Moto Guzzi Cali Cafe Racer Build thread

Discussion

The electrics tray for the Guzzi is done now, and the rectifier bolted to its underside. It sits between the seat frame rails, and should hold all the electrics, bar the battery. I also made a stainless base to bolt to the seat unit, as it needed a bit more support. I still need to make another vertical piece which will bolt to the seat hump. Then the seat needs to be raised about 10mm as its resting on the shock mounts otherwise.

Edited by Merch131 on Wednesday 19th June 09:18

Got a good deal on an S&S Super E carb for the Ironhead/Norton cafe project, so went for it and bought a manifold and velocity stack seperately, it was much cheaper than buying a full kit, and I didnt want the S&S teardrop air filter anyway. Seems I still need a spacer/insulator block to go between the manifold and carb, wasnt sure, but without it the manifold clamp touches the throttle linkage..

May not go with the velocity stack, its a bit extreme, though be good for sucking in the odd bumble bee, cat, dog, small child ..

Old carb had been chromed which was now peeling off..

New carb

May not go with the velocity stack, its a bit extreme, though be good for sucking in the odd bumble bee, cat, dog, small child ..

Old carb had been chromed which was now peeling off..

New carb

Edited by Merch131 on Wednesday 19th June 09:19

I was lucky today to be able to borrow a few bits and bobs that will the help the Ironhead project along.. First the alloy petrol tank has some weird old british thread for the fuel tap, which I eventually found out was 1/4 inch BSPT (British standard pipe thread). I was given an old style fuel tap to try out and surprisingly it fit. Though, I'm not sure if its meant to be used on a bike, still at least i know for sure the thread now. I'll be going to the Stafford Classic show in a couple of weeks, and will try to find a better tap there..

Next I 'borrowed' a mint pair of forks from a 900 Hornet, which I can have if I want them..which I do, as they're the right length, and at 43mm not too big or small for what I'm looking for. They're not adjustable, but thats ok, they'll be far better than those fitted to std Sportster, and they can always be tweaked a bit if they prove to be too soft. The forks came without yokes, which I didnt want to use and of course the stem wouldnt fit in anycase..

So I raided my mate Jeffs shed and found a couple of unfinished alloy yokes that looked promising. I wanted something a bit retro looking, nothing too thick or angular. A bonus was that both sets of yokes handnt been drilled for risers yet, as I would be fitting clip ons. The top pair in the photo seemed to work best, so I'll have them, and maybe do a bit more machining to make them more interesting and 'cafe racer-ish'..

I'll need to find/make a suitable stem next and then try to find a suitable pair of spoked wheels.. probably 18 inch front and back.

Next I 'borrowed' a mint pair of forks from a 900 Hornet, which I can have if I want them..which I do, as they're the right length, and at 43mm not too big or small for what I'm looking for. They're not adjustable, but thats ok, they'll be far better than those fitted to std Sportster, and they can always be tweaked a bit if they prove to be too soft. The forks came without yokes, which I didnt want to use and of course the stem wouldnt fit in anycase..

So I raided my mate Jeffs shed and found a couple of unfinished alloy yokes that looked promising. I wanted something a bit retro looking, nothing too thick or angular. A bonus was that both sets of yokes handnt been drilled for risers yet, as I would be fitting clip ons. The top pair in the photo seemed to work best, so I'll have them, and maybe do a bit more machining to make them more interesting and 'cafe racer-ish'..

I'll need to find/make a suitable stem next and then try to find a suitable pair of spoked wheels.. probably 18 inch front and back.

Made a bit more progress yesterday, the forks fit the yokes ok, and I salvaged a steering stem from an old set of Harley evo XL yokes. When I pressed the stem out it was quite badly scored, looks like someone had removed it once before. So far this front end hasnt cost a penny, just swapped a few parts I didnt need for them. Next step is to machine the billet yokes to fit the old stem, then continue the hunt for a good pair of spoked wheels..

The old stem has now been fitted to the billet yokes, along with a cheap pair of clip ons from the far east, it doesnt look too bad. I havent fitted the lower bearing race yet, as once its on, they tend to want to stay on the stem. The lower yoke will need a bit more work yet, to make steering stops, and a final polish. While the top yoke will need drilling to fit the instruments, when I decide what they will be.

Been busy working on the house recently, so not made much progress with the bikes. One job has been to empty all the junk from my loft, surprised the ceilings didnt give with all the stuff up there. I did find a couple of interesting things though.. first the original fairing from my MHR, been gathering dust up there for about twenty years.. wonder if its worth anything these days..

And a small box of spare parts that I was given about ten years ago, they came off a turbo XJR I think. I never really looked at the stuff, just thought, may come in handy one day, and put them away in the loft, then forgot all at about it..

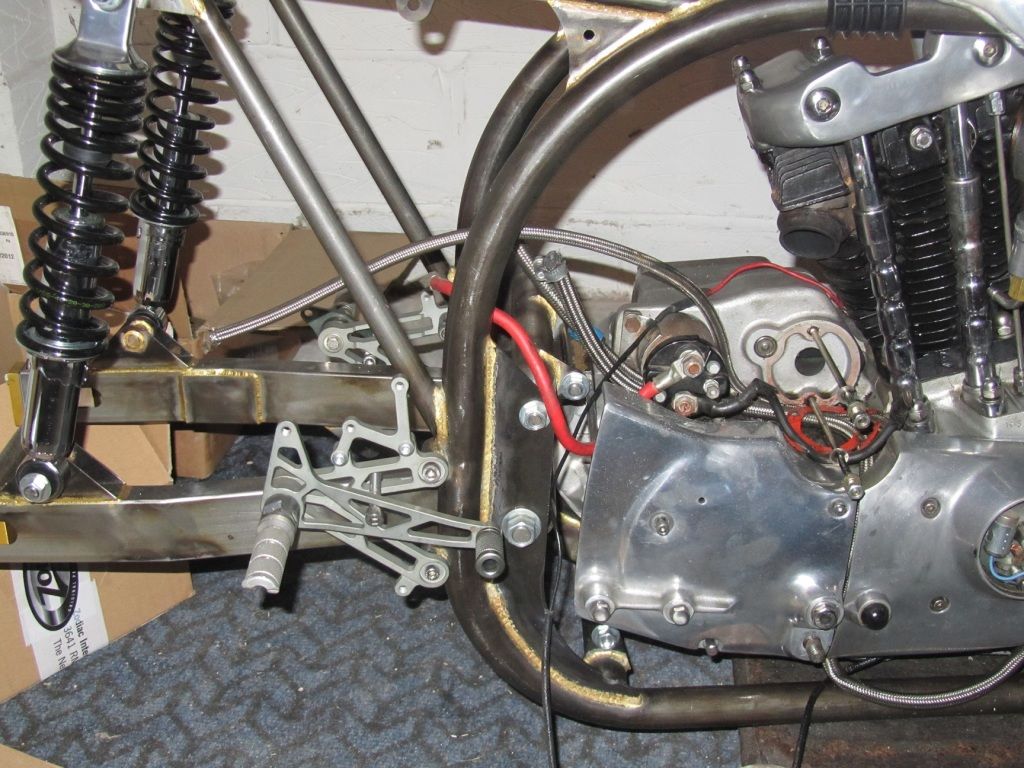

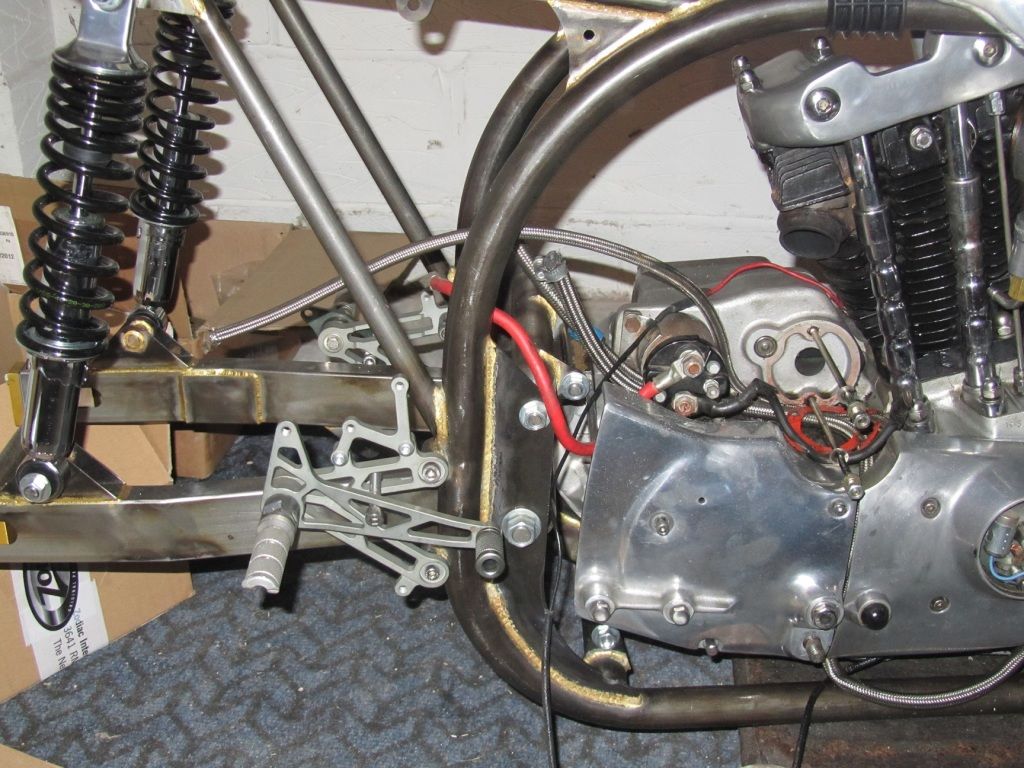

Amongst a few useless bits and bobs, there was a mismatched set of unused LSL rearsets.. turns out there was enough to make up almost a full set, though anodised in different colours. They are nicely made, so I tried the mounting plates on the Norley frame, they dont quite fit, but only by a couple of mm, so with a bit of work I think I can use them. I'll see if the anodising will polish off ok, and if it does, I'll polish the levers and leave the mounting brackets as they are.

And a small box of spare parts that I was given about ten years ago, they came off a turbo XJR I think. I never really looked at the stuff, just thought, may come in handy one day, and put them away in the loft, then forgot all at about it..

Amongst a few useless bits and bobs, there was a mismatched set of unused LSL rearsets.. turns out there was enough to make up almost a full set, though anodised in different colours. They are nicely made, so I tried the mounting plates on the Norley frame, they dont quite fit, but only by a couple of mm, so with a bit of work I think I can use them. I'll see if the anodising will polish off ok, and if it does, I'll polish the levers and leave the mounting brackets as they are.

Been busy making mounts for the clocks, as the stainless brackets that came with the clocks didnt look right. I made a cock up when drilling the mounting holes in the underside of the top yoke, I was so intent on making sure I didnt drill all the way through the yoke, that I mistakenly used an 8mm drill bit for the M8 sized holes.. thats too big to allow a thread to be ct using a M8 tap. So as usual when I mess up I went over to see my mate Jeff with my sorry tale and while I drank tea he kindly drilled the holes out a bit more and used helicoil thread inserts to get back to an M8. Well, since I was there, we made a couple of stainless pieces for the steering lock and drilled the lower yoke where I guessed they should go. Cant say for sure, as the frame doesnt have a tab on the headstock, its one of those things I'll have to sort out later. We made them a bit longer than they probably will need to be, that way they can be machined down a bit if needed, once everything is together on the bike.

I made the new brackets from an offcut of alloy plate, using the original to trace out the shape and drill the three holes in each. Then it was a case of hacksawing out the shape and spending a long time with a file and wet and dry to get a reasonable finish.Still need to pretty it up, but its doesnt look too bad so far. I've still to make the idiot light bracket, which is a bit more complex, so far I've drilled all the holes and cut out the shape I need roughly with the hacksaw. Wish I had use of Jeffs miller, it would be much quicker and neater, but its in use all week, making a blower manifold for the drag bike..

I made the new brackets from an offcut of alloy plate, using the original to trace out the shape and drill the three holes in each. Then it was a case of hacksawing out the shape and spending a long time with a file and wet and dry to get a reasonable finish.Still need to pretty it up, but its doesnt look too bad so far. I've still to make the idiot light bracket, which is a bit more complex, so far I've drilled all the holes and cut out the shape I need roughly with the hacksaw. Wish I had use of Jeffs miller, it would be much quicker and neater, but its in use all week, making a blower manifold for the drag bike..

I've modded the rearset mounts slightly, so they fit ok now, they are quite away back, but think they'll be ok in use. I've tried an old Nissin and a Brembo master cylinder but neither fit the mount on the brake mount. May have to make a new bracket, but would be better if I could keep the original.

The gearchange linkage will be interesting to do, as I dont want to use the same style as on Buells and XR1200s, I want something neater with the linkage rod below the pegs and not above.

But first, time for chemistry experiment, a solution of Caustic soda, vinegar as a neutraliser, and a few mismatched alloy parts that I want to remove the anodising from...

what could go wrong?

Lots of fizzing and bubbles..erm, somat is happening..

Half an hour later and a wash down... not too bad..

I'll polish them now.. oh, and todays lesson, next time I use caustic soda, I'll follow the instructions and wear gloves

The gearchange linkage will be interesting to do, as I dont want to use the same style as on Buells and XR1200s, I want something neater with the linkage rod below the pegs and not above.

But first, time for chemistry experiment, a solution of Caustic soda, vinegar as a neutraliser, and a few mismatched alloy parts that I want to remove the anodising from...

what could go wrong?

Lots of fizzing and bubbles..erm, somat is happening..

Half an hour later and a wash down... not too bad..

I'll polish them now.. oh, and todays lesson, next time I use caustic soda, I'll follow the instructions and wear gloves

Oh,I'm no engineer, but I like to try to make stuff, and when I get stuck, I've got a couple of mates who usually get my out of the hole I've dug for myself.

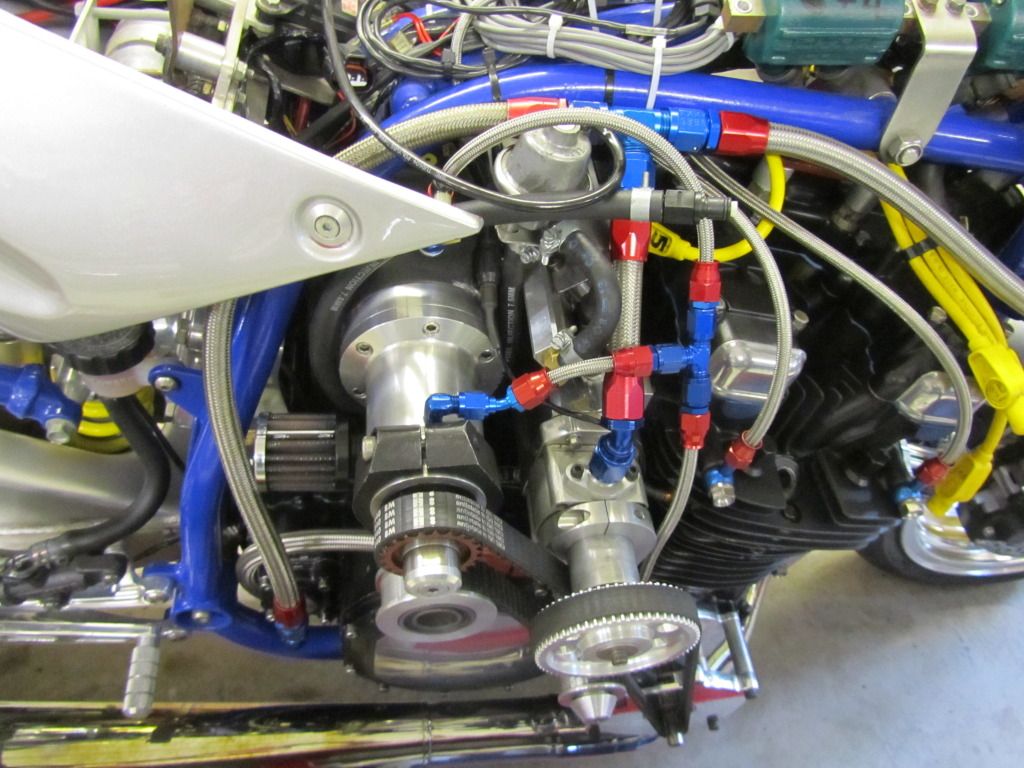

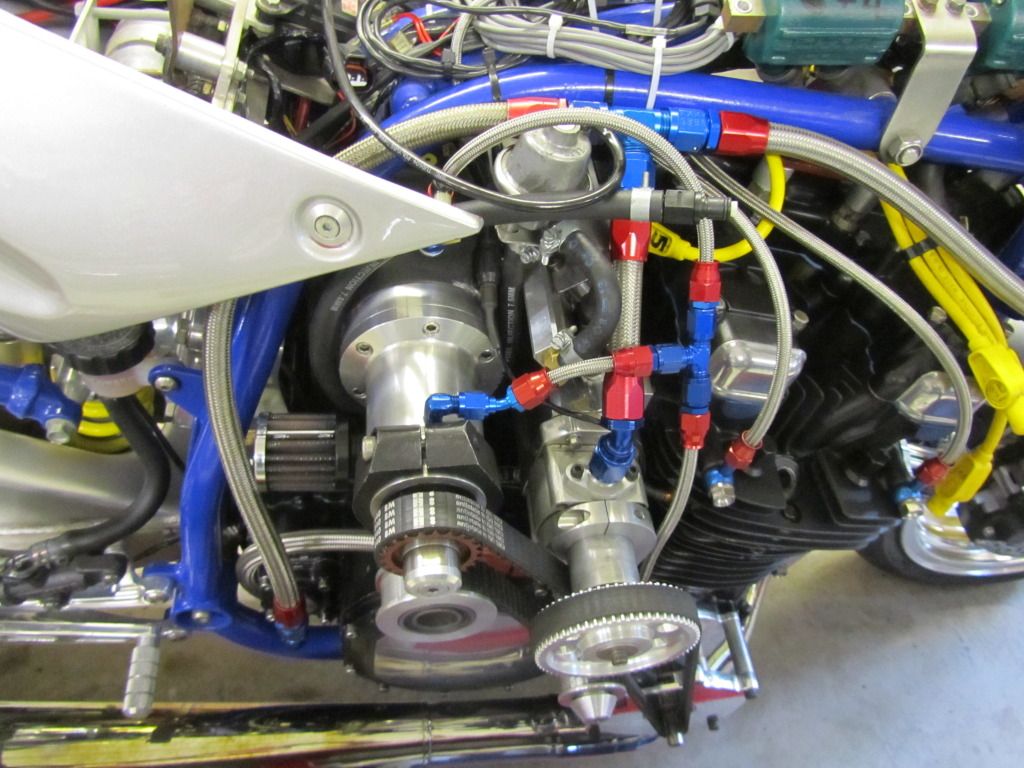

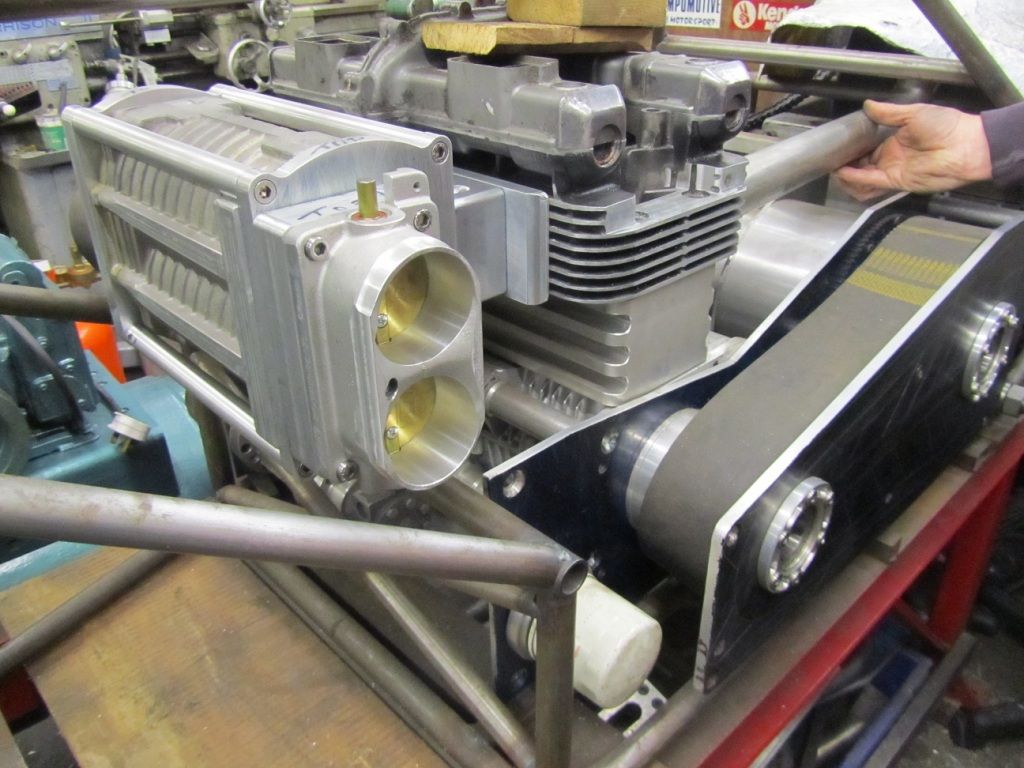

This is a project one of them has been working on for about ten years.. started life as a 78 Z1000.. its all made in a shed for not a lot of money.. the styling is dated now, but the engineering is impressive.. one off injection system, superchsarged, 8 plug heads, mono shocked and a lot more...

http://youtu.be/ZUSoGDy4x3s

This is a project one of them has been working on for about ten years.. started life as a 78 Z1000.. its all made in a shed for not a lot of money.. the styling is dated now, but the engineering is impressive.. one off injection system, superchsarged, 8 plug heads, mono shocked and a lot more...

http://youtu.be/ZUSoGDy4x3s

I thought I'd tell you about a couple of the kind of problems you have when building a special on a budget, a Heinz 57, trying to make parts fit together which werent made to.

The first job this week was to do something about the head steady which lives beneath the tank and is used to hold the top motor mount. On a std Harley this is a hefty bracket hanging down from the frame top tube. With the Norton frame, it has to take the form of a long bracket bolted on the back of the headstock. I had cut a chunk out of this long bracket, to clear the underside of the tank. I made a bit of mistake as I ended up moving the tank forward slightly, which meant the cut out ended up being a lot bigger and uglier than I had intended. The bracket would no doubt to its job fine, but it looked a bit flimsy to me, so I decided to make a replacement in ally, which would be lighter and stronger, and look better one I'd polished it.

To begin, I went over to my mates workshop and liberated a suitable piece of scrap 6mm aircraft spec alloy. Between cups of tea, I painted the alloy with 'Engineers blue', which is a quick drying dye, then marked out the shape of the old bracket with a scribe. Next I drilled the two mounting holes, as these would give me a datum point to work from. Basically its a lot easier to drill all the key holes before you begin to cut and shape the alloy.

Cutting out the shape in the plate with a hacksaw is far too much like hardwork, so I chain drilled it instead, its a lot easier to do if you have access to a piller drill, though you can use a hand drill..

That done it didnt take long to 'join the dots' and cut out the bracket..

If I was in my garage, I'd be faced with hours of filing to slowly clean up the edges and make it look respectable. But my mate Jeff has a milling machine in the corner of his workshop, so we used it to cut a neat straight line in a couple of minutes. We could have used the miller to cut the corners too, but it would take too long to set the miller up to do that, so I rounded the corners with a file.

At this point, I stopped as I wanted to go home and check it fit ok, before doing anymore work. Luckily it did, so the next job is to drill some 'cafe racerish' holes to lighten it. The original had four holes, which was a faux pas, as it'll always look better with an odd number of holes, is the case for any repeated pattern. I've marked out a new pattern of five holes, and I'll go over to Jeff's place soon to drill them, then it'll just need an hour or two with wet and dry and a final polish and it'll be done.

My next task is to sort out the front spindle and spacers. The Honda front end uses a 20mm spindle, while the new Harley twin disc hub I just bought uses a 3/4 inch spindle, which is about 19 mm. Now I could try to find new bearings, but that'll cost money, so instead I'm going to machine an old Harley 3/4 inch spindle to fit the Honda forks, I couldnt use the Honda spindle as its hollow and reducing its diameter isnt a good idea. Jap bike parts are made as light as practical, without much extra meat, whereas Harley stuff is made out of pig iron lol.

When I was playing around with my new shiny hubs (I'm going to have a go at lacing them myself, using stainless spokes and alloy Morad 18 inch rims.. when I can afford them), I noticed a future problem, the Nissin calipers will hit the spokes. So I'll have to move them out a bit or maybe try a different set of calipers, which in turn means having to make spacers to move the discs out.. Oh well, keeps me busy..

The first job this week was to do something about the head steady which lives beneath the tank and is used to hold the top motor mount. On a std Harley this is a hefty bracket hanging down from the frame top tube. With the Norton frame, it has to take the form of a long bracket bolted on the back of the headstock. I had cut a chunk out of this long bracket, to clear the underside of the tank. I made a bit of mistake as I ended up moving the tank forward slightly, which meant the cut out ended up being a lot bigger and uglier than I had intended. The bracket would no doubt to its job fine, but it looked a bit flimsy to me, so I decided to make a replacement in ally, which would be lighter and stronger, and look better one I'd polished it.

To begin, I went over to my mates workshop and liberated a suitable piece of scrap 6mm aircraft spec alloy. Between cups of tea, I painted the alloy with 'Engineers blue', which is a quick drying dye, then marked out the shape of the old bracket with a scribe. Next I drilled the two mounting holes, as these would give me a datum point to work from. Basically its a lot easier to drill all the key holes before you begin to cut and shape the alloy.

Cutting out the shape in the plate with a hacksaw is far too much like hardwork, so I chain drilled it instead, its a lot easier to do if you have access to a piller drill, though you can use a hand drill..

That done it didnt take long to 'join the dots' and cut out the bracket..

If I was in my garage, I'd be faced with hours of filing to slowly clean up the edges and make it look respectable. But my mate Jeff has a milling machine in the corner of his workshop, so we used it to cut a neat straight line in a couple of minutes. We could have used the miller to cut the corners too, but it would take too long to set the miller up to do that, so I rounded the corners with a file.

At this point, I stopped as I wanted to go home and check it fit ok, before doing anymore work. Luckily it did, so the next job is to drill some 'cafe racerish' holes to lighten it. The original had four holes, which was a faux pas, as it'll always look better with an odd number of holes, is the case for any repeated pattern. I've marked out a new pattern of five holes, and I'll go over to Jeff's place soon to drill them, then it'll just need an hour or two with wet and dry and a final polish and it'll be done.

My next task is to sort out the front spindle and spacers. The Honda front end uses a 20mm spindle, while the new Harley twin disc hub I just bought uses a 3/4 inch spindle, which is about 19 mm. Now I could try to find new bearings, but that'll cost money, so instead I'm going to machine an old Harley 3/4 inch spindle to fit the Honda forks, I couldnt use the Honda spindle as its hollow and reducing its diameter isnt a good idea. Jap bike parts are made as light as practical, without much extra meat, whereas Harley stuff is made out of pig iron lol.

When I was playing around with my new shiny hubs (I'm going to have a go at lacing them myself, using stainless spokes and alloy Morad 18 inch rims.. when I can afford them), I noticed a future problem, the Nissin calipers will hit the spokes. So I'll have to move them out a bit or maybe try a different set of calipers, which in turn means having to make spacers to move the discs out.. Oh well, keeps me busy..

The Ironhead now has a genuine Ducati part  .. a Brembo rear master cylinder from a Monster. It was free and cleaned up ok, so I made a simple bracket to fit it to the LSL rearsets. I marked out where the holes should go, drilled them with my trusty hand drill, then hacksawed out the basic shape before cleaning it up with a file. Still want to do a bit more work on it, but itw as minus 2 in the garage with no heating, so that can wait for a warmer day..

.. a Brembo rear master cylinder from a Monster. It was free and cleaned up ok, so I made a simple bracket to fit it to the LSL rearsets. I marked out where the holes should go, drilled them with my trusty hand drill, then hacksawed out the basic shape before cleaning it up with a file. Still want to do a bit more work on it, but itw as minus 2 in the garage with no heating, so that can wait for a warmer day..

I've also made a stainless link rod for the gearchange, I think it'll work ok, but with the pegs being so far back the link rod has to be long too, dont really like it, but not sure what else to do. It may not be so noticable when the bike is on its wheels..

.. a Brembo rear master cylinder from a Monster. It was free and cleaned up ok, so I made a simple bracket to fit it to the LSL rearsets. I marked out where the holes should go, drilled them with my trusty hand drill, then hacksawed out the basic shape before cleaning it up with a file. Still want to do a bit more work on it, but itw as minus 2 in the garage with no heating, so that can wait for a warmer day..

.. a Brembo rear master cylinder from a Monster. It was free and cleaned up ok, so I made a simple bracket to fit it to the LSL rearsets. I marked out where the holes should go, drilled them with my trusty hand drill, then hacksawed out the basic shape before cleaning it up with a file. Still want to do a bit more work on it, but itw as minus 2 in the garage with no heating, so that can wait for a warmer day..

I've also made a stainless link rod for the gearchange, I think it'll work ok, but with the pegs being so far back the link rod has to be long too, dont really like it, but not sure what else to do. It may not be so noticable when the bike is on its wheels..

The Mark one gear linkage is done now, not sure about the link rod still, seems miles too long, though it may not annoy me quite so much when the bike is on its wheels. The good news is that it seems to work ok, which is what counts, oh and it cost nothing but time to make..

On the brake side, my master cylinder mount didnt impress my mate Jeff.. he said I shouldve used thicker 10mm plate instead of the 6mm I used. That way I could've tapped a thread in the plate and saved having to use nuts on the back to hold everything together, which looked 'untidy'. So I borrowed a bit of 10mm plate from his scrap pile, and made a Mark two version. Surprising how long it takes, it was an afternoon with plenty of tea breaks before it was done.

The next task was to make a push rod for the master cylinder. I was a bit worried about this, as it must be a complex shape, with some clever way to keep the rod in the master cylinder. But no, there is nothing to keep the push rod in place, it just sits in a hollow inside the master cylinder. So we used a stainless M8 bolt as a starting point, as thats the diameter of the push rod. We machined a ball end and a groove half way along for the rubber boot to sit in, then reduced the other end to 6mm and threaded it, to take a 6mm rose joint. Job done? Nope.. the brake lever had a 8mm hole where the rose joint would be bolted up. I didnt use a 8mm rosejoint as it looked far too big. So we had to make a tiny reducer spacer to so a 6mm bolt would fit snuggly through the gear lever.

On the brake side, my master cylinder mount didnt impress my mate Jeff.. he said I shouldve used thicker 10mm plate instead of the 6mm I used. That way I could've tapped a thread in the plate and saved having to use nuts on the back to hold everything together, which looked 'untidy'. So I borrowed a bit of 10mm plate from his scrap pile, and made a Mark two version. Surprising how long it takes, it was an afternoon with plenty of tea breaks before it was done.

The next task was to make a push rod for the master cylinder. I was a bit worried about this, as it must be a complex shape, with some clever way to keep the rod in the master cylinder. But no, there is nothing to keep the push rod in place, it just sits in a hollow inside the master cylinder. So we used a stainless M8 bolt as a starting point, as thats the diameter of the push rod. We machined a ball end and a groove half way along for the rubber boot to sit in, then reduced the other end to 6mm and threaded it, to take a 6mm rose joint. Job done? Nope.. the brake lever had a 8mm hole where the rose joint would be bolted up. I didnt use a 8mm rosejoint as it looked far too big. So we had to make a tiny reducer spacer to so a 6mm bolt would fit snuggly through the gear lever.

Dibble said:

What's the idea of the blue on the bracket? Bobski's mentioned "Engineering blue" before, and a quick Wiki suggests its used to highlight high spots/contact, but I don't understand why you'd need it on a flat bracket?

Of course, I am thick, and Bobski's engineering blue is probably some VERY niche dwarf-based porn.

Its a quick drying ink, I used to mark out shapes with a scribe, to help make sure I dont cut / drill / machine the wrong bits. I've not used to to highlight high spots / contacts, but then with the simple stuff I make there is no need. If you look at the photo of the bracket in the vice, with the tap wrench cutting a thread, you can see where I've marked out on the bracket the outline of the m/c, so Iknow where to cut and file the edges. For something so simple, its not really required, though I need all the help I can get. BTW, if you look in the background of that photo, you can see a thick block of billet, thats going be made into a cylinder block.. for our Compbike.. puts my little projects into perspective..Of course, I am thick, and Bobski's engineering blue is probably some VERY niche dwarf-based porn.

The HD front hub has been causing a headache, I couldnt find any bearings that would fit the hub and work with the Honda 20mm spindle. Nor could I just machine down the spindle to 3/4 of an inch, as it was hollow and I didnt want to weaken it too much. Somehow I had to modify the original Ironhead wheel spindle to fit the Honda forks..

Well, there was only one thing to do.. hand the problem over to my mate Jeff and his trusty lathe.. 5 hours of machining later the job was done..

With the forks back on the bike, the next task is to buy a pair of 18 inch Morad alloy rims and spokes and build the wheels, it'll be a few more weeks before that happens. Then I can work out where the oil tank has to sit and make its mounts, along with a thousand other little jobs....

BTW the forks I'm using came off a Honda Hornet 900, which now has a pair of GSXR K7 usds in billet stepped yokes, along with loads of other mods including a Zorstec exhaust..

Well, there was only one thing to do.. hand the problem over to my mate Jeff and his trusty lathe.. 5 hours of machining later the job was done..

With the forks back on the bike, the next task is to buy a pair of 18 inch Morad alloy rims and spokes and build the wheels, it'll be a few more weeks before that happens. Then I can work out where the oil tank has to sit and make its mounts, along with a thousand other little jobs....

BTW the forks I'm using came off a Honda Hornet 900, which now has a pair of GSXR K7 usds in billet stepped yokes, along with loads of other mods including a Zorstec exhaust..

It neednt cost an arm and a leg to restore or build an interesting special. I've done quite over the years and spent a fortune outsourcing jobs as I didnt have the time or inclination to do it myself. These days I have a lot more time and a lot less money, so I try to do as much as possible. Although it can be frustrating having to wait till I can spare the money to buy parts (such as the wheel rims), it does make the project more interesting. I havent worked out actually how much the Guzzi and Norley have cost so far, but roughly the Guzzi stands me at £2500 (£1500 purchase and £1000 on parts.. the tyres being the biggest expense so far). The Norley is a bit more, again £1500 for the original bike, a bargain given it had £3000 orf receipts and a full engine rebuild, plus £2200 for the frame kit including the oil and petrol tanks, and another £600 or so on parts. Some of which werent strictly necessary, ie the new S&S carb. I dont build them to make money, but so long as they dont lose me too much overall I'm happy.

When I 'retired' a couple of years ago, I soon got bored, so bought this Honda 400/4 for £400, it was very original and ran fine, just looked worse than it really was. I restored it, and sold it at a small profit when it was done. Lots of tedius cleaning and polishing, but nothing anyone couldnt manage with a bit of effort..

Before..

After

When I 'retired' a couple of years ago, I soon got bored, so bought this Honda 400/4 for £400, it was very original and ran fine, just looked worse than it really was. I restored it, and sold it at a small profit when it was done. Lots of tedius cleaning and polishing, but nothing anyone couldnt manage with a bit of effort..

Before..

After

It took awhile, but I finally bought the Morad alloy rims I need. Both 18 inch a 3.0 on the back and a 2.15 for the front. I got them from Central Wheels in Birmingham, despite having the correct dimensions of the hubs (Width, PCD) they were relunctant to sell the correct length spokes. Maybe I just got them on a bad day. I'll walk around the corner tomorrow and see old chap who restores old bikes, and used to rebuild wheels for pocket money. Bill is in his late 80s, last time I saw him he was completing this 'works' 1926 Sunbeam, which had been found buried in a scrap yard. He has a few old bikes, including a Vincent he's owned since the late 50s, though Bill has recently had to give up riding due to poor health.

Yesterday was a big day, my stainless spokes finally arrived, though to be fair, I think they were made for me. Later in the day I also got a big parcel from Unity Equipe, which I've not even had time to open yet.. it should contain a few goodies.. seat, stainless sidestand and tank strap and catch.

In the morning I cycled over the other side of town to see Jeff and drink tea, we'd agreed he'd make me a wheel stand so I can true the wheels up. As often happens I had a sketch of the simplest stand I'd seen, but before long the design evolved a bit and now its going to be much more useful, as I'll be able to use it on any size wheels, with or without a spindle. Hopefully it'll e ready in a few days.

Then I had a go at lacing a wheel for the first time. I made a few silly mistakes along the way, but the rear wheel wasnt as difficult as I'd thought. Though of course I still need to true it. Full of confidence, I started on the front wheel, expecting to be finished in no time. After three attempts I gave up for the evening, I'll try again later. The main problem is that all the holes in the hub for the spokes are all bevelled on one side only, so all the spokes have to be seated on the same side. When the spokes cross it means that one of the spokes doesnt sit in its seat correctly. Obviously I'm lacing it in the srong way, but I cant see the right way at the moment.

Rear wheel..

Front wheel.. going ok, then it all went wrong

In the morning I cycled over the other side of town to see Jeff and drink tea, we'd agreed he'd make me a wheel stand so I can true the wheels up. As often happens I had a sketch of the simplest stand I'd seen, but before long the design evolved a bit and now its going to be much more useful, as I'll be able to use it on any size wheels, with or without a spindle. Hopefully it'll e ready in a few days.

Then I had a go at lacing a wheel for the first time. I made a few silly mistakes along the way, but the rear wheel wasnt as difficult as I'd thought. Though of course I still need to true it. Full of confidence, I started on the front wheel, expecting to be finished in no time. After three attempts I gave up for the evening, I'll try again later. The main problem is that all the holes in the hub for the spokes are all bevelled on one side only, so all the spokes have to be seated on the same side. When the spokes cross it means that one of the spokes doesnt sit in its seat correctly. Obviously I'm lacing it in the srong way, but I cant see the right way at the moment.

Rear wheel..

Front wheel.. going ok, then it all went wrong

Gassing Station | Biker Banter | Top of Page | What's New | My Stuff