Honda VRX400 1995 "barn find" restoration

Discussion

It's candy-apple orange, but toxic earwax did make me laugh !

No fear guys, in the flesh it's a bit more toned down than the photos make it out ... ignore the "flares" in the photo (the really bright bits), that's just the silver coat showing through the orange over-coat, which you don't see with the human eye.

No fear guys, in the flesh it's a bit more toned down than the photos make it out ... ignore the "flares" in the photo (the really bright bits), that's just the silver coat showing through the orange over-coat, which you don't see with the human eye.

Very pleased with the job that Faircharm, Leicester have done. Quick, loose "plonk everything in place" to get an idea of the finished bike ... everything's off the bike again now and on the dining room table to harden off for 2-3 weeks.

I haven't decided what I'm doing with the seat yet ... I've a few ideas though.

And a reminder / flashback ...

STILL ... A LONG WAY TO GO YET !! Right, enough stargazing, let's crack on with that rear wheel ...

I haven't decided what I'm doing with the seat yet ... I've a few ideas though.

And a reminder / flashback ...

STILL ... A LONG WAY TO GO YET !! Right, enough stargazing, let's crack on with that rear wheel ...

Fascinating thread, evil len, more so because I own one of these bikes.

Surprised by your colour choice as you're restoring rather than modding - looks good though.

One thought: are you replacing the tank badges in original chrome? They might look better in black to match the frame and contrast with the orange.

It's a shame you didn't get to ride it before you started as once it's done it'll be so shiny and new you won't want to dirty it!

Good luck with the remainder - I look forward to reading the posts.

Surprised by your colour choice as you're restoring rather than modding - looks good though.

One thought: are you replacing the tank badges in original chrome? They might look better in black to match the frame and contrast with the orange.

It's a shame you didn't get to ride it before you started as once it's done it'll be so shiny and new you won't want to dirty it!

Good luck with the remainder - I look forward to reading the posts.

Hadn't thought about that ref the badges, will have a think. I know you can't get the chrome badges new any more, not sure about the black versions ...

Come on FDVictor ... photos of yours please !

Added the new brake disk to the rear wheel

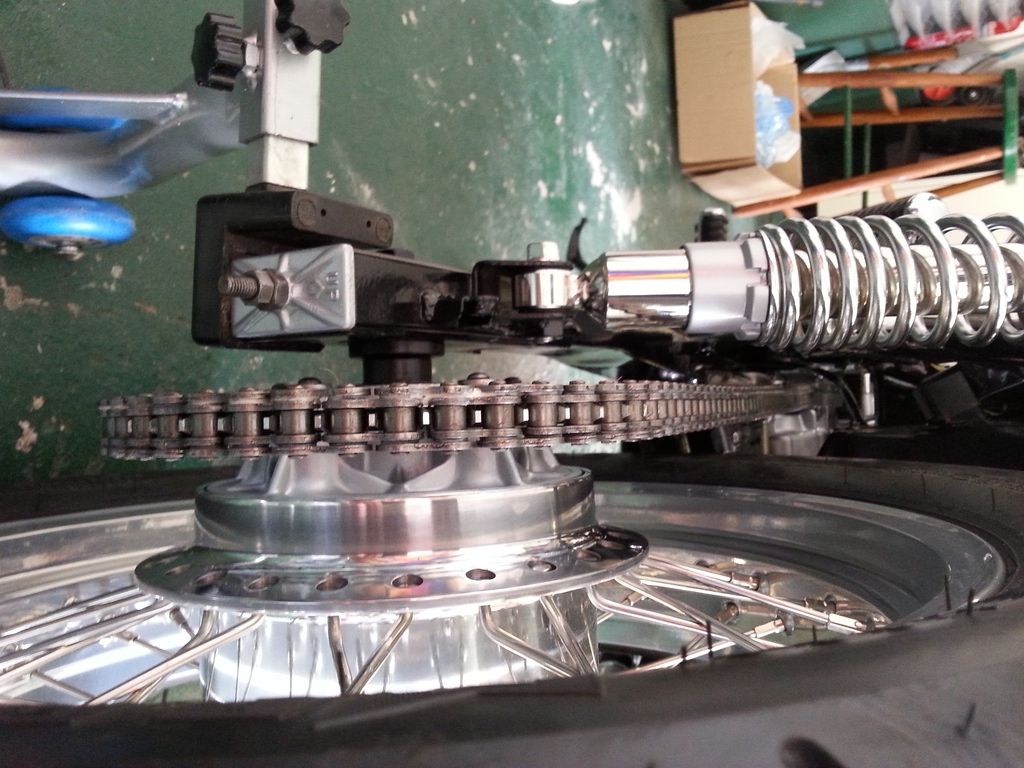

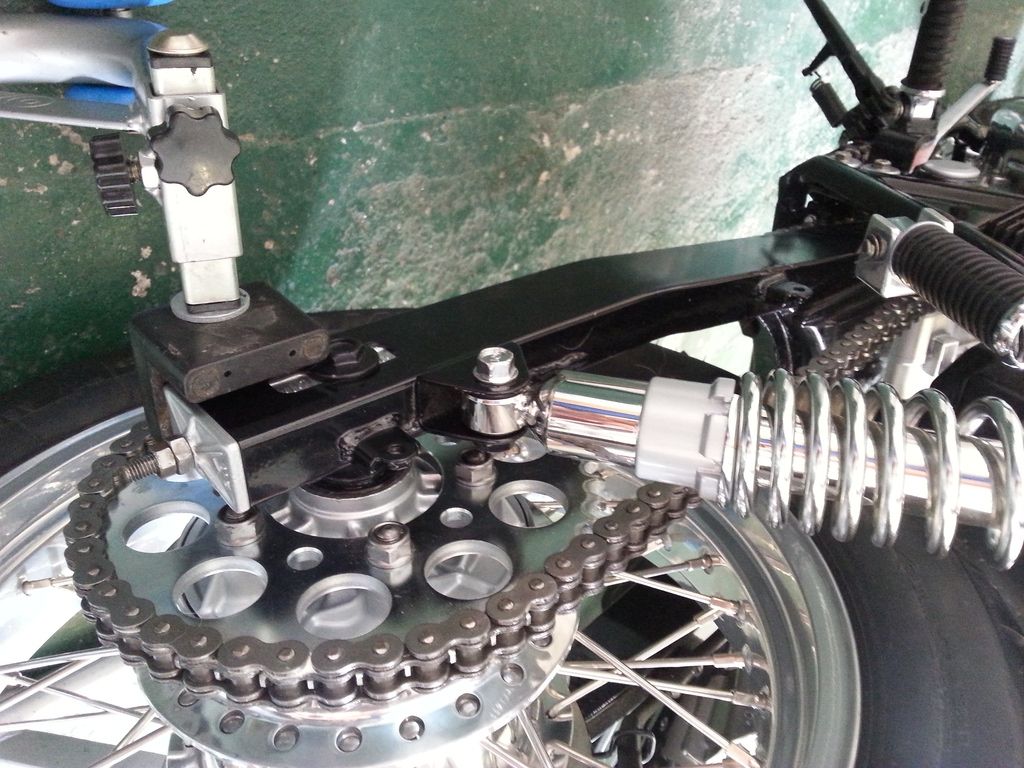

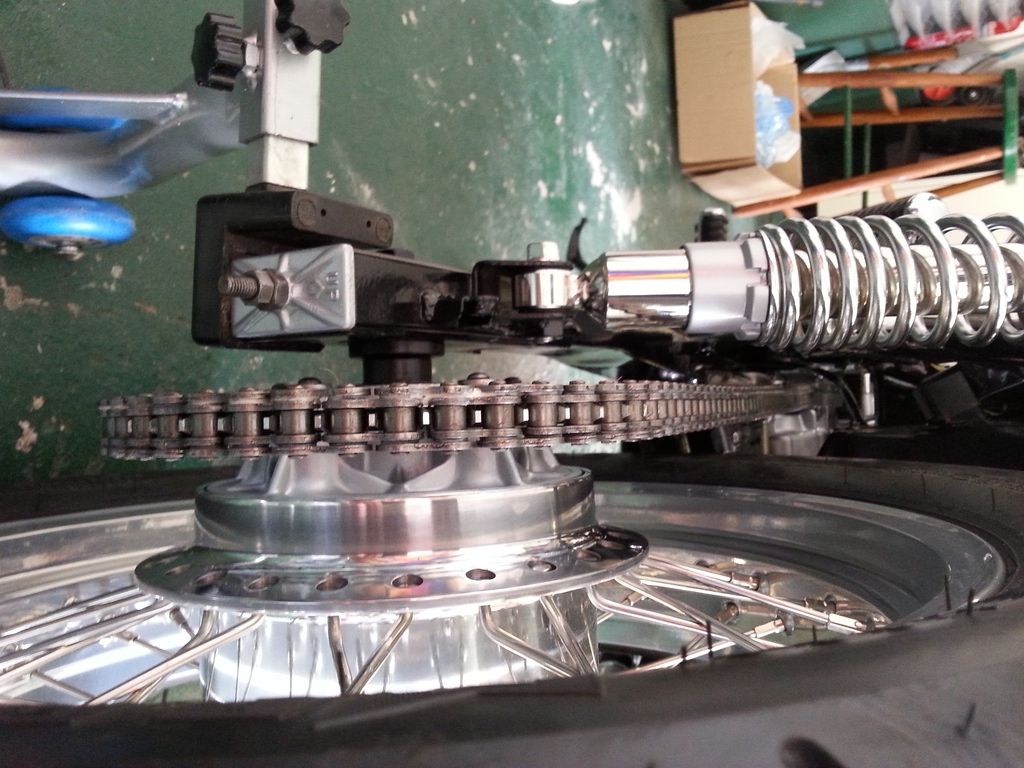

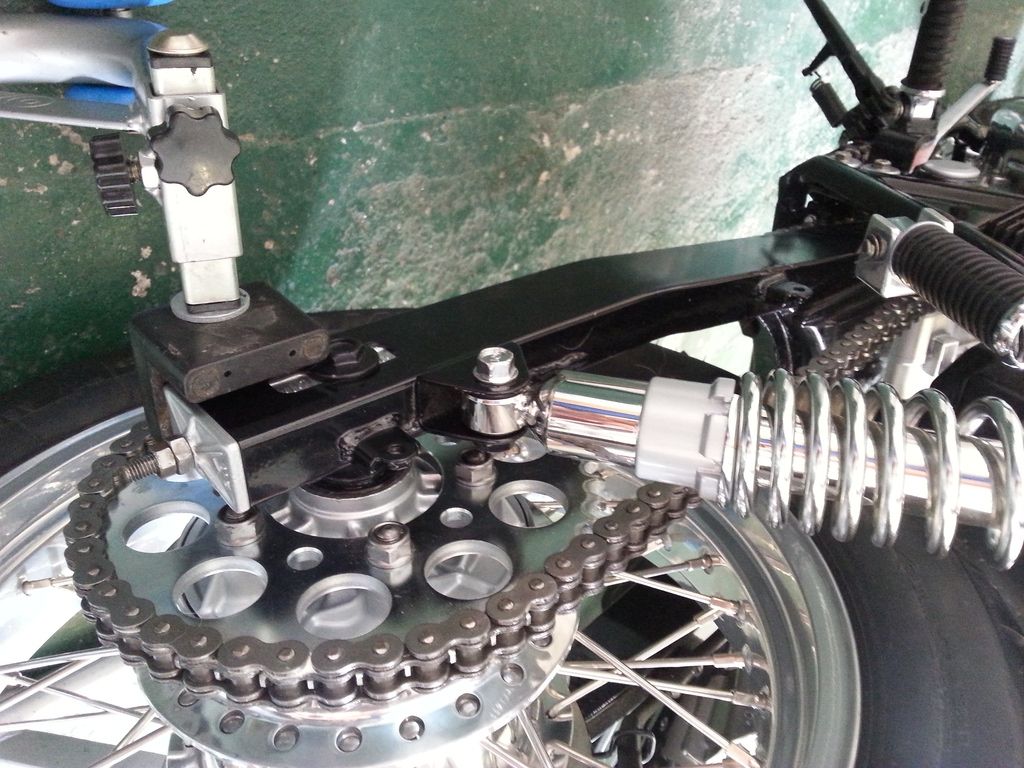

If you ever wondered what a cush drive looks like, then here you go. Basically the rear sprocket isn't actually fixed to the rest of the rear wheel ... it's 'buffered' with rubber, just to soften the drive a little.

And in position. It just plonks in place. Guess how many times this fell out again whilst trying to fit the rear wheel.

Rear wheel fitted, along with spacers and carrier for the rear brake. Rear spindle was greased gently. The wheel was a proper pig to fit ... probably took about 4 attempts to get right.

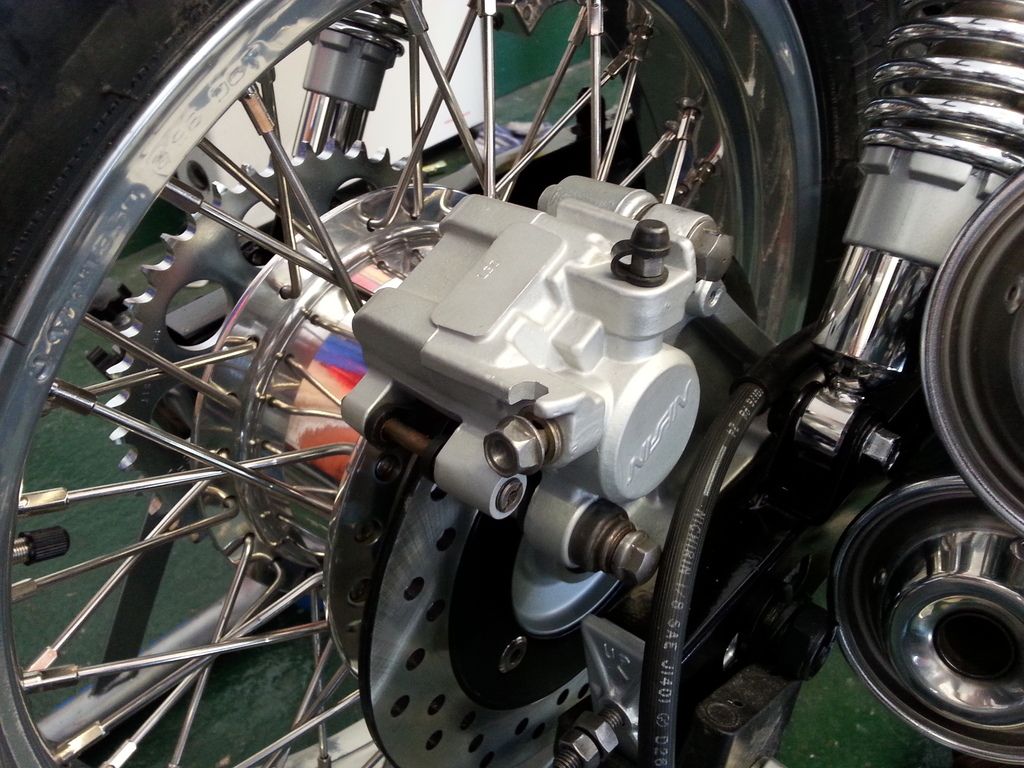

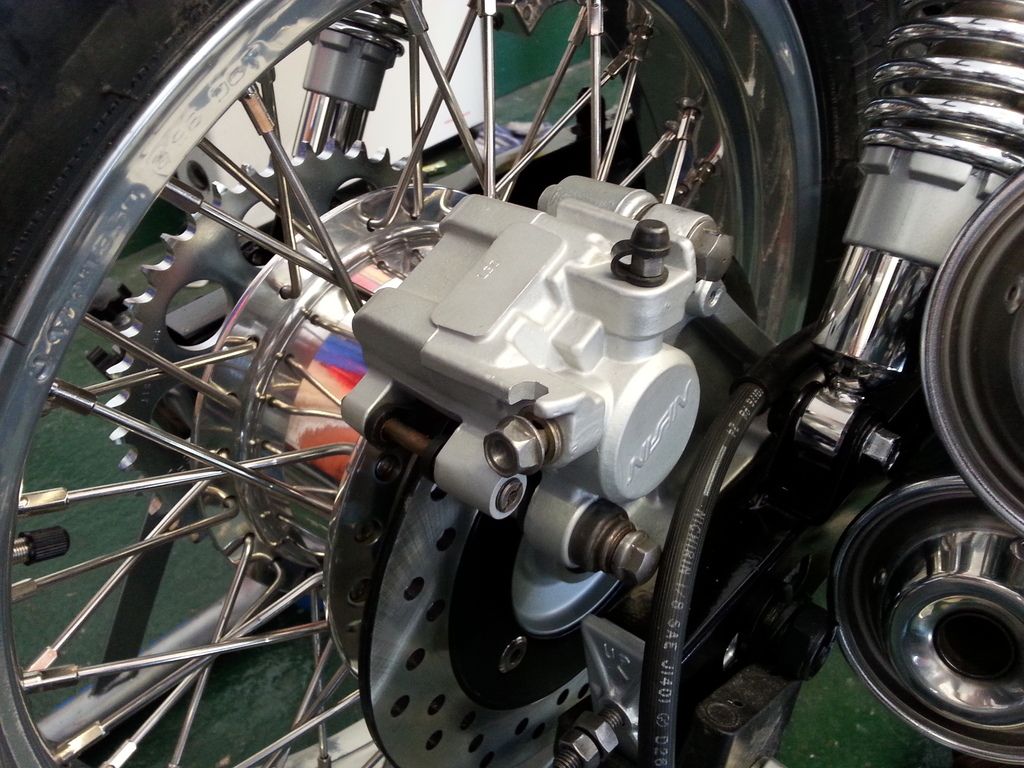

Started working on the rear brake caliper, which looks like this.

Ideally you use the hydraulics of the brake system in place to pump out the piston, with the pads removed. Of course I forgot to do this, so had to resort to clamping on mole grips then using screw drivers each side to lever out the piston slowly (it's a tight fit) (that's what she said).

And totally disassembled.

Come on FDVictor ... photos of yours please !

Added the new brake disk to the rear wheel

If you ever wondered what a cush drive looks like, then here you go. Basically the rear sprocket isn't actually fixed to the rest of the rear wheel ... it's 'buffered' with rubber, just to soften the drive a little.

And in position. It just plonks in place. Guess how many times this fell out again whilst trying to fit the rear wheel.

Rear wheel fitted, along with spacers and carrier for the rear brake. Rear spindle was greased gently. The wheel was a proper pig to fit ... probably took about 4 attempts to get right.

Started working on the rear brake caliper, which looks like this.

Ideally you use the hydraulics of the brake system in place to pump out the piston, with the pads removed. Of course I forgot to do this, so had to resort to clamping on mole grips then using screw drivers each side to lever out the piston slowly (it's a tight fit) (that's what she said).

And totally disassembled.

SHE RUNS !

With the wheels on and the side stand on (I connected the side stand switch yesterday, which was fiddly) I thought I'd see if she would fire up. Refitted the battery, along with the last few electrical connectors (apart from the indicators and headlight). Turn the ignition key, and all the tell tail lights on the clocks work excluding ignition. Taking a spark plug out and turning the engine over and there's a nice healthy spark, so I suspect the bulb. I turned the engine over a few times till the oil pressure light went out, to get the oil moving round the engine.

Now, how to get fuel into her ? I don't really want to fit the tank yet ... I haven't cleaned it out etc, plus I want to be able to get to the carbs in case I need to play. After a couple of abortive efforts I came up with the idea of using a washing up liquid bottle ... inserted into the fuel inlet pipe, I could squeeze/inject enough fuel into the carbs to fill the float chambers ... enough to run for a couple of minutes anyway.

Oh, I also fitted a fuel filter (which the bike doesn't have as standard) though I think I'm going to have to move it a bit as it's a bit too close to the carbs currently for comfort.

So ... fuel, check. Battery, check. Spark, check. Lets give this a go. As I haven't fitted the throttle cables yet, I've got to open the throttle mech on the carbs by hand.

She's turning over with vigour, but not starting ... she wants to start, with a light chuff, but doesn't catch. After a few minutes of head scratching I realised I'd missed one vital thing ... CHOKE ! Dur. I'm that used these days to not having to use a choke, I'd forgotten. Engage the choke and she fires up instantly.

She sounds pretty good actually ! Chuggy/chuffy in an agricultural way, "rorty". First couple of times I ran her, she was grumpy and misfiring a bit, but settled down as she got warmer. Better than I'd expect from a semi rebuilt engine. But improved by the third, longer run.

However the biggest problem was that she would rev sweetly to 6k, then just hit a brick wall (redline is 8k). After some playing and messing, sealing the vacuum take off for the fuel tap (which isn't on yet) and semi-covering the air intake means she'd rev happily to 8k. So, I think I just need to finish off all the air intake and pipe work (put the air filter on etc). I think someone did mention on this thread last year about the lack of revs (which she also did before I stripped her down) being down to running too lean due to air filter not being on.

No water or oil leaks that I can see (though I will inspect closely another day when she's cooled down, also check the fluid levels). She runs up and down the gears just fine. Exhaust seems gas tight, though one pipe which was reconditioned by "Maple Vauxhall" is yellowing badly (expected I guess) but also seems to be bubbling slightly. Will have to keep an eye on that ... I'm not surprised frankly, the s t job they did in every other respect. Luckily this is covered by a large chrome cover which I hadn't put on till I was sure the exhaust was gas tight ... I can do that now, and hide it away.

t job they did in every other respect. Luckily this is covered by a large chrome cover which I hadn't put on till I was sure the exhaust was gas tight ... I can do that now, and hide it away.

I'll do you a video when I don't need both hands to keep her running well.

Niggles :

- The ignition tell tail light doesn't work. Presume a blown bulb or bad connector. If the former that'll be annoying as I'll have to take it all apart again.

- The (rebuilt) starter motor sometimes just spins without engaging ... or rather that's what it sounds like, bearing in mind it's a direct drive. Will have to take off and apart again.

- There's a light rattle from somewhere towards the front of the engine at idle.

- Light bubbling of chrome on one exhaust pipe where it attaches to the engine

In other news ...

Rear brake calliper cleaned up and painted with heat proof paint, then cured in the oven (Wife : "Darling, what are you cooking ? Me : "Er ... nothing")

(Wife : "Darling, what are you cooking ? Me : "Er ... nothing")

The brake piston may be saveable (below after cleaning up) but I think I'll see if I can get a new one as it's borderline.

New rubbers

Just shows how brake fluid expands rubber ... old on left, new on right

Cleaned, derusted, primed and painted fuel tap.

With the wheels on and the side stand on (I connected the side stand switch yesterday, which was fiddly) I thought I'd see if she would fire up. Refitted the battery, along with the last few electrical connectors (apart from the indicators and headlight). Turn the ignition key, and all the tell tail lights on the clocks work excluding ignition. Taking a spark plug out and turning the engine over and there's a nice healthy spark, so I suspect the bulb. I turned the engine over a few times till the oil pressure light went out, to get the oil moving round the engine.

Now, how to get fuel into her ? I don't really want to fit the tank yet ... I haven't cleaned it out etc, plus I want to be able to get to the carbs in case I need to play. After a couple of abortive efforts I came up with the idea of using a washing up liquid bottle ... inserted into the fuel inlet pipe, I could squeeze/inject enough fuel into the carbs to fill the float chambers ... enough to run for a couple of minutes anyway.

Oh, I also fitted a fuel filter (which the bike doesn't have as standard) though I think I'm going to have to move it a bit as it's a bit too close to the carbs currently for comfort.

So ... fuel, check. Battery, check. Spark, check. Lets give this a go. As I haven't fitted the throttle cables yet, I've got to open the throttle mech on the carbs by hand.

She's turning over with vigour, but not starting ... she wants to start, with a light chuff, but doesn't catch. After a few minutes of head scratching I realised I'd missed one vital thing ... CHOKE ! Dur. I'm that used these days to not having to use a choke, I'd forgotten. Engage the choke and she fires up instantly.

She sounds pretty good actually ! Chuggy/chuffy in an agricultural way, "rorty". First couple of times I ran her, she was grumpy and misfiring a bit, but settled down as she got warmer. Better than I'd expect from a semi rebuilt engine. But improved by the third, longer run.

However the biggest problem was that she would rev sweetly to 6k, then just hit a brick wall (redline is 8k). After some playing and messing, sealing the vacuum take off for the fuel tap (which isn't on yet) and semi-covering the air intake means she'd rev happily to 8k. So, I think I just need to finish off all the air intake and pipe work (put the air filter on etc). I think someone did mention on this thread last year about the lack of revs (which she also did before I stripped her down) being down to running too lean due to air filter not being on.

No water or oil leaks that I can see (though I will inspect closely another day when she's cooled down, also check the fluid levels). She runs up and down the gears just fine. Exhaust seems gas tight, though one pipe which was reconditioned by "Maple Vauxhall" is yellowing badly (expected I guess) but also seems to be bubbling slightly. Will have to keep an eye on that ... I'm not surprised frankly, the s

t job they did in every other respect. Luckily this is covered by a large chrome cover which I hadn't put on till I was sure the exhaust was gas tight ... I can do that now, and hide it away.

t job they did in every other respect. Luckily this is covered by a large chrome cover which I hadn't put on till I was sure the exhaust was gas tight ... I can do that now, and hide it away.

I'll do you a video when I don't need both hands to keep her running well.

Niggles :

- The ignition tell tail light doesn't work. Presume a blown bulb or bad connector. If the former that'll be annoying as I'll have to take it all apart again.

- The (rebuilt) starter motor sometimes just spins without engaging ... or rather that's what it sounds like, bearing in mind it's a direct drive. Will have to take off and apart again.

- There's a light rattle from somewhere towards the front of the engine at idle.

- Light bubbling of chrome on one exhaust pipe where it attaches to the engine

In other news ...

Rear brake calliper cleaned up and painted with heat proof paint, then cured in the oven

(Wife : "Darling, what are you cooking ? Me : "Er ... nothing")

(Wife : "Darling, what are you cooking ? Me : "Er ... nothing")

The brake piston may be saveable (below after cleaning up) but I think I'll see if I can get a new one as it's borderline.

New rubbers

Just shows how brake fluid expands rubber ... old on left, new on right

Cleaned, derusted, primed and painted fuel tap.

Seeing as you asked, evil len, here is my bike, which unfortunately is more like your 'before' pics.

Mine had a rusted exhaust similar to yours and, as the only replacement I could find was £300, I wrapped the down-pipes and fitted a pair of slip-on silencers. I've also bobbed the rear mudguard and fitted LED rear lights. I'll be interested to see what you do with your seat as mine is similarly ripped.

Future plans include dropping the forks/fitting shorter rear shocks, some mini front indicators and possibly some flatter bars.

[url]

[url]

|http://thumbsnap.com/m8qVl14f[/url]

|http://thumbsnap.com/m8qVl14f[/url]

(PS. Sorry about the lens flare - my camera seems to have gone all JJ Abrams!)

Mine had a rusted exhaust similar to yours and, as the only replacement I could find was £300, I wrapped the down-pipes and fitted a pair of slip-on silencers. I've also bobbed the rear mudguard and fitted LED rear lights. I'll be interested to see what you do with your seat as mine is similarly ripped.

Future plans include dropping the forks/fitting shorter rear shocks, some mini front indicators and possibly some flatter bars.

[url]

[url] |http://thumbsnap.com/m8qVl14f[/url]

|http://thumbsnap.com/m8qVl14f[/url](PS. Sorry about the lens flare - my camera seems to have gone all JJ Abrams!)

Thanks for posting FDVictor ... I like the bobbed tail !

Rear calliper overhauled and back together.

Mounted on the carrier.

Now I know the exhaust doesn't leak, fitted the two chrome covers over the joints between back box and downpipes. The two bolts holding them on are Triumph Tiger 800 'beak' mounting bolts, would you believe.

I forgot to fit two metal disks on the pillion footrests, which meant they flapped around a bit ... so I took them apart and fitted them.

b d b

d b d b

d b d b

d b d !

d !

Fitting the wire hanger for the rear brake hose, one bolt suddenly unexplicably went tight ... then wouldn't tighten ... then wouldn't undo ... and then snapped !

I've got to take the whole b d rear end apart and wheel off again, so I can drill and tap the hole. COCK !

d rear end apart and wheel off again, so I can drill and tap the hole. COCK !

Rear calliper overhauled and back together.

Mounted on the carrier.

Now I know the exhaust doesn't leak, fitted the two chrome covers over the joints between back box and downpipes. The two bolts holding them on are Triumph Tiger 800 'beak' mounting bolts, would you believe.

I forgot to fit two metal disks on the pillion footrests, which meant they flapped around a bit ... so I took them apart and fitted them.

b

d b

d b d b

d b d b

d b d !

d !Fitting the wire hanger for the rear brake hose, one bolt suddenly unexplicably went tight ... then wouldn't tighten ... then wouldn't undo ... and then snapped !

I've got to take the whole b

d rear end apart and wheel off again, so I can drill and tap the hole. COCK !

d rear end apart and wheel off again, so I can drill and tap the hole. COCK !

Dry your tear little cirian75 ... this gives me the opportunity to show you how to save a broken bolt.

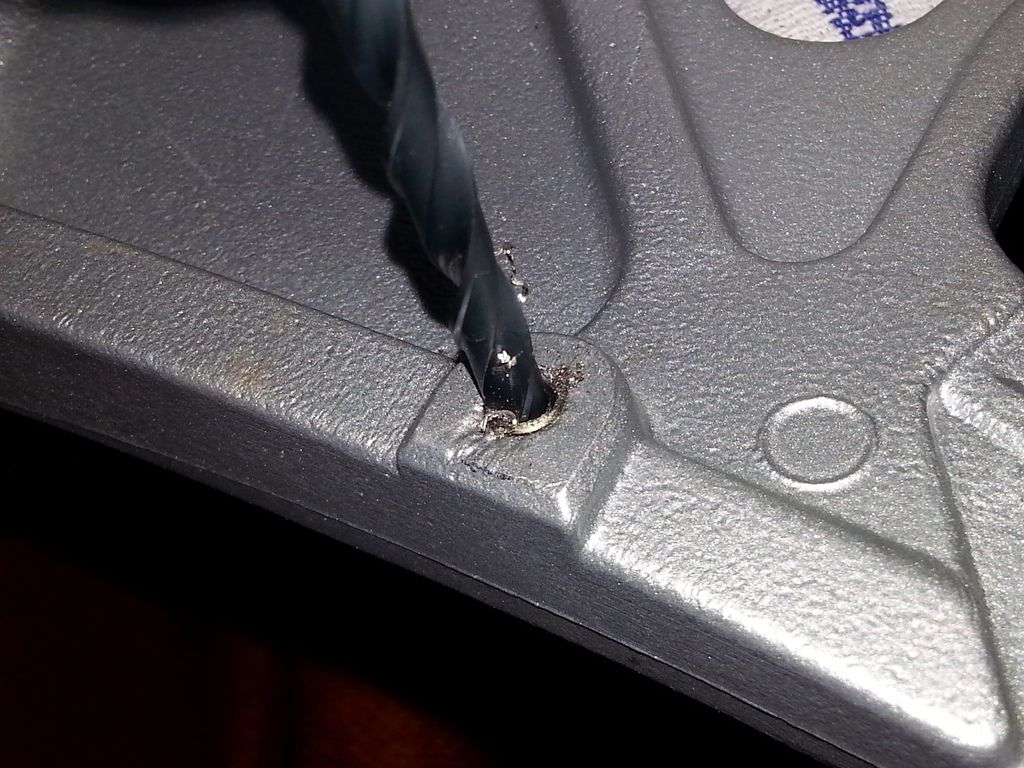

First, centre pop the broken bolt. It's very important to get it right in the middle of the bolt, or as near as you can. Take your time with this bit.

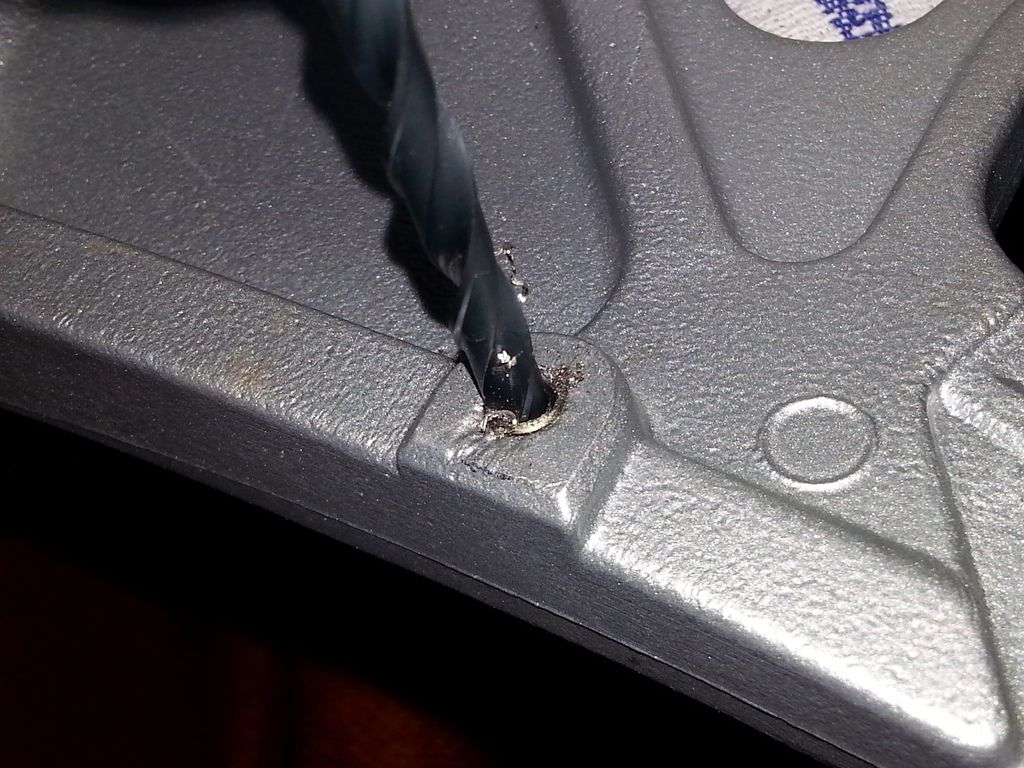

Start by drilling a small pilot hole all the way through the bolt. Again, it pays you to take your time on this early stage, and ensure the hole is straight and in the middle of the bolt. Don't over heat your drill bit, and allow it to cool occasionally (bolts are normally made of quite hard steel). Use oil to lubricate and cool the drill bit. (Sorry for photobucket being an arse and rotating images again)

Once the pilot hole is all the way through, use increasing sized drills to drill continue to expand the hole. It's easier, and more controllable, to do it this way. I used 4 different sized drills in the end. Remember to keep using small amounts of oil.

Hey, would you look at that ... I must have been pretty close to the centre. Some of the thread of the broken bolt comes out as a coil ! This is a 6mm thread, so I'm drilling to 5mm. Use a chart like this to know what size hole you need to drill for the tap. http://www.shender4.com/metric_thread_chart.htm

This leaves you with a hole like this ... clean all the swarf up as much as you can.

Taps come in threes (two shown) per size, with increasing tapers. I'm going to start with the biggest taper. If I was tapping a blind hole I'd work my way up to the 'fattest' tap (to ensure the thread goes all the way to the bottom) but this hole goes all the way through the casting, so I don't need to worry about that.

I decided to tap from the OTHER side ... the side with the good, original thread still there. This ensured that I didn't cross threads when I went from the 'bad' area to the good thread. I had to stop several times, back up, and clean out the tap as it started to jam. I also ran paper towel through the hole, trying to get the swarf out. Remember, it's 1/2 a turn forward, then back off 1/4 a turn.

And would you look at that ! The tap ended up working as a stud remover, and wound out a lot of the old bolt's thread ! I guess I got that hole pretty central.

This left me with a tapped hole like this. It's slightly rougher and slightly looser than original (as you'd expect) but perfectly serviceable.

I ran the tap down the other hole to clean it out, just in case. Problem sorted.

Time to refit all the rear end again. Sigh ...

First, centre pop the broken bolt. It's very important to get it right in the middle of the bolt, or as near as you can. Take your time with this bit.

Start by drilling a small pilot hole all the way through the bolt. Again, it pays you to take your time on this early stage, and ensure the hole is straight and in the middle of the bolt. Don't over heat your drill bit, and allow it to cool occasionally (bolts are normally made of quite hard steel). Use oil to lubricate and cool the drill bit. (Sorry for photobucket being an arse and rotating images again)

Once the pilot hole is all the way through, use increasing sized drills to drill continue to expand the hole. It's easier, and more controllable, to do it this way. I used 4 different sized drills in the end. Remember to keep using small amounts of oil.

Hey, would you look at that ... I must have been pretty close to the centre. Some of the thread of the broken bolt comes out as a coil ! This is a 6mm thread, so I'm drilling to 5mm. Use a chart like this to know what size hole you need to drill for the tap. http://www.shender4.com/metric_thread_chart.htm

This leaves you with a hole like this ... clean all the swarf up as much as you can.

Taps come in threes (two shown) per size, with increasing tapers. I'm going to start with the biggest taper. If I was tapping a blind hole I'd work my way up to the 'fattest' tap (to ensure the thread goes all the way to the bottom) but this hole goes all the way through the casting, so I don't need to worry about that.

I decided to tap from the OTHER side ... the side with the good, original thread still there. This ensured that I didn't cross threads when I went from the 'bad' area to the good thread. I had to stop several times, back up, and clean out the tap as it started to jam. I also ran paper towel through the hole, trying to get the swarf out. Remember, it's 1/2 a turn forward, then back off 1/4 a turn.

And would you look at that ! The tap ended up working as a stud remover, and wound out a lot of the old bolt's thread ! I guess I got that hole pretty central.

This left me with a tapped hole like this. It's slightly rougher and slightly looser than original (as you'd expect) but perfectly serviceable.

I ran the tap down the other hole to clean it out, just in case. Problem sorted.

Time to refit all the rear end again. Sigh ...

Forgot to mention, remember to oil your tap too.

Fitted the air filter housing complete with new filter. Luckily a lot of that plastic is behind the tank.

Of course I had to give the rear brake hanger and calliper a light dust over with spray, to cover small marks caused by the on-off-on-off-on-off-on-off ...

Fitted the air filter housing complete with new filter. Luckily a lot of that plastic is behind the tank.

Of course I had to give the rear brake hanger and calliper a light dust over with spray, to cover small marks caused by the on-off-on-off-on-off-on-off ...

Seem to have spent all day today on "Jane", for not a lot of visible progress.

Fitted the fuel tank.

Along with the new fuel cap. Quite satisfying.

The mating surface for the cap had to be cleaned of a bit of paint which would have stopped a good seal.

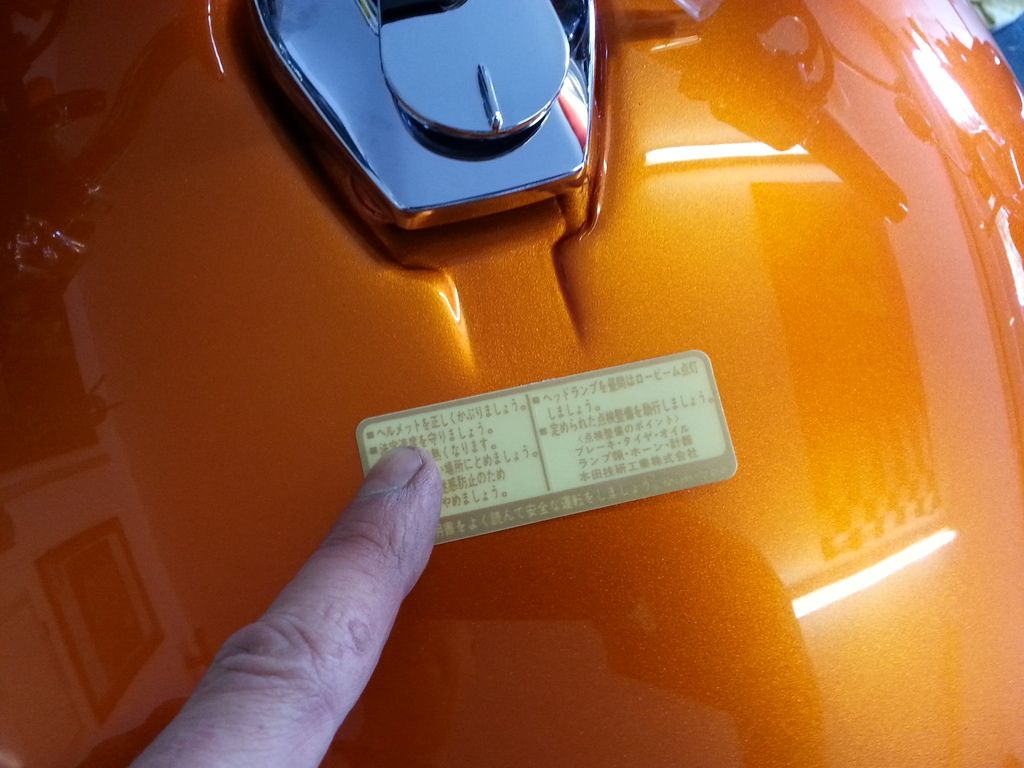

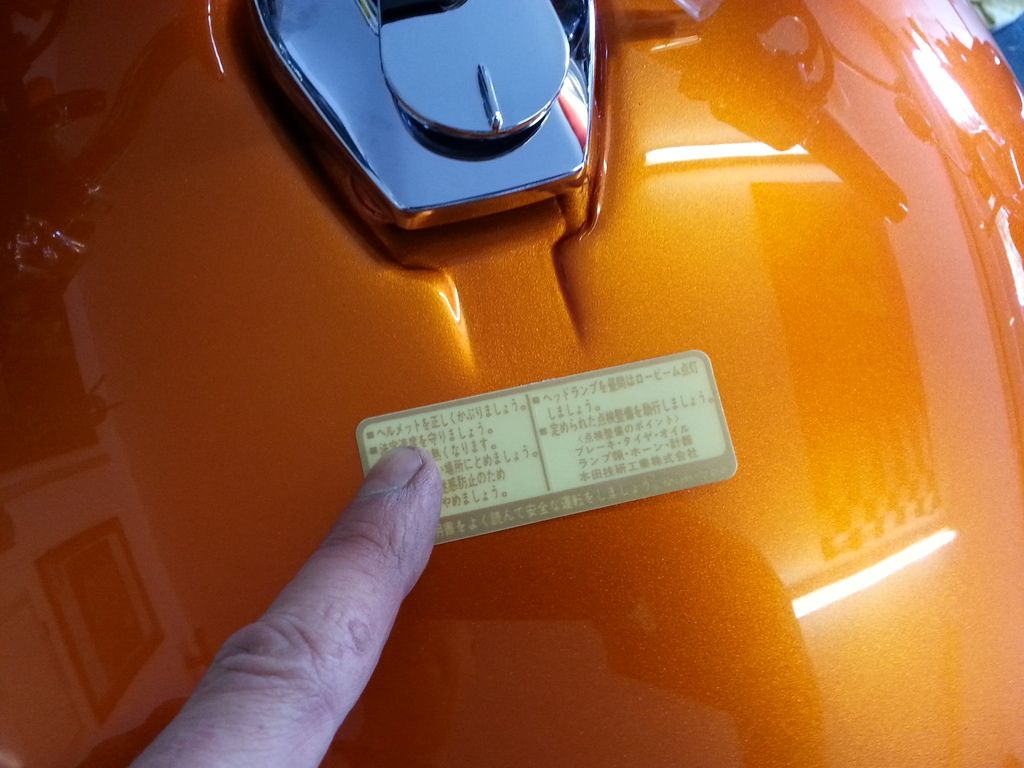

Trying to decide whether to put this original sticker back on ... current thinking is 'no'.

Reminder of the sticker on the original paint.

Fitted the two cables for the throttle. This took a lot of buggeration factor, to get it so both cables ran smoothly and the throttle returned to its stop, whilst not having any slack, and working at both extremes of the turned handlebars. This probably consumed a good couple of hours. But the throttle is now working.

And, successfully bled the front brake. Again though, working from a dry system this took foreeeeever ...

Think I was paranoid about getting brake fluid on anything ?

Bleeding was done in the traditional manner ... brake off / undo nipple / brake on / do nipple. Rinse and repeat a million times. Of all the songs I listened to on Radio 2 for the duration of bleeding this brake, Rivers of Babylon by Boney M had the best beat/tempo to bleed along with.

And hooked up the fuel line, vacuum line, fuel tap and here you can also see the other end of the two throttle cables. Originally she didnt have a fuel filter, but I thought it wise to fit one, especially as the fuel tank's been blasted and painted (grit and dust).

Fitted the fuel tank.

Along with the new fuel cap. Quite satisfying.

The mating surface for the cap had to be cleaned of a bit of paint which would have stopped a good seal.

Trying to decide whether to put this original sticker back on ... current thinking is 'no'.

Reminder of the sticker on the original paint.

Fitted the two cables for the throttle. This took a lot of buggeration factor, to get it so both cables ran smoothly and the throttle returned to its stop, whilst not having any slack, and working at both extremes of the turned handlebars. This probably consumed a good couple of hours. But the throttle is now working.

And, successfully bled the front brake. Again though, working from a dry system this took foreeeeever ...

Think I was paranoid about getting brake fluid on anything ?

Bleeding was done in the traditional manner ... brake off / undo nipple / brake on / do nipple. Rinse and repeat a million times. Of all the songs I listened to on Radio 2 for the duration of bleeding this brake, Rivers of Babylon by Boney M had the best beat/tempo to bleed along with.

And hooked up the fuel line, vacuum line, fuel tap and here you can also see the other end of the two throttle cables. Originally she didnt have a fuel filter, but I thought it wise to fit one, especially as the fuel tank's been blasted and painted (grit and dust).

Okay then so it's a no to the stickers

Chain fitted, adjusted, and the rear wheel bolt tightened up.

Spend some time playing with the engine, she's running quite sweetly now. Also the starter appears (?) to have 'fixed' itself (for now anyway)

However ... with the chain now on, I drove her forward a few feet (pedal backwards, repeat) within the garage. Huston, we have a problem. Clutch works okay, but squeals like a b h. If it were a car clutch I'd say the release bearing had gone. Cock. Cock cockity cock. So ... that's all going to have to come apart again then. That's ... annoying.

h. If it were a car clutch I'd say the release bearing had gone. Cock. Cock cockity cock. So ... that's all going to have to come apart again then. That's ... annoying.

To be honest the exhaust has got to come off again anyway as the lower silencer is touching the rear wheel bolt. I guess I've got to expect snags which have to be sorted, after taking a bike completely apart ... there's going to be things that don't quite work first time.

Latest video :

https://www.youtube.com/watch?v=Zh_kCEUM4cM

Chain fitted, adjusted, and the rear wheel bolt tightened up.

Spend some time playing with the engine, she's running quite sweetly now. Also the starter appears (?) to have 'fixed' itself (for now anyway)

However ... with the chain now on, I drove her forward a few feet (pedal backwards, repeat) within the garage. Huston, we have a problem. Clutch works okay, but squeals like a b

h. If it were a car clutch I'd say the release bearing had gone. Cock. Cock cockity cock. So ... that's all going to have to come apart again then. That's ... annoying.

h. If it were a car clutch I'd say the release bearing had gone. Cock. Cock cockity cock. So ... that's all going to have to come apart again then. That's ... annoying. To be honest the exhaust has got to come off again anyway as the lower silencer is touching the rear wheel bolt. I guess I've got to expect snags which have to be sorted, after taking a bike completely apart ... there's going to be things that don't quite work first time.

Latest video :

https://www.youtube.com/watch?v=Zh_kCEUM4cM

Gassing Station | Biker Banter | Top of Page | What's New | My Stuff