Lund's MG Metro 1275 Engine Build

Discussion

Hi all, small update, I currently have the flywheel understress withthe remover, I think I need a few protein shakes and a can of Relentless to crack the bugger off; does it really take that much force?

Also is it possible to have the centre fly bolt screwed too far in for the fly to be removed?

On another note, I have de-greased the engine block, but managed to knock my pan of oil all over the garage whilst trying to force the fly off.

Nothing is ever plain sailing...

Also is it possible to have the centre fly bolt screwed too far in for the fly to be removed?

On another note, I have de-greased the engine block, but managed to knock my pan of oil all over the garage whilst trying to force the fly off.

Nothing is ever plain sailing...

FWDRacer said:

Have you tried a kettle (s)full of boiling water on the centre part of the flywheel when the puller is under full tension. That and a few huge hits with a copper mallet? The expansion of the flywheel material and shocking is sometimes just enough to loose the taper.

Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

I've got it off, it didn't shoot off or crack off, to be honest I had no idea it had come loose until the whole shabang fell off onto the floor! I was like, 'oh, I've done it!'Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

Now to seperate the gearbox from the block...another nightmare >.<

ETA:

Cheeky!

Tom

Edited by Mini_Lund on Wednesday 4th February 18:46

There's one bolt in the way of me removing the block from the gearbox and the spanners chewing up the head, by the time I realised it was a tad too late. I cannot get a ratchet spanner on it. I've sprayed the bolt with WD40 and Gunk, however it will not shift. Bugger! What are my options?

minimatt1967 said:

Can you get a deep socket on it? Alternatively try counselling, you seem to be having a lot of luck with this engine unfortunately its all bad

This is exactly my luck...not much! The head bolt is also still welded the the head, it just wont shift!! No doubt the block will also be welded to the gearbox!

rufusruffcutt said:

Mini_Lund said:

There's one bolt in the way of me removing the block from the gearbox and the spanners chewing up the head, by the time I realised it was a tad too late. I cannot get a ratchet spanner on it. I've sprayed the bolt with WD40 and Gunk, however it will not shift. Bugger! What are my options?

Sorry to hear your having problems.Exactly which bolt is it on the block/gearbox? i.e next to the flywheel housing, front, back? If its one of the more accessible bolts, could you grind some new flats onto the head of the bolt. And then try again (carefully!) with an open ended spanner?

You'll need a dremmel sized grinder for this though!.

If this does not work, grind the bolt head off so you can at least split the block and gearbox, but then you will have the delicate task of drilling out the remaining bolt from the block and then re-cutting the threads...

Anyone else got any ideas...

Edited by rufusruffcutt on Thursday 5th February 14:43

Have you lot been praying for me? I got the snap-on tools out and hammered a 'size down' socket onto the bolt (p.s Dont let dad know!) and used the elbow joint to allow me to get a ratchet onto the socket.

Have you lot been praying for me? I got the snap-on tools out and hammered a 'size down' socket onto the bolt (p.s Dont let dad know!) and used the elbow joint to allow me to get a ratchet onto the socket....

Counted the teeth on the CW & P

Pinion had 19.

Crownwheel had 59.

Diff Ratio of 3:1 (I think) - How does that sound?

minimadmotorman said:

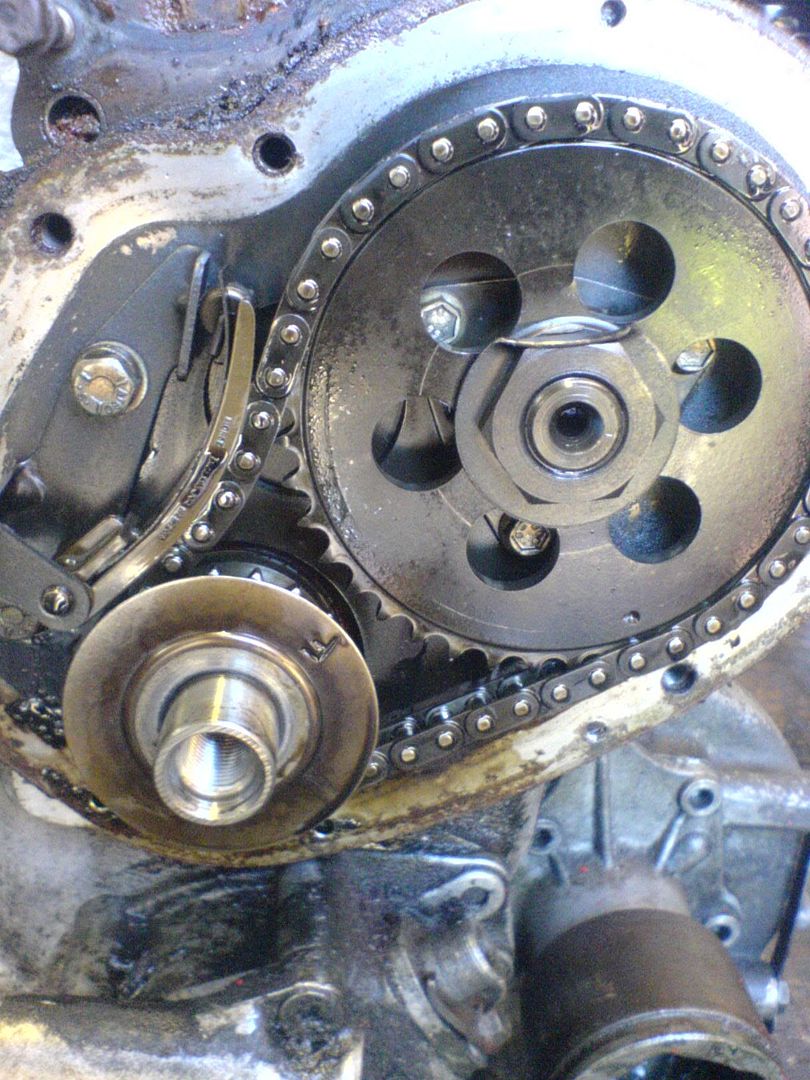

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Okay, by undoing the 4 bolts on the cam cover, does this make the cam out of time? The engine has been previously rolling roaded, and is as it was set-up; Minus the dizzy now though. Yes I'm using the MG engine. Duplex timing chain just makes it quiter doesn't it? What are the benefits of this?The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

robminiman said:

Mini_Lund said:

minimadmotorman said:

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Okay, by undoing the 4 bolts on the cam cover, does this make the cam out of time? The engine has been previously rolling roaded, and is as it was set-up; Minus the dizzy now though. Yes I'm using the MG engine. Duplex timing chain just makes it quiter doesn't it? What are the benefits of this?The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

I de-coked the head as I have managed to get the inlet valves out also. You can see the bolt that wont budge!

Thanks guys I'll give all of the above a good try! It really wont shift. I've screwed 2 bolts onto the thread but the second bolt is giving way before the stud in the head, no matter how hard I jam them together! I'll have to pick up a new can of butane from somewhere.

In regards to my Diff and ratio, am I right in thinking I have a 3:1 ratio?

In regards to my Diff and ratio, am I right in thinking I have a 3:1 ratio?

minimadmotorman said:

Get the head face down on something flat and tough with a hole for the stud and give it a clout with a BFH!

As for duplex. A 1275 A+ wont have duplex as standard. benefit of duplex is less stretch so your cam timing stays more accurate.

Cam's are only timed dot to dot in the factory and this isnt necessarily the optimum. If you use a cast duplex setup and an appropriate offset key you could unlease a few ponies without spending much money at all.

The problem is , I'm unaware of what the cam is! Will I need to know what Cam it is to time it in correctly? - I also have no idea on cam timing or how to do it... brilliant!As for duplex. A 1275 A+ wont have duplex as standard. benefit of duplex is less stretch so your cam timing stays more accurate.

Cam's are only timed dot to dot in the factory and this isnt necessarily the optimum. If you use a cast duplex setup and an appropriate offset key you could unlease a few ponies without spending much money at all.

Edited by Mini_Lund on Friday 6th February 11:04

minimadmotorman said:

Sounds like a 3.1 to me. Good diff with a 1275 & 10" wheels.

Brilliant. What sort of top speed would I be looking at, hopefully it's more keyed for acceleration and town driving, aswel as fun on the lanes.Think I'll pull the cam out and see what it is. Is this a good idea? Basically just so I know what I've got.

minimadmotorman said:

always a good idea to pull the cam if you are giving the engine a refresh then you can see if its in good fettle.

Cheers for the response guys, I'll have to have a look at how to remove more engine components, as I have no idea now it comes down to the nitty gritty. This is all a learning curve for me. I'm 19, but thats no excuse! And sorry yes, I meant to say Nuts rather than bolts.Oh and on another note, I managed to remove the head stud from the cylinder head

minimadmotorman said:

by what method?

I got the work bench out (which has several holes in it) layed the cylinder head down flat, screwed a nut onto the bolt and it then met my friend 'Thor hammer' out of the garage cupboard

Again I will sound stupid, but I have removed all of the bolts on the timing cover and noted whereabouts they go, but I cannot remove the cover due to the pulley on the end of the crankshaft, do I have to undo the crankshaft bolt or will the pulley come off without undoing this bolt? I really have no idea.

Edited by Mini_Lund on Friday 6th February 16:59

guru_1071 said:

id guess so.

nice use of 'xmas' sweet tins there!!!

Oh right, well there doesn't seem to be any wear and tear, maybe its a cam out of a GTA or a Turbo? Apparently it has been changed, but there were no signs to say this. & yes, the Xmas sweet tins are great for holding all of the bolts!nice use of 'xmas' sweet tins there!!!

I hate to admit it but it looks like It's going to need a rebore, I wasn't intending on taking this engine build the full 9 yards, but it looks like i'm going to have to! There's quite a lip on the top of one of the bores from the pistons. Looks like I'm going to have to enquire about a re-bore, and re-grind the crank etc etc.. ££££

Power washed the full lot, dried and WD'd for now. Its all looking okay.

Power washed the full lot, dried and WD'd for now. Its all looking okay.

Edited by Mini_Lund on Saturday 7th February 17:41

robminiman said:

i apollagise for my previouse post saying 1275s had duplex timing chain.

i had mine rebored and it cost me £200 for a rebore and 4 pistons with rings and gudgen pin etc, crank regrind with thrusts and shells was £120 then i also had the cam bearings done which was £30

money very well spent

i think it was guru or cooperman who said to me "build it cheap build it twice"

Okay, I guess I'm now going the whole 9 yards! I was intending to try get away without having to rebore, but I'm still abit unsure whether or not it needs it or not? - I have a honer in the garage somwhere i had mine rebored and it cost me £200 for a rebore and 4 pistons with rings and gudgen pin etc, crank regrind with thrusts and shells was £120 then i also had the cam bearings done which was £30

money very well spent

i think it was guru or cooperman who said to me "build it cheap build it twice"

Are there any specific guidelines?

I will require your advice on oversize pistons, compression ratio's, unleaded fuel and the latter.

I take it my block is standard, and will be overbored; usually about +.020 (I think) Now does that take it upto 1293, or am I going wrong somewhere?

Please do excuse all of the numpty questions, I know what I'm like, asking lots of questions rather than doing my own research...

Thanks

Edited by Mini_Lund on Sunday 8th February 11:25

Dino42 said:

Mini_Lund said:

.... having to rebore, but I'm still abit unsure whether or not it needs it or not? ...Are there any specific guidelines?

Yes, but you won't have the specific equipment needed to measure the bores and crank accuratly.

It's best to take all the bits to a decent machine shop and ask their advice - they're going to do the work after all.

miniLund said:

..I will require your advice on oversize pistons, compression ratio's, unleaded fuel...

The standarc rebore sizes are:+0.020" = 1293cc

+0.040" = 1310

+0.060" = 1330

Just go to the next one up from what the block's at now. (You can't assume it's standard now btw)

Minispares 21251 pistons are fine for a road engine.

Aim for a compression ratio of something like 9.75:1

Unleaded fuel: it's really a question of whether your head has hardened inserts in the exhaust seats, if not you can use an additive.

Edited by Dino42 on Sunday 8th February 11:55

I'll strip the engine to the bare block and get some enquiries from birkenhead engines.

Hi all, brief update;

The engine is in the machine shop now. It is a fresh block and has never been rebored. I'll find out by how much it has been bored-out by, sometime soon. I have opted for 'high compression' pistons. It's costing me in the region of £320 + VAT. Which is'nt too bad I don't suppose?

The engine is in the machine shop now. It is a fresh block and has never been rebored. I'll find out by how much it has been bored-out by, sometime soon. I have opted for 'high compression' pistons. It's costing me in the region of £320 + VAT. Which is'nt too bad I don't suppose?

Edited by Mini_Lund on Thursday 12th March 16:52

Not too much to report, but bring on saturday! I'll be collecting the rest of the MG engine, hopefully as complete as possible inc. Carb, inlet, filter etc & I'll also be picking up the engine from the machiners! I, cleaned up the timing cover, its just in primer at the moment until I buy some gloss black VHT paint. The finish on the primer isn't all that brilliant, it could do with a light sand as the flies took a liking to the freshly sprayed paint, but I'm not that bothered as once its in, I wont be seeing much of the timing cover;

Primered:

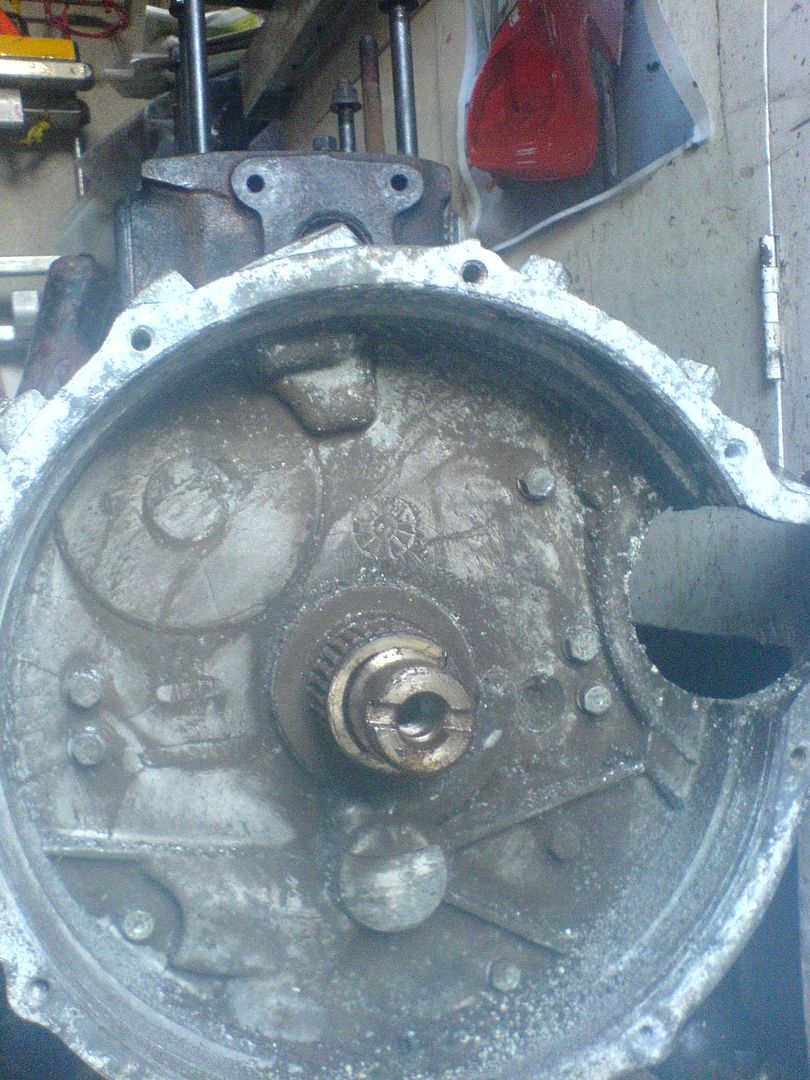

The selector on the gearbox has become loose, from me playing around with it selecting gears! Is this a 'gears out' job? Im reluctant to rebuild the box, because it scares me, and I can't really afford a rebuild with having to buy S disc brakes also

Tom

Primered:

The selector on the gearbox has become loose, from me playing around with it selecting gears! Is this a 'gears out' job? Im reluctant to rebuild the box, because it scares me, and I can't really afford a rebuild with having to buy S disc brakes also

Tom

Edited by Mini_Lund on Thursday 12th March 16:53

Cooperman said:

If you are going to fit a duplex timing chain you need to make sure that the timing cover won't hit the chain. In particular, from the picture of your cover, you'll notice that at about 30 degrees up and to the right of the crank aperture, there is a small detent which you should gently hammer out to ensure chain clearance. Also, inside the cover there may be a semi-circular flange about 3/8" high. This needs to be ground off to get chain clearance. I've just posted this on another thread then I noticed your photos.

Thanks Pete, you're quite right; Any excuse to get the hammer out  I'll hammer that dent, and have a look on the inside for the potential snagging areas. Am I right In thinking that I should buy the duplex chain, set up the DTI, time it best I can and then decide what offset keys I need to get it more or less spot on? Is it worth buying the lightened chain? i.e would you buy the lightened or non lightened for your engine build?

I'll hammer that dent, and have a look on the inside for the potential snagging areas. Am I right In thinking that I should buy the duplex chain, set up the DTI, time it best I can and then decide what offset keys I need to get it more or less spot on? Is it worth buying the lightened chain? i.e would you buy the lightened or non lightened for your engine build?guru_1071 said:

lund

it just goes back in when you rotate it, you may have to jiggle the selectors a little just to line it all up.

from memory there is one bad spot where it will jam if you try and force it, but the tounge has to be pointing down for that to happen

Okay thanks, I'll have to have another fiddle to see if I can miraculously fix it back into place! it just goes back in when you rotate it, you may have to jiggle the selectors a little just to line it all up.

from memory there is one bad spot where it will jam if you try and force it, but the tounge has to be pointing down for that to happen

Edited by Mini_Lund on Thursday 12th March 19:15

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff