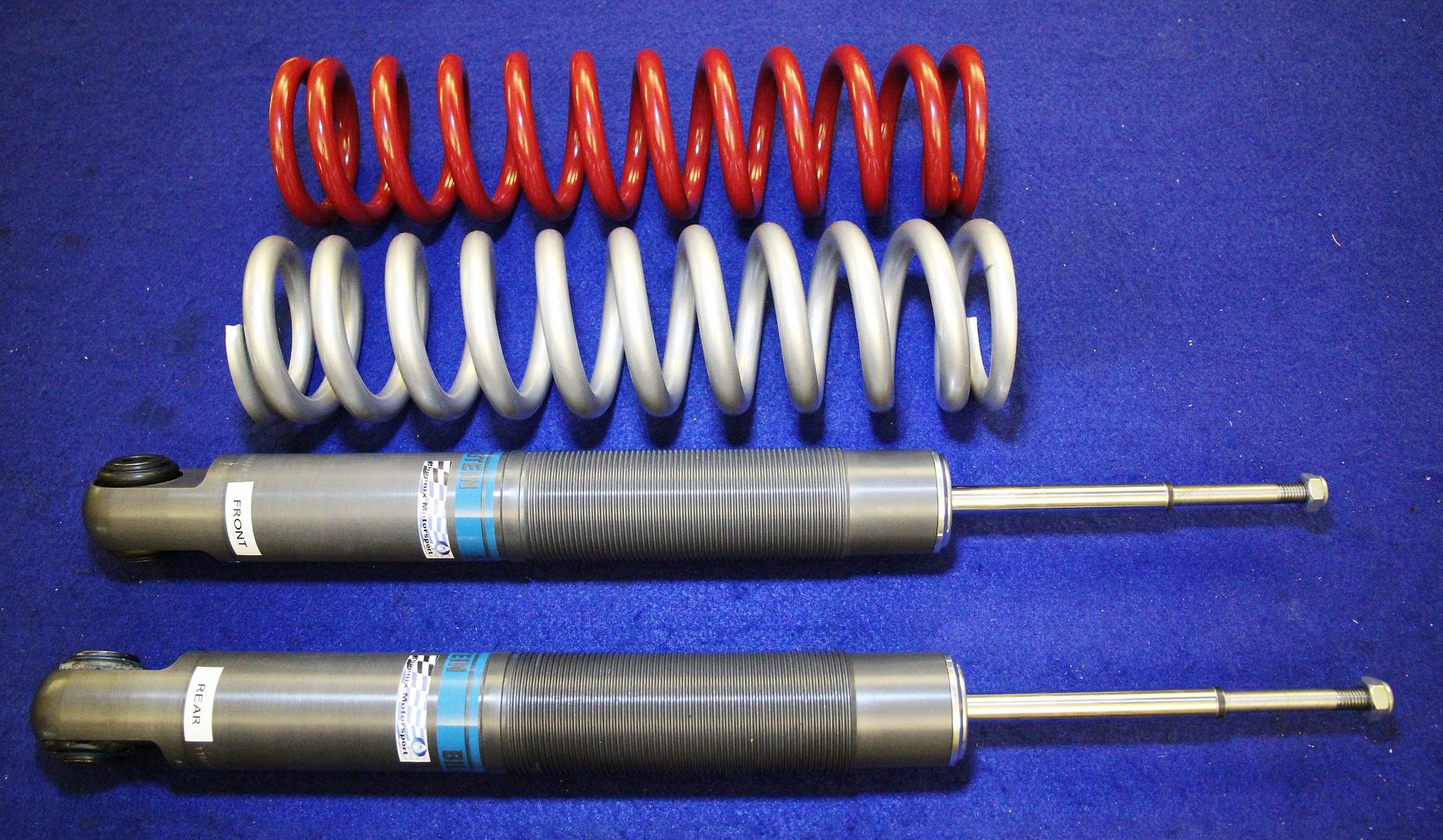

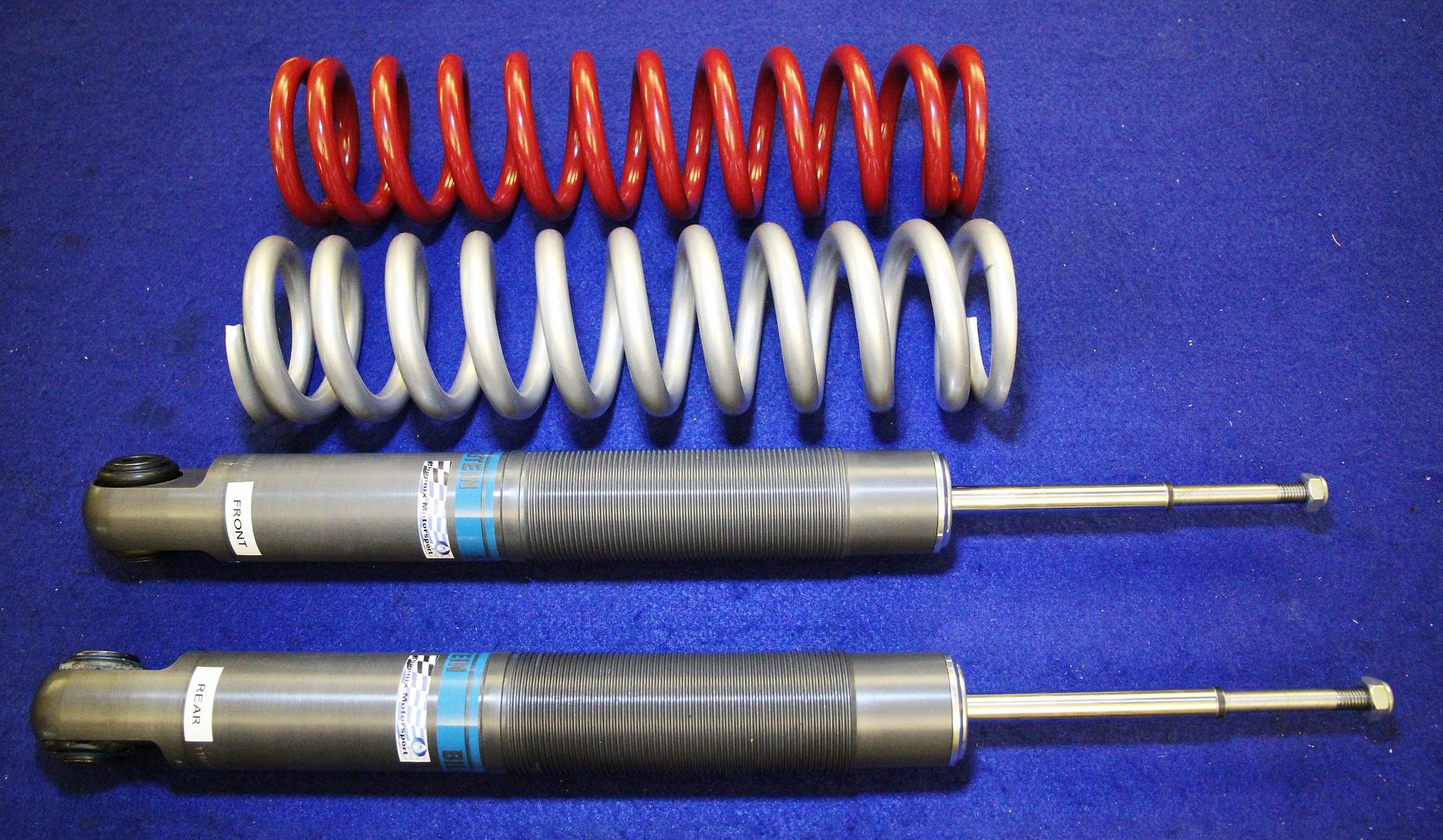

As I will be uprating the springs, it follows that the damper rates will also need to be uprated by a similar amount so I will be using some coilover tubes, seen here on the left against the stock DB9 shock on the right, and building bespoke dampers that will also be adjustable for ride height. Very, very similar to the race shocks from the N24 Vantage Race car.

[pic] [/pic]

[/pic]

Units will be built in around 2 -3 weeks and then after installation, I can start fine tuning from my calculated settings.

Stay "Tuned".

The first point of call was to find out what springs were installed on the DB9 Coupe. I used this as a starting point because that was where Aston based their rates for the Sport Pack springs. We know these were then uprated 63% and 68% for front and rear and extensive testing showed this to be a little too harsh.

However, 63%/68% of what? That was what I needed to find out.

So, removing a set of springs from a DB9 Coupe, I set about finding just what we were starting with.

The equipment used was an IST (Institute of Spring Technology) LT4-30000-3.

http://www.ist.org.uk/spring-load-testers-LT4.php

[pic]

[/pic]

[/pic]I loaded the springs into the computer controlled machine, rod through the middle of the spring is for safety, and the testing was fully automated from there. The spring is compressed to coil bind, and then unloaded until there is no load but the spring is in contact. This gives the machine the range of movement which it then divides into 100 to give a reading of load every 1% of the springs travel.

[poc]

[/pic]

[/pic]The machine then automatically compresses the spring again to coil bind, measuring the load every 1% of travel and then plots a graph of load against reflection.

We can then see both the spring rate at any point plus whether the spring is linear or progressive.

Below are the plots I got from the springs...........

FRONT.......

[pic]

[/pic]

[/pic]REAR.......

[pic]

[/pic]

[/pic]Both of these graphs show a very soft spring rate and I suspect this is designed for maximum comfort rather than performance and would explain partly the need for such large roll bars to control the body as there will be little help from the springs.

As I will be uprating the springs, it follows that the damper rates will also need to be uprated by a similar amount so I will be using some coilover tubes, seen here on the left against the stock DB9 shock on the right, and building bespoke dampers that will also be adjustable for ride height. Very, very similar to the race shocks from the N24 Vantage Race car.

[pic]

[/pic]

[/pic]Units will be built in around 2 -3 weeks and then after installation, I can start fine tuning from my calculated settings.

Stay "Tuned".

Edited by 8Tech on Sunday 4th August 18:16

yeti said:

What are you trying to do?

There are several routes that have already been taken with great success; from the basics of replacing the springs with H&Rs lowering ones to the full magnetorheological damper (and spring) set up that I and a good few others have.

You may not have to reinvent the wheel here

H&R's are double the price they should be, they are really not THAT good.There are several routes that have already been taken with great success; from the basics of replacing the springs with H&Rs lowering ones to the full magnetorheological damper (and spring) set up that I and a good few others have.

You may not have to reinvent the wheel here

I will need to Google your "magnetorheological damper (and spring) set up", because if its the same as the BMW system, then reliability and again cost are really not that attractive.

I am looking for a driver tunable system, bespoke for the function the driver wants from his car.

8Tech said:

yeti said:

What are you trying to do?

There are several routes that have already been taken with great success; from the basics of replacing the springs with H&Rs lowering ones to the full magnetorheological damper (and spring) set up that I and a good few others have.

You may not have to reinvent the wheel here

H&R's are double the price they should be, they are really not THAT good.There are several routes that have already been taken with great success; from the basics of replacing the springs with H&Rs lowering ones to the full magnetorheological damper (and spring) set up that I and a good few others have.

You may not have to reinvent the wheel here

I will need to Google your "magnetorheological damper (and spring) set up", because if its the same as the BMW system, then reliability and again cost are really not that attractive.

I am looking for a driver tunable system, bespoke for the function the driver wants from his car.

not a fan of the magnetic switchable systems (its crap on my Scirroco

not a fan of the magnetic switchable systems (its crap on my Scirroco  )

) I had a set of Nitron tracks with 3 types of adjustment on top of ride height

If you know what you are doing far better

Interesting thread, A.M. didn't omit the rear anti-roll bar and fit a smaller front one to reduced cost, it was more to do with the softer GT brief that the DB9 Volante was designed to meet and also to best mesh with the lower rigidity/longer length of the chassis.

I have been looking into rigidity for the next edition of the guide, Aston are very coy about exact figures, but it is interesting (torsional rigidity is measured by the force in Newton Metres required to flex the structure through 1 degree)...as a guide..........

The original DB9 Volante offered around 15.5 kNm and the DB9 Coupe 27 kNm, while the Volante is still pretty stiff by soft top standards you can see that it is vastly less rigid than the Coupe and prone to scuttle shake, which would be increased with stiffer suspension and roll bars. The Vantage Roadster does feature stiffer suspension and a rear anti-roll (21kNm). In 09 Aston improved the DB9's rigidity and again for DBS, Virage and 13MY DB9 (mainly - but not exclusively - by using various new sheer panels).

In upgrading Yeti's Volante's suspension BR seem to have done a thorough job by ensuring they have added new underbody panels to increase the car's rigidity to best mesh with the new set-up.

I appreciate bodyshell rigidity is only part of the equation, but if you are going to stiffen all the suspension and add thick anti-roll bars, I would recommend talking to BR or an official expert on the correct addition of sheer panels to improve the overall driving dynamics, which I assume is your aim?

I have been looking into rigidity for the next edition of the guide, Aston are very coy about exact figures, but it is interesting (torsional rigidity is measured by the force in Newton Metres required to flex the structure through 1 degree)...as a guide..........

The original DB9 Volante offered around 15.5 kNm and the DB9 Coupe 27 kNm, while the Volante is still pretty stiff by soft top standards you can see that it is vastly less rigid than the Coupe and prone to scuttle shake, which would be increased with stiffer suspension and roll bars. The Vantage Roadster does feature stiffer suspension and a rear anti-roll (21kNm). In 09 Aston improved the DB9's rigidity and again for DBS, Virage and 13MY DB9 (mainly - but not exclusively - by using various new sheer panels).

In upgrading Yeti's Volante's suspension BR seem to have done a thorough job by ensuring they have added new underbody panels to increase the car's rigidity to best mesh with the new set-up.

I appreciate bodyshell rigidity is only part of the equation, but if you are going to stiffen all the suspension and add thick anti-roll bars, I would recommend talking to BR or an official expert on the correct addition of sheer panels to improve the overall driving dynamics, which I assume is your aim?

8Tech said:

As I will be uprating the springs, it follows that the damper rates will also need to be uprated by a similar amount so I will be using some coilover tubes, seen here on the left against the stock DB9 shock on the right, and building bespoke dampers that will also be adjustable for ride height. Very, very similar to the race shocks from the N24 Vantage Race car.

[pic] [/pic]

[/pic]

Units will be built in around 2 -3 weeks and then after installation, I can start fine tuning from my calculated settings.

Stay "Tuned".

HI @8TECH[pic]

[/pic]

[/pic]Units will be built in around 2 -3 weeks and then after installation, I can start fine tuning from my calculated settings.

Stay "Tuned".

Edited by 8Tech on Sunday 4th August 18:16

Can you clarify if you mean the left "coilver tube" is the threaded sleeve, or the the actual whole unit? i.e is the damper a bilestein insert into the strut tube?

The reason I ask is, I was going to fit a coilver "sleeve kit" for height adjustment to some 2nd hand DBS damper/Spring units. However if the damper is an insert, then I could get some Bilstein damptronic damper inserts.. rather than buying 2nd hand DBS complete units and re-valving etc (as I hear the DBS units are Bilsteins).

The Bilstein Coilover "sleeve" i was thinking of using:

http://www.summitracing.com/parts/bsn-b4boa0000117...

interestng to see how you came up with the treaded body, as to me it looks like the strut itself is threaded rather than using a sleeve..

Hello Sydney,

Firstly, thanks for showing some interest in the project. You are clearly looking along the same lines as I did originally, so to hopefully assist you in making your own decision, I can save you some time and effort with the following info.

Here we have a stripped standard front strut, the stock lower seat collar and a 2.25" ID spring sleeve similar to that you indicated from Summit.

[pic] [/pic]

[/pic]

The sleeve for the 2.25" ID spring has an ID of 50.6mm so that it will sleeve over a 2.0" strut body. However, the strut has an OD of 51.66 mm and this is far too much for an interfearance fit. The sleeve is designed to either weld to the strut body or use the spring preload to hold it in position on an internal step at the top of the sleeve.

The strut body then tapers out to 54mm below the original spring seat that is held in position on the taper and a circlip as shown on the pic. FYI, the circlip is 116 mm down the strut body.

My best design, which I decided not to proceed with, was a sleeve made with the internal profile to match the external profile of the original strut body, with a press fit interfearance. The external thread could then be cut into that sleeve. This will also be the lightest option and would reinforce the strut tube.

The reason I never moved forward with this was that I wanted to have adjustable damping and the design really only gave ride height and spring rate options. feel free to go with that design though.

Your other issue is the top mount, if being reused...............

[pic] [/pic]

[/pic]

has a sloped/stepped seat because the OEM spring is flat ground at the bottom and stepped at the top. Almost all aftermarket racing springs are ground flat both ends. (the rubber seat from the top mount is not shown but is stepped the same).

It is easy enough to machine the top mount flat without losing any strength, but you cannot install a 2.25" spring on these struts, you need to go to a 2.5" spring. This gives you the problem of finding a 2.5" sleeve kit or making it yourself.

You cannot really use the top collars that come with the kits because of the 3 stud fixing on the Aston strut top and fitting the supplied collar under the original mount reduces the strut travel excessively.

The original dampers will then need to be revalved for you to suit your spring choice. It is not easily possible to get the metric spring sizes fitted to the OEM struts in appropriate rates, and certainly no sleeves.

My solution is proper threaded strut bodies, not sleeves, to be built up with Bespoke inserts.

Feel free to use my graphs of the OEM spring rates to select your preferred springs.

Hope that helps.

8Tech.

Firstly, thanks for showing some interest in the project. You are clearly looking along the same lines as I did originally, so to hopefully assist you in making your own decision, I can save you some time and effort with the following info.

Here we have a stripped standard front strut, the stock lower seat collar and a 2.25" ID spring sleeve similar to that you indicated from Summit.

[pic]

[/pic]

[/pic]The sleeve for the 2.25" ID spring has an ID of 50.6mm so that it will sleeve over a 2.0" strut body. However, the strut has an OD of 51.66 mm and this is far too much for an interfearance fit. The sleeve is designed to either weld to the strut body or use the spring preload to hold it in position on an internal step at the top of the sleeve.

The strut body then tapers out to 54mm below the original spring seat that is held in position on the taper and a circlip as shown on the pic. FYI, the circlip is 116 mm down the strut body.

My best design, which I decided not to proceed with, was a sleeve made with the internal profile to match the external profile of the original strut body, with a press fit interfearance. The external thread could then be cut into that sleeve. This will also be the lightest option and would reinforce the strut tube.

The reason I never moved forward with this was that I wanted to have adjustable damping and the design really only gave ride height and spring rate options. feel free to go with that design though.

Your other issue is the top mount, if being reused...............

[pic]

[/pic]

[/pic]has a sloped/stepped seat because the OEM spring is flat ground at the bottom and stepped at the top. Almost all aftermarket racing springs are ground flat both ends. (the rubber seat from the top mount is not shown but is stepped the same).

It is easy enough to machine the top mount flat without losing any strength, but you cannot install a 2.25" spring on these struts, you need to go to a 2.5" spring. This gives you the problem of finding a 2.5" sleeve kit or making it yourself.

You cannot really use the top collars that come with the kits because of the 3 stud fixing on the Aston strut top and fitting the supplied collar under the original mount reduces the strut travel excessively.

The original dampers will then need to be revalved for you to suit your spring choice. It is not easily possible to get the metric spring sizes fitted to the OEM struts in appropriate rates, and certainly no sleeves.

My solution is proper threaded strut bodies, not sleeves, to be built up with Bespoke inserts.

Feel free to use my graphs of the OEM spring rates to select your preferred springs.

Hope that helps.

8Tech.

Edited by 8Tech on Sunday 18th August 12:43

8Tech said:

Hello Sydney,

Firstly, thanks for showing some interest in the project. You are clearly looking along the same lines as I did originally, so to hopefully assist you in making your own decision, I can save you some time and effort with the following info.

Here we have a stripped standard front strut, the stock lower seat collar and a 2.25" ID spring sleeve similar to that you indicated from Summit.

[pic] [/pic]

[/pic]

The sleeve for the 2.25" ID spring has an ID of 50.6mm so that it will sleeve over a 2.0" strut body. However, the strut has an OD of 51.66 mm and this is far too much for an interfearance fit. The sleeve is designed to either weld to the strut body or use the spring preload to hold it in position on an internal step at the top of the sleeve.

The strut body then tapers out to 54mm below the original spring seat that is held in position on the taper and a circlip as shown on the pic. FYI, the circlip is 116 mm down the strut body.

My best design, which I decided not to proceed with, was a sleeve made with the internal profile to match the external profile of the original strut body, with a press fit interfearance. The external thread could then be cut into that sleeve. This will also be the lightest option and would reinforce the strut tube.

The reason I never moved forward with this was that I wanted to have adjustable damping and the design really only gave ride height and spring rate options. feel free to go with that design though.

Your other issue is the top mount, if being reused...............

[pic] [/pic]

[/pic]

has a sloped/stepped seat because the OEM spring is flat ground at the bottom and stepped at the top. Almost all aftermarket racing springs are ground flat both ends. (the rubber seat from the top mount is not shown but is stepped the same).

It is easy enough to machine the top mount flat without losing any strength, but you cannot install a 2.25" spring on these struts, you need to go to a 2.5" spring. This gives you the problem of finding a 2.5" sleeve kit or making it yourself.

You cannot really use the top collars that come with the kits because of the 3 stud fixing on the Aston strut top and fitting the supplied collar under the original mount reduces the strut travel excessively.

The original dampers will then need to be revalved for you to suit your spring choice. It is not easily possible to get the metric spring sizes fitted to the OEM struts in appropriate rates, and certainly no sleeves.

My solution is proper threaded strut bodies, not sleeves, to be built up with Bespoke inserts.

Feel free to use my graphs of the OEM spring rates to select your preferred springs.

Hope that helps.

8Tech.

That was a BLOODY USEFUL post!! Thanks!Firstly, thanks for showing some interest in the project. You are clearly looking along the same lines as I did originally, so to hopefully assist you in making your own decision, I can save you some time and effort with the following info.

Here we have a stripped standard front strut, the stock lower seat collar and a 2.25" ID spring sleeve similar to that you indicated from Summit.

[pic]

[/pic]

[/pic]The sleeve for the 2.25" ID spring has an ID of 50.6mm so that it will sleeve over a 2.0" strut body. However, the strut has an OD of 51.66 mm and this is far too much for an interfearance fit. The sleeve is designed to either weld to the strut body or use the spring preload to hold it in position on an internal step at the top of the sleeve.

The strut body then tapers out to 54mm below the original spring seat that is held in position on the taper and a circlip as shown on the pic. FYI, the circlip is 116 mm down the strut body.

My best design, which I decided not to proceed with, was a sleeve made with the internal profile to match the external profile of the original strut body, with a press fit interfearance. The external thread could then be cut into that sleeve. This will also be the lightest option and would reinforce the strut tube.

The reason I never moved forward with this was that I wanted to have adjustable damping and the design really only gave ride height and spring rate options. feel free to go with that design though.

Your other issue is the top mount, if being reused...............

[pic]

[/pic]

[/pic]has a sloped/stepped seat because the OEM spring is flat ground at the bottom and stepped at the top. Almost all aftermarket racing springs are ground flat both ends. (the rubber seat from the top mount is not shown but is stepped the same).

It is easy enough to machine the top mount flat without losing any strength, but you cannot install a 2.25" spring on these struts, you need to go to a 2.5" spring. This gives you the problem of finding a 2.5" sleeve kit or making it yourself.

You cannot really use the top collars that come with the kits because of the 3 stud fixing on the Aston strut top and fitting the supplied collar under the original mount reduces the strut travel excessively.

The original dampers will then need to be revalved for you to suit your spring choice. It is not easily possible to get the metric spring sizes fitted to the OEM struts in appropriate rates, and certainly no sleeves.

My solution is proper threaded strut bodies, not sleeves, to be built up with Bespoke inserts.

Feel free to use my graphs of the OEM spring rates to select your preferred springs.

Hope that helps.

8Tech.

Edited by 8Tech on Sunday 18th August 12:43

So from that I take it the standard strut does not have an insert? So basically the better method is in fact a threaded strut, with new bilstein damptronic insert..

next stupid question from me would be, are you making an extra set of threaded struts? LOL

8Tech said:

If the design works, and I get everything set up properly, then yes, I will offer the struts as available.

ok, great, as the 2.5" sleeve is easily obtainable, doesn't work for me as the hydraulic lift kit I want to use for the front only works with a 2-2.23" strut... (as in the maximum width of the threaded section is would have to be 2.22-2.23").So, as promised, we have an update.

I now have the Eibach ERS (Eibach Race System) springs in my choice of length and rate as I have calculated. I now have the new coil-over strut bodies built and valved to suit the mass of the car and the spring rates to give a suitable suspension frequency.

[pic] [/pic]

[/pic]

Over the next week, I will be fabricating the upper and lower spring seats and making some Delrin washers to isolate the springs against the seats to make on-vehicle adjustments easier and to locate the upper seat more precisely. I have ordered some original gaiters and bump-stops for now but will upgrade to closed cell bumpstops as soon as I have the final size I will need.

I suppose I could have waited until they were all done but getting these components on hand was a milestone I wanted to share.

I will post again on the final assembly of the units.

The test then will be the seat-of-the-pants road test to see how far out my calculations are!

8Tech

I now have the Eibach ERS (Eibach Race System) springs in my choice of length and rate as I have calculated. I now have the new coil-over strut bodies built and valved to suit the mass of the car and the spring rates to give a suitable suspension frequency.

[pic]

[/pic]

[/pic]Over the next week, I will be fabricating the upper and lower spring seats and making some Delrin washers to isolate the springs against the seats to make on-vehicle adjustments easier and to locate the upper seat more precisely. I have ordered some original gaiters and bump-stops for now but will upgrade to closed cell bumpstops as soon as I have the final size I will need.

I suppose I could have waited until they were all done but getting these components on hand was a milestone I wanted to share.

I will post again on the final assembly of the units.

The test then will be the seat-of-the-pants road test to see how far out my calculations are!

8Tech

Hey guys,

I am here to try and give some informative postings and if there is anything you would like me to try and explain a little more in depth, please ask.

I am sure there will be plenty more owners trying to understand what I am doing and why so please, just ask because I don't want to babble on explaining what I am doing if it makes a tedious read.

Cheers,

8Tech.

I am here to try and give some informative postings and if there is anything you would like me to try and explain a little more in depth, please ask.

I am sure there will be plenty more owners trying to understand what I am doing and why so please, just ask because I don't want to babble on explaining what I am doing if it makes a tedious read.

Cheers,

8Tech.

SydneySE said:

ok, great, as the 2.5" sleeve is easily obtainable, doesn't work for me as the hydraulic lift kit I want to use...

Hello Sydney. Are you trying to build out a driver adjustable front lift system like that on a Gallardo or some 911s - so the driver can click a button and raise the nose to get round speed bumps and whatever?

Gassing Station | Aston Martin | Top of Page | What's New | My Stuff