Moto Guzzi Cali Cafe Racer Build thread

Discussion

MotorsportTom said:

Everytime I see this thread it just gets better.

IMO paint it black with the fins highlighted to match the rest.

Good luck with the rest I can't wait to see the completed article

As above, copy the detail from the regulator, when you finish the bike, let us all of us know where your maiden voyage will be and who's cutting the ribbon and we will all come along and cheer you on. Fantastic job.IMO paint it black with the fins highlighted to match the rest.

Good luck with the rest I can't wait to see the completed article

Bit more progress..

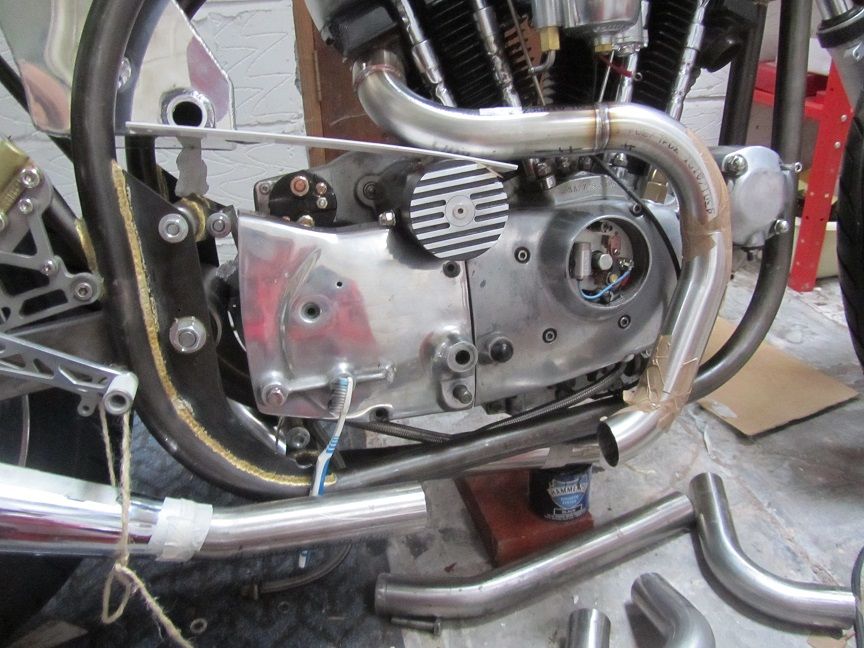

Painted the starter cover to match the regulator, I should've made it a few mm deeper, but got away with the mistake by making a new mounting bracket which you cant see..

The rear wheel spacers are done now, along with the brake caliper mount and alloy torque arm (with stainless clevis joints). Jeff wouldn't let me 'borrow' some of his precious stock of Ti for the wheel spacers, so we used stainless instead and lost a bit of weight by cross drilling them..

Also fitted a hard anodised alloy sprocket, had to be specially ordered from Renthal as it isn't a std part..

Painted the starter cover to match the regulator, I should've made it a few mm deeper, but got away with the mistake by making a new mounting bracket which you cant see..

The rear wheel spacers are done now, along with the brake caliper mount and alloy torque arm (with stainless clevis joints). Jeff wouldn't let me 'borrow' some of his precious stock of Ti for the wheel spacers, so we used stainless instead and lost a bit of weight by cross drilling them..

Also fitted a hard anodised alloy sprocket, had to be specially ordered from Renthal as it isn't a std part..

Thanks for the comments, the next task is to make an exhaust system, but that has to wait until mid July when I have the spare cash to buy the stainless tubing it'll need. In the meantime, there are lots of small jobs to do, like losing some weight.. a whole 6 grams per sprocket bolt from machining the bolt heads

Now for something a bit different, this isn't one of my projects, but I do have an interest in it...Last year my mate Tim (who owns the local bike shop with the dyno), asked me to help him find a bike as the basis for a winter project. Since I have plenty of time on my hands these days, I agreed, though I was surprised when he told me what bike he was looking for... a Harley XL883, as they normally work on jap stuff. I tracked down a suitable bike, 883 with a 5speed box and chain drive, ran well and I knew the owner, all for a bargain price. Tim bought it put it to one side as he was too busy to work on it during last summer.

Since he runs a dyno, it was no surprise when Tim told me the engine was going to get a big bore kit, cams, carb and so on and added he didn't want to spend too much on it.. well, we'll see I thought to myself lol.. this is a rough idea of what he was aiming for...

By this time I'd got my old ironhead, and I joked that his 883 may end up more powerful than mine, but mine would be far cooler .. Tim must have been watching too much Discovery channel, as he suggested we should have our very own mini 'biker build off'.. hardly a fair match I said, you've got a fully equipped workshop and access to parts at wholesale prices.. but then again, why not...

With a change of tank and a RS125 seat, looks really different already..

It didn't take long for his budget to go out of the window, as he's just got a new alloy swing arm, gsxr K9 forks and a pair of remote reservoir progressive shocks. Then again he's changed his mind about the look, he's now going for a semi flat tracker / super motard styley.. with 17inch wheels..

Since he runs a dyno, it was no surprise when Tim told me the engine was going to get a big bore kit, cams, carb and so on and added he didn't want to spend too much on it.. well, we'll see I thought to myself lol.. this is a rough idea of what he was aiming for...

By this time I'd got my old ironhead, and I joked that his 883 may end up more powerful than mine, but mine would be far cooler .. Tim must have been watching too much Discovery channel, as he suggested we should have our very own mini 'biker build off'.. hardly a fair match I said, you've got a fully equipped workshop and access to parts at wholesale prices.. but then again, why not...

With a change of tank and a RS125 seat, looks really different already..

It didn't take long for his budget to go out of the window, as he's just got a new alloy swing arm, gsxr K9 forks and a pair of remote reservoir progressive shocks. Then again he's changed his mind about the look, he's now going for a semi flat tracker / super motard styley.. with 17inch wheels..

Edited by Merch131 on Sunday 4th August 22:58

This is how it looks now... One off yokes, GSXR USD forks, 17inch KTM front wheel, rear HD hub build up with another 17 inch rim, Metchemex swing arm, fancy shocks. It had a RSD exhaust but he didn't like it, so its getting a one off system which will take up some of the space where the oil tank lives, so that's being moved too. sorry for the crappy pic..

Not much progress with the Ironhead, almost finished the motor mount, just got to make the mount for the ignition key and polish it. In the meantime picked up this 2 inch SU carb with separate float bowl. They used to be ten a penny but they're getting rarer now, especially in good condition. This one needs a good clean but its hardly worn, so should be about the right size to feed the superchargered Evo 2ltr motor. I could go injected but that adds complexity that for now we don't need, at least until everything is running ok.

Time to sort out a stainless exhaust system. I know what I want, the problem is finding somewhere to make it to a good standard at a fair price. Another problem is getting the bike to the exhaust maker, wherever that may be. Fortunately my mate Tim was getting to the same stage with his HD XL scrambler, so we agreed I'd find somewhere and we'd take both bikes in his van.

I liked the work of OJZ engineering, but they were busy for a couple of months ahead, and quoted me approx. £700 to make the system I wanted. That's not too bad for a custom system, but I kept looking.

I'd seen a lovely system on a trick RD350, which came from a place in York. I called and was quoted £400 to make a system.. that's better....Northern prices! He asked me to email some pics of the bikes and what we wanted, which I did the same day. Never had a reply.. so that's a fail in my book.

With the hassles of getting the bikes to a specialist.. taking them, wait for the systems to be made, then another day lost to collect the bikes..hoping they'd done what we wanted, I suggested we made our own. So that's what we're going to do.

Yesterday I took a trip to Macclesfield to JP exhausts, who were very helpful and let me take my pick of their stock of 1 3/4 inch stainless bends and tubing. I came home with 4m of straight tubing and a good mix of bends which I hope will be more than enough for two systems.. total cost £108 plus vat..

I'm away next week, so I left the lot at Tim's bike shop, he reckons by the time I get back his will be done ..

I liked the work of OJZ engineering, but they were busy for a couple of months ahead, and quoted me approx. £700 to make the system I wanted. That's not too bad for a custom system, but I kept looking.

I'd seen a lovely system on a trick RD350, which came from a place in York. I called and was quoted £400 to make a system.. that's better....Northern prices! He asked me to email some pics of the bikes and what we wanted, which I did the same day. Never had a reply.. so that's a fail in my book.

With the hassles of getting the bikes to a specialist.. taking them, wait for the systems to be made, then another day lost to collect the bikes..hoping they'd done what we wanted, I suggested we made our own. So that's what we're going to do.

Yesterday I took a trip to Macclesfield to JP exhausts, who were very helpful and let me take my pick of their stock of 1 3/4 inch stainless bends and tubing. I came home with 4m of straight tubing and a good mix of bends which I hope will be more than enough for two systems.. total cost £108 plus vat..

I'm away next week, so I left the lot at Tim's bike shop, he reckons by the time I get back his will be done ..

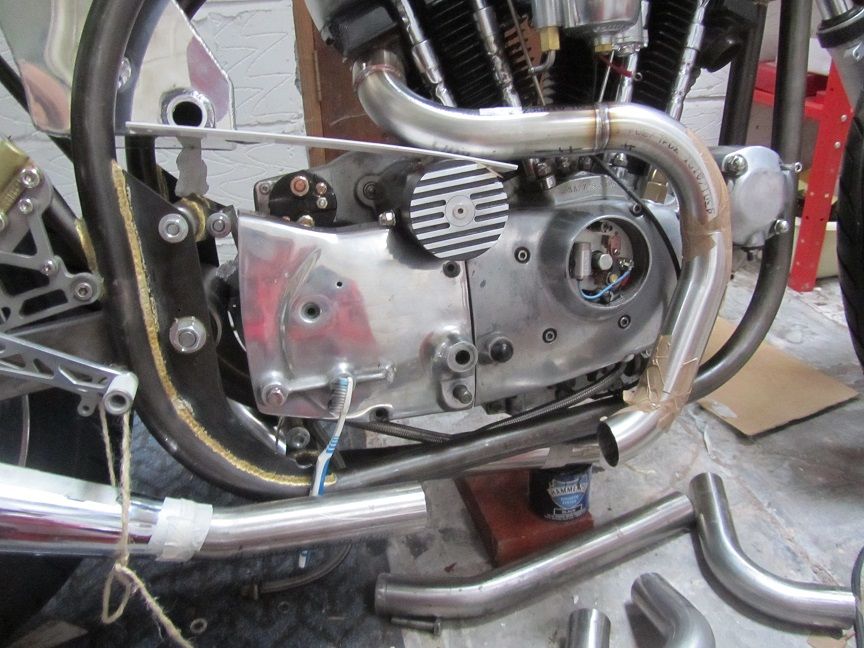

The exhaust is pretty much done, though still needs to be polished, and one pipe under engine needs to be expanded to give me a slip joint. I'll get a couple hooks welded on and use exhaust springs to hold it together next week. And the brackets holding the silencers are temporary, now I know how long they should be, I'll make a new neater pair..

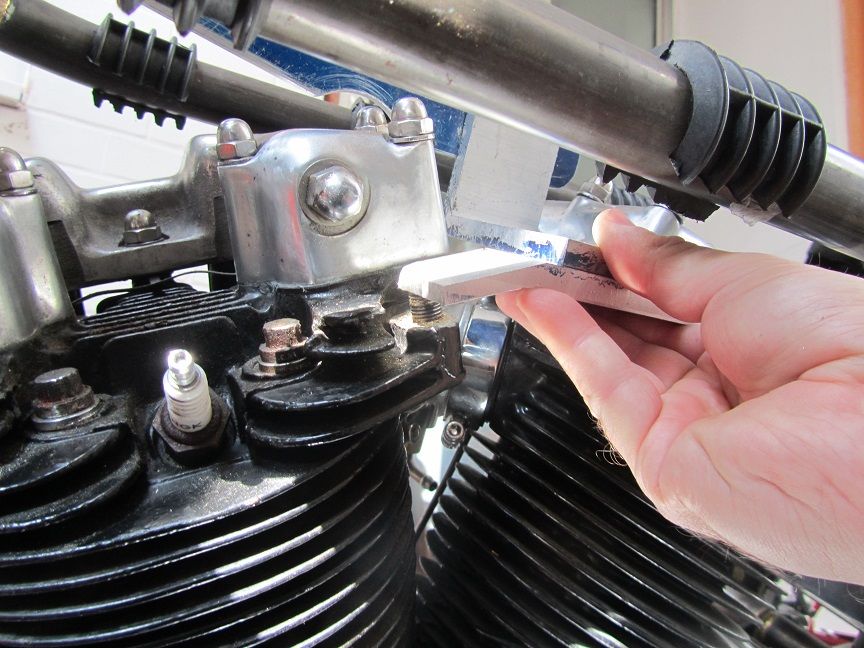

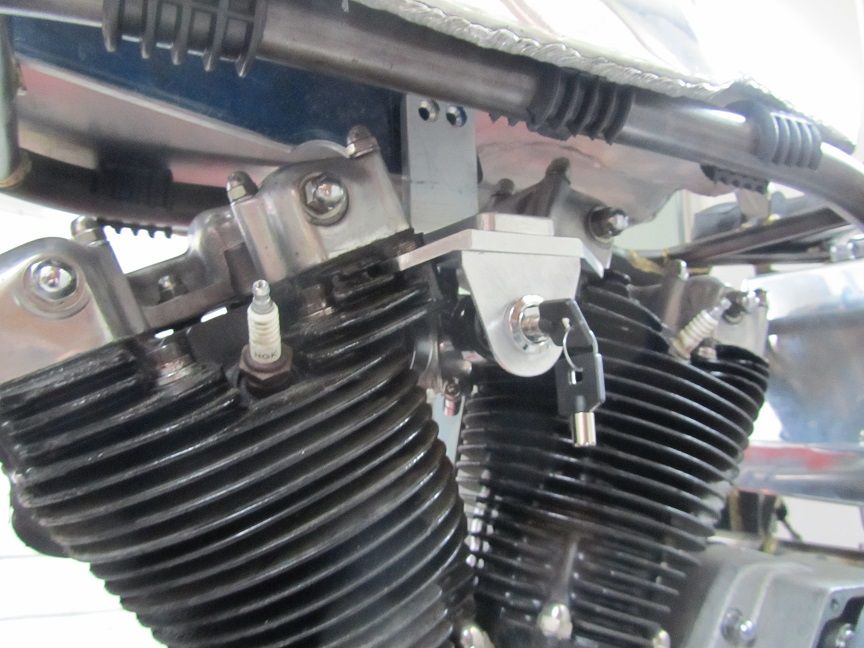

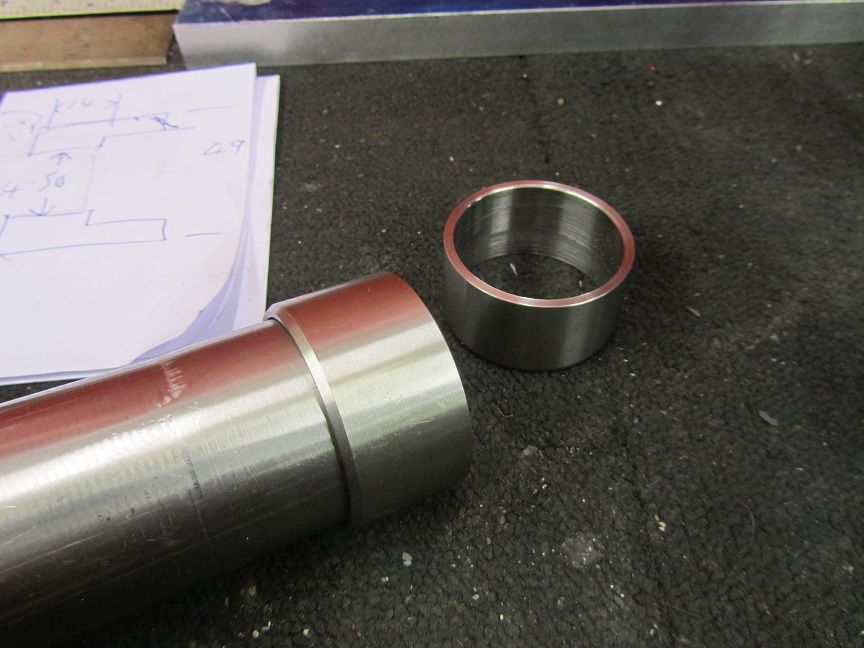

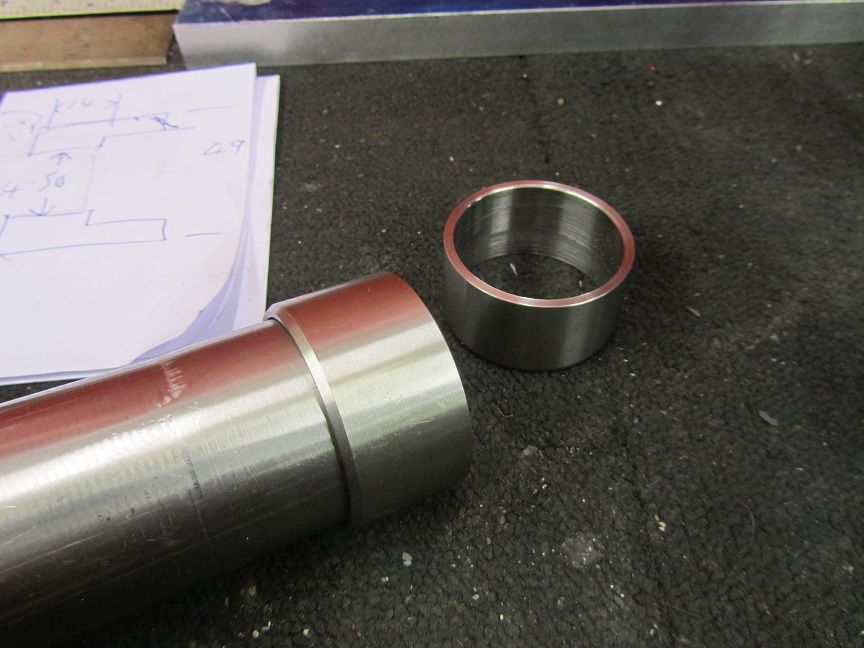

Last week my mate Tim gave me the remaining stainless bends left over from his build to get me started. The first problem was that the tubing wouldn't slide over the exhaust stubs on the heads. The tubes would need to be expanded. But I didn't know which tubes I'd end up using, and nearest place I knew that could expand the 16 gauge tubing was a 60 mile round trip. So we made two collars which would be welded on the end of the headers (when I'd worked out which tubing to use). They were machined with an internal step, so they'd be a snug fit on the tubing and the exhaust stub..

Another problem I had was that some of the bends I had to cut were deformed, which would've made welding them to a straight piece look awful, so they were binned..

Some bends were deformed when cut in half..

Using the good bends I did have, I could've gone for this option, as it involved a minimum of welded joints..

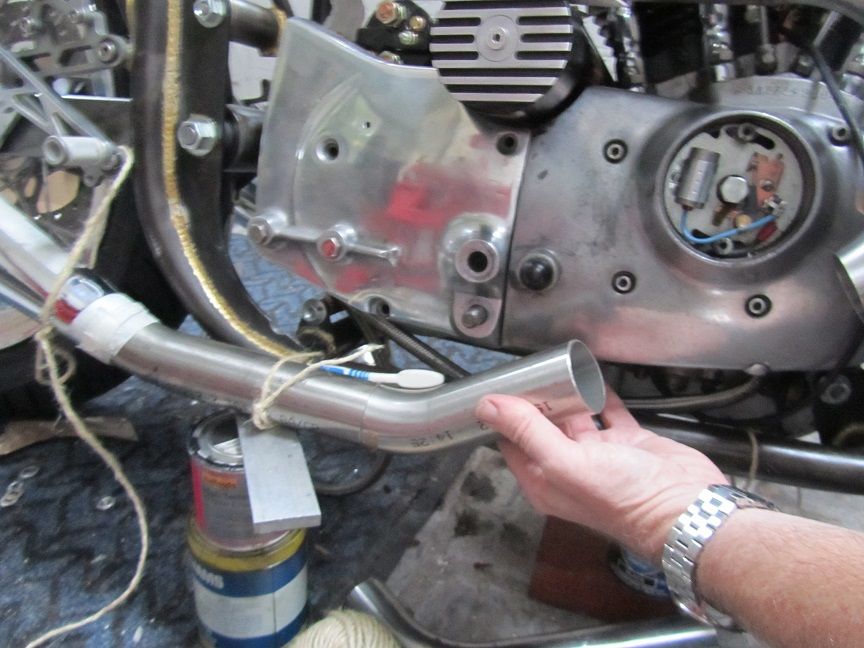

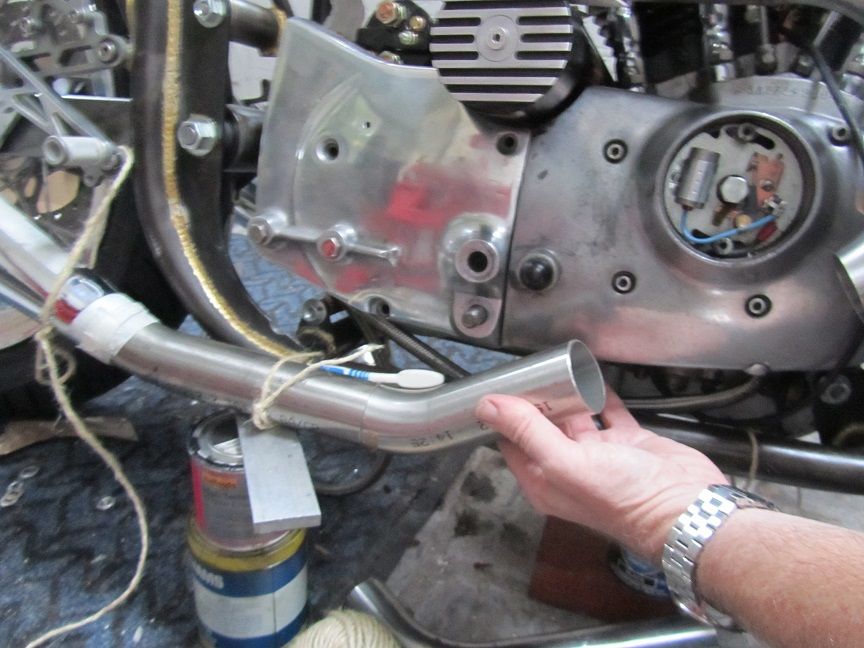

But it didn't look quite right, so I tried again and came up with this instead.. note all the string, tape and even an old tooth brush I used to hold everything in place, it was tricky with just one pair of hands

A few more trips back to the welder and its done.. It would've been better if the megas were a little higher and tilted up, but the gearchange linkage means this is as far as they could go on the left and the right hand side had to mirror the left..

Last week my mate Tim gave me the remaining stainless bends left over from his build to get me started. The first problem was that the tubing wouldn't slide over the exhaust stubs on the heads. The tubes would need to be expanded. But I didn't know which tubes I'd end up using, and nearest place I knew that could expand the 16 gauge tubing was a 60 mile round trip. So we made two collars which would be welded on the end of the headers (when I'd worked out which tubing to use). They were machined with an internal step, so they'd be a snug fit on the tubing and the exhaust stub..

Another problem I had was that some of the bends I had to cut were deformed, which would've made welding them to a straight piece look awful, so they were binned..

Some bends were deformed when cut in half..

Using the good bends I did have, I could've gone for this option, as it involved a minimum of welded joints..

But it didn't look quite right, so I tried again and came up with this instead.. note all the string, tape and even an old tooth brush I used to hold everything in place, it was tricky with just one pair of hands

A few more trips back to the welder and its done.. It would've been better if the megas were a little higher and tilted up, but the gearchange linkage means this is as far as they could go on the left and the right hand side had to mirror the left..

Edited by Merch131 on Friday 8th November 16:42

Edited by Merch131 on Friday 8th November 16:54

I've spent far too many hours trying to get the exhaust system how I wanted, with the two megas at the same height and angle. With the last piece welded, I stood back and had to admit to myself it wasn't right. So the back half of the downpipes have been cut up, to be redone with the megas tilted up more. But first had to move the rear sets forward and out of the way, as they were too far back. So I made a couple of simple test plates with a few mounting holes, so I could try different peg positions. The final version will be much neater, made from 15mm alloy plate, so the frame mounting bolts can be countersunk while the plate will be tapped to take the rear set bolts. Its only moved the pegs 40mm, but it feels much better, and gives the clearance I need for the megas, and to ensure the LHS downpipe isn't too low where it turns out and up from the under engine.

Gassing Station | Biker Banter | Top of Page | What's New | My Stuff