New machine not doing what it is ment to.

Discussion

I don't think the toolpost being out by a few degrees is the cause to be honest, the height is far more likely to cause a problem, maybe try a different type of tool- even just a cheap HSS with coolant. The other thing as someone mentioned is get the gibs checked, if they are too tight it could be affecting the cut.

Are the watermarks actually in the body of the material ? Are they random or do they follow a repeated pattern ? When machining cast aluminium if the water marks are actually in the body of the material and random in location it could be platelets of silicon. The silicon is added to cast aluminium to make the aluminium more fluid. Most road wheels are made from grades BS1490 LM9 OR LM25 or European AC42000. Silicon does not dissolve in the aluminium easily....imagine oil and water.The oil lays on the top of the water. This is similar to silicon laying on the aluminium. If it is silicon there is nothing you can do.

if its not silicon

I would check the height of the tool post to make sure its on center

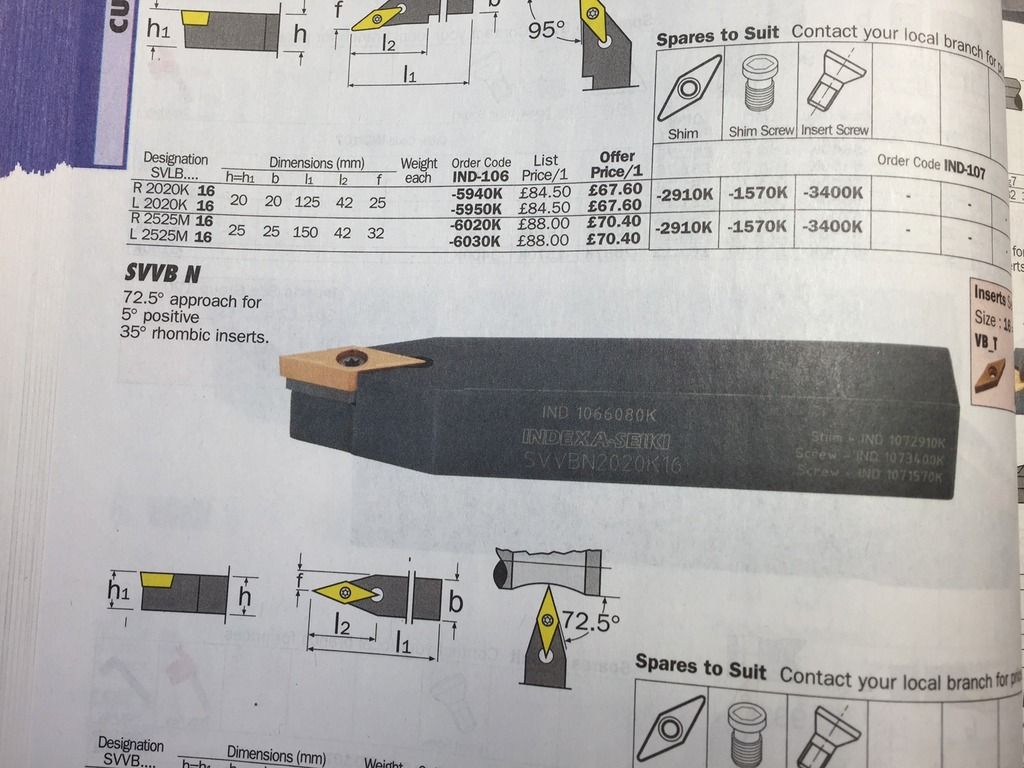

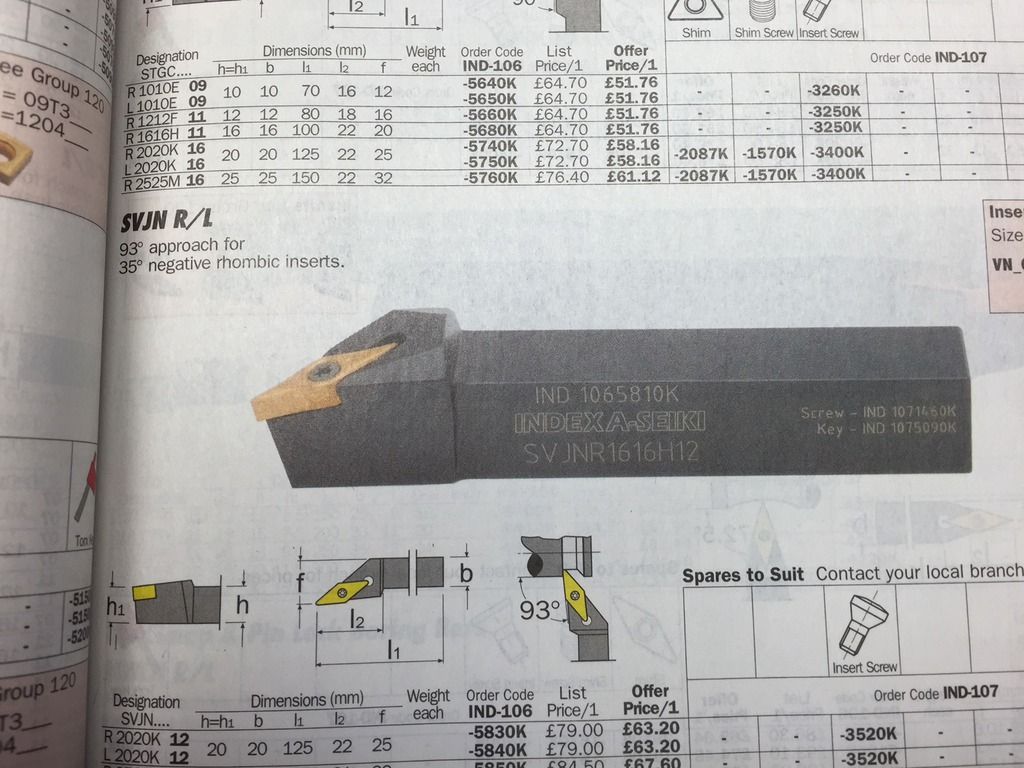

Talk to a Engineering supplies company that specialists in lathe and Mill diamond cutting tools and get there advice.

We do not use diamond tipped tools but we always cut our casting using a high quality cutting coolant.

BUT REALLY YOU HAVE PAID GOOD MONEY FOR A MACHINE THAT APPEARS NOT TO BE FIT FOR PURPOSE SO GET THE SUPPLIER IN TO SORT IT OUT !

either that or Reject the machine and pay more to buy a Haas lathe that will do the job

if its not silicon

I would check the height of the tool post to make sure its on center

Talk to a Engineering supplies company that specialists in lathe and Mill diamond cutting tools and get there advice.

We do not use diamond tipped tools but we always cut our casting using a high quality cutting coolant.

BUT REALLY YOU HAVE PAID GOOD MONEY FOR A MACHINE THAT APPEARS NOT TO BE FIT FOR PURPOSE SO GET THE SUPPLIER IN TO SORT IT OUT !

either that or Reject the machine and pay more to buy a Haas lathe that will do the job

Edited by Redarress on Tuesday 31st May 08:31

Can you get to your local metal dealer and get a raw ali blank and try that?

Also have you tried degreasing the wheel after its been cut and then maybe getting it cleaned with something like acid (might have to be v careful!)? It defo looks like something to do with oxidisation to me - skins on things like Caterhams go exactly like this in the winter if they are not well looked after..

Autosmart do a product called Red 7 that might do it...

Also have you tried degreasing the wheel after its been cut and then maybe getting it cleaned with something like acid (might have to be v careful!)? It defo looks like something to do with oxidisation to me - skins on things like Caterhams go exactly like this in the winter if they are not well looked after..

Autosmart do a product called Red 7 that might do it...

shakotan said:

thebraketester said:

DIamond cut finish, it's not supposed to be mirror finished.Diamond cut feels like the surface of a record when you run a fingernail over it.

Are you degreasing and cleaning the wheels before turning? what kind of extraction does the kit have for the swarf, could it be swarf sticking to the wheel and damaging the finish? coolant/cutting fluid usually clear this off, but you say it doesn't use any. not sure what else to suggest, lots of people in here with more knowledge than me, been 20 years since I did lathe/cnc stuff.

I'm really new to using a lathe but in my learning I was getting that finish on some practice peices.

Iirc it was down to the tool angle, I was using too much of the side of the tool. It looked like it was glazing the surface by rubbing it instead of cutting and getting spots.

What does the waste look like?

Iirc it was down to the tool angle, I was using too much of the side of the tool. It looked like it was glazing the surface by rubbing it instead of cutting and getting spots.

What does the waste look like?

No was user error.

The tool post thing is not really a problem (I think) as the tool cutting edge doesn't know what angle it's being held at as you should be setting it up at the cutting surface.

I'm trying to say - If you can set the tool at the work properly it will cut. If you assume if you put this tool in this hole it will cut - fail you will.

IMHO To me the surface in the pic doesn't look like its been cut, more like dragged off.

The training course thing IMO doesn't mean anything.

When you installed the machine did you level it properly? Back to front left to right?

And make sure the feet are equally weighted?

Did you lift it and place it or did you push into place?

These makes a difference because it could be the machine has some twist in the bed.

The tool post thing is not really a problem (I think) as the tool cutting edge doesn't know what angle it's being held at as you should be setting it up at the cutting surface.

I'm trying to say - If you can set the tool at the work properly it will cut. If you assume if you put this tool in this hole it will cut - fail you will.

IMHO To me the surface in the pic doesn't look like its been cut, more like dragged off.

The training course thing IMO doesn't mean anything.

When you installed the machine did you level it properly? Back to front left to right?

And make sure the feet are equally weighted?

Did you lift it and place it or did you push into place?

These makes a difference because it could be the machine has some twist in the bed.

Edited by DanSaff on Tuesday 31st May 11:49

I don't think the toolpost being out by a few degrees is the cause to be honest, the height is far more likely to cause a problem, maybe try a different type of tool- even just a cheap HSS with coolant. The other thing as someone mentioned is get the gibs checked, if they are too tight it could be affecting the cut.

Guys, THANK YOU so much for all your help, the company sent down their trainer today, but it's a 4-5 hrs trip on a good run, due to the moody weather we had here in the south east today he was late arriving, so back tomorrow to finish off.

He did give the machine a once over and said things like the offsets, centres, tooling and such had all been set up correctly by my lads.

Will keep you all informed. Thanks again.

He did give the machine a once over and said things like the offsets, centres, tooling and such had all been set up correctly by my lads.

Will keep you all informed. Thanks again.

Quattromaster said:

Guys, THANK YOU so much for all your help, the company sent down their trainer today, but it's a 4-5 hrs trip on a good run, due to the moody weather we had here in the south east today he was late arriving, so back tomorrow to finish off.

I'd have saved 8-10 hours on the road by spending £35 on a Travelodge!Did the trainer agree that the finish was unacceptable? Surely he could see straight away and would have passed

a comment there and then?

Some posters on this thread are not up to date with the concept of diamond turning.

Diamond (well a man made diamond called PCD)can produce fine machined surfaces BUT needs high surface speeds together with light depths of cut and a slowish feed. The alloy wheel should be spun fast but not so fast that it causes the machine to vibrate due to out of balance forces. I will be very surprised if the trainer does not increase the speed considerably.

(Take a look at the Wicked Wheels web site and watch some of the videos available.)

a comment there and then?

Some posters on this thread are not up to date with the concept of diamond turning.

Diamond (well a man made diamond called PCD)can produce fine machined surfaces BUT needs high surface speeds together with light depths of cut and a slowish feed. The alloy wheel should be spun fast but not so fast that it causes the machine to vibrate due to out of balance forces. I will be very surprised if the trainer does not increase the speed considerably.

(Take a look at the Wicked Wheels web site and watch some of the videos available.)

Gassing Station | Business | Top of Page | What's New | My Stuff