Lund's MG Metro 1275 Engine Build

Discussion

minimadmotorman said:

Head has probably just had a recon then.

Yeah thats most likely. I managed to pry the head from the block on one side with the scissor jack, however it needs to be removed flat otherwise it wont come off. I got the straw on the WD and sprayed all between the block and the head, so that should free things up abit. I think the head studs are snagging the head therefore not pulling off. I've even had the engine upside down, hitting the head with a rubber mallet...no avail! I put the plugs back in and turned the engine over, hoping the compression would blow the head through the roof, but...no avail. I suspect the head has had a recon as the bronze valve guides suggest this. I think I'll be taking a dremel to the ports like I did on the 850.

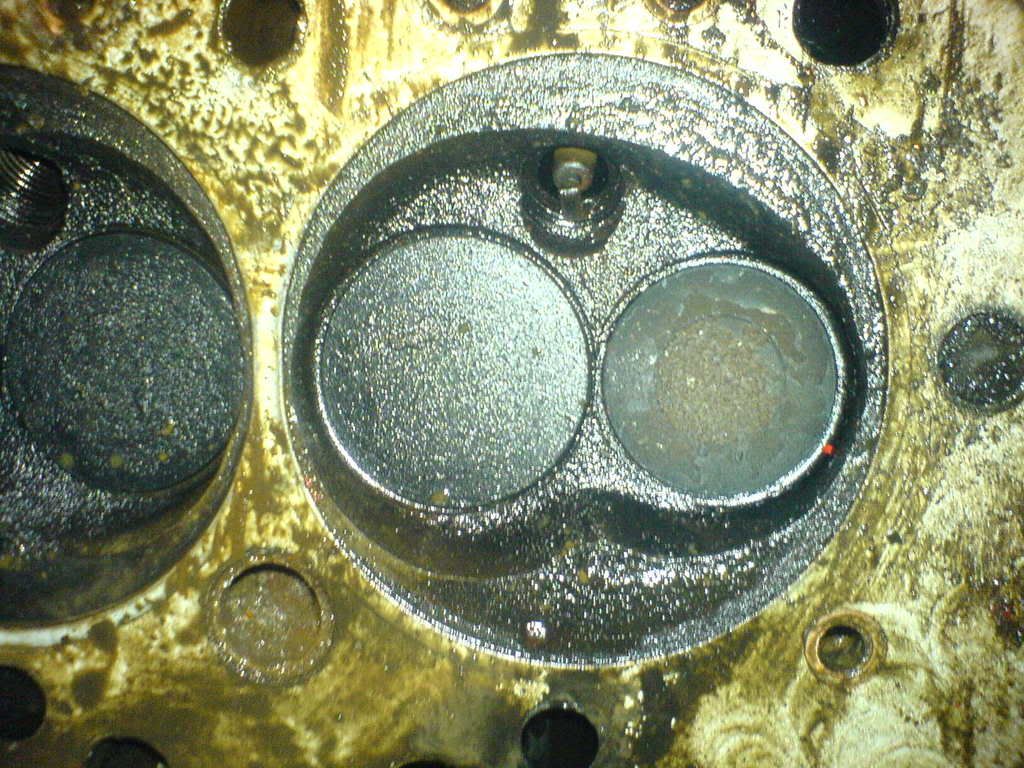

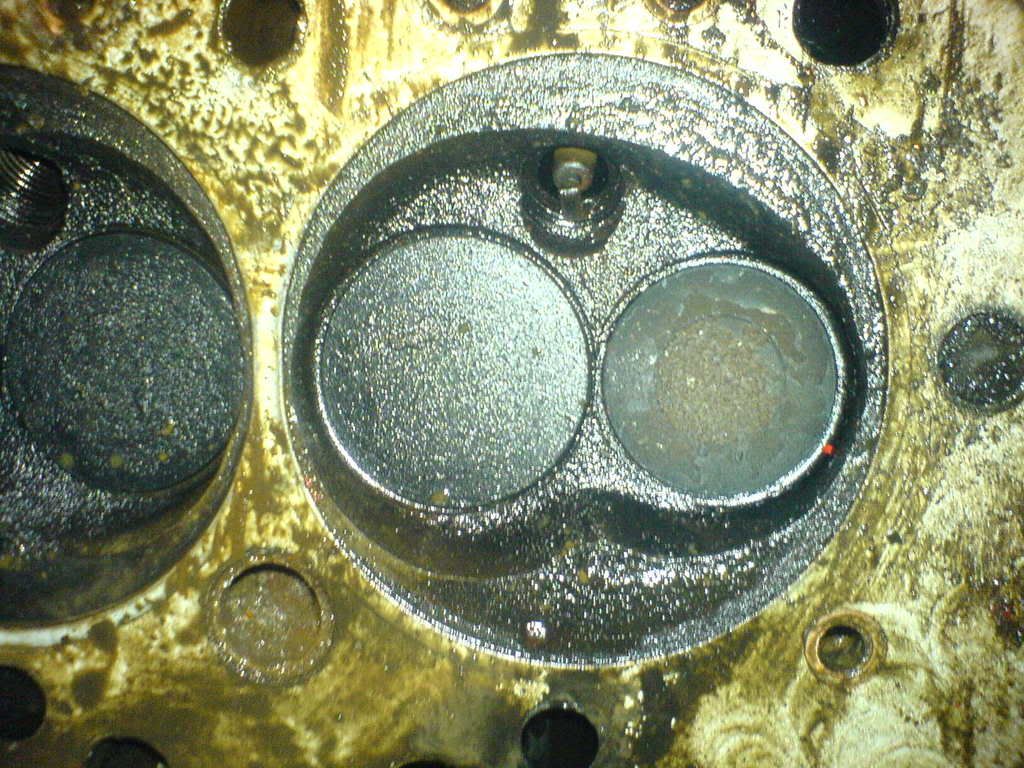

Managed to get the head off. The central head bolt is actually rusted onto the 'sleeve' if you like , of the cylinder head i.e the stud has been removed from the block but is stuck in the head. I removed all of the head bolts and spun the head round on the bolt to remove it. On inspection, all looks well. Excuse the poor picture quality, I'm using my phone:

Are these chambers standard?

How should I go about cleaning the tops of the pistons, and chambers. I have done it before, but unsure how to approach it this time round - what works best?

Tom

Are these chambers standard?

How should I go about cleaning the tops of the pistons, and chambers. I have done it before, but unsure how to approach it this time round - what works best?

Tom

guru_1071 said:

1275 a plus motors do have a habit of sticking on that centre bolt - i think at some time the hole centres moved a little in the heads. that one is always the worse cuplret.

ive had to resort to various methods before to get them off!

...and those various methods are? ive had to resort to various methods before to get them off!

I'm leaving the MG engine alone for a while now, Im going to hack the gearbox off the 1275 and diff off the 998...wish me luck, there's no doubt in my mind that its going to be a struggle!

I'm leaving the MG engine alone for a while now, Im going to hack the gearbox off the 1275 and diff off the 998...wish me luck, there's no doubt in my mind that its going to be a struggle! Mini_Lund said:

...and those various methods are?

1) heating the head up with oxy bottles and spraying WD40 around the stud - worked ok. - but took ages, about a week of warming it up and leaving it overnight - i didnt want to damage the head by getting it too hot.

2) welding a nut onto the stud and winding it out with a socket - worked the best (this works with thermostat studs as well!)

3) hanging the engine from a decent chain (attached to the head) and jumping up and down on the gearbox. did work, but not recomended!!!!

4) getting the head up about 5mm and sawing the studs through with a hacksaw blade wrapped in tape.......not a exercise i will ever repeat, no matter how stuck the owner of the car is. this was before i owned decent tools, a trailer etc etc!!!!!

interestingly heads sticking to blocks was such a common problem for 1950's bentleys, they actually had a special tool that could be attached which would 'jack' the head off the block in situ!

fortunatley the heads ok on ours (at the expense of body work, but hey ho!)

i have ad an engine in the past that had obviously had this problem, when i removed the head and cleaned it the centre front studhole casting 'lump' was flattened and the casting had a hair line crack about 1" from the top surface downwards, caused by some fool braying at the head with a large hammer.

Edited by guru_1071 on Sunday 18th January 19:44

guru_1071 said:

Mini_Lund said:

...and those various methods are?

1) heating the head up with oxy bottles and spraying WD40 around the stud - worked ok. - but took ages, about a week of warming it up and leaving it overnight - i didnt want to damage the head by getting it too hot.

2) welding a nut onto the stud and winding it out with a socket - worked the best (this works with thermostat studs as well!)

3) hanging the engine from a decent chain (attached to the head) and jumping up and down on the gearbox. did work, but not recomended!!!!

4) getting the head up about 5mm and sawing the studs through with a hacksaw blade wrapped in tape.......not a exercise i will ever repeat, no matter how stuck the owner of the car is. this was before i owned decent tools, a trailer etc etc!!!!!

interestingly heads sticking to blocks was such a common problem for 1950's bentleys, they actually had a special tool that could be attached which would 'jack' the head off the block in situ!

fortunatley the heads ok on ours (at the expense of body work, but hey ho!)

i have ad an engine in the past that had obviously had this problem, when i removed the head and cleaned it the centre front studhole casting 'lump' was flattened and the casting had a hair line crack about 1" from the top surface downwards, caused by some fool braying at the head with a large hammer.

Edited by guru_1071 on Sunday 18th January 19:44

for getting the head off on a mates engine i managed to prye the head up about 5-6mm then got 4 wooden wedges and kept braying them in with hammer and soaking it with wd40 i found this worked very well but dont ever try this with the engine still in the car it dosnt work. to get a suck head off in the car i found that it was easiest just to put the engine lifting brackets on and get the crane out and just put a little pressure off and give it a few taps with and copper mallet.

hope this helps

hope this helps

I have put the MG 1275 to one side for the moment. Today I took the diff off the 998, and then decided I'll use the box on the 998 as its the same casting as the 1275 box, and the gears engage nicely using the selector. Of course I cannot tell which is the better box without takin the box off, but I'll gamble and try my luck with the 998 box as it has all been sealed with plenty of oil in. The 1275 is missing the diff.

Both castings are D5626. The diff looks clean and in good condition - I have never had a diff off or a box off the block, so I didn't havt a clue what to expect...

I have loosely put the diff back on the 998 box, (just 4 bolts for now). I have managed to loosen most of the bolts fixing the box to the block, however am I right in thinking I need to get the flywheel and housing cover off to do this? I've have undone most of the bolts, but can't get to some as they are behind the fly.

I removed the large bolt in the centre of the fly and the several bolts around the outer edge, but it will not shift - do I require a flywheel puller?

Thanks in advance, Tom

Both castings are D5626. The diff looks clean and in good condition - I have never had a diff off or a box off the block, so I didn't havt a clue what to expect...

I have loosely put the diff back on the 998 box, (just 4 bolts for now). I have managed to loosen most of the bolts fixing the box to the block, however am I right in thinking I need to get the flywheel and housing cover off to do this? I've have undone most of the bolts, but can't get to some as they are behind the fly.

I removed the large bolt in the centre of the fly and the several bolts around the outer edge, but it will not shift - do I require a flywheel puller?

Thanks in advance, Tom

Lost track of you gearbox/diff combo but if you are swapping diffs keep diff housing with its original box.

When you pull flywheel make sure you remove the washer and wind the big bolt back in leaving a few mm gap. If that flywheel hangs on there they cant half go across the floor or worse if its on a bench and falls on your foot.

When you pull flywheel make sure you remove the washer and wind the big bolt back in leaving a few mm gap. If that flywheel hangs on there they cant half go across the floor or worse if its on a bench and falls on your foot.

MHM said:

Lost track of you gearbox/diff combo but if you are swapping diffs keep diff housing with its original box.

When you pull flywheel make sure you remove the washer and wind the big bolt back in leaving a few mm gap. If that flywheel hangs on there they cant half go across the floor or worse if its on a bench and falls on your foot.

Sorry, I have even managed to confuse myself. Bare with me! I will be using both the 998 box and 998 diff as the gearbox is the same as that on the 1275. I've heard about central oil pickup pipes, is that a welcomed modification to my gearbox?When you pull flywheel make sure you remove the washer and wind the big bolt back in leaving a few mm gap. If that flywheel hangs on there they cant half go across the floor or worse if its on a bench and falls on your foot.

guru_1071 said:

yep

you need a puller to get the flywheel off

then the transfer case can be removed.

then the engine can be lifted of the box.

Thanks for the heads up, I'll put the bolt back in so the fly doesnt scream across the room! Apparently they don't half make a 'crack' when they are removed. you need a puller to get the flywheel off

then the transfer case can be removed.

then the engine can be lifted of the box.

When I removed the diff a small spring popped out, I can see a small ball bearing on the gearbox case itself, (bottom right) with diff removed, im guessing it has popped out from there when I removed it.

ETA: On another note, I managed to knock all the conrods out of order!

So where do I stand with the conrods; Do I buy new ones or put these back in and wear the engine in. They all seem in good condition. & & I never noticed how the MG 1275 is a shorter block than a mini 1275. No head bypass hose or tappet chests.

So where do I stand with the conrods; Do I buy new ones or put these back in and wear the engine in. They all seem in good condition. & & I never noticed how the MG 1275 is a shorter block than a mini 1275. No head bypass hose or tappet chests.Edited by Mini_Lund on Monday 19th January 18:36

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff