Moto Guzzi Cali Cafe Racer Build thread

Discussion

While I wait for a few parts to arrive, time for some arty farty stuff. I wanted to add some sort of logo or image to the points cover. After some thought, I decided on the simple Norley logo, and used a scribe and ink to mark it on to the cover. I did a test on the back of the cover, trying to carve the letters into the alloy using my trusty Dremel. Then trying again this time carving away the spaces around the letters to leave them standing proud. The second option seemed the easiest, so that's what I went for. If it turned out cr*p I could always skim it smooth again, or make a new cover..

Had to finally think about the dreaded electrics. I hate electrics, dunno why, just never bothered with it. Made a start by replacing the points ignition with a single fire electronic 'in cone' ignition. Wasn't too difficult once I'd got my head around the instructions. Spent along time working out the wiring diagram, think I've got something that will work, now waiting on a delivery of wires, connectors, heat shrink and relays..

I settled on the type of oil line to use.. braided steel and those lovely blue and red anodised fittings would usually be my default choice, but that was too modern, while simple black nitrile hosing seemed a little too plain and low rent. So I went for over braided nitrile tubing with stainless clamps.

The oil filter mount placed the oil lines too close the chain for comfort, so it was modified to angle the lines down to clear the chain. Its a bodge for now, using a short bracket with the original billet mounting plate, its something I'll revisit another time.

With the oil lines done, that allowed the sprocket cover to be fitted (left it undrilled for now), and the exhaust which needed some last minute work to give more clearance from the frame tubes. The front pipe is still close to the down tubes, but should be ok.

Still being held up waiting for the promised brake lines, but getting them at mates rates so shouldn't really complain.

Here's a short vid I took this evening, in a couple of weeks hope to have it running at last.

http://youtu.be/SE-o0zMiv7E

I settled on the type of oil line to use.. braided steel and those lovely blue and red anodised fittings would usually be my default choice, but that was too modern, while simple black nitrile hosing seemed a little too plain and low rent. So I went for over braided nitrile tubing with stainless clamps.

The oil filter mount placed the oil lines too close the chain for comfort, so it was modified to angle the lines down to clear the chain. Its a bodge for now, using a short bracket with the original billet mounting plate, its something I'll revisit another time.

With the oil lines done, that allowed the sprocket cover to be fitted (left it undrilled for now), and the exhaust which needed some last minute work to give more clearance from the frame tubes. The front pipe is still close to the down tubes, but should be ok.

Still being held up waiting for the promised brake lines, but getting them at mates rates so shouldn't really complain.

Here's a short vid I took this evening, in a couple of weeks hope to have it running at last.

http://youtu.be/SE-o0zMiv7E

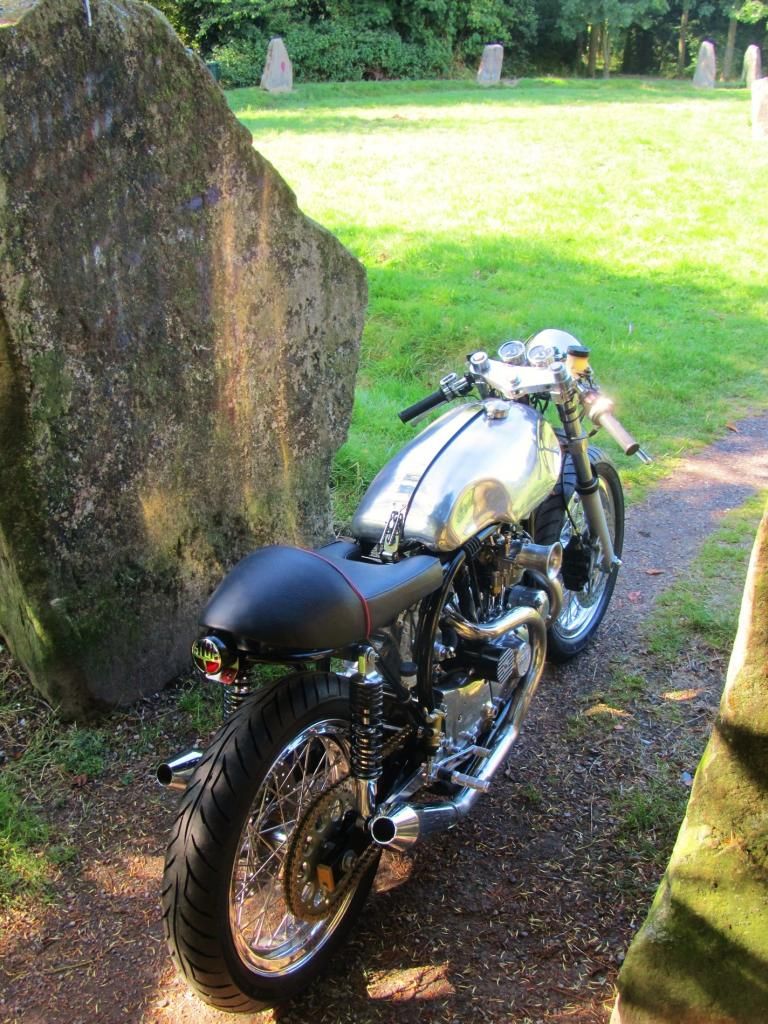

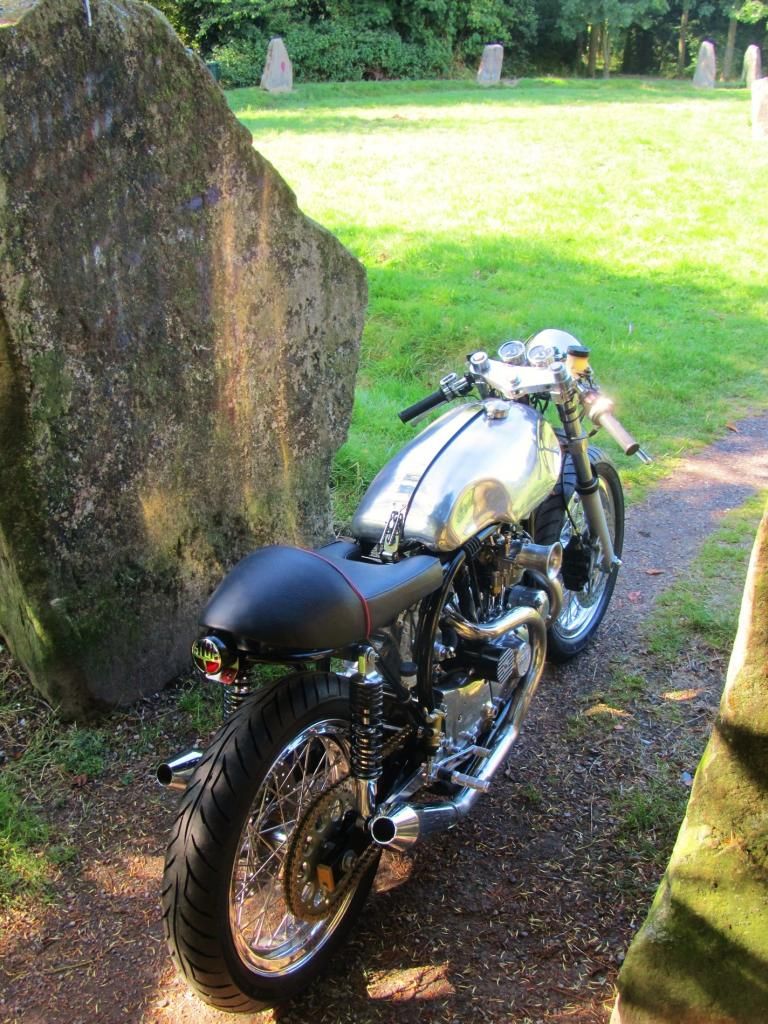

Got the electrics done, had to rebuild the clutch and brake master cylinders, still a few things I want to improve, but its finished for this year at least. I took it to a place near me with a circle of standing stones and took some pics before I got told off. Already started a new project.

So here's an ancient artefact next to some stones..

So here's an ancient artefact next to some stones..

Fantastic job Merch. Damn, that cafe is a KILLER!

Your Cafe Racer build is being featured in the BikeBuilds.net

directory here: Merch131's Cali Cafe Racer build

We’re currently displaying only a reduced-size photo (similar to what you’d find in Google

Images). We'd like to ask for your permission to publish the original full-size image with your

build listing.

If anyone would like to have a build of their own listed, just send me a message with a link to

the build thread and we’ll take care of the rest.

Al

Your Cafe Racer build is being featured in the BikeBuilds.net

directory here: Merch131's Cali Cafe Racer build

We’re currently displaying only a reduced-size photo (similar to what you’d find in Google

Images). We'd like to ask for your permission to publish the original full-size image with your

build listing.

If anyone would like to have a build of their own listed, just send me a message with a link to

the build thread and we’ll take care of the rest.

Al

They say custom bikes are never really finished, as there's always something that could be improved or changed in the light of riding the thing. So it is with my Norley. Before I start on my next big project I want to fix a couple of issues, the main one being the heavy clutch. The clutch activation is a one off hydraulic system, using a master cylinder from a Honda VTR1000 and slave cylinder from a Ducati 900 Monster, with a custom billet housing. When we made it, I knew it was an experiment and there was a good chance the ratio of Master to Slave wouldn't be perfect when used on an old Harley engine. Sure enough it turned out to be very heavy, too heavy for me, particularly if I was ever caught in slow moving traffic for more than a short time. Also the bleed nipple was part of the banjo bolt fitting, which made bleeding the system very difficult, unless I could somehow tip the bike on its side, which I couldn't.

Time to make a Mark 2 version..The Ducati Slave is 26mm in diameter, so to make an lighter clutch, it would need to be replaced with a bigger diameter slave. How much bigger ? No idea ! So I went with a Honda 36mm Slave cylinder to match the Honda master.

For this Mark 2 version I wanted to avoid making a completely unique slave body, because if it failed/wore it would be a lot of work to make a new one. Much better if I could use the standard Honda part and just make some kind of adaptor to fit it to the Harley.

So that's what we did, here's the new version roughly machined with its thread just cut by a proper machine shop (cost me a packet of Mr Kipling mince pies ..) as we couldn't do that bit. Before the holes were drilled to mount the Honda Slave, I took it home and screwed it tight to the engine case and noted where to position the slave so it was orientated correctly.

Time to make a Mark 2 version..The Ducati Slave is 26mm in diameter, so to make an lighter clutch, it would need to be replaced with a bigger diameter slave. How much bigger ? No idea ! So I went with a Honda 36mm Slave cylinder to match the Honda master.

For this Mark 2 version I wanted to avoid making a completely unique slave body, because if it failed/wore it would be a lot of work to make a new one. Much better if I could use the standard Honda part and just make some kind of adaptor to fit it to the Harley.

So that's what we did, here's the new version roughly machined with its thread just cut by a proper machine shop (cost me a packet of Mr Kipling mince pies ..) as we couldn't do that bit. Before the holes were drilled to mount the Honda Slave, I took it home and screwed it tight to the engine case and noted where to position the slave so it was orientated correctly.

Before I did anymore work on the adaptor I wanted to make sure it all worked, but when I came to bolt up the clutch hose, I found it wouldn't fit the new banjo location, so had to order a new hose from HEL, which arrived in a few days. That gave the time to shape the adaptor to match the profile of the slave cylinder and to take some weight off, and add a bronze bush to guide the now longer pushrod. Just hope it worked after all this effort..

The new clutch line arrived yesterday, so once fitted I spent ages bleeding the system until the lever firmed up and it all seems to work well. The lever effort is now much lighter as expected, while there is enough movement in the slave cylinder to disengage the clutch. It'll be awhile before I can try it out on the road, but I'm happy with the change so far. I may polish the slave cylinder or have it anodised maybe over the winter..

It will be four years next month since I bought the Guzzi Cali 3,and its still not done, about time I got on with it..

The first job was to do something about the seat unit, how to mount it to the frame and make a seat base to be upholstered.

When I cut off the old frame brackets and tabs I went a bit far and now I wish I'd left the seat mounts in place, as they would've made life much easier. In addition, with the seat unit resting on the frame rails the seat is too low, I now realise why all the Guzzi specials I see online have a slightly awkward looking seat which sits an inch or two above the frame rails.

The best option would be to strip the bike down again, get the frame welded as needed, which would then require it to be powder coated again, then finally put it all back together. All that's a lot of hassle and more importantly more expense, so I had to look at alternatives.

But first the lump moulded into the Rickman seat unit had to go, it didn't take long to cut it out, I'll fibreglass over the resulting hole later. To lift the seat a bit without welding brackets on the frame, I cut up an old foam floor tile and sandwiched and inch or so of the foam between the underside of the seat unit and the stainless plate I'd made ages ago to strengthen the seat. This lifted the seat unit just enough..

The first job was to do something about the seat unit, how to mount it to the frame and make a seat base to be upholstered.

When I cut off the old frame brackets and tabs I went a bit far and now I wish I'd left the seat mounts in place, as they would've made life much easier. In addition, with the seat unit resting on the frame rails the seat is too low, I now realise why all the Guzzi specials I see online have a slightly awkward looking seat which sits an inch or two above the frame rails.

The best option would be to strip the bike down again, get the frame welded as needed, which would then require it to be powder coated again, then finally put it all back together. All that's a lot of hassle and more importantly more expense, so I had to look at alternatives.

But first the lump moulded into the Rickman seat unit had to go, it didn't take long to cut it out, I'll fibreglass over the resulting hole later. To lift the seat a bit without welding brackets on the frame, I cut up an old foam floor tile and sandwiched and inch or so of the foam between the underside of the seat unit and the stainless plate I'd made ages ago to strengthen the seat. This lifted the seat unit just enough..

I want to use a lithium battery on the Guzzi, hiding inside the seat hump which would need to be mounted to the frame somehow. While the seat unit itself would need supporting too, all without welding any extra brackets to the frame...

soooo I had an idea ...make two threaded bungs, slightly tapered for a very tight interference fit into the back of the frame rails (which had been cut and shortened when I had hacked up the frame back when I first started this project many years ago..)

...make two threaded bungs, slightly tapered for a very tight interference fit into the back of the frame rails (which had been cut and shortened when I had hacked up the frame back when I first started this project many years ago..)

They don't quite fit as is as planned, but they're in the freezer overnight and hopefully with a big hammer they'll fit securely into the frame rails tomorrow. If that works then the battery mount can be made to bolt to these two threaded bungs..

soooo I had an idea

...make two threaded bungs, slightly tapered for a very tight interference fit into the back of the frame rails (which had been cut and shortened when I had hacked up the frame back when I first started this project many years ago..)

...make two threaded bungs, slightly tapered for a very tight interference fit into the back of the frame rails (which had been cut and shortened when I had hacked up the frame back when I first started this project many years ago..)They don't quite fit as is as planned, but they're in the freezer overnight and hopefully with a big hammer they'll fit securely into the frame rails tomorrow. If that works then the battery mount can be made to bolt to these two threaded bungs..

Gassing Station | Biker Banter | Top of Page | What's New | My Stuff

don't get me wrong, it's great, I just really want to now see what the Guzzi will turn out like

don't get me wrong, it's great, I just really want to now see what the Guzzi will turn out like