Lund's MG Metro 1275 Engine Build

Discussion

guru_1071 said:

all the 1275 blocks are the same height - there may be a few mm differance (to account for the piston heights), but if its more than that you either have serious problems, or something very expensive....

Yeah, I just noticed. I was comparing the 1275 to the 998 and was sitting in the garage like 'hold on a minute!' minimadmotorman said:

When you say conrods do you actually mean pushrods?

I think so yes, the rods that push the tappets.Im just embarrasing myself now, you'll all be thinking its a bloody miracle if i get this engine working...

minimadmotorman said:

Don't worry about mixing the pushrods up.

Okay thanks, Just my old fella had a go at me and I couldn't understand why...

ETA: I need to find my puller before I can make any real progress

&& my 850's running rough, I suspect the carb, it wont idle for long just the ignition light comes on and then it cuts out. Its an absolute nightmare to drive. No revs behind the accelerator pedal > too lean?

Edited by Mini_Lund on Tuesday 20th January 12:57

Hi all, small update, I currently have the flywheel understress withthe remover, I think I need a few protein shakes and a can of Relentless to crack the bugger off; does it really take that much force?

Also is it possible to have the centre fly bolt screwed too far in for the fly to be removed?

On another note, I have de-greased the engine block, but managed to knock my pan of oil all over the garage whilst trying to force the fly off.

Nothing is ever plain sailing...

Also is it possible to have the centre fly bolt screwed too far in for the fly to be removed?

On another note, I have de-greased the engine block, but managed to knock my pan of oil all over the garage whilst trying to force the fly off.

Nothing is ever plain sailing...

Have you tried a kettle (s)full of boiling water on the centre part of the flywheel when the puller is under full tension. That and a few huge hits with a copper mallet? The expansion of the flywheel material and shocking is sometimes just enough to loose the taper.

Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

FWDRacer said:

Have you tried a kettle (s)full of boiling water on the centre part of the flywheel when the puller is under full tension. That and a few huge hits with a copper mallet? The expansion of the flywheel material and shocking is sometimes just enough to loose the taper.

Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

I've got it off, it didn't shoot off or crack off, to be honest I had no idea it had come loose until the whole shabang fell off onto the floor! I was like, 'oh, I've done it!'Do not be standing in the flight path of this bad boy when the f'ing thing finally comes off

Ohhh, and get the sawdust out. Broom. Sweep.

Now to seperate the gearbox from the block...another nightmare >.<

ETA:

Cheeky!

Tom

Edited by Mini_Lund on Wednesday 4th February 18:46

There's one bolt in the way of me removing the block from the gearbox and the spanners chewing up the head, by the time I realised it was a tad too late. I cannot get a ratchet spanner on it. I've sprayed the bolt with WD40 and Gunk, however it will not shift. Bugger! What are my options?

minimatt1967 said:

Can you get a deep socket on it? Alternatively try counselling, you seem to be having a lot of luck with this engine unfortunately its all bad

This is exactly my luck...not much! The head bolt is also still welded the the head, it just wont shift!! No doubt the block will also be welded to the gearbox!

Mini_Lund said:

There's one bolt in the way of me removing the block from the gearbox and the spanners chewing up the head, by the time I realised it was a tad too late. I cannot get a ratchet spanner on it. I've sprayed the bolt with WD40 and Gunk, however it will not shift. Bugger! What are my options?

Sorry to hear your having problems.Exactly which bolt is it on the block/gearbox? i.e next to the flywheel housing, front, back? If its one of the more accessible bolts, could you grind some new flats onto the head of the bolt. And then try again (carefully!) with an open ended spanner?

You'll need a dremmel sized grinder for this though!.

If this does not work, grind the bolt head off so you can at least split the block and gearbox, but then you will have the delicate task of drilling out the remaining bolt from the block and then re-cutting the threads...

Anyone else got any ideas...

Edited by rufusruffcutt on Thursday 5th February 14:43

rufusruffcutt said:

Mini_Lund said:

There's one bolt in the way of me removing the block from the gearbox and the spanners chewing up the head, by the time I realised it was a tad too late. I cannot get a ratchet spanner on it. I've sprayed the bolt with WD40 and Gunk, however it will not shift. Bugger! What are my options?

Sorry to hear your having problems.Exactly which bolt is it on the block/gearbox? i.e next to the flywheel housing, front, back? If its one of the more accessible bolts, could you grind some new flats onto the head of the bolt. And then try again (carefully!) with an open ended spanner?

You'll need a dremmel sized grinder for this though!.

If this does not work, grind the bolt head off so you can at least split the block and gearbox, but then you will have the delicate task of drilling out the remaining bolt from the block and then re-cutting the threads...

Anyone else got any ideas...

Edited by rufusruffcutt on Thursday 5th February 14:43

Have you lot been praying for me? I got the snap-on tools out and hammered a 'size down' socket onto the bolt (p.s Dont let dad know!) and used the elbow joint to allow me to get a ratchet onto the socket.

Have you lot been praying for me? I got the snap-on tools out and hammered a 'size down' socket onto the bolt (p.s Dont let dad know!) and used the elbow joint to allow me to get a ratchet onto the socket....

Counted the teeth on the CW & P

Pinion had 19.

Crownwheel had 59.

Diff Ratio of 3:1 (I think) - How does that sound?

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

minimadmotorman said:

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Okay, by undoing the 4 bolts on the cam cover, does this make the cam out of time? The engine has been previously rolling roaded, and is as it was set-up; Minus the dizzy now though. Yes I'm using the MG engine. Duplex timing chain just makes it quiter doesn't it? What are the benefits of this?The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Mini_Lund said:

minimadmotorman said:

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Okay, by undoing the 4 bolts on the cam cover, does this make the cam out of time? The engine has been previously rolling roaded, and is as it was set-up; Minus the dizzy now though. Yes I'm using the MG engine. Duplex timing chain just makes it quiter doesn't it? What are the benefits of this?The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

robminiman said:

Mini_Lund said:

minimadmotorman said:

I take it you are going to use the MG engine? If so while it is in pieces i would be tempted to time the cam in and get some duplex timing gear in there.

The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

Okay, by undoing the 4 bolts on the cam cover, does this make the cam out of time? The engine has been previously rolling roaded, and is as it was set-up; Minus the dizzy now though. Yes I'm using the MG engine. Duplex timing chain just makes it quiter doesn't it? What are the benefits of this?The best modifications you can make are usually to optimise what you currently have. A poorly timed cam can cost you a lot of power/torque not to mention economy.

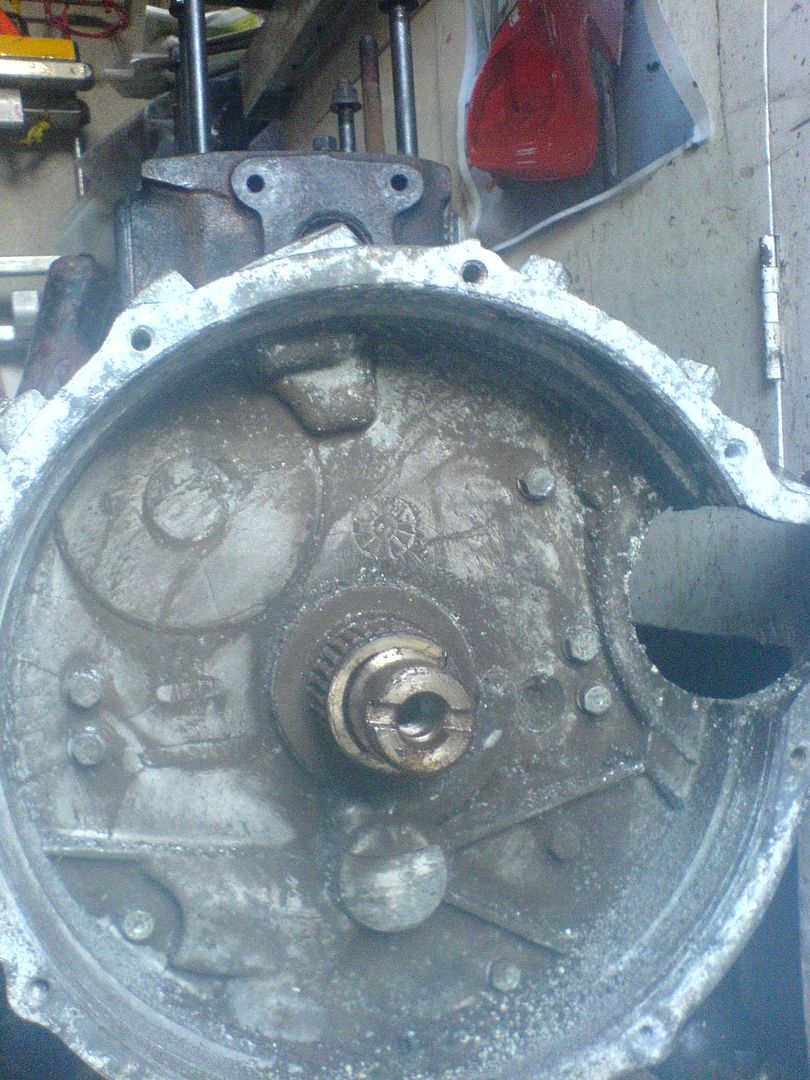

I de-coked the head as I have managed to get the inlet valves out also. You can see the bolt that wont budge!

Get the head face down on something flat and tough with a hole for the stud and give it a clout with a BFH!

As for duplex. A 1275 A+ wont have duplex as standard. benefit of duplex is less stretch so your cam timing stays more accurate.

Cam's are only timed dot to dot in the factory and this isnt necessarily the optimum. If you use a cast duplex setup and an appropriate offset key you could unlease a few ponies without spending much money at all.

As for duplex. A 1275 A+ wont have duplex as standard. benefit of duplex is less stretch so your cam timing stays more accurate.

Cam's are only timed dot to dot in the factory and this isnt necessarily the optimum. If you use a cast duplex setup and an appropriate offset key you could unlease a few ponies without spending much money at all.

Thinking out loud....

Why is the stud stuck, it's either corrosion or it is jammed because it has bent some how.

Seems to me either of the above methods should work, the heat would certainly break any corrosion, if its jammed then only the aforementioned BFH will succeed

Definition of a Precision Engineer: One who has different size hammers for different jobs.

Why is the stud stuck, it's either corrosion or it is jammed because it has bent some how.

Seems to me either of the above methods should work, the heat would certainly break any corrosion, if its jammed then only the aforementioned BFH will succeed

Definition of a Precision Engineer: One who has different size hammers for different jobs.

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff