The ebay generator restoration thread

Discussion

BFG TERRANO said:

Silent1 said:

Brilliant thread, now to find the chap who mentioned 2 stroke flymos as i need to fix mine

What's up with it!??

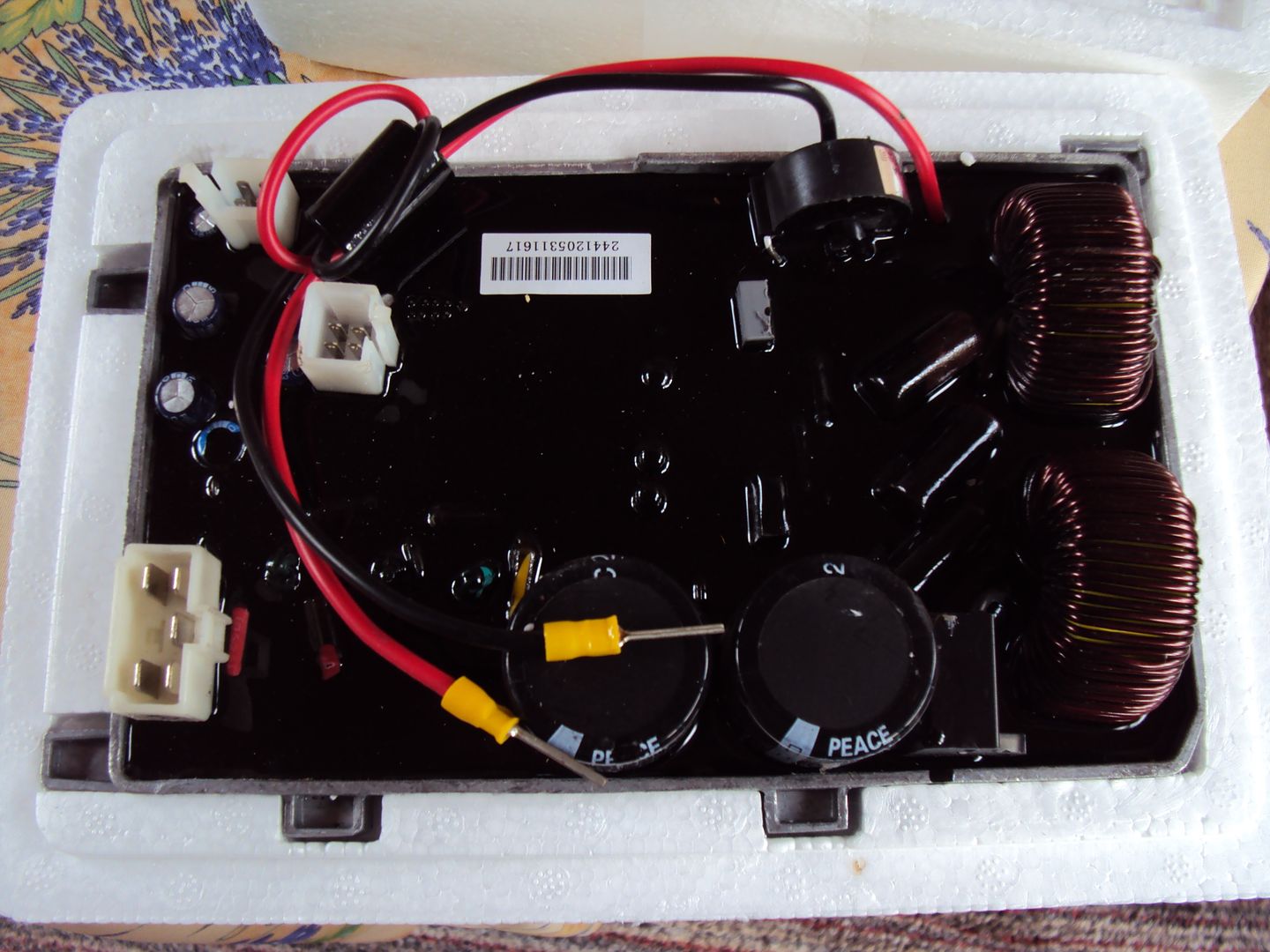

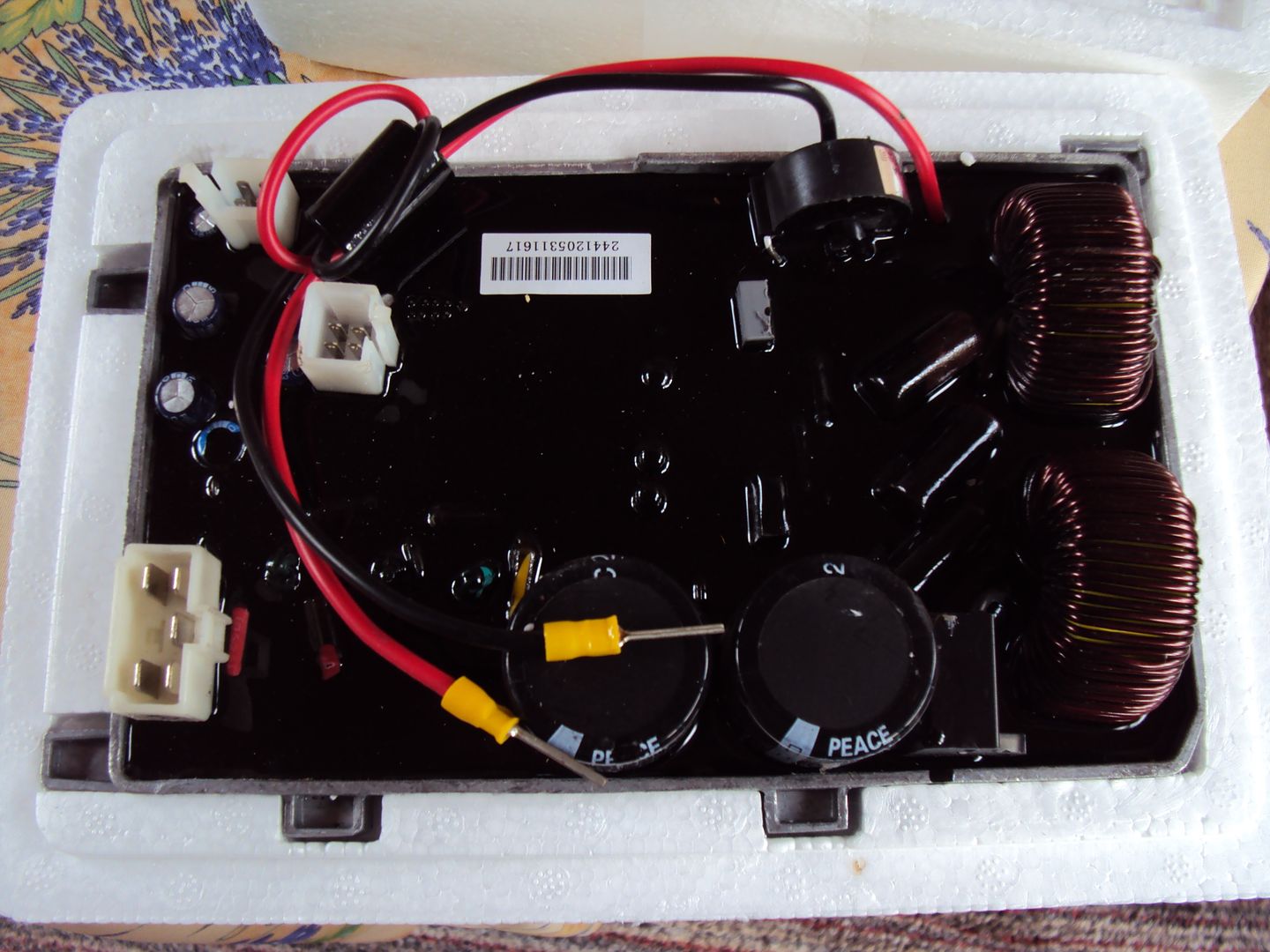

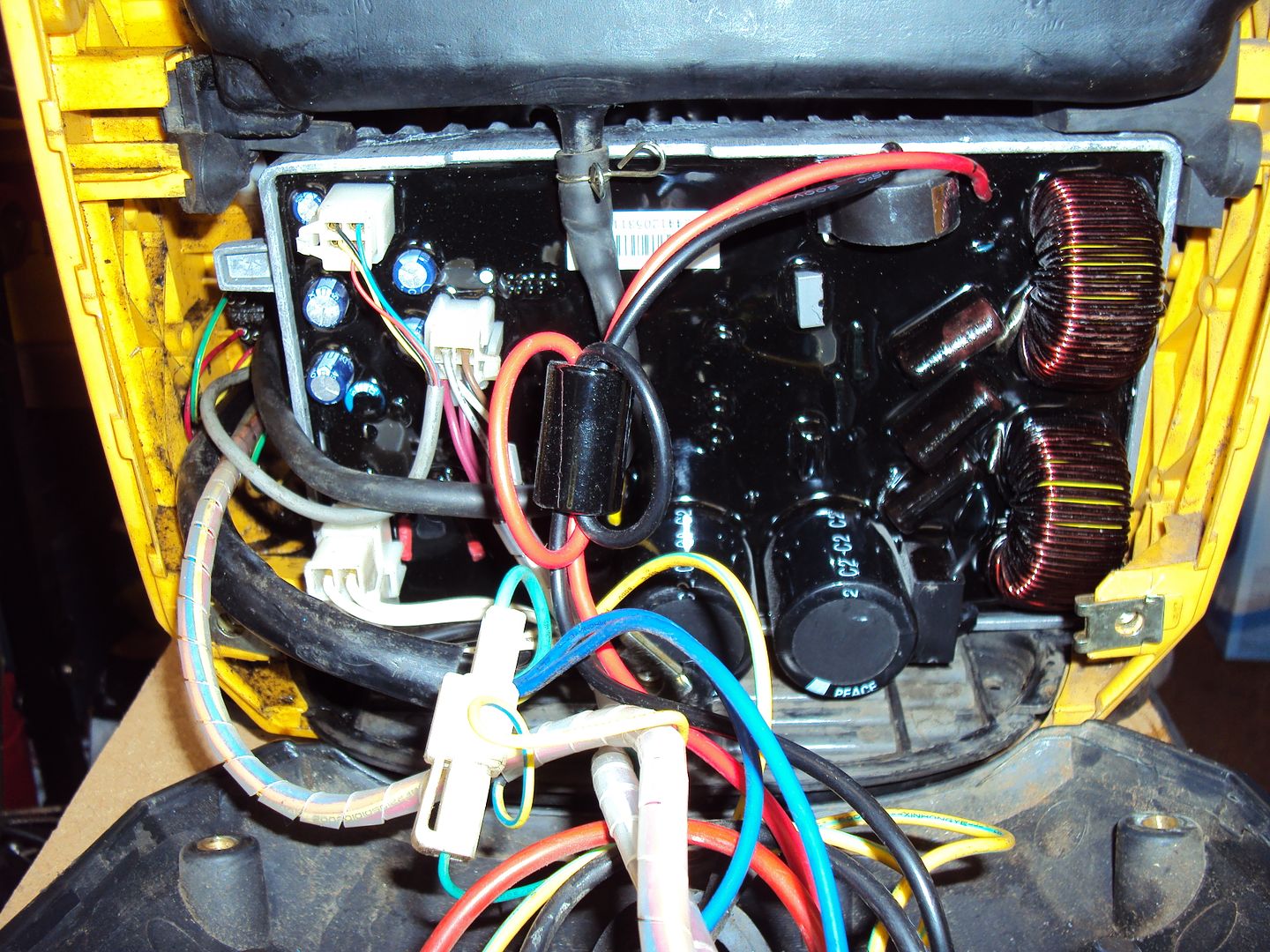

The new inverter from Kipor arrived, the design has changed a bit as it doesn’t have the big capacitor anymore.

I picked up the next project during the week, another non starter, this one has the same engine as the last one, but with the added bonus of optional electric start.

After a bit of poking around we found there was no spark, even though the ignition system all checked out ok. We determined the spark plug was at fault, when tested with the multimeter it was open circuit.

Resistance of a good plug

After replacing the sparkplug the engine spluttered into life, however there were a couple of problems. The first was there was a very loud metallic rattle, the second was it would only run with the choke on.

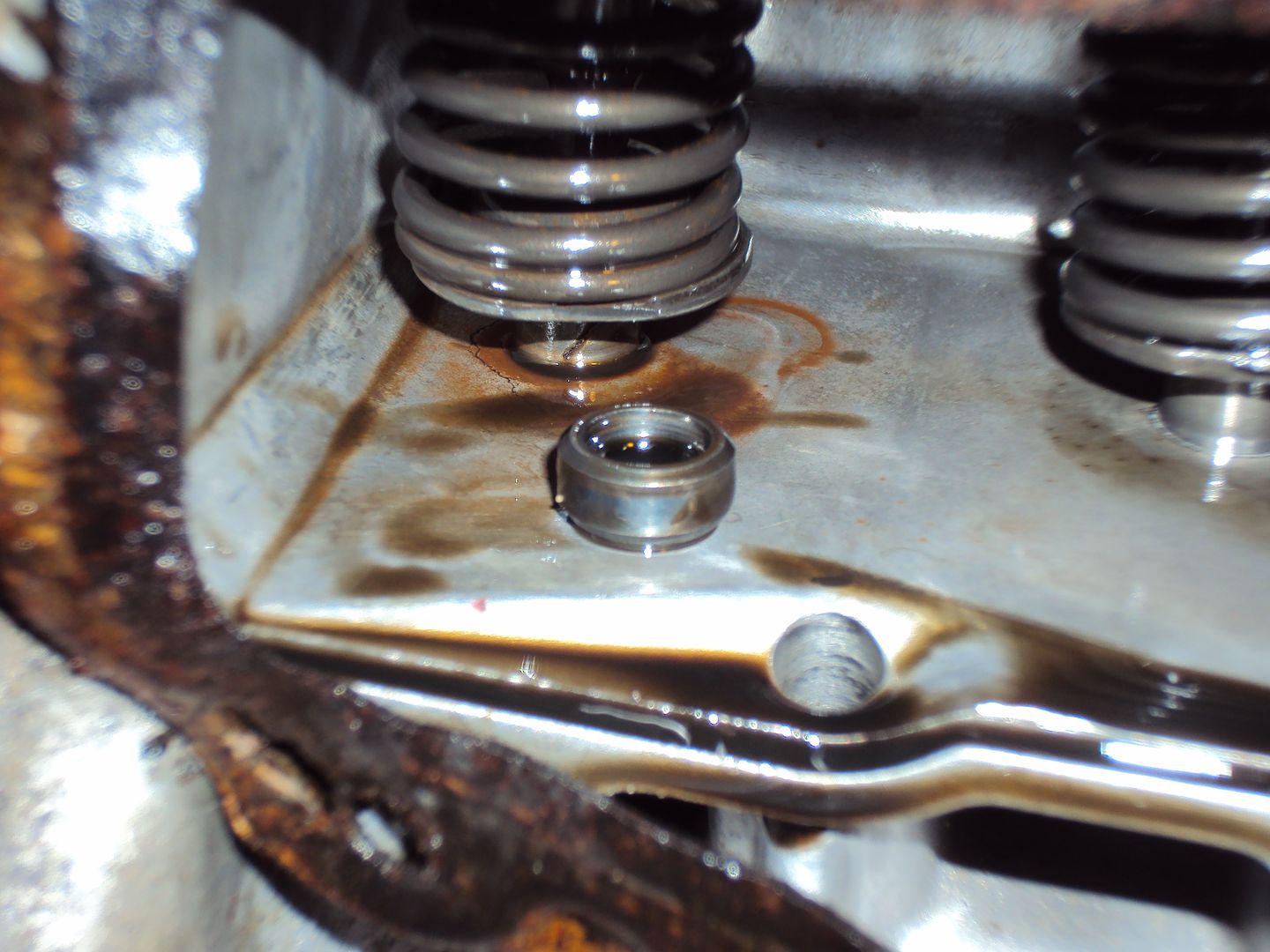

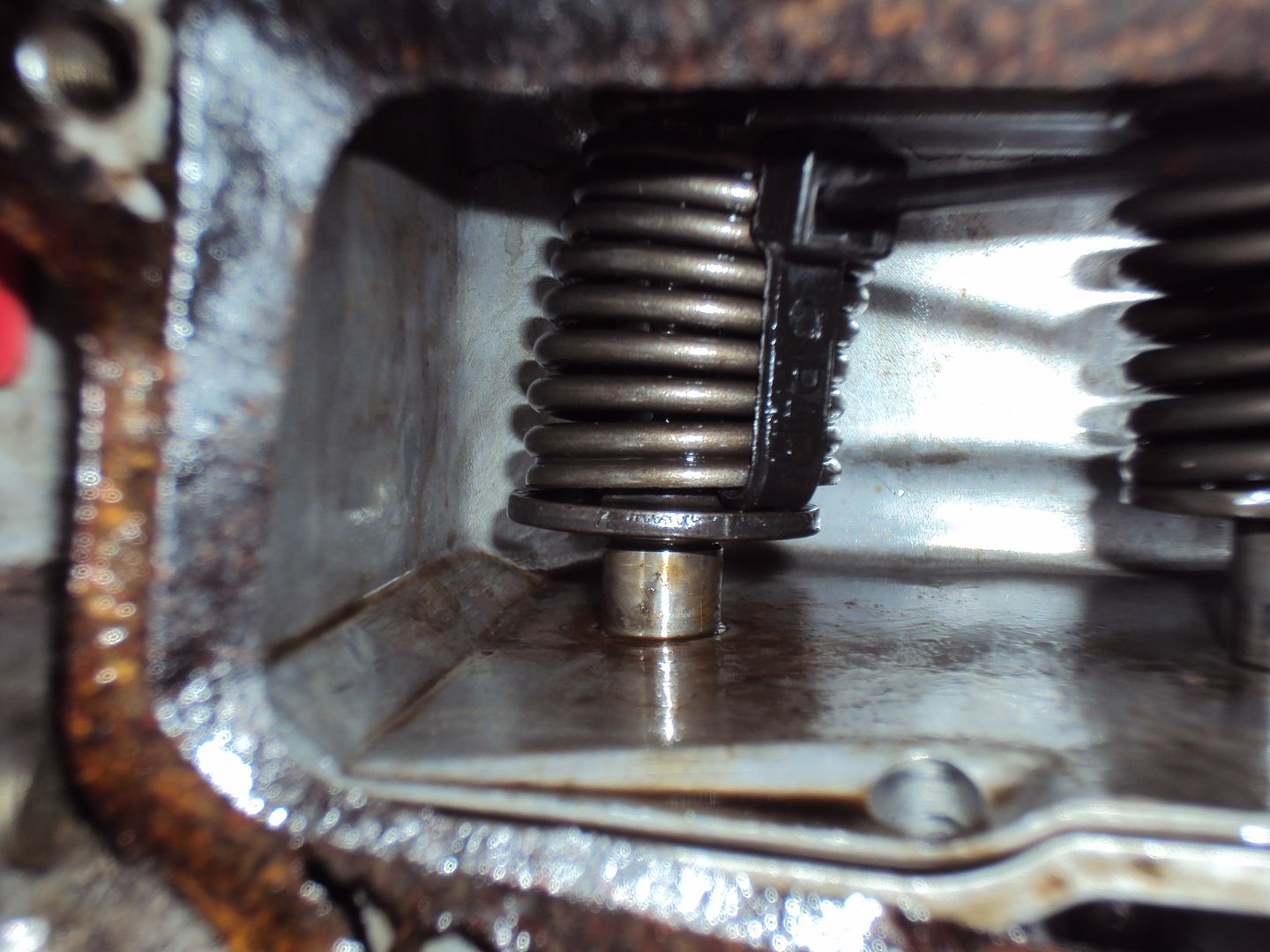

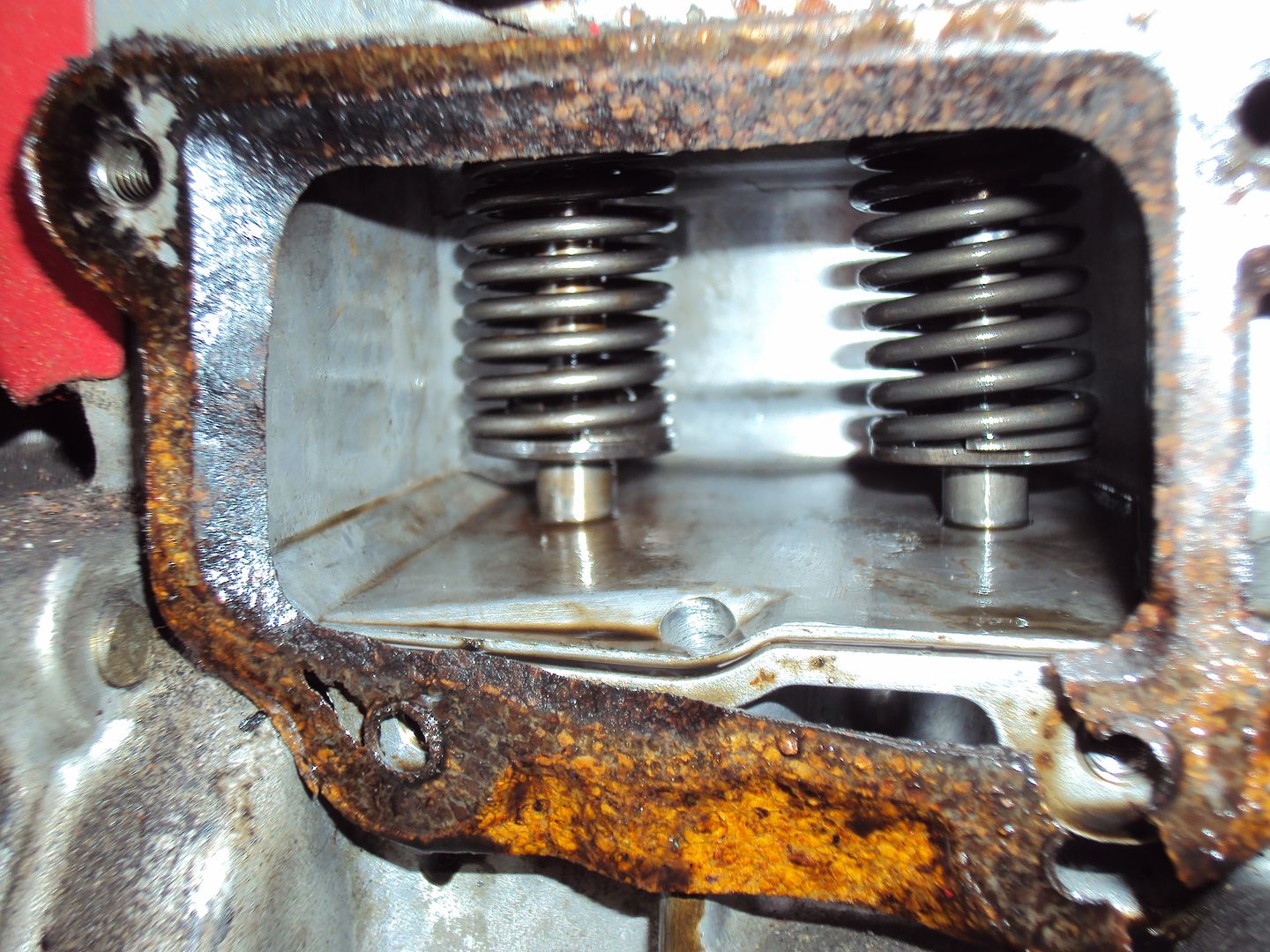

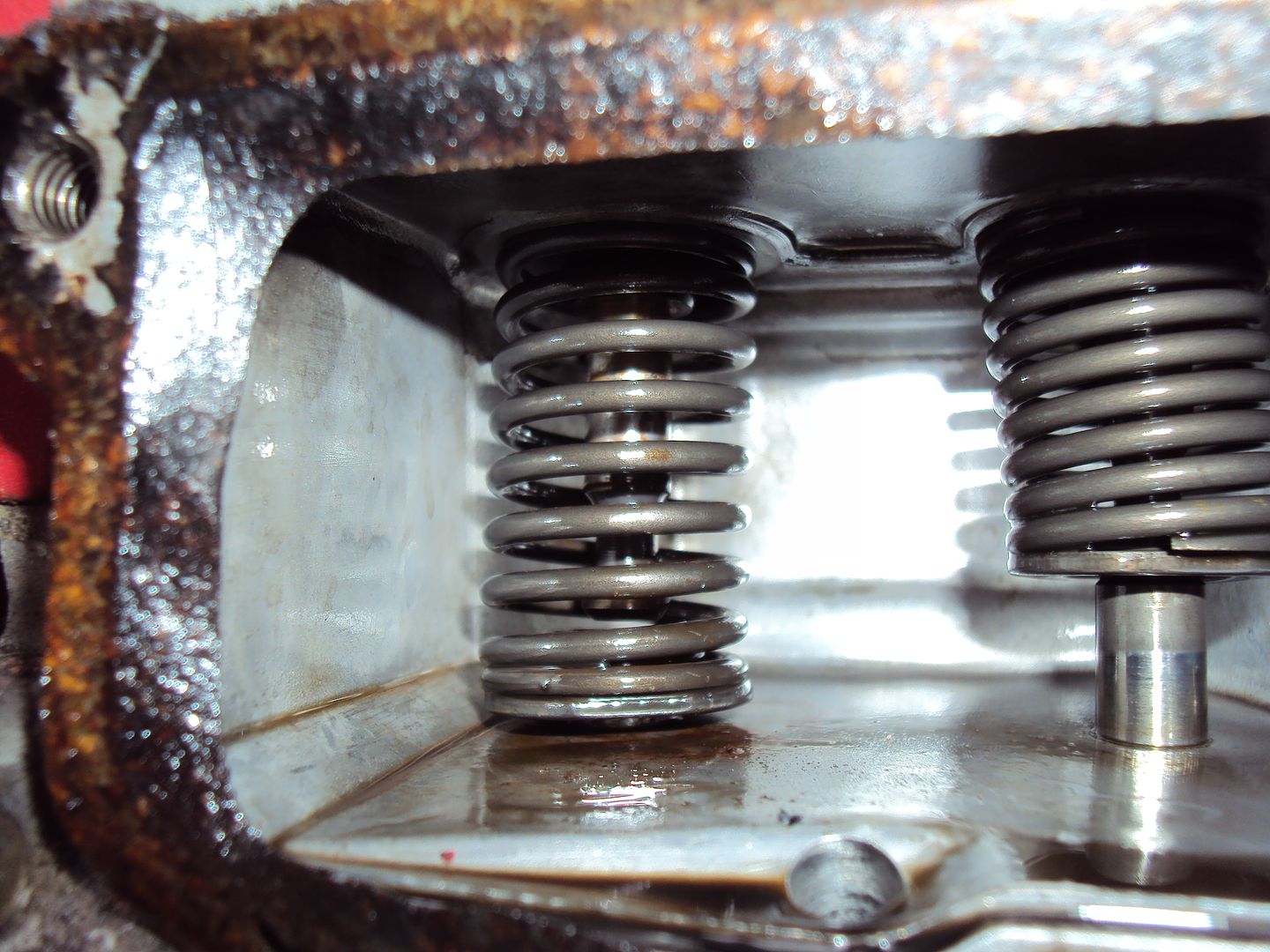

I started with looking for the source of the rattle, I removed the valve chest cover and found a loose part.

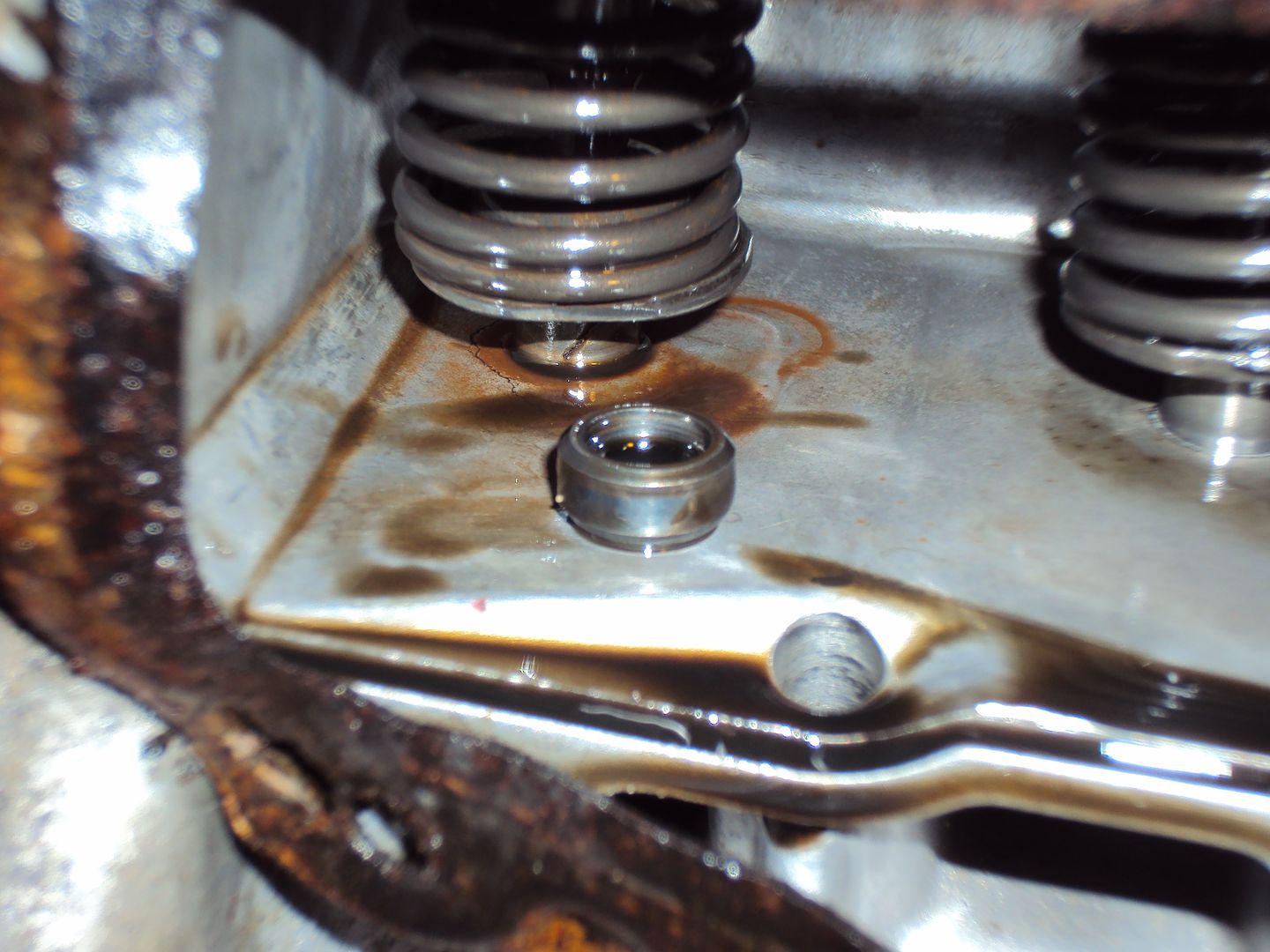

The cap should be on top of the tappet against the valve stem.

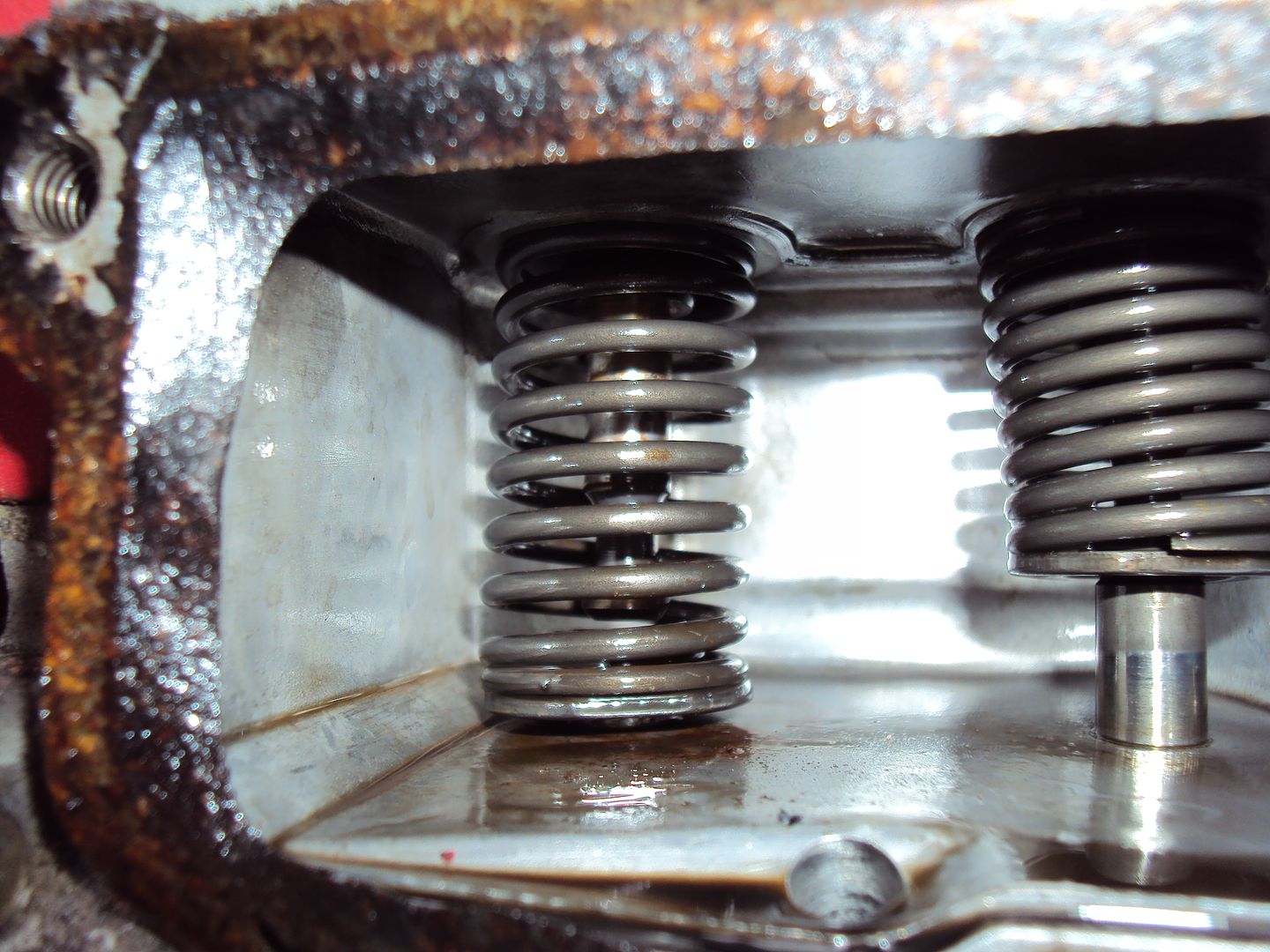

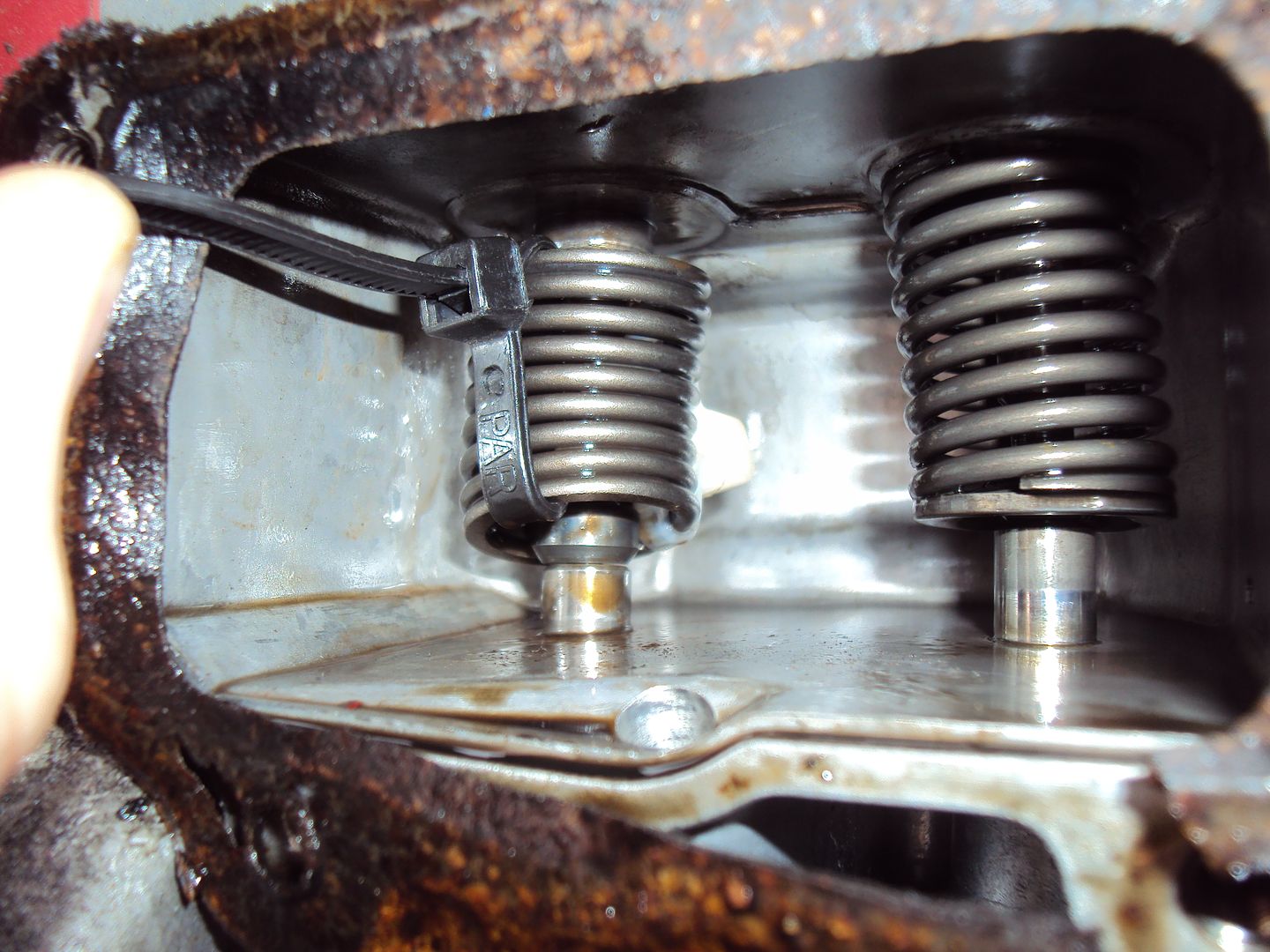

The valve spring retainer was removed so the valve could be lifted out and the spring removed.

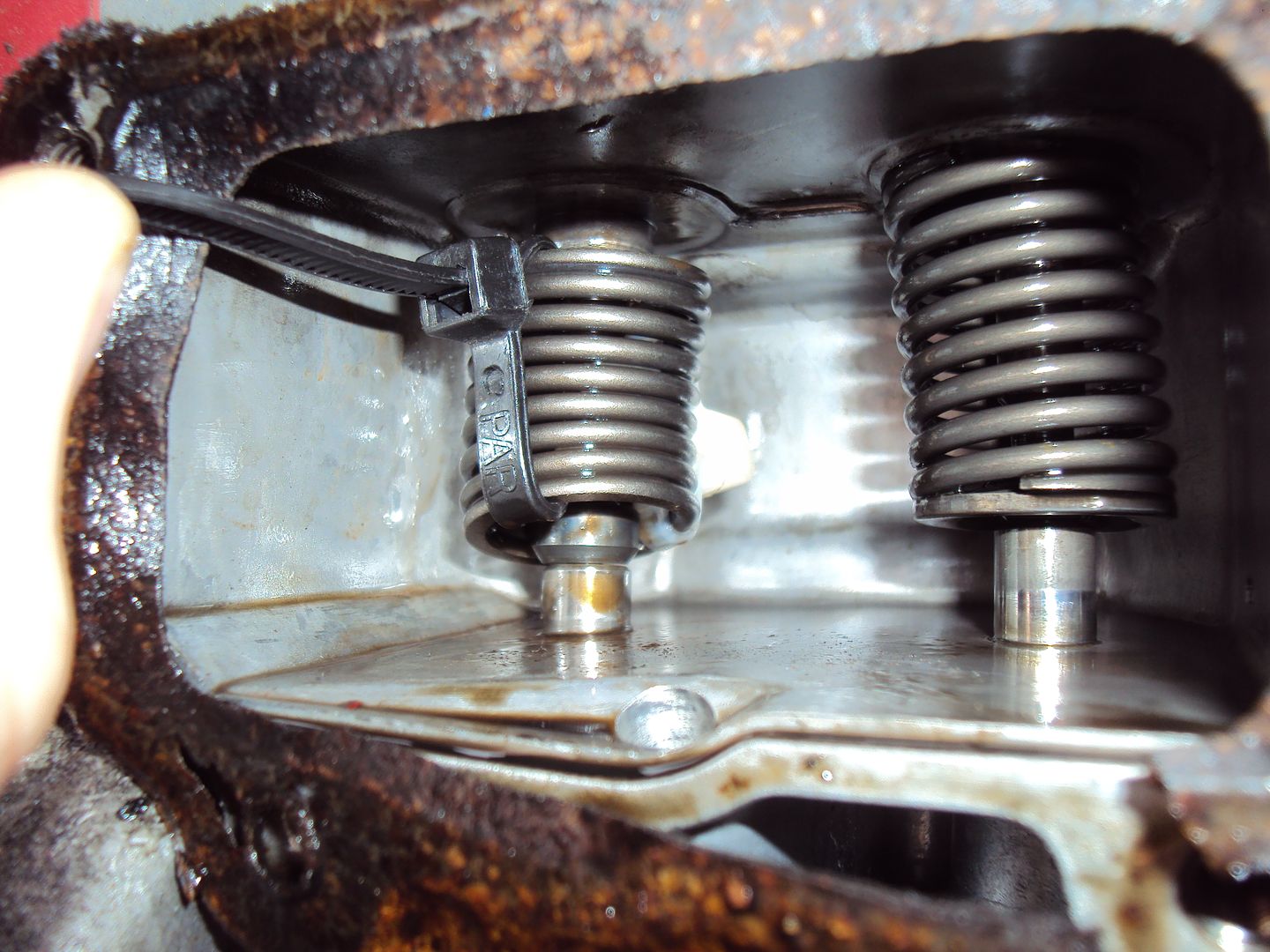

Ghetto valve spring compressor

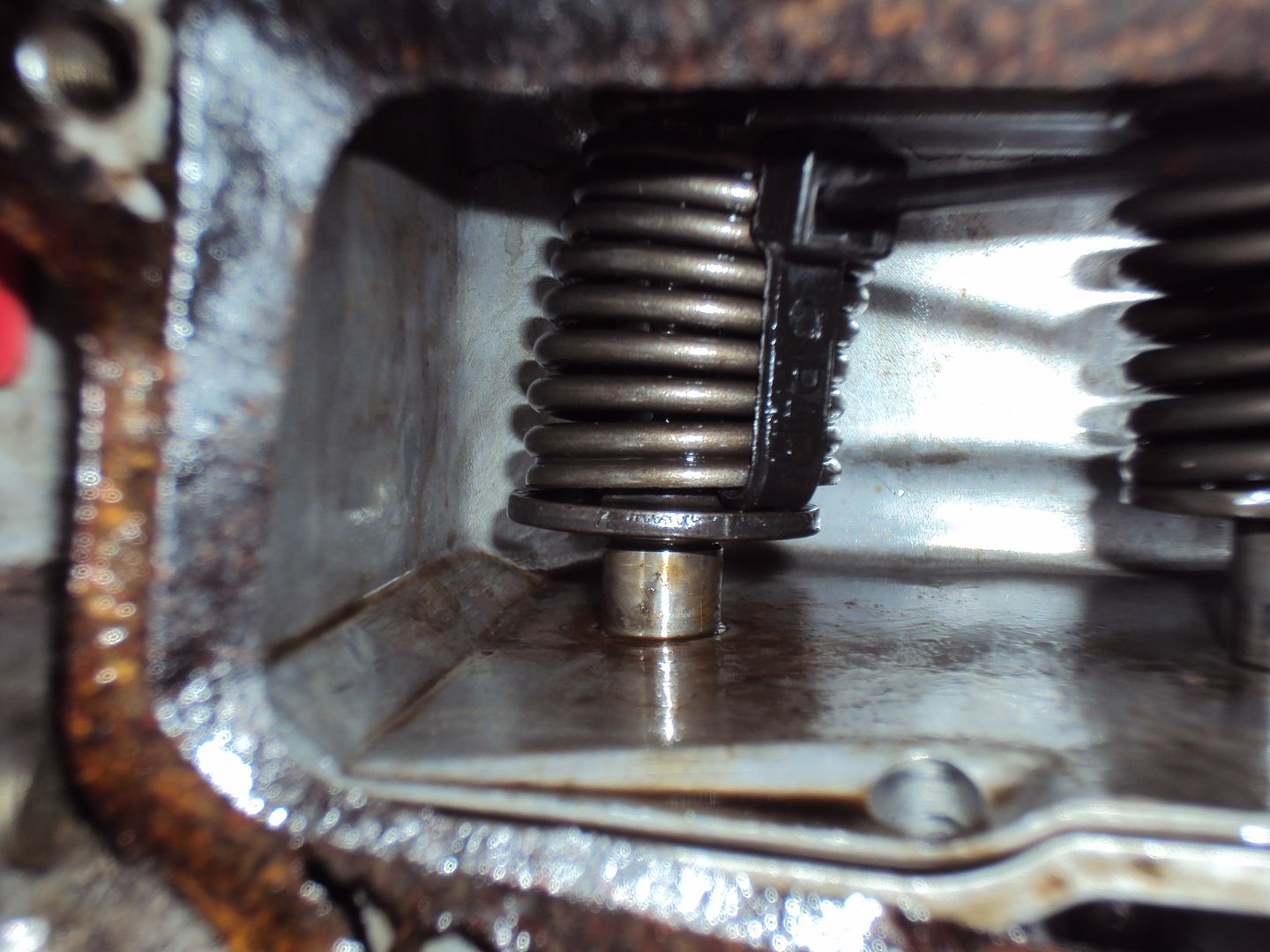

Cap back in place

Valve spring retainer back in place

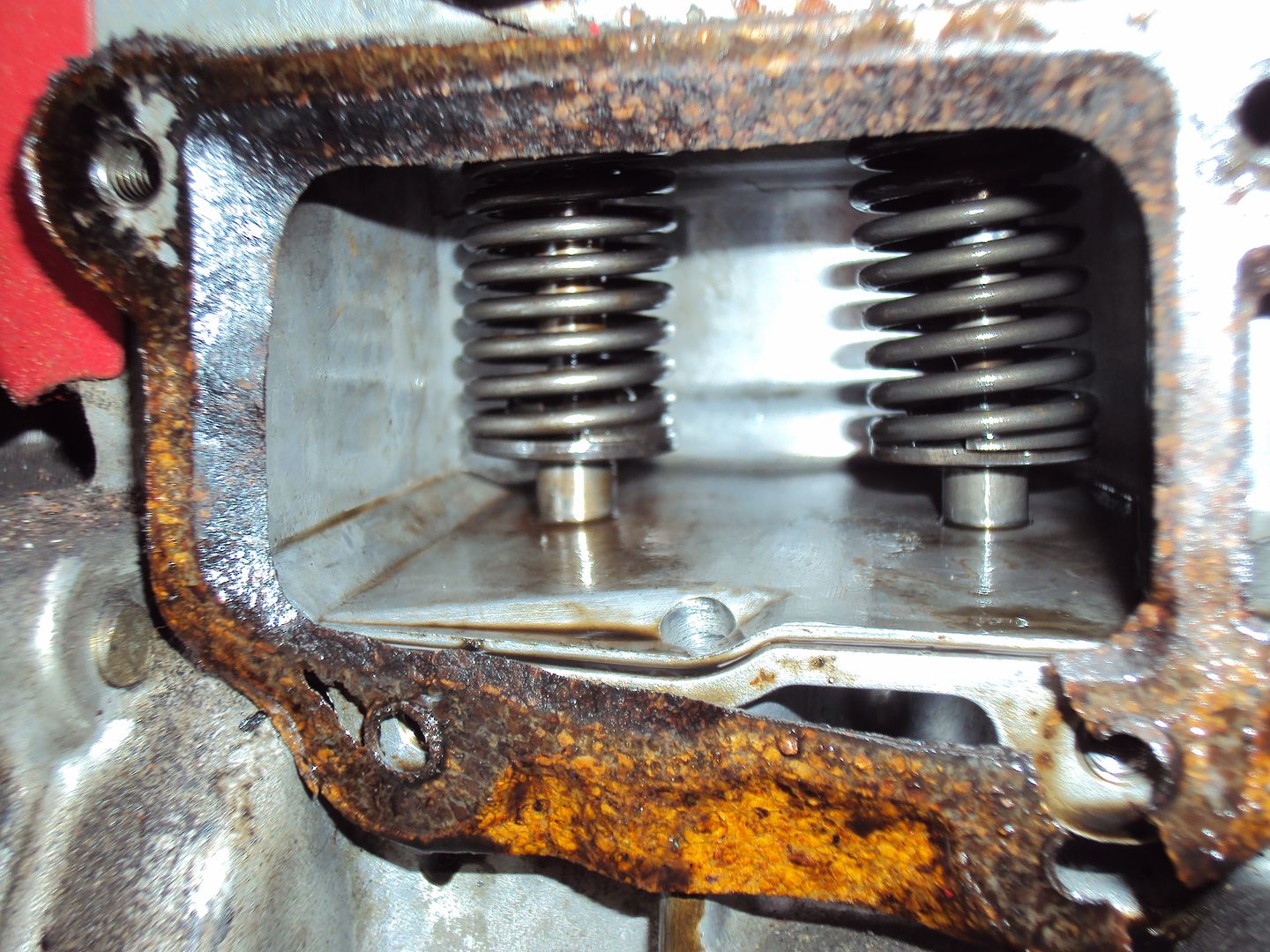

All back together

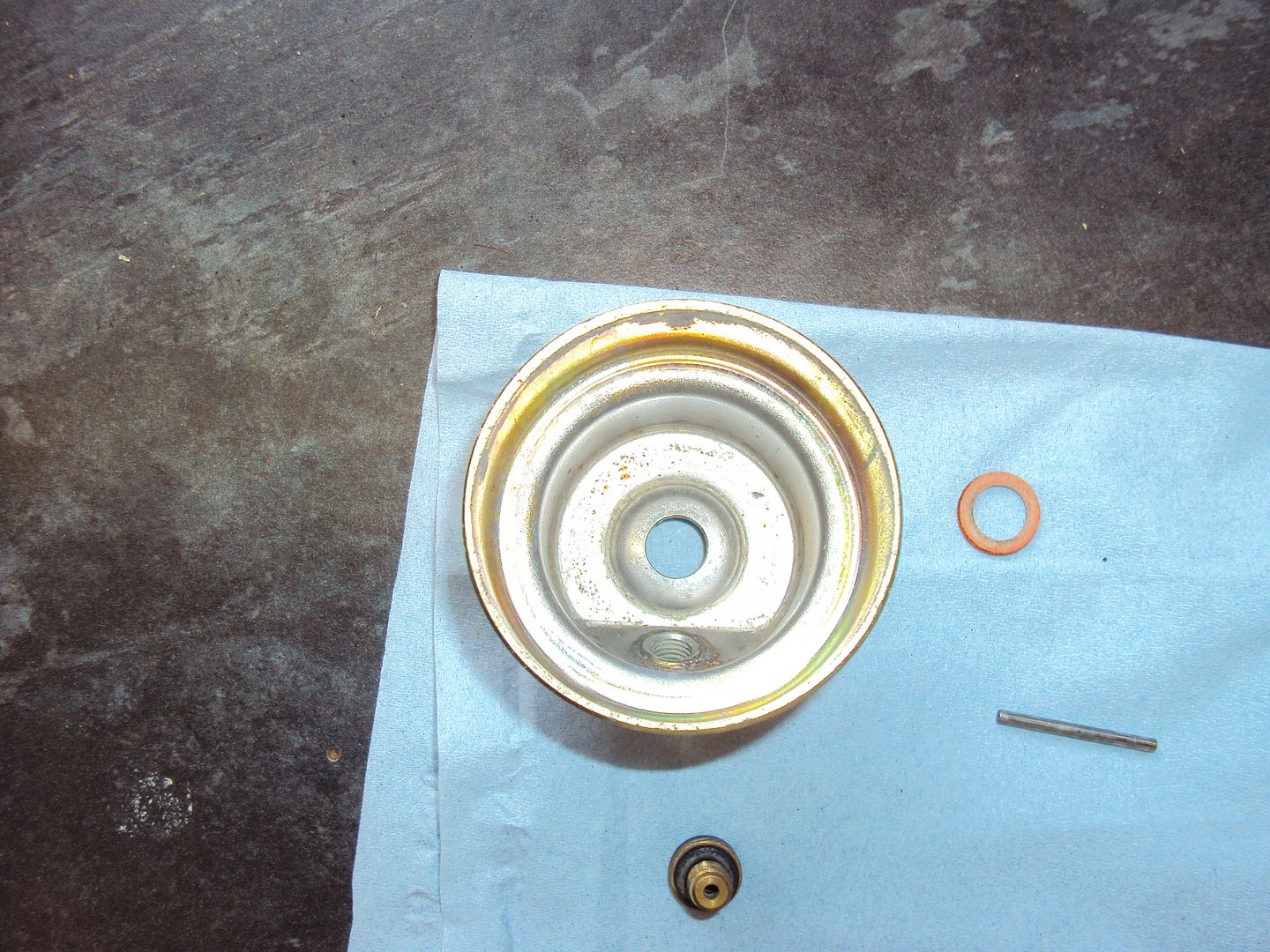

Once everything was re-assembled we go the engine running and it sounded a lot better but still needed the choke to be on to allow it to run. We started stripping the carburettor, there was a fair bit of sediment in the bowl

Pickup tube for main jet

The main jet had a fair bit of crud around it

More to follow

I picked up the next project during the week, another non starter, this one has the same engine as the last one, but with the added bonus of optional electric start.

After a bit of poking around we found there was no spark, even though the ignition system all checked out ok. We determined the spark plug was at fault, when tested with the multimeter it was open circuit.

Resistance of a good plug

After replacing the sparkplug the engine spluttered into life, however there were a couple of problems. The first was there was a very loud metallic rattle, the second was it would only run with the choke on.

I started with looking for the source of the rattle, I removed the valve chest cover and found a loose part.

The cap should be on top of the tappet against the valve stem.

The valve spring retainer was removed so the valve could be lifted out and the spring removed.

Ghetto valve spring compressor

Cap back in place

Valve spring retainer back in place

All back together

Once everything was re-assembled we go the engine running and it sounded a lot better but still needed the choke to be on to allow it to run. We started stripping the carburettor, there was a fair bit of sediment in the bowl

Pickup tube for main jet

The main jet had a fair bit of crud around it

More to follow

jet_noise said:

A little bit more of a challenge this one.

Have you ever had to admit defeat?

regards,

Jet

Yep this one had a bit more to do which makes it more interesting, was getting bored with the easy fixes.Have you ever had to admit defeat?

regards,

Jet

The only one which has defeated me so far was a diesel one similar to the one in the photo at the beginning. The alternator was burnt out and only worked on 110v, it ended up being shipped out to Africa.

I fitted the inverter to the Kipor, so that one is finished now.

Carried on with cleaning the carburettor, the holes in the main jet were cleared using thin wire.

Float bowl all clean

Everything clean and ready to go back together

I re-assembled and refitted the carburettor and started the engine. All was fine after a few seconds the engine settled down to a constant speed and was running without the choke.

The next task is to find out why the electric starter motor isn’t working.

Slight hijack, but as you're a man with many generators and a 'scope it's worth an ask.

How good\bad is the output from a typical DIY-Shed generator like this sort, though my particular one was a B&Q own-brand one, http://www.amazon.co.uk/Generator-Petrol-2-8kva-6-...

Reason being, I'd like to use one to run the central heating during power cuts. Nothing fancy, simple oil boiler and a pump to match.

How good\bad is the output from a typical DIY-Shed generator like this sort, though my particular one was a B&Q own-brand one, http://www.amazon.co.uk/Generator-Petrol-2-8kva-6-...

Reason being, I'd like to use one to run the central heating during power cuts. Nothing fancy, simple oil boiler and a pump to match.

shtu said:

Slight hijack, but as you're a man with many generators and a 'scope it's worth an ask.

How good\bad is the output from a typical DIY-Shed generator like this sort, though my particular one was a B&Q own-brand one, http://www.amazon.co.uk/Generator-Petrol-2-8kva-6-...

Reason being, I'd like to use one to run the central heating during power cuts. Nothing fancy, simple oil boiler and a pump to match.

The output would be ok for the simple appliances you mentioned, it will probably keep the fridge running as well. How good\bad is the output from a typical DIY-Shed generator like this sort, though my particular one was a B&Q own-brand one, http://www.amazon.co.uk/Generator-Petrol-2-8kva-6-...

Reason being, I'd like to use one to run the central heating during power cuts. Nothing fancy, simple oil boiler and a pump to match.

We have used a similar genny to run the house during a power cut a few years ago. The only thing which got upset was the UPS on the computer, it couldn't decide if he mains was there or not.

herewego said:

Why was the valve stem cap displaced and won't that happen again?

Not sure why the cap fell out, only guess is the engine might have been over revved?? Blue32 said:

The output would be ok for the simple appliances you mentioned, it will probably keep the fridge running as well.

We have used a similar genny to run the house during a power cut a few years ago. The only thing which got upset was the UPS on the computer, it couldn't decide if he mains was there or not.

Excellent, that's what I was thinking\hoping. The entire heating system doesn't trouble a 2 amp fuse, so it shouldn't strain the generator.We have used a similar genny to run the house during a power cut a few years ago. The only thing which got upset was the UPS on the computer, it couldn't decide if he mains was there or not.

Must try testing this before the power goes off.

shtu said:

Excellent, that's what I was thinking\hoping. The entire heating system doesn't trouble a 2 amp fuse, so it shouldn't strain the generator.

Must try testing this before the power goes off.

all you need to do is find the kw rating of the equipment you want to power, and match it to a generator , i would allow 25% spare as they souldent run at 100% all the time.Must try testing this before the power goes off.

just make sure the mains is totally disconnected when you're on generator.

UPS's will not use power if it is outside of their tight voltage and frequency window, so if the gen is small, loads will cause the voltage and Hz to move around in and out of the window.

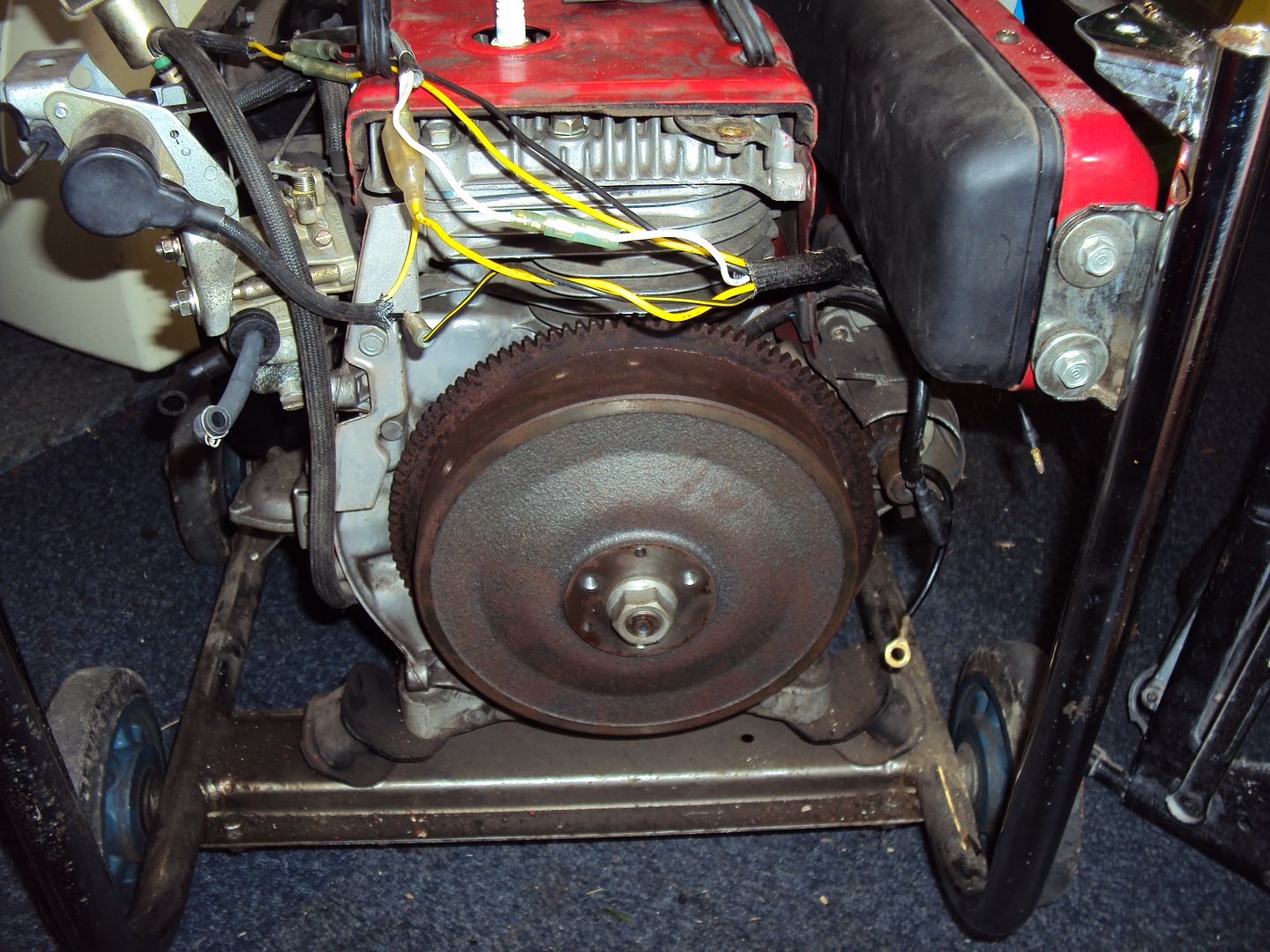

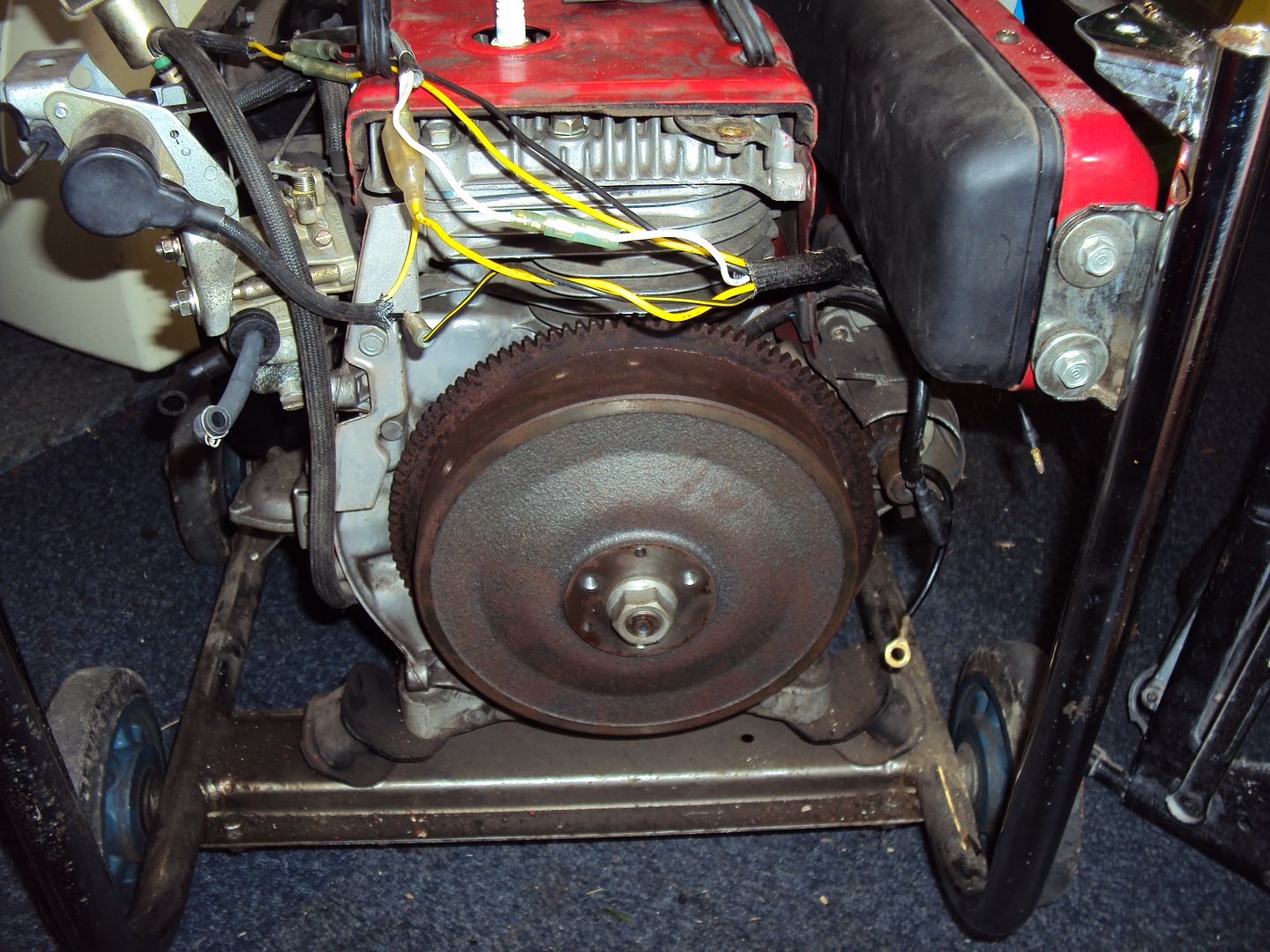

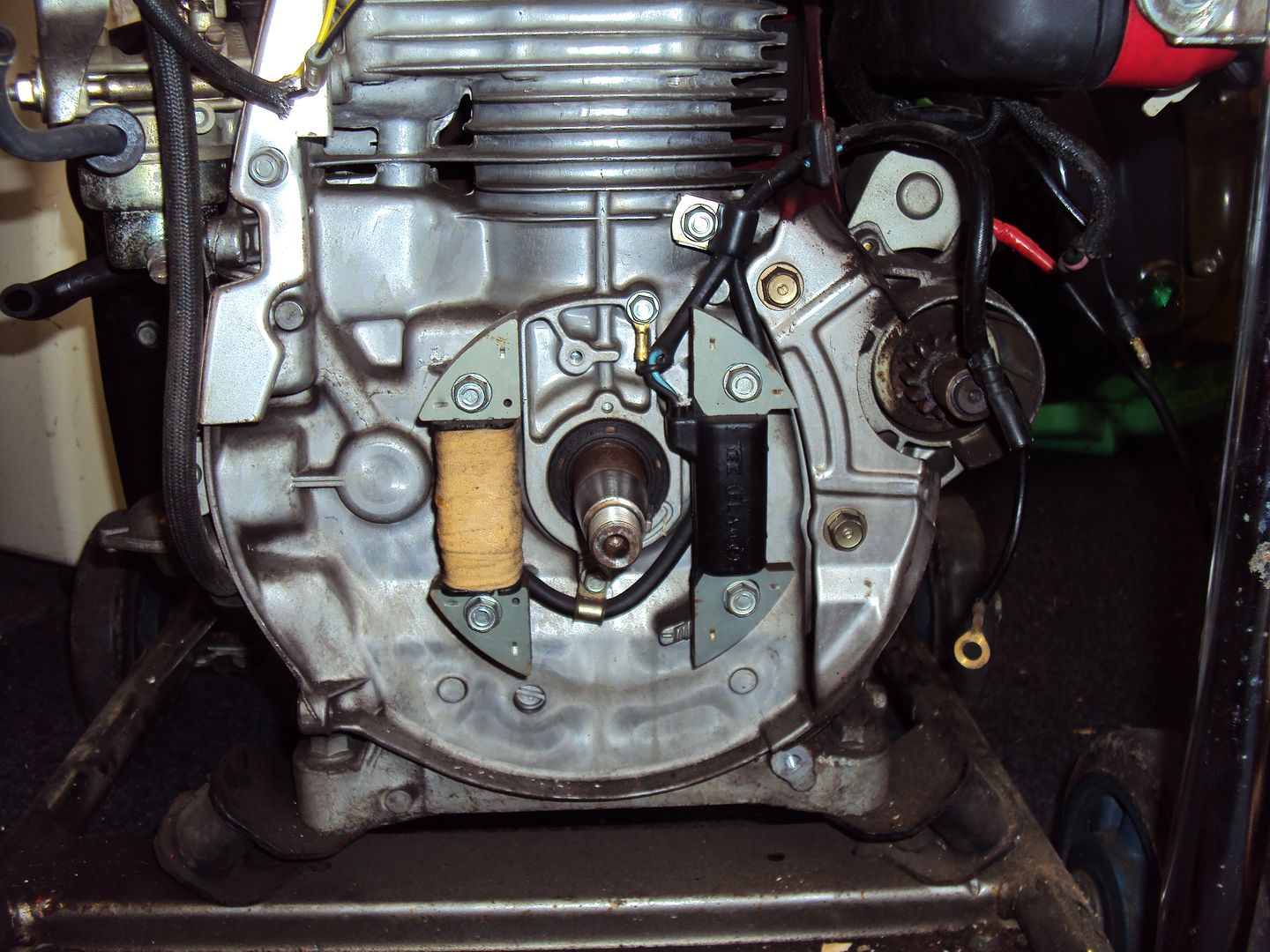

Today’s task was to get the starter motor working, To remove the starter motor, the flywheel needs to be removed.

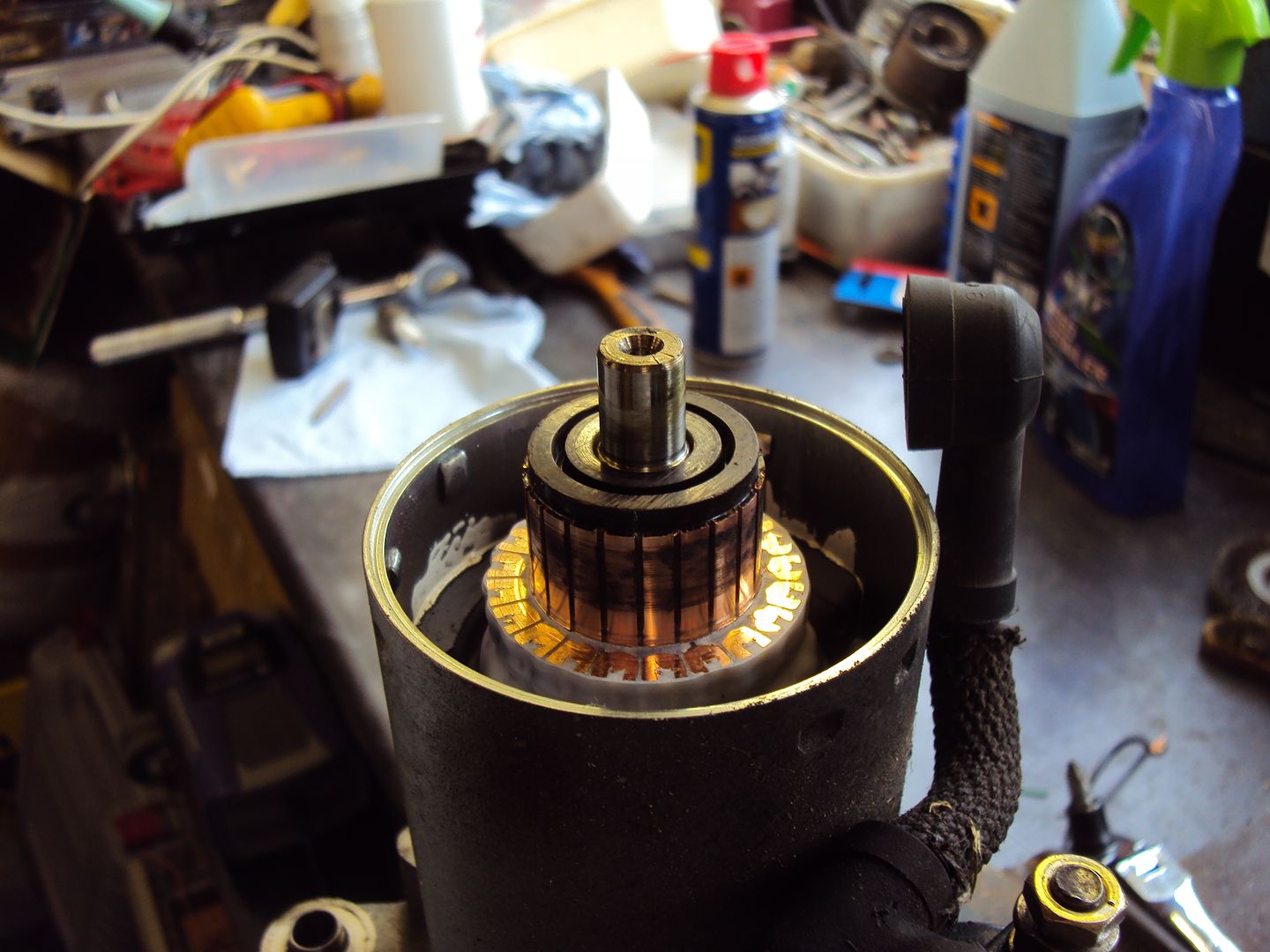

Flywheel removed

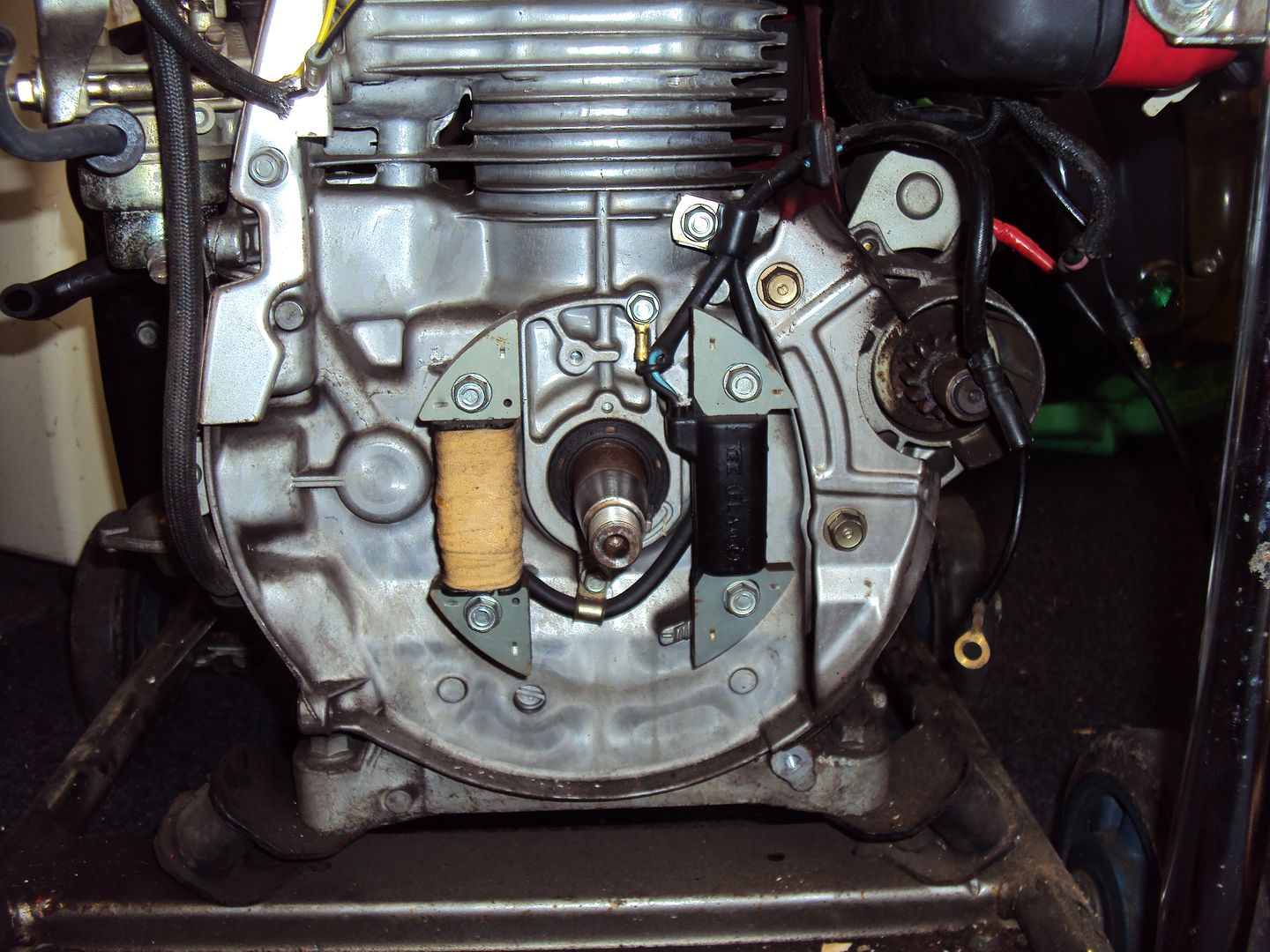

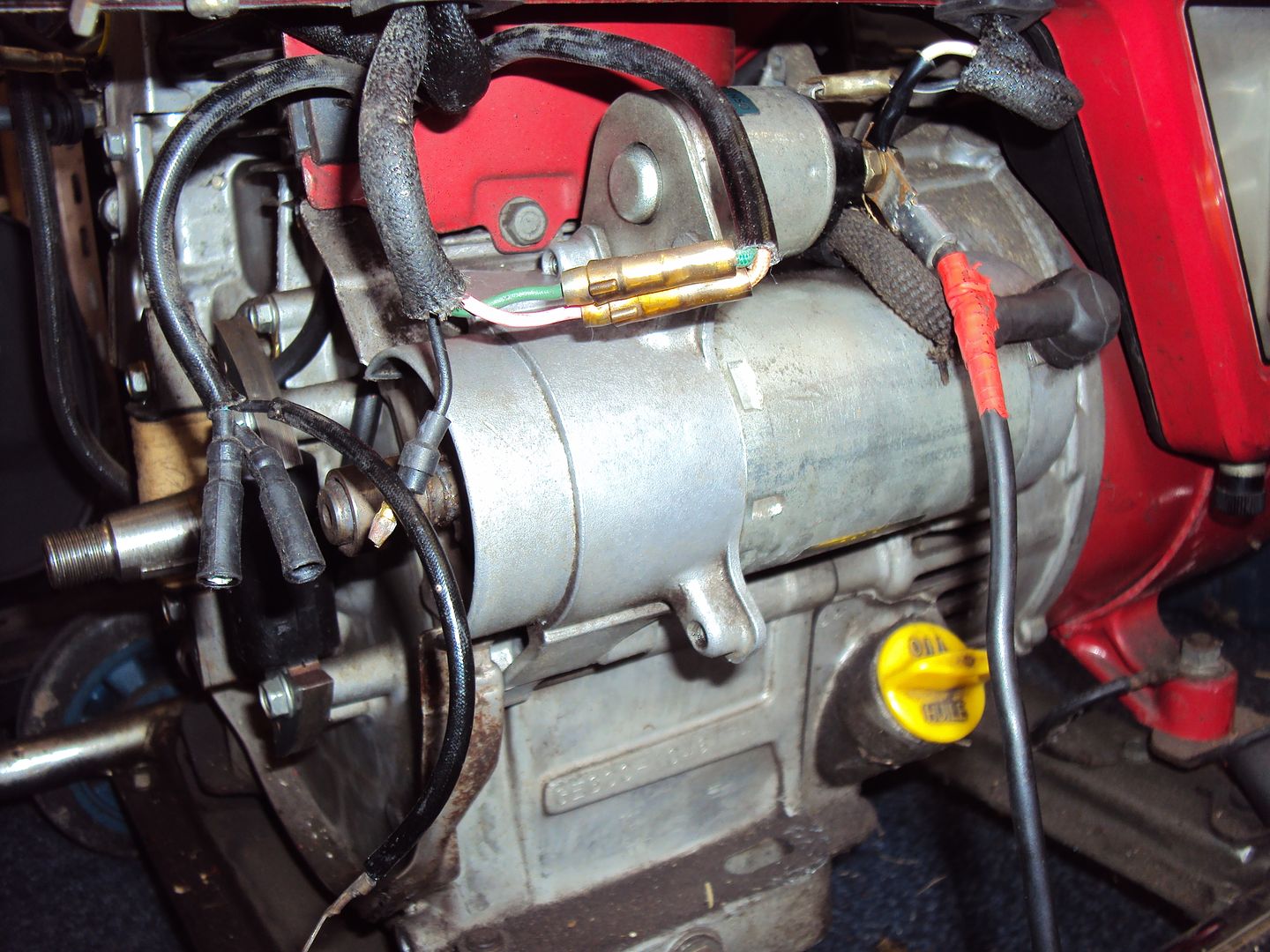

Starter motor removed

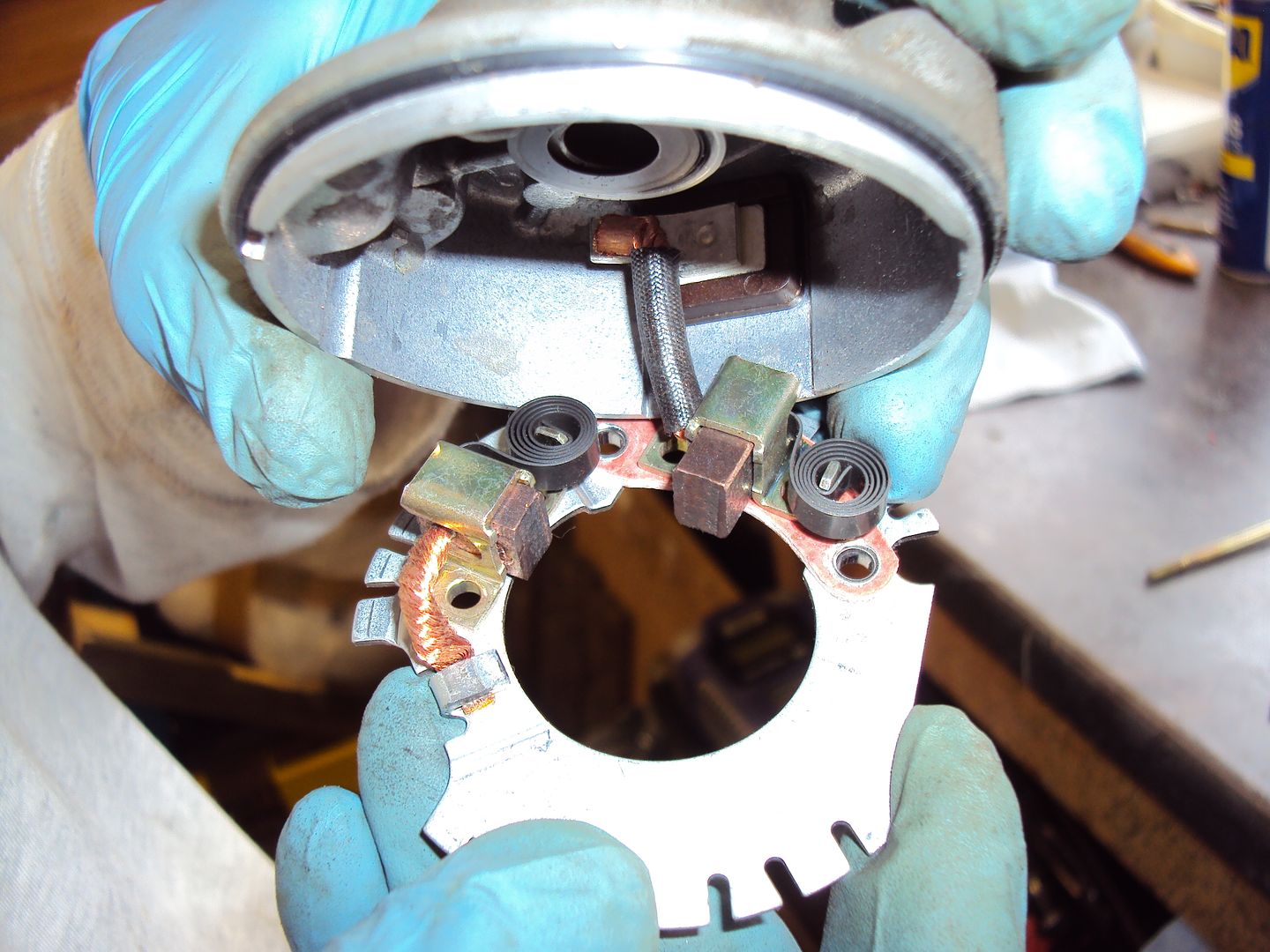

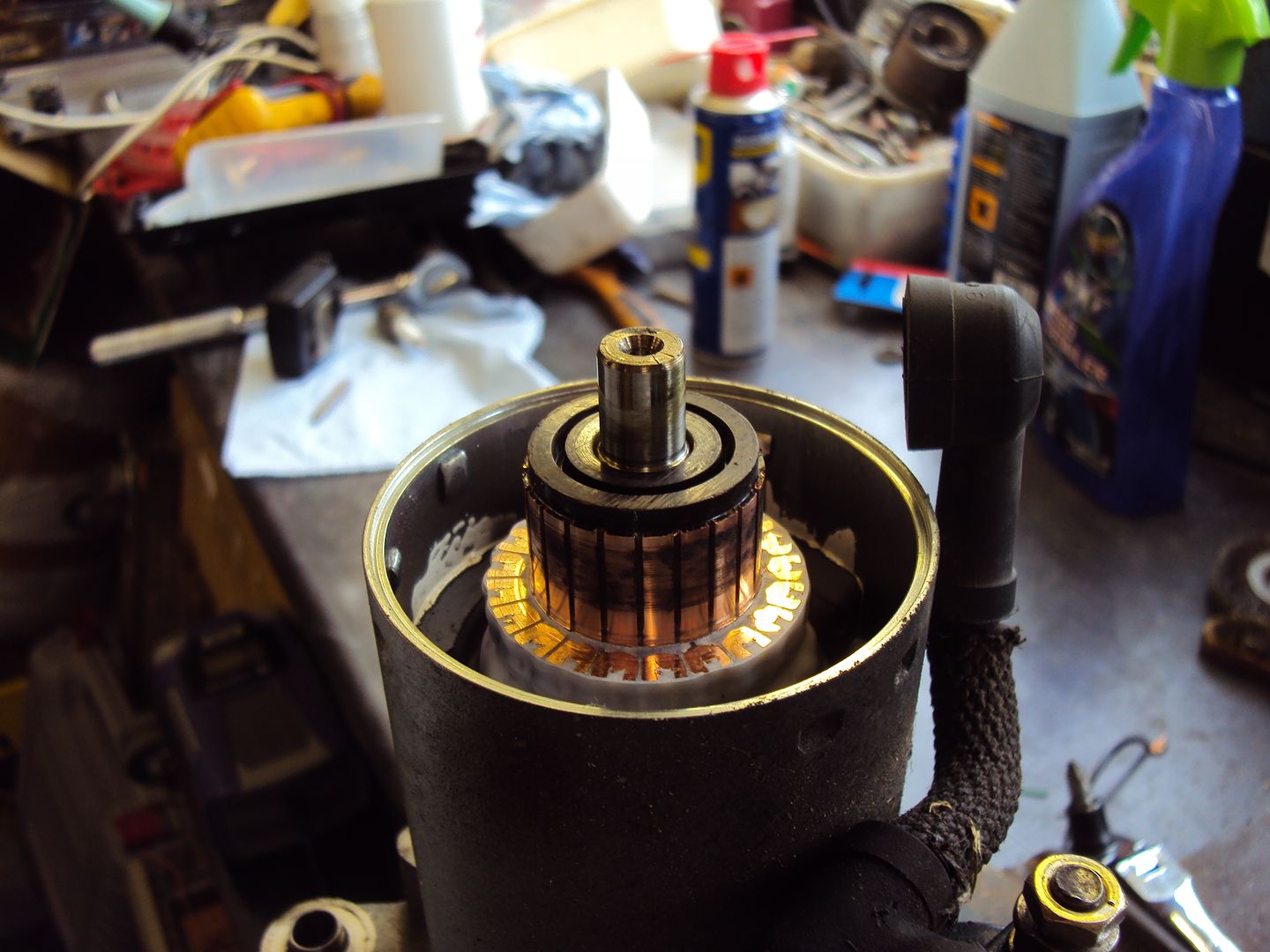

We removed the end cap from the motor, and found the commutator was in great condition. This is because when new, the generator is supplied with the starter motor. However an optional kit has to be purchased which consists of a battery cradle and wiring to enable the electric start.

This generator never had it fitted so the starter motor had never been used.

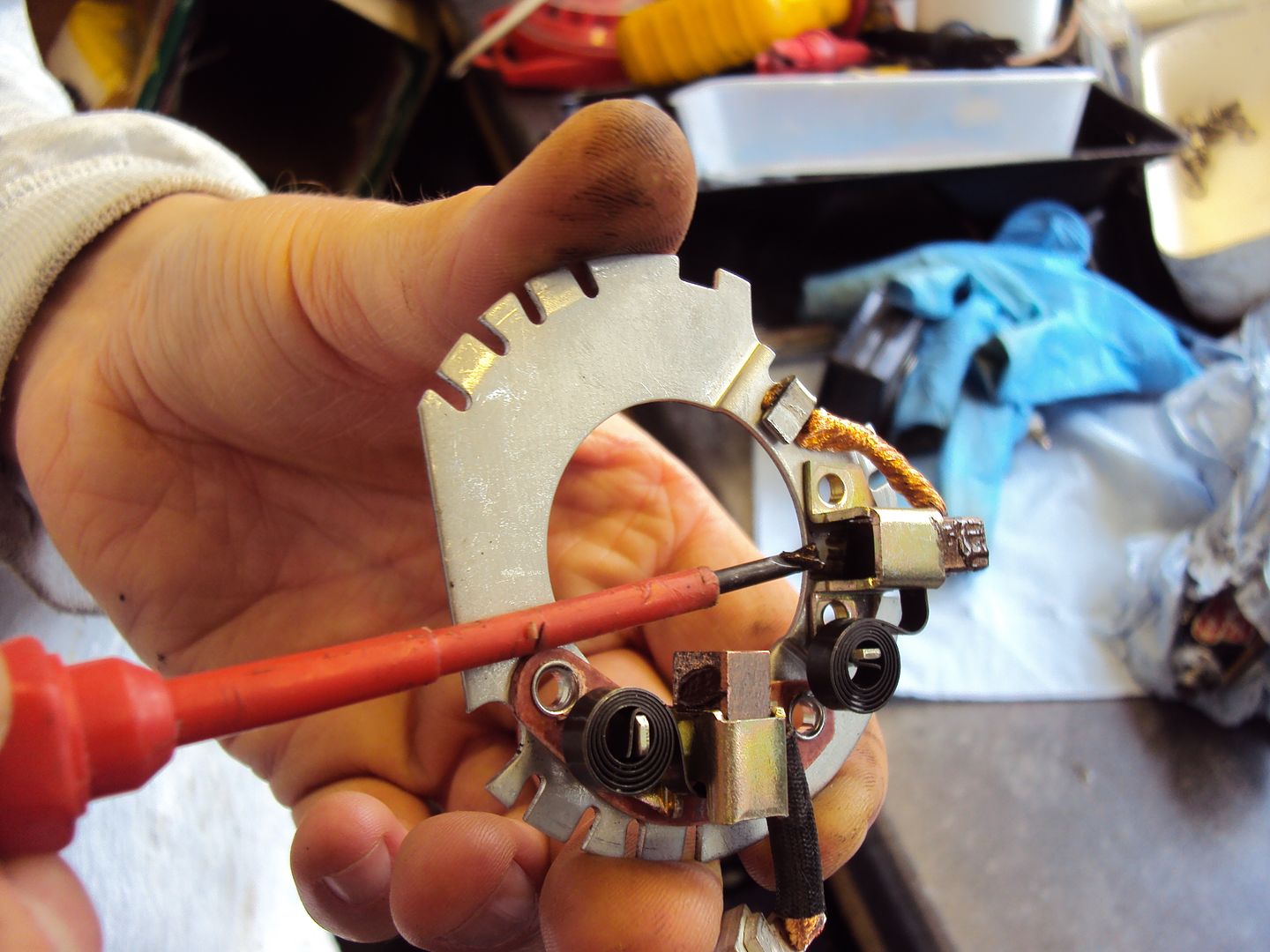

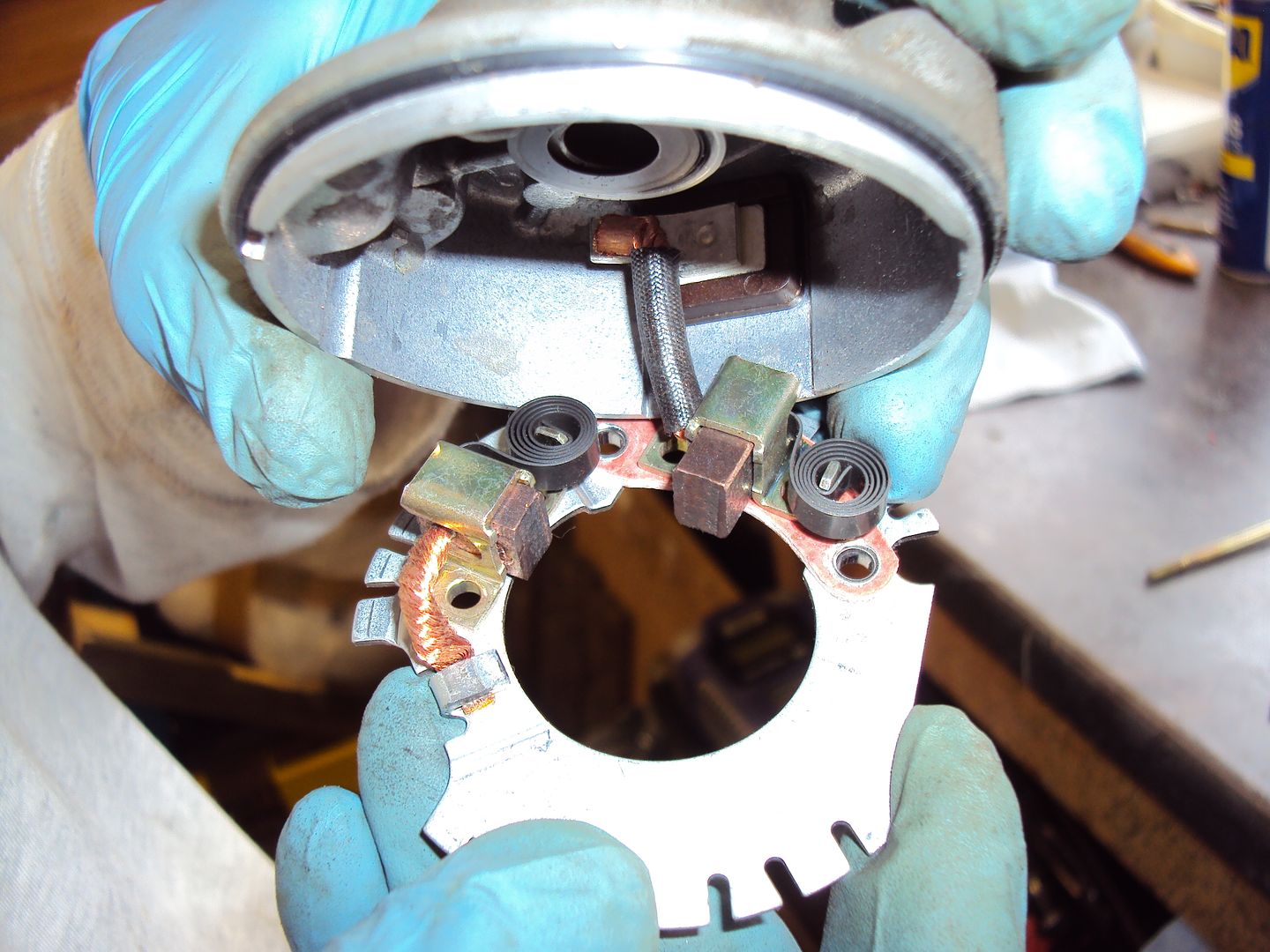

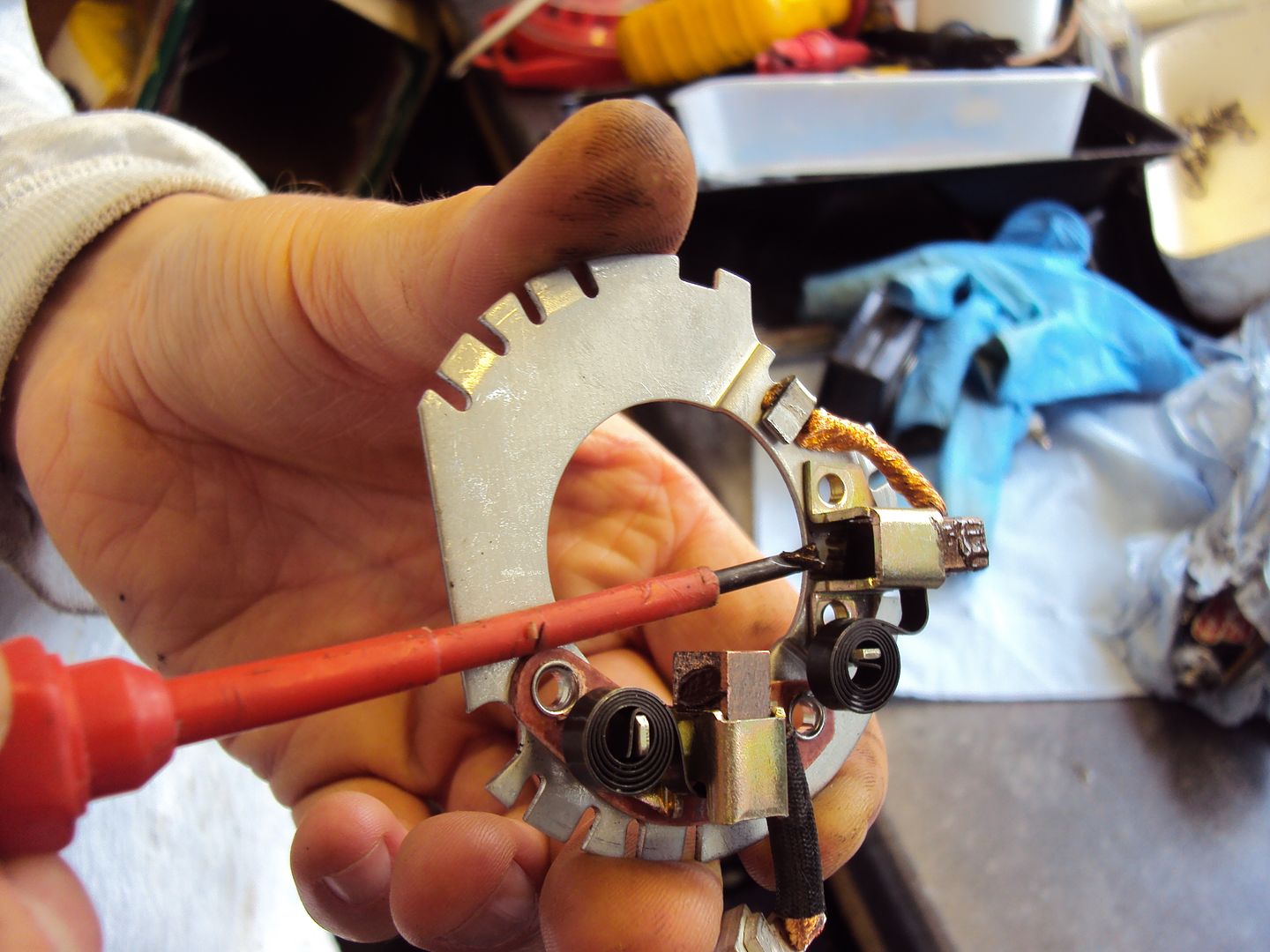

We removed the brush holder and found the –ve brush was stuck (top left) whereas the +ve (top right) brush moved freely.

After a liberal application of copper grease the brush was moving freely again

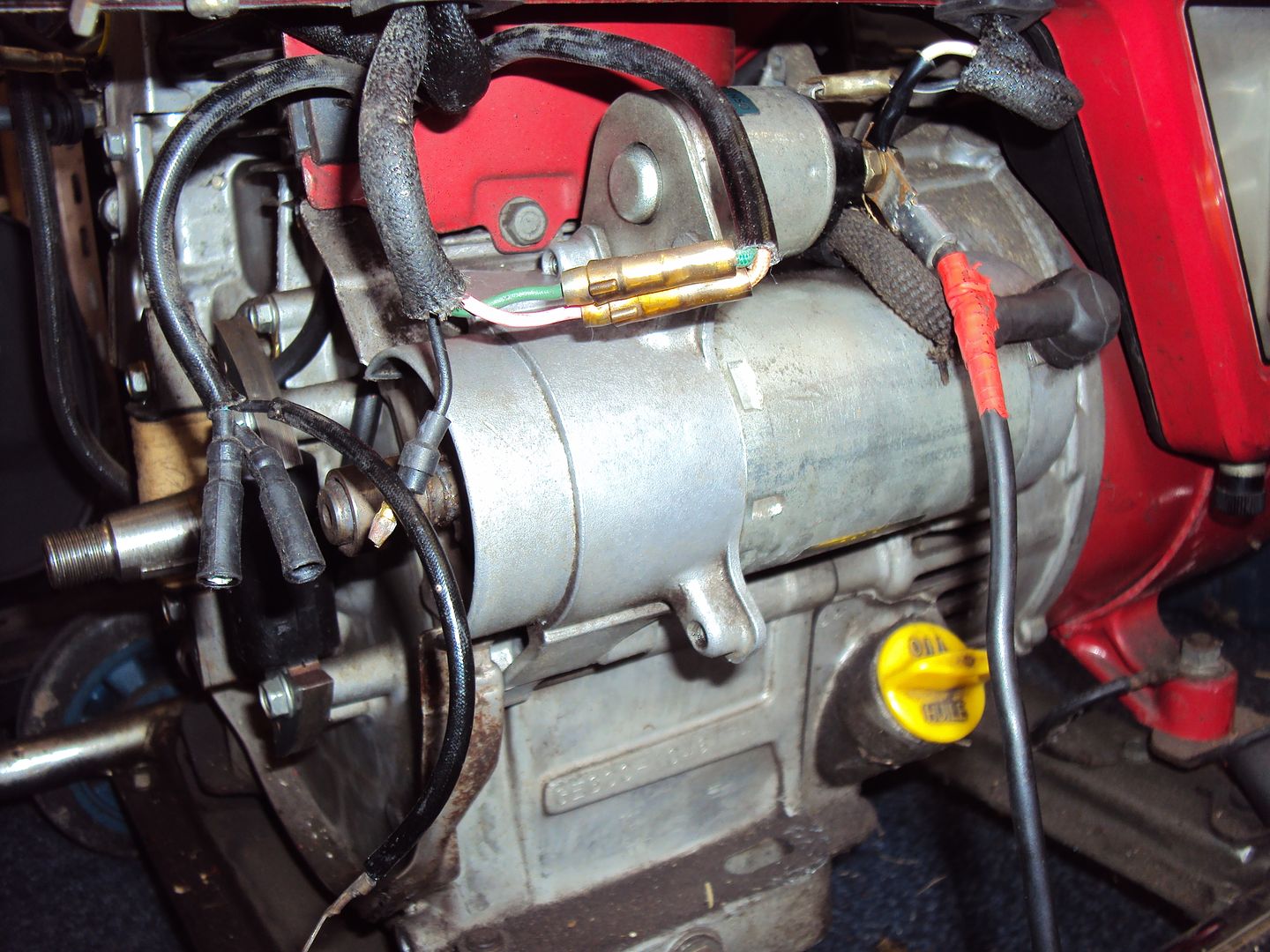

The motor was re-assembled, cleaned and re-fitted to the engine

We hooked up a battery using jump leads, turned the key and it worked.

When I originally collected the generator, it was missing the air filter carrier and cover

After a bit of searching I found a complete new air cleaner for £34.00 (copy of the Honda parts) which was a lot cheaper than the nearly £80! For the 2 genuine Honda parts I needed. I just needed the filter carrier (middle) and cover (right)from the replacement unit

The filter carrier bolted straight into the original housing

And the cover clipped straight on.

Next I started on making the wire to link the starter motor to the battery

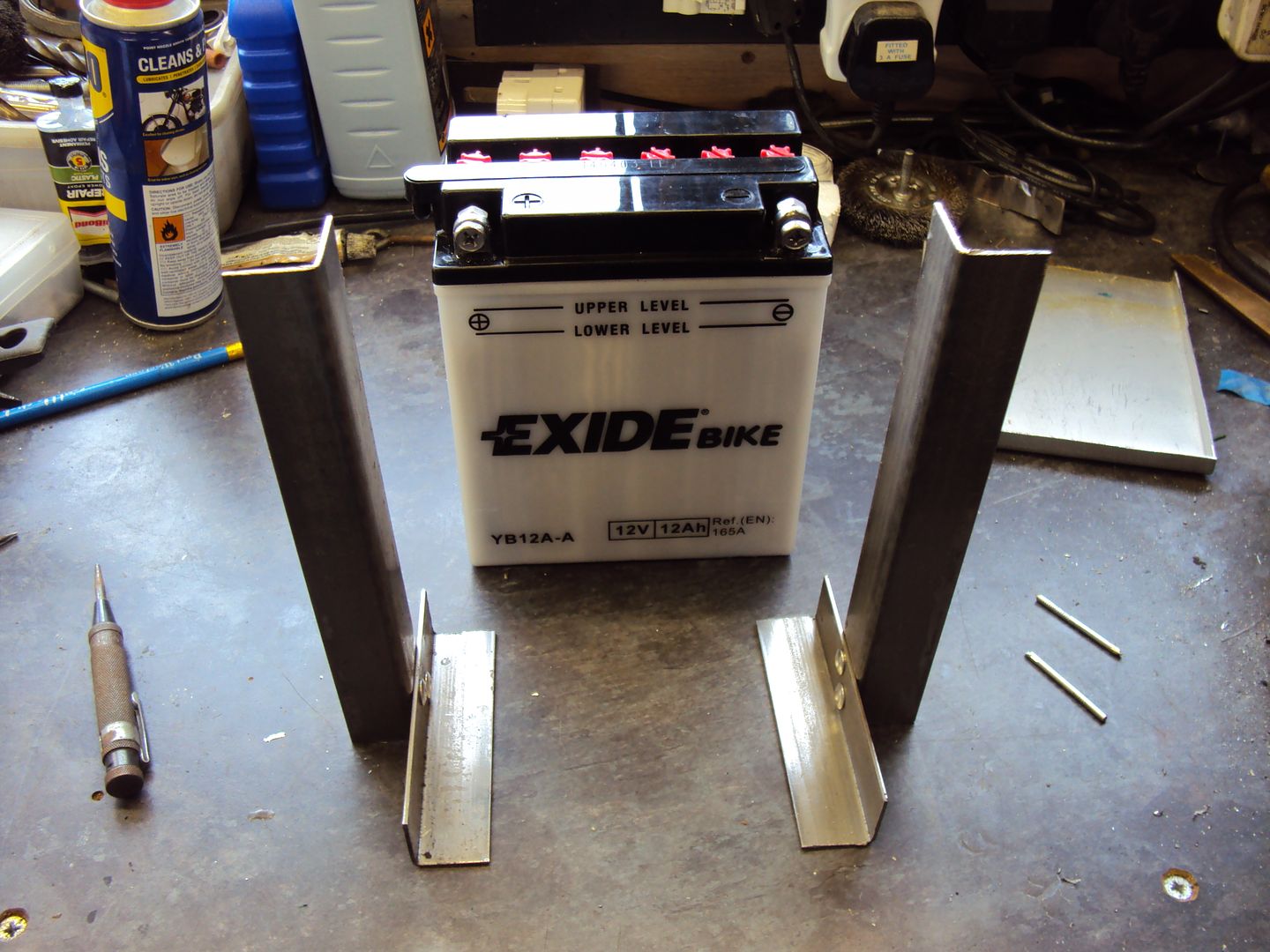

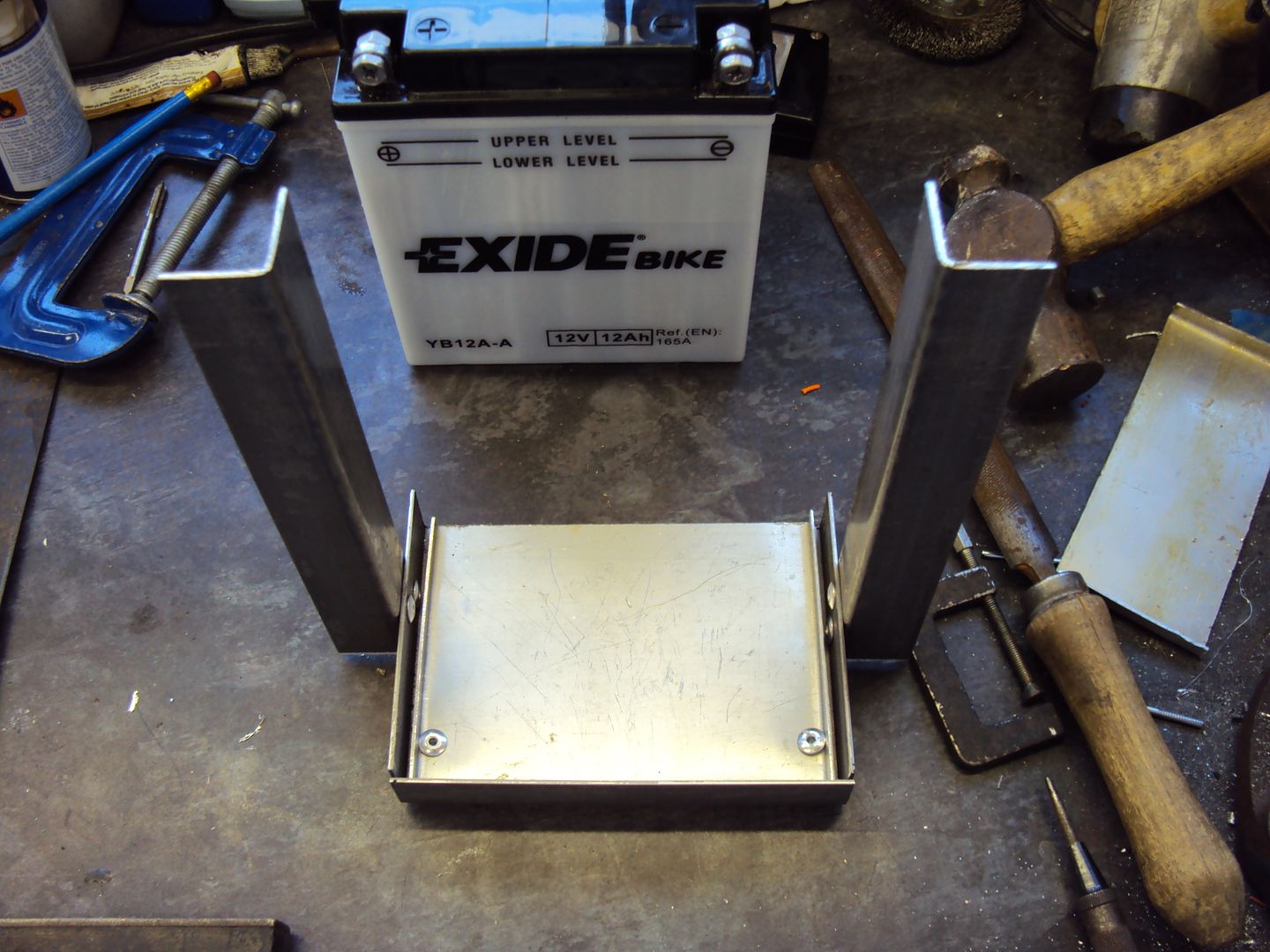

Just need to build the cradle to hold the battery, the genuine battery fitting kit costs over £250! So I’m not buying one of those.

We picked up some bits from B&Q which will hopefully enable us to build a suitable cradle.

Flywheel removed

Starter motor removed

We removed the end cap from the motor, and found the commutator was in great condition. This is because when new, the generator is supplied with the starter motor. However an optional kit has to be purchased which consists of a battery cradle and wiring to enable the electric start.

This generator never had it fitted so the starter motor had never been used.

We removed the brush holder and found the –ve brush was stuck (top left) whereas the +ve (top right) brush moved freely.

After a liberal application of copper grease the brush was moving freely again

The motor was re-assembled, cleaned and re-fitted to the engine

We hooked up a battery using jump leads, turned the key and it worked.

When I originally collected the generator, it was missing the air filter carrier and cover

After a bit of searching I found a complete new air cleaner for £34.00 (copy of the Honda parts) which was a lot cheaper than the nearly £80! For the 2 genuine Honda parts I needed. I just needed the filter carrier (middle) and cover (right)from the replacement unit

The filter carrier bolted straight into the original housing

And the cover clipped straight on.

Next I started on making the wire to link the starter motor to the battery

Just need to build the cradle to hold the battery, the genuine battery fitting kit costs over £250! So I’m not buying one of those.

We picked up some bits from B&Q which will hopefully enable us to build a suitable cradle.

Edited by Blue32 on Saturday 27th September 19:03

RDM said:

As many have said this is, at the moment, the best thread on Pistonheads by far.

Keep it up.

Thanks, glad it's providing some entertainment even if it is a bit Keep it up.

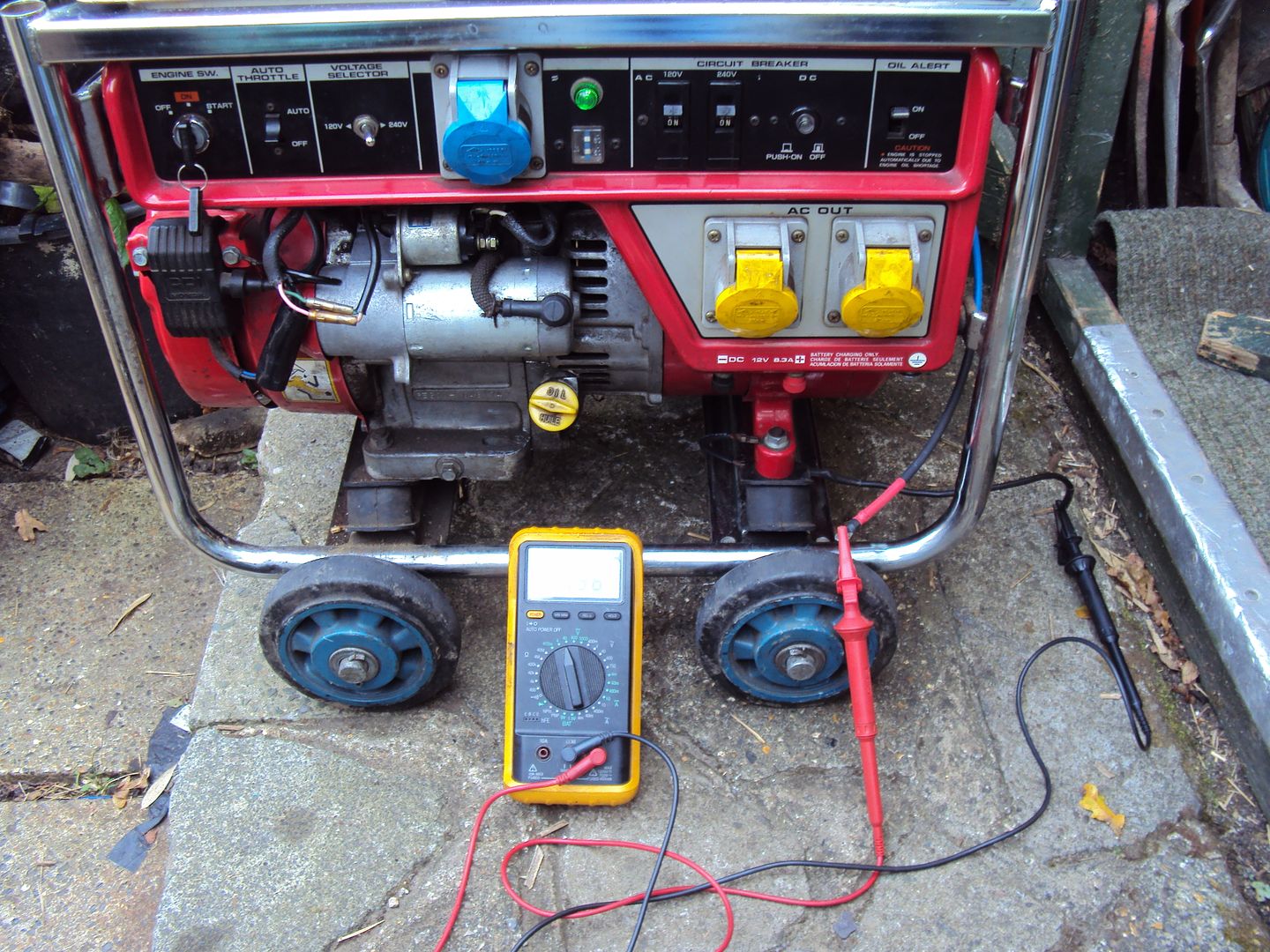

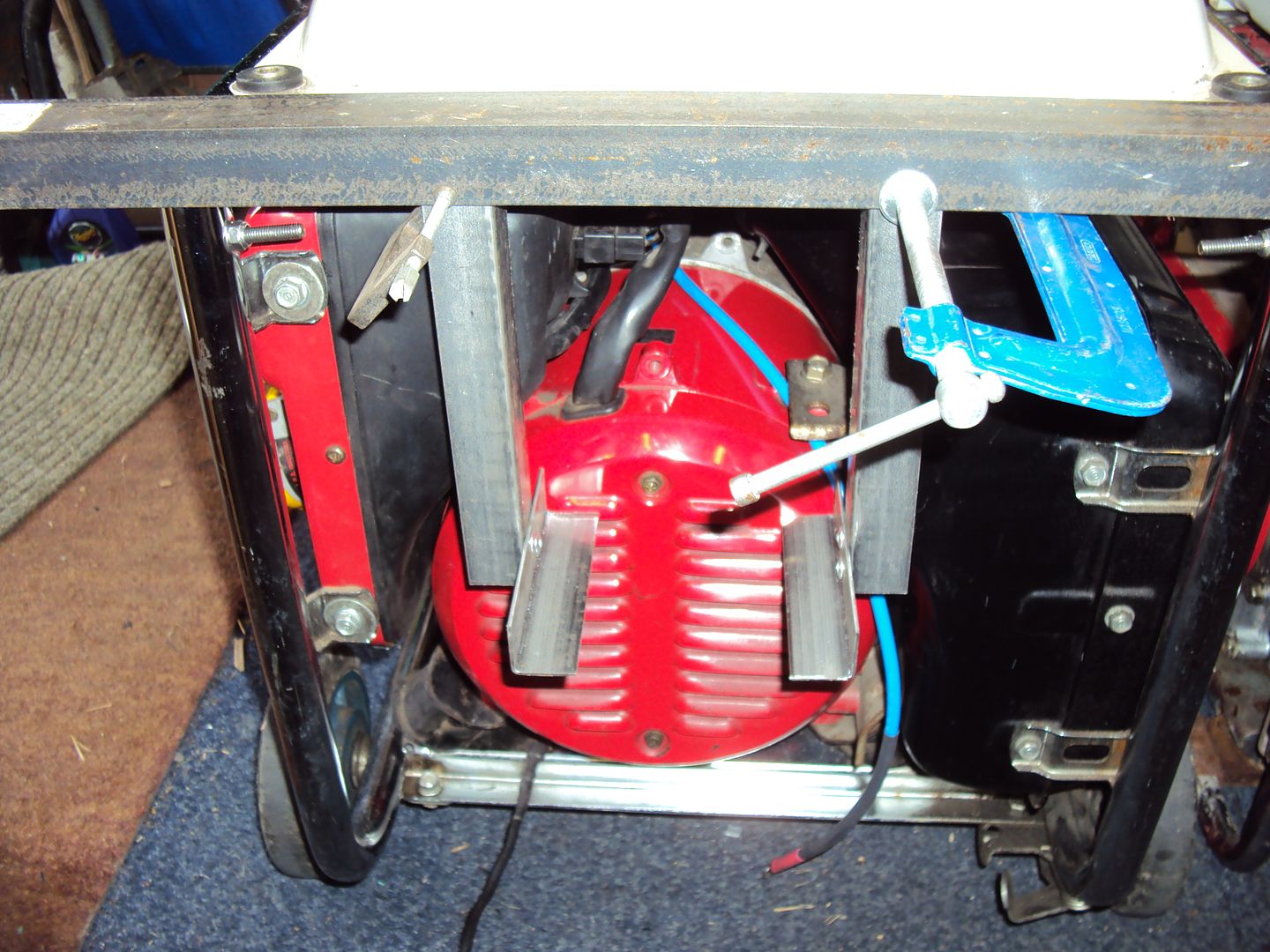

I connected the new battery to test the wiring and start working on a cradle to mount the battery in.

After a few starts I noticed it was starting to struggle to crank the engine, I found the battery was nearly flat. After a bit if investigation it turned out that the battery charging circuit wasn’t working, as with the engine running the charge voltage was 4v not 12 like it should be.

Testing the charging circuit

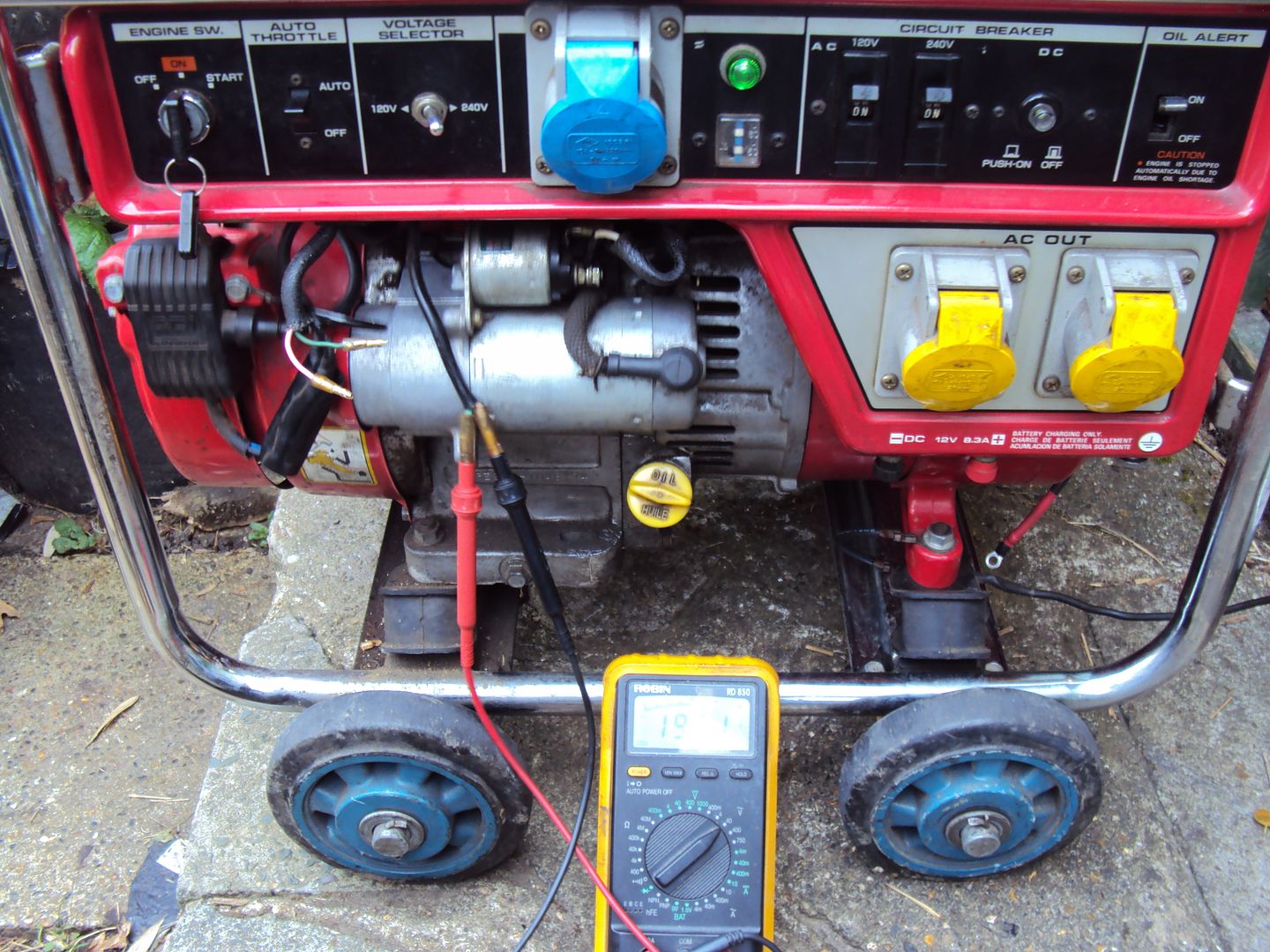

Charge voltage

The charge voltage is from a coil mounted behind the flywheel, I disconnected the coil from the control box and hooked up the multimeter to see what the output was,

Voltage from the charge coil

So the coil works….. the output is an AC voltage which goes into a rectifier in the control box to convert it into DC voltage suitable for charging the battery.

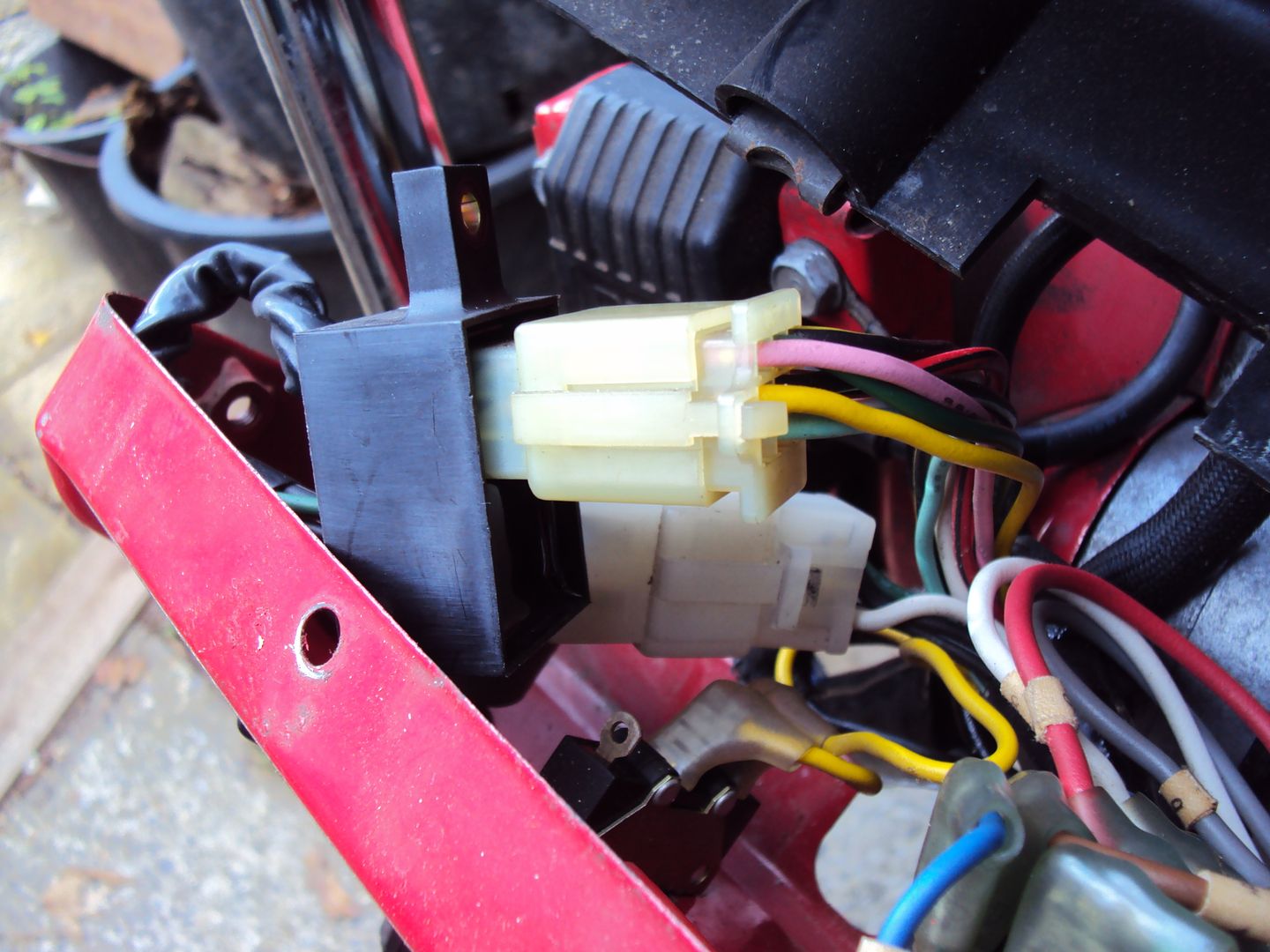

I opened the control box and found the rectifier unit

I was expecting it to have 4 wires going to it, looking at the circuit diagram it looks like there are other components inside the unit which would account for the extra wires. It looks like the other components in the module are working as they should so, the plan is to build a simple charging circuit which will replace the rectifier part of the module and will be better for the battery as the voltage will be controlled.

Whilst thinking about the charging circuit I made a tray for the battery to sit in

The tray will be supported using steel bar which will be attached to the generator frame.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff

]

]