Manifold fitting - an alternative to slotting

Discussion

I actually had some analyzed by specialists a few years ago, and they weren't at all impressed by the material once the hardened coat was scraped off (even in terms of tensile strength). Then again to be better than yank mass production where every 0.000000000c

counts, you don't have to be a genius to make anything much better?

counts, you don't have to be a genius to make anything much better?

bobfather said:

Actually very easy, bolt in a vice, centre pop all round. It now latches to the nordlock very strongly

Excellent bobfarther, that looks like a solution that will really work, I've got access to a big old ancient Colchester lathe, I wonder if I could get a knurling tool on the head flange

TBH I thought ARPs were hard as hell too, the slippery polished stainless finish deceived me. Perhaps the reason my ARP & Nordlocks are working properly now is because the washers have finally bitten into the bolt flange which we can now see is softer than we'd all first assumed.

In frustration I must admit I properly crammed them up last time, this brutal approach seems to finally have worked.

I see you can get proper matched bolt and ramping washers in the States, the ramping washers are trapped on the bolt so they stay put when fitting, I'd also assume the bolt material has been selected to work with their ramping washers.

Here's what Proform say about their product:

Proform wedge locking header bolts are permanently assembled with a pair of special washers. When the bolts are torqued to 28 ft.-lbs., the washers' super-hardened external teeth bite into and grip the bottom of the bolt head and the top surface of the header. After being self-locked in this manner, any bolt-loosening rotation is blocked by a wedge-locking action created by the washers' interfacing, matching cams. Because this simple wedge-locking method uses tension instead of friction, contact with oil actually facilitates the wedge effect. When changing headers, the Proform wedge locking header bolts can be loosened with a normal wrench, lubricated, and reused.

https://www.youtube.com/watch?v=_mmZg-pLdds

https://www.proformparts.com/product-exec/product_...

Cheap enough too, buy them from Summit Racing:

http://www.summitracing.com/int/search/product-lin...

Edited by ChimpOnGas on Saturday 31st January 08:31

They look good. In hindsight I would have looked further rather than just buying what appeared to be popular and I think ACT selling the ARP/norlock combo gives a degree of undeserved credibility.

The ARP flange is too small and as you say the polished surface works counter to the nordlock process. I'm always wary of over tightening into an alloy block. I have had to run a tap down several of my bolt holes to enable the new ARP's to find a start, that also runs the risk of oversizing or otherwise weakening the female tread.

Perhaps the only true benefit on ARP's is the small AF size and corrosion resistance

The ARP flange is too small and as you say the polished surface works counter to the nordlock process. I'm always wary of over tightening into an alloy block. I have had to run a tap down several of my bolt holes to enable the new ARP's to find a start, that also runs the risk of oversizing or otherwise weakening the female tread.

Perhaps the only true benefit on ARP's is the small AF size and corrosion resistance

bobfather said:

They look good. In hindsight I would have looked further rather than just buying what appeared to be popular and I think ACT selling the ARP/norlock combo gives a degree of undeserved credibility.

The ARP flange is too small and as you say the polished surface works counter to the nordlock process. I'm always wary of over tightening into an alloy block. I have had to run a tap down several of my bolt holes to enable the new ARP's to find a start, that also runs the risk of oversizing or otherwise weakening the female tread.

Perhaps the only true benefit on ARP's is the small AF size and corrosion resistance

All excellent points, I couldn't have summarised it better myself The ARP flange is too small and as you say the polished surface works counter to the nordlock process. I'm always wary of over tightening into an alloy block. I have had to run a tap down several of my bolt holes to enable the new ARP's to find a start, that also runs the risk of oversizing or otherwise weakening the female tread.

Perhaps the only true benefit on ARP's is the small AF size and corrosion resistance

Apparently the Proform locking bolts do work as advertised from what I've read on various Yank forums.

Can someone confirm the size, Proform offer a 16 bolt set in 3/8" x 3/4"L (p/n 66752).

To be exact...

Their thread size is: 3/8-16 in

Their length is: 0.750 in

Are these the set we need for the Rover V8?

If so I think they could be the solution, once you've shipped the Proforms in from the States the price looks to be about the same as a set of ARP bolts and Nordlock washers from ACT.

If you use the Summit Racing E-Bay store it appears you can bring a set of Proforms in from the US for £40.00 all in.

http://www.ebay.co.uk/itm/Proform-Wedge-Locking-He...

Edited by ChimpOnGas on Saturday 31st January 10:17

You WANT 1" due to the thickness of the manifold flange - add on any extra length if you use packing washers (ie nordlock etc) IMHO.

Many heads seem to have nearly 10mm lead in to the thread after years of monster tightening &/ clumsy engagement...

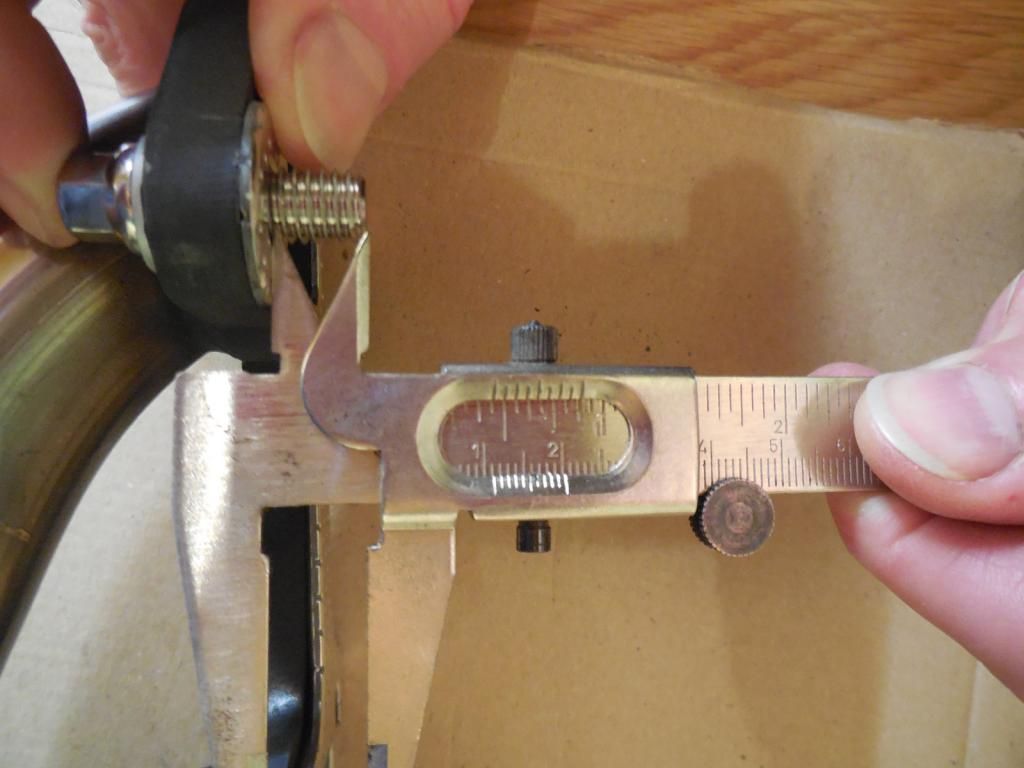

Before you accuse me of doom'n'gloom, I'd advise you tp get your vernier out and measure the thicknesses, clean out a head tapping and screw in to measure the depth (¬e how much lead-in before engagement).. plot it all on a bit of paper & you may be horrified by what you see regarding thread in use.

Many heads seem to have nearly 10mm lead in to the thread after years of monster tightening &/ clumsy engagement...

Before you accuse me of doom'n'gloom, I'd advise you tp get your vernier out and measure the thicknesses, clean out a head tapping and screw in to measure the depth (¬e how much lead-in before engagement).. plot it all on a bit of paper & you may be horrified by what you see regarding thread in use.

spend said:

You WANT 1" due to the thickness of the manifold flange - add on any extra length if you use packing washers (ie nordlock etc) IMHO.

Many heads seem to have nearly 10mm lead in to the thread after years of monster tightening &/ clumsy engagement...

Before you accuse me of doom'n'gloom, I'd advise you tp get your vernier out and measure the thicknesses, clean out a head tapping and screw in to measure the depth (¬e how much lead-in before engagement).. plot it all on a bit of paper & you may be horrified by what you see regarding thread in use.

Hmmm, interesting and I'm listening Many heads seem to have nearly 10mm lead in to the thread after years of monster tightening &/ clumsy engagement...

Before you accuse me of doom'n'gloom, I'd advise you tp get your vernier out and measure the thicknesses, clean out a head tapping and screw in to measure the depth (¬e how much lead-in before engagement).. plot it all on a bit of paper & you may be horrified by what you see regarding thread in use.

Proform do offer 1" bolts, (3/8" x 1"L) their p/n being 66753 but it looks like these come in sets of 12 only. I have to wonder with the ramping washers being fixed to the bolt where Proform are actually taking the length measurement from

Do they consider the washer face the bolt shoulder?

If so perhaps it's still possible the 3/8" x 3/4"L set would be sufficiently long?

How much thread is left on an ARP bolt when Norlocks are used?

jojackson4 said:

Great, thanks for that.So by my reckoning the Proform 16 bolt set in 3/8" x 3/4"L (p/n 66752) give you just 3mm less thread than an ARP bolt with a Nordlock on it, which we all know have no thread length issues.

Assuming you can still get the 3mm shorter Preform to start I cant see there being an issue with the 3/4 length (p/n 66752) set.

I guess if you went with the 1" Proforms you could always cut them them down a fraction if they showed to be bottoming out, but as these 1" version only come in a set of 12 you're into buying two sets.

A way to do it cheaper would be buy 3 sets of 12 to give you 36 and share them with a friend, that way each of you only have 2 spare bolts left over

Because you'll be shipping in two sets the postage will be cheaper when shared, I expect each set of 18 x 1" Proforms will end up the same price as one set of 16 x 3/4".

Genius

All you need is a like minded friend

I can insert 2mm +/- 0.3mm on all but two. Those two are both 5mm. This measured at the point that the bolt can no longer be withdrawn

I therefore generally have 9mm with two at 6mm of engaged thread. Not much considering the weakness of alloy threads and the bolting force needed to create a flat gasket seal

I therefore generally have 9mm with two at 6mm of engaged thread. Not much considering the weakness of alloy threads and the bolting force needed to create a flat gasket seal

You definately need all of the 1 inch long bolt as Spend says. This in my mind still gives very little grab in terms of engaged threads. The problem is you cant go longer than 1 inch bolts, ( on the lower ones, ok on the top ), otherwise you wouldnt physically get the lower bolts into the flanges due to the close proximity of the header tubes. I suppose this is where studs on the lower ones help as you can engage all the threads and use longer bolts in the top ones.

Nice find tho Dave, something certainly needs sorting re our forever loosening header bolts, maybe these are the best solution to date. I like the look of the Stage 8 fasteners from Summitt but they are sooo expensive.

Nice find tho Dave, something certainly needs sorting re our forever loosening header bolts, maybe these are the best solution to date. I like the look of the Stage 8 fasteners from Summitt but they are sooo expensive.

carsy said:

Just watched the proform video. I cant see any difference to the Nordlocks. Surely Nordlock washers with a relatively soft material bolts so they grab the bolts will be just as effective and cheaper.

Well in a way you're right, its just the Pro form bolts trap the ramping washers making instaltion easier. I guess you could use a dab of superglue to achieve the same thing as it would break free as you tightened the bolts.

I still have my original mild steel bolts and can see from the point that corrosion stops that they didn't have much engaged thread either. If you consider the force that can be applied to a standard nut and bolt fastening and consider the length of engaged thread in the nut then we're 2 to 3 times more than that.

Force & reaction... Everything you use to exert extra clamping under the bolt is acting in reverse on the threads. It's just a warning to use some common sense rather than the "oh bugger - just tighten it up some more".. approach.

I always see it as with more thread engagement the differential expansion between alloy head & steel bolt works to lock the bolt tight, which leads to an obvious deduction of why so many suffer loose bolts?

ETA: which is a big advantage with slotting : you can get bolts / studs in nicely with good engagement.

I always see it as with more thread engagement the differential expansion between alloy head & steel bolt works to lock the bolt tight, which leads to an obvious deduction of why so many suffer loose bolts?

ETA: which is a big advantage with slotting : you can get bolts / studs in nicely with good engagement.

Gassing Station | Chimaera | Top of Page | What's New | My Stuff