The ebay generator restoration thread

Discussion

spikey78 said:

Hi, I wonder if you could help me with an old Honda genny I've got.. I think it's a gx240 engine, it all works fine but I wonder if there is supposed to be some kind of idle control? The problem is that when running off load it's fine-as soon as you start putting electrical load on the genny the idle drops way down and then off course the power output drops too.

I seem to remember that it should maintain the rpm? Whereas now I have to manually wind up the idle when it's under load..

Hope that makes some kind of sense!

Thanks

What are you using to increase the speed when under load? Are you manually holding the throttle open/I seem to remember that it should maintain the rpm? Whereas now I have to manually wind up the idle when it's under load..

Hope that makes some kind of sense!

Thanks

The engine speed should be controlled by a governor which operates an arm that opens/closes the throttle.

It could be worth checking the carburettor as it is most likely the main jet is blocked, the carburettor should be the same as the one in the link I posted earlier (bottom of page 6)

Can you post some photos?

spikeyhead said:

I'll take a guess that the multimeter is counting harmonics rather than the main waveform. To see the real frequency you'll need an oscilloscope.

Nope!I have been designing building and testing generators and generator control systems for over 27 years , all you need is a proper RMS multimeter, Fluke for example, cheaper meters pick up the harmonics etc. using an oscilloscope on 230VAC is extremely dangerous if you don't know what you're doing.

grahamr88 said:

Thanks, I'll pick up a new capacitor this weekend and see if it helps. Got to be worth a try! The governor mechanism moves freely enough, the spring seems fairly weak though, I wonder if that's part of the problem.

UPDATE: I went to get a new capacitor earlier, and the place offered to test the old one. It had a capacitance of 9.5 µF, so within the tolerance, and they were confident that it wasn't the problem.

They did suggest that I give the contacts a good clean up to ensure that it's connecting properly, which I did, and now when I test it with a 1 kW load, the voltage is around 280 V (+/- 10 V), so slightly better, but still not good. May be totally unrelated to cleaning the contacts of course!

I forgot to mention before that this also has a 110 V output, which I measured at around 140 V without any load, and I unfortunately don't have any 110 V tools I can connect to it. So whatever the problem is, it seems to be affecting both outputs, unless the 110 will droop down to where it should be under load.

The voltage control will be independent of the speed control but they are directly related, so an increase in speed will cause a voltage drift, you set the speed to be 50.5 HZ at full load and you can normally adjust the voltage the same way (droop), if the speed control is poor then you will have voltage stability problems . if set at full load its the regulation of the engine & alternator that will determine the speed and voltage of the set at no load. if the speed drops quickly on load then it could be glazed bores caused by running the engine on light load for long periods.(if not the carburetor). the Hz will be 50-55 (66Hz max 110% if is a 50/60Hz machine) normally. the 150Hz is just a noisy waveform you are reading.UPDATE: I went to get a new capacitor earlier, and the place offered to test the old one. It had a capacitance of 9.5 µF, so within the tolerance, and they were confident that it wasn't the problem.

They did suggest that I give the contacts a good clean up to ensure that it's connecting properly, which I did, and now when I test it with a 1 kW load, the voltage is around 280 V (+/- 10 V), so slightly better, but still not good. May be totally unrelated to cleaning the contacts of course!

I forgot to mention before that this also has a 110 V output, which I measured at around 140 V without any load, and I unfortunately don't have any 110 V tools I can connect to it. So whatever the problem is, it seems to be affecting both outputs, unless the 110 will droop down to where it should be under load.

Edited by grahamr88 on Friday 31st October 11:37

Blue32 said:

What are you using to increase the speed when under load? Are you manually holding the throttle open/

The engine speed should be controlled by a governor which operates an arm that opens/closes the throttle.

It could be worth checking the carburettor as it is most likely the main jet is blocked, the carburettor should be the same as the one in the link I posted earlier (bottom of page 6)

Can you post some photos?

I just adjust up the idle screw (the black plastic cross head screw) it does have some kind of mechanism from the governor but it doesn't appear to do much. The engine speed should be controlled by a governor which operates an arm that opens/closes the throttle.

It could be worth checking the carburettor as it is most likely the main jet is blocked, the carburettor should be the same as the one in the link I posted earlier (bottom of page 6)

Can you post some photos?

I've cleaned out the carb and it will idle fine-until I put the kettle on!

Will get photos, but might take a while as it's in my lorry which is miles away!

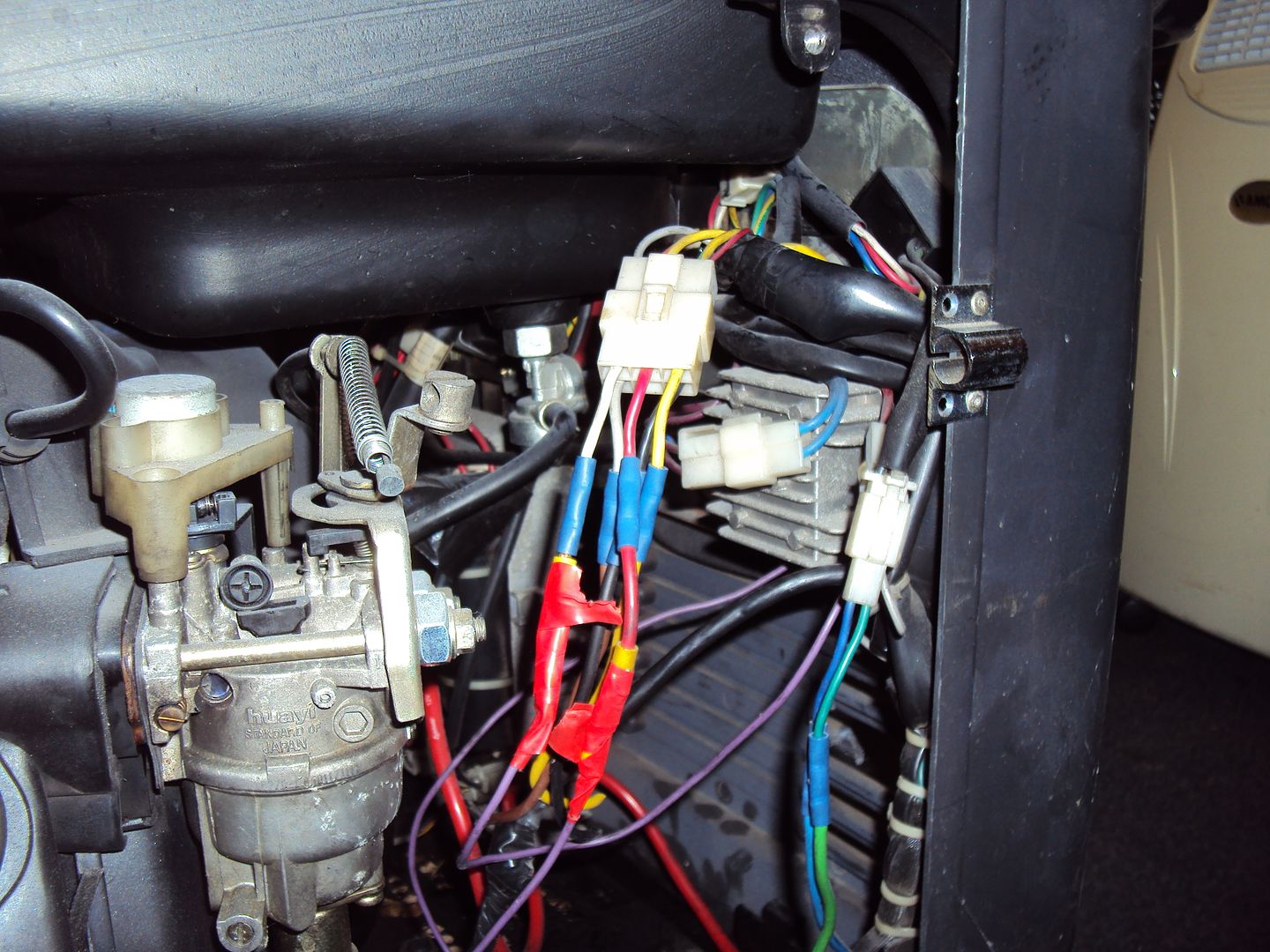

The last Honda found a new home a couple of weeks ago which left space for the next project.

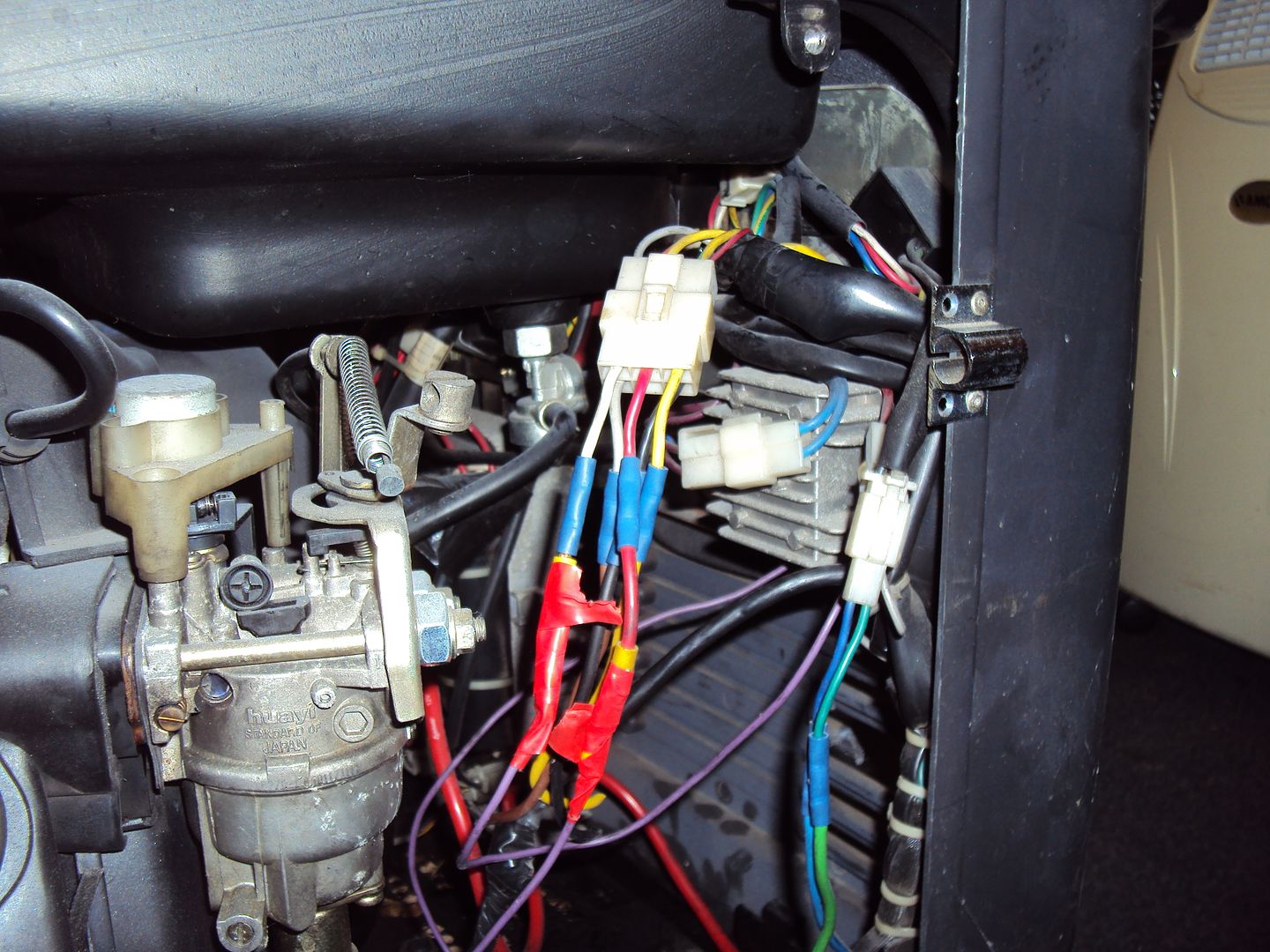

A Kipor 6kVA Inverter generator, this one had been removed from a race support truck.

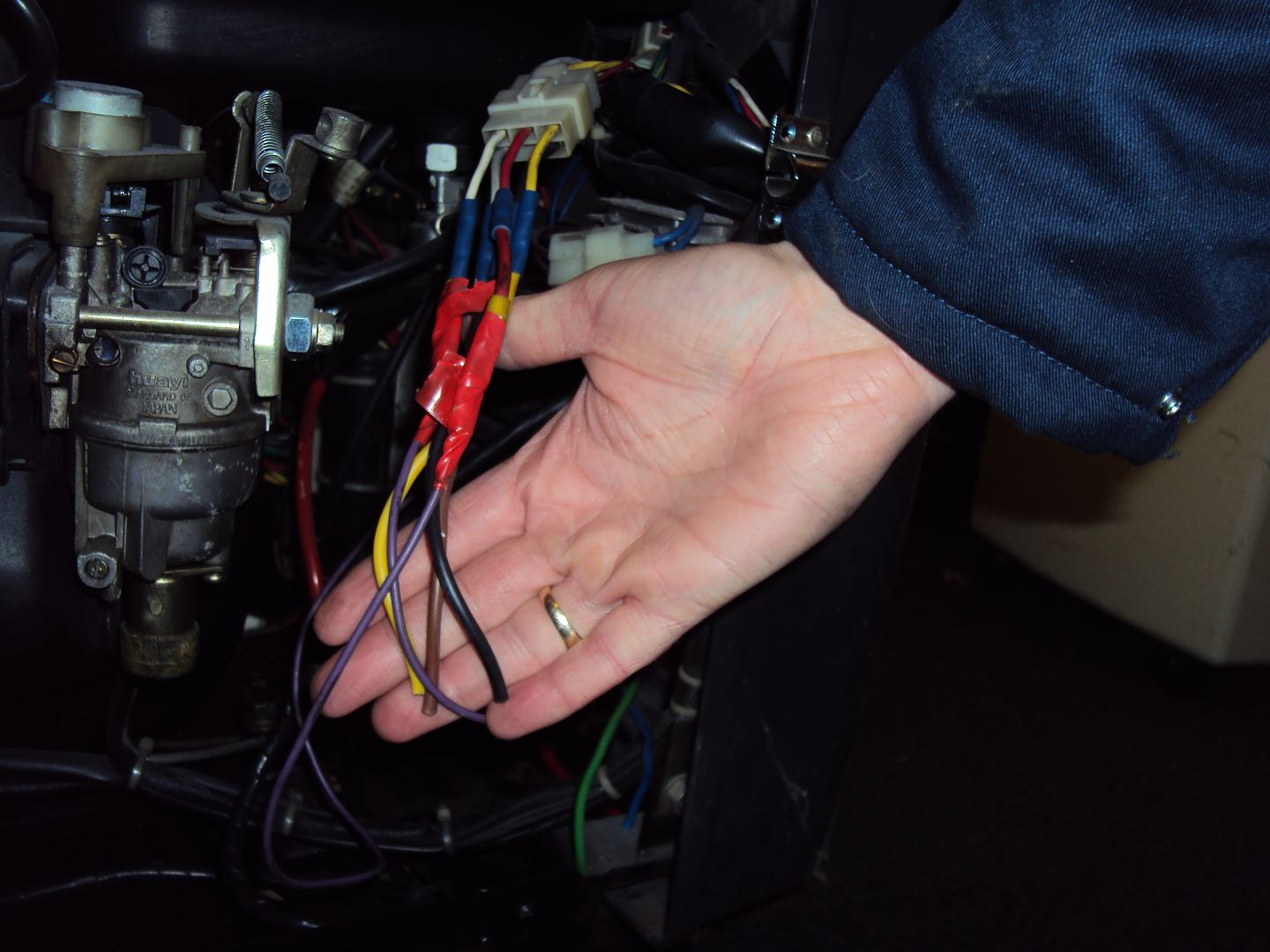

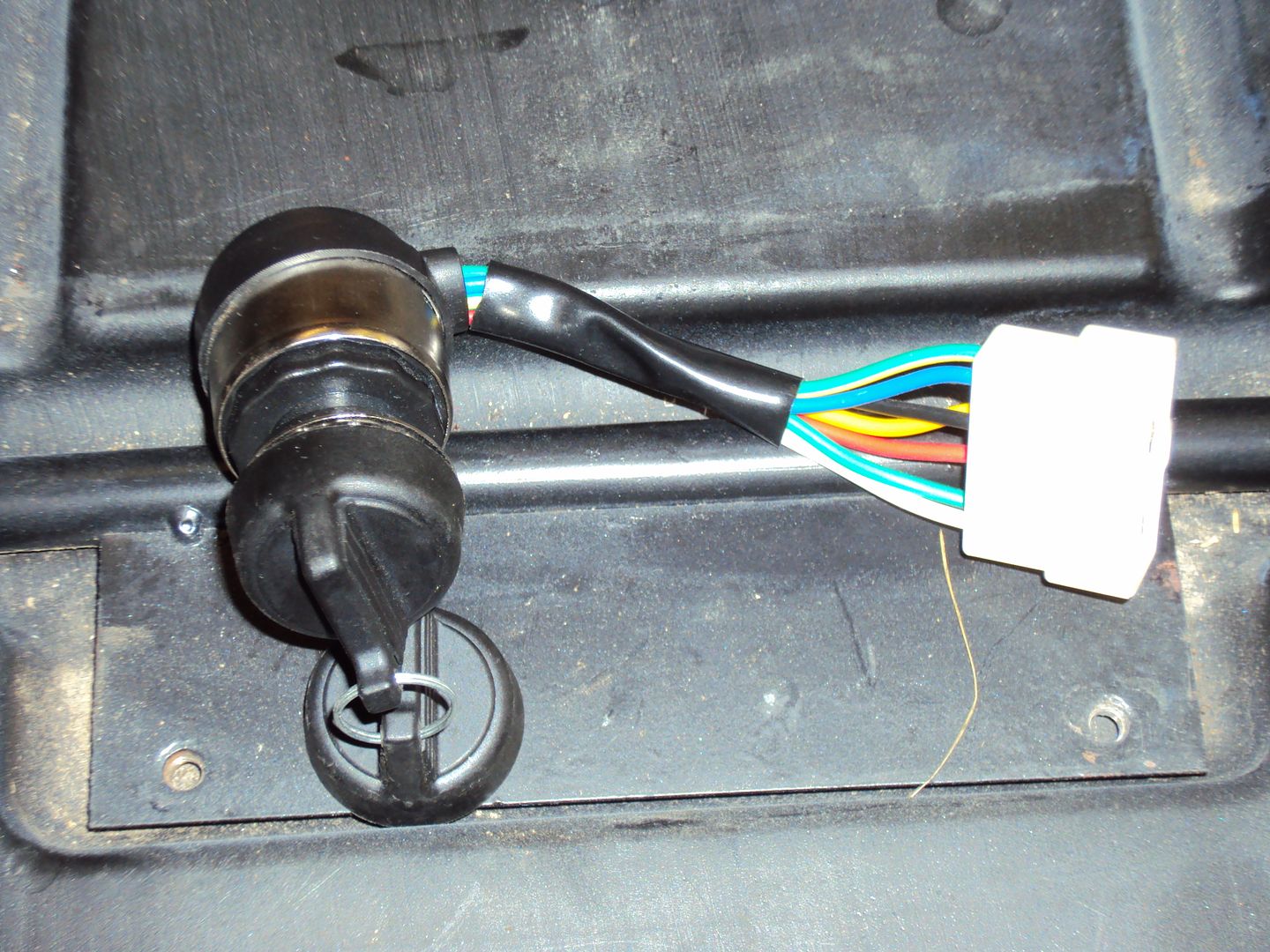

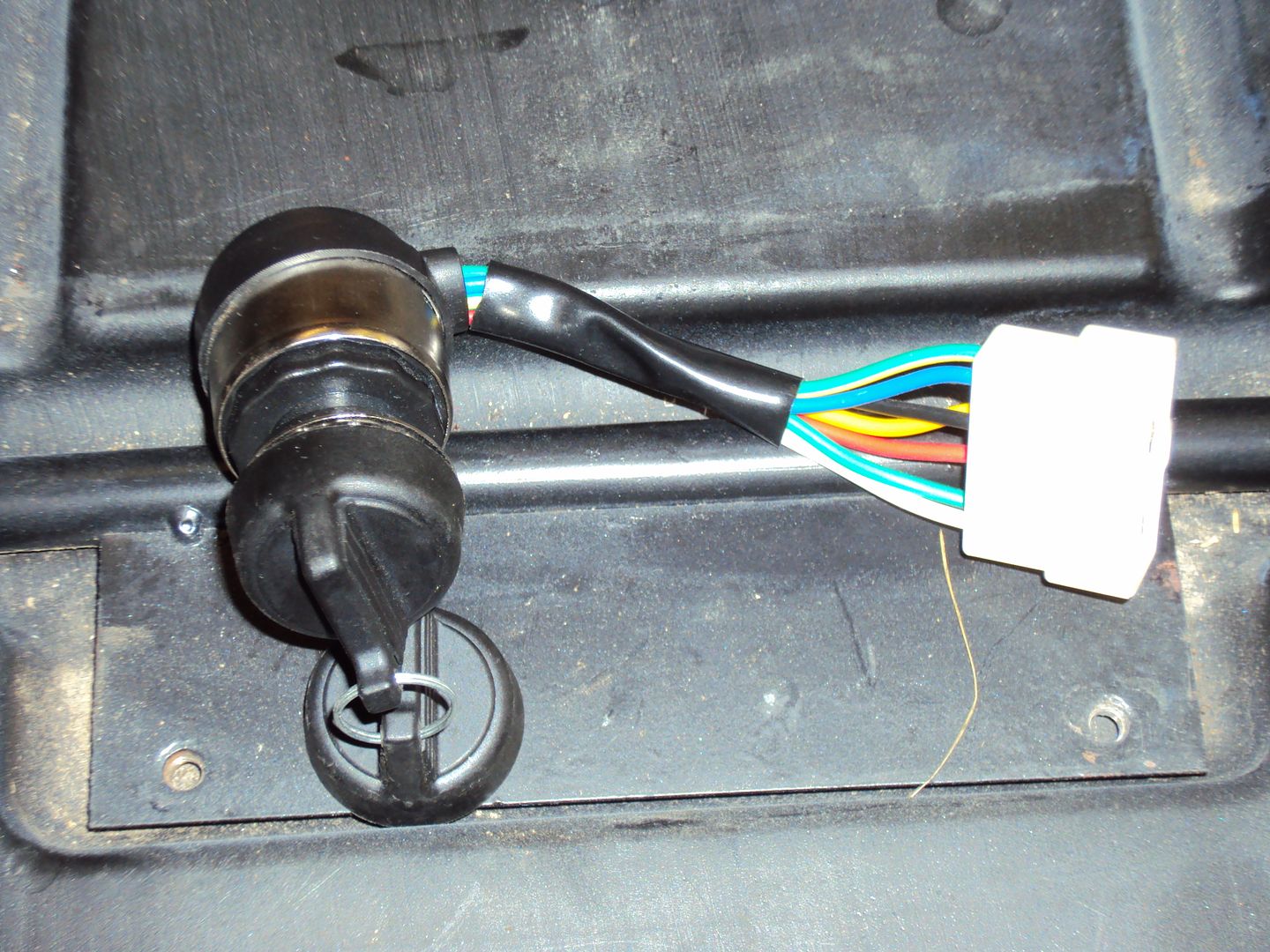

The problem was that the ignition key switch was relocated to the truck cab, unfortunately when removed a record wasn’t kept of where wires went so it won’t start or run.

so it won’t start or run.

Fortunately the seller gave me a new ignition key switch when I collected it

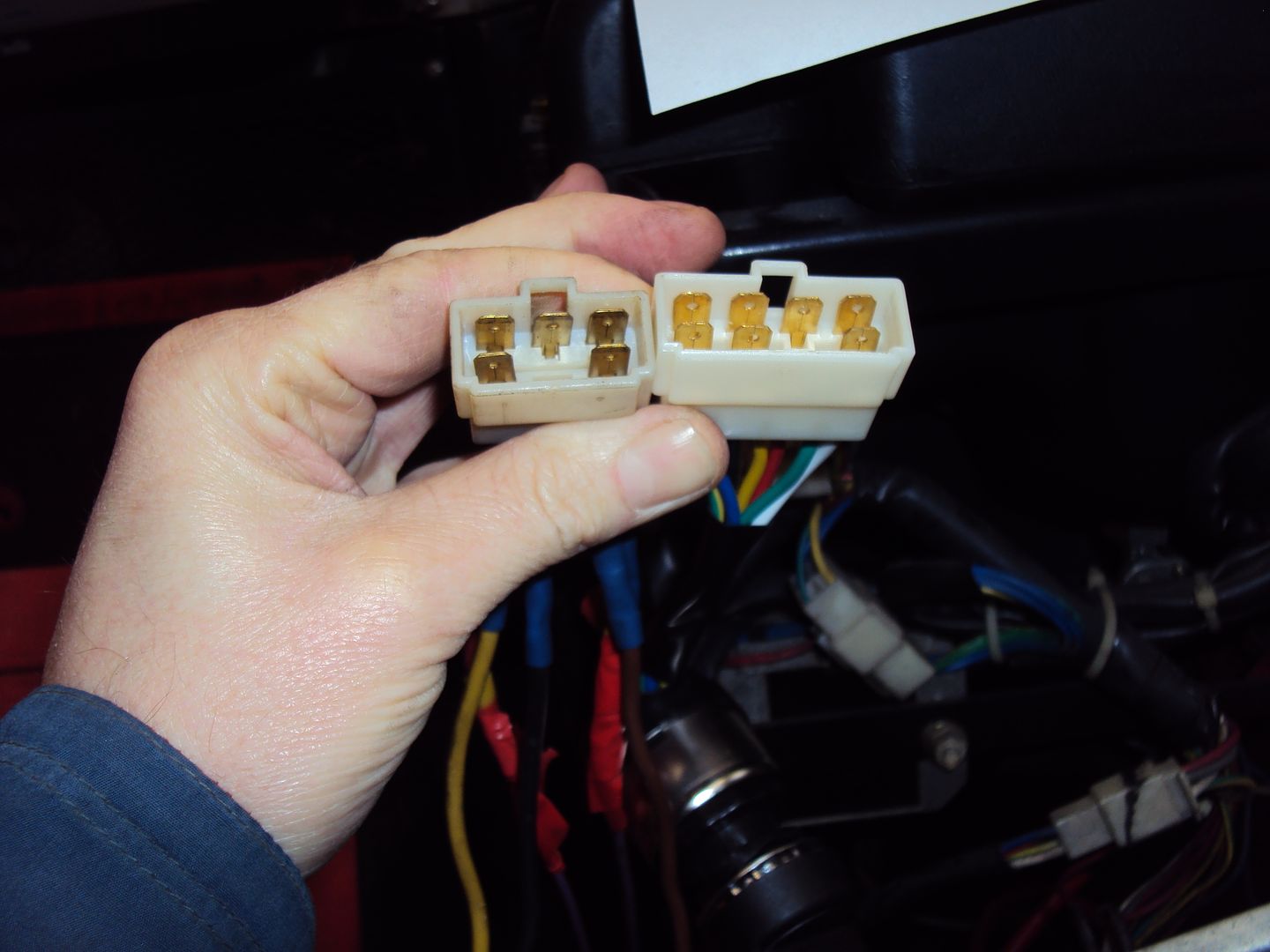

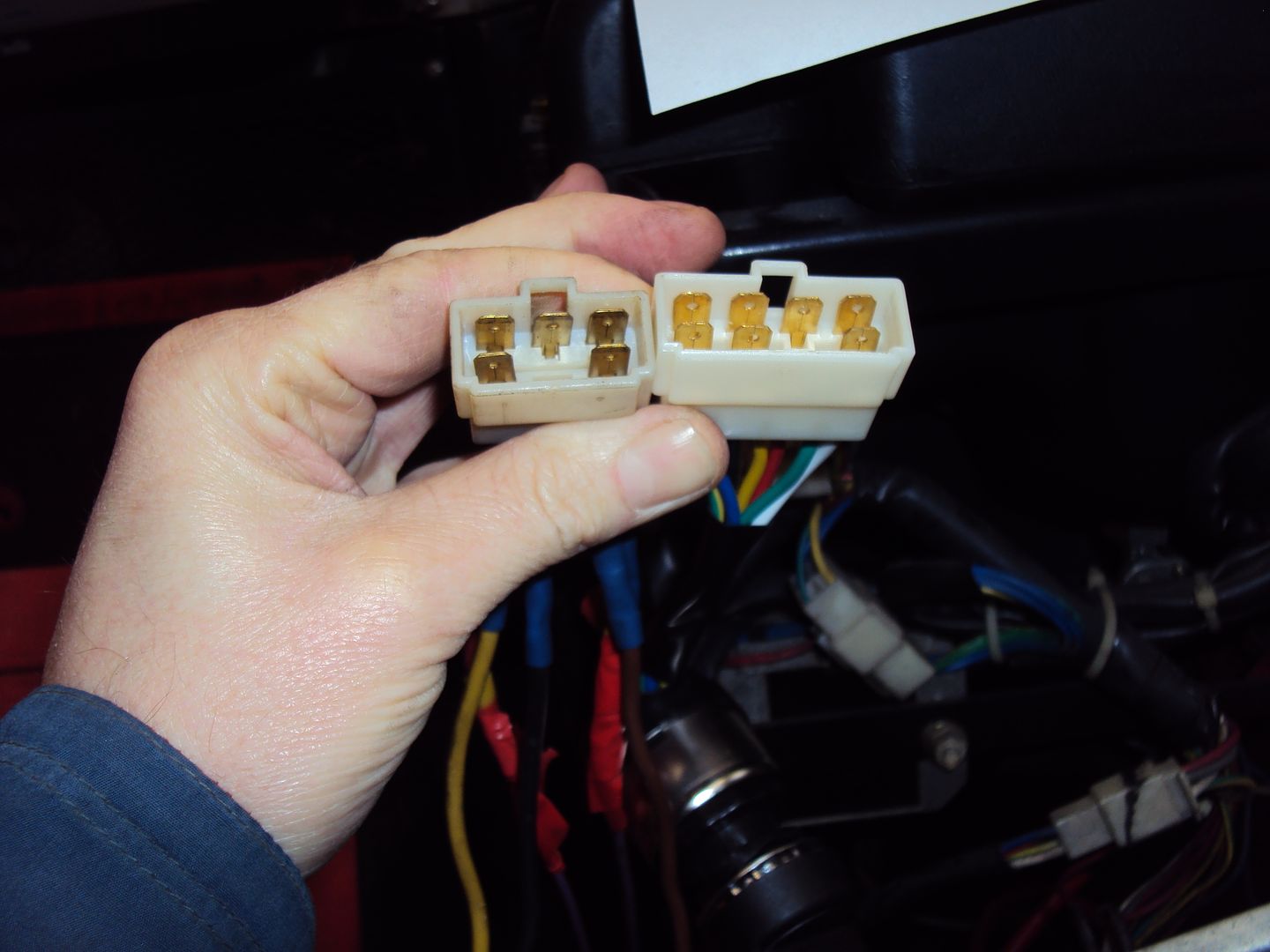

The only problem was that the connector on the new switch (right) is different to the original (left)

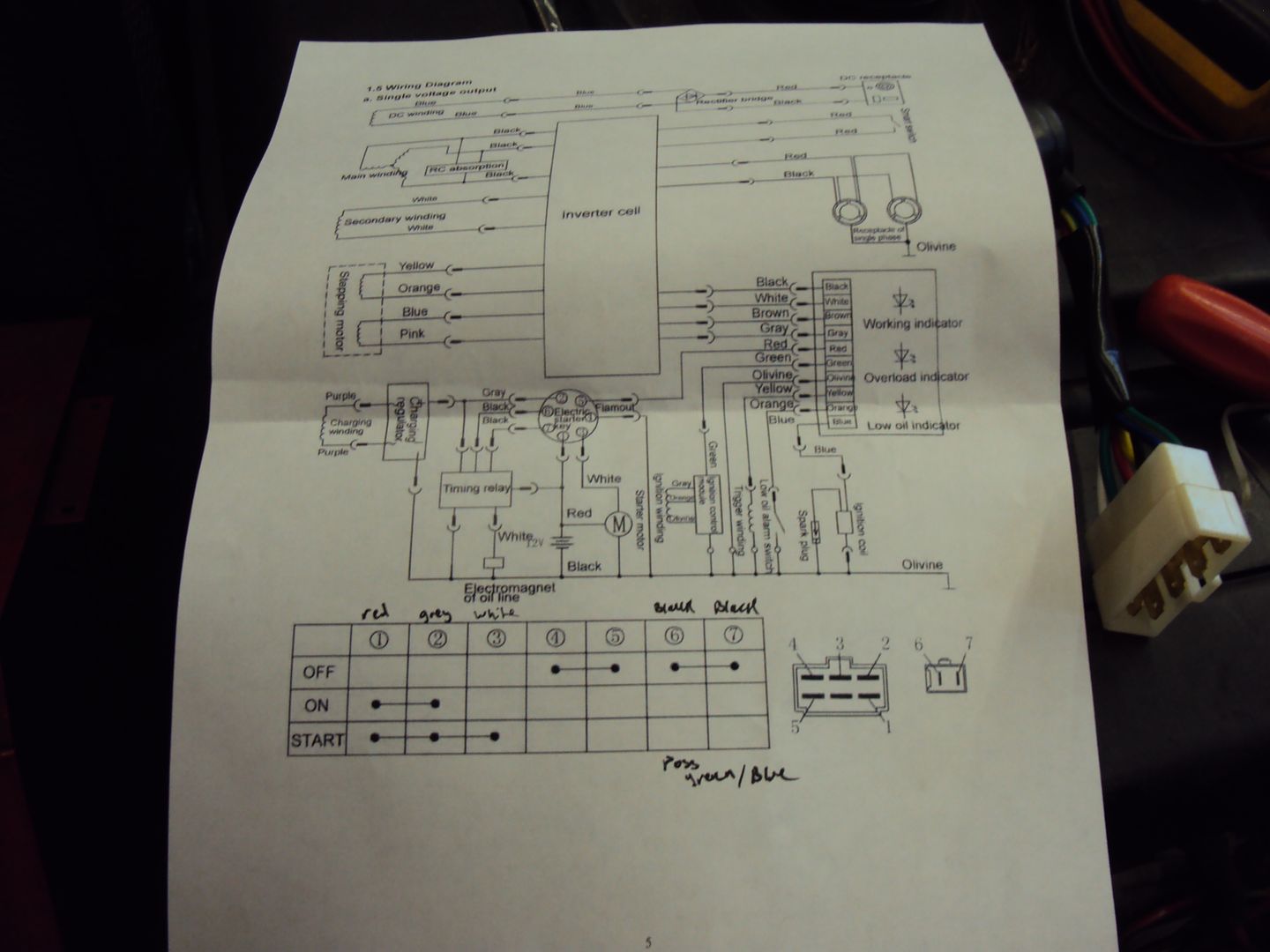

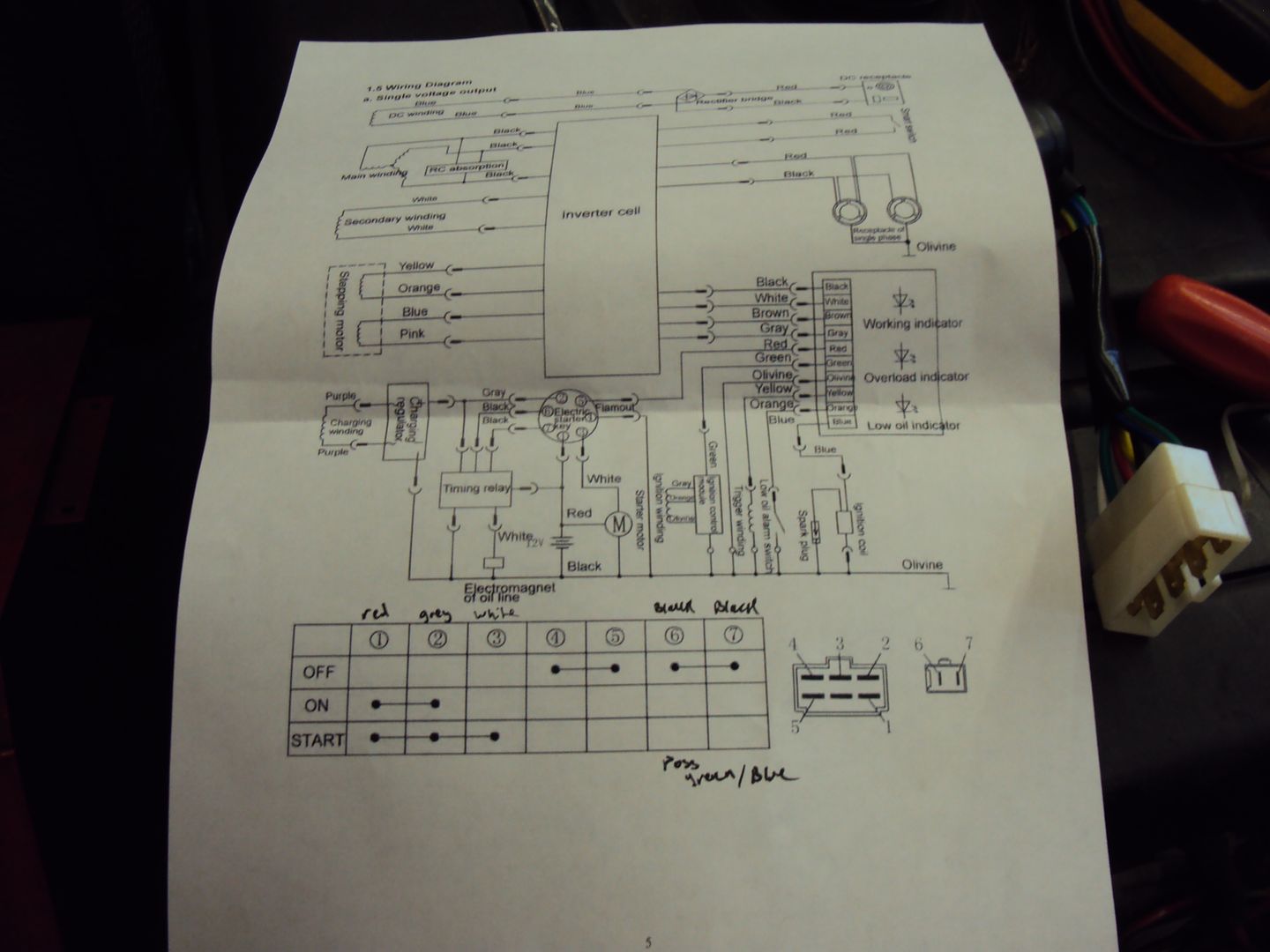

So armed with the wiring diagram I figured out how it needed to be connected.

I figured out how it needed to be connected.

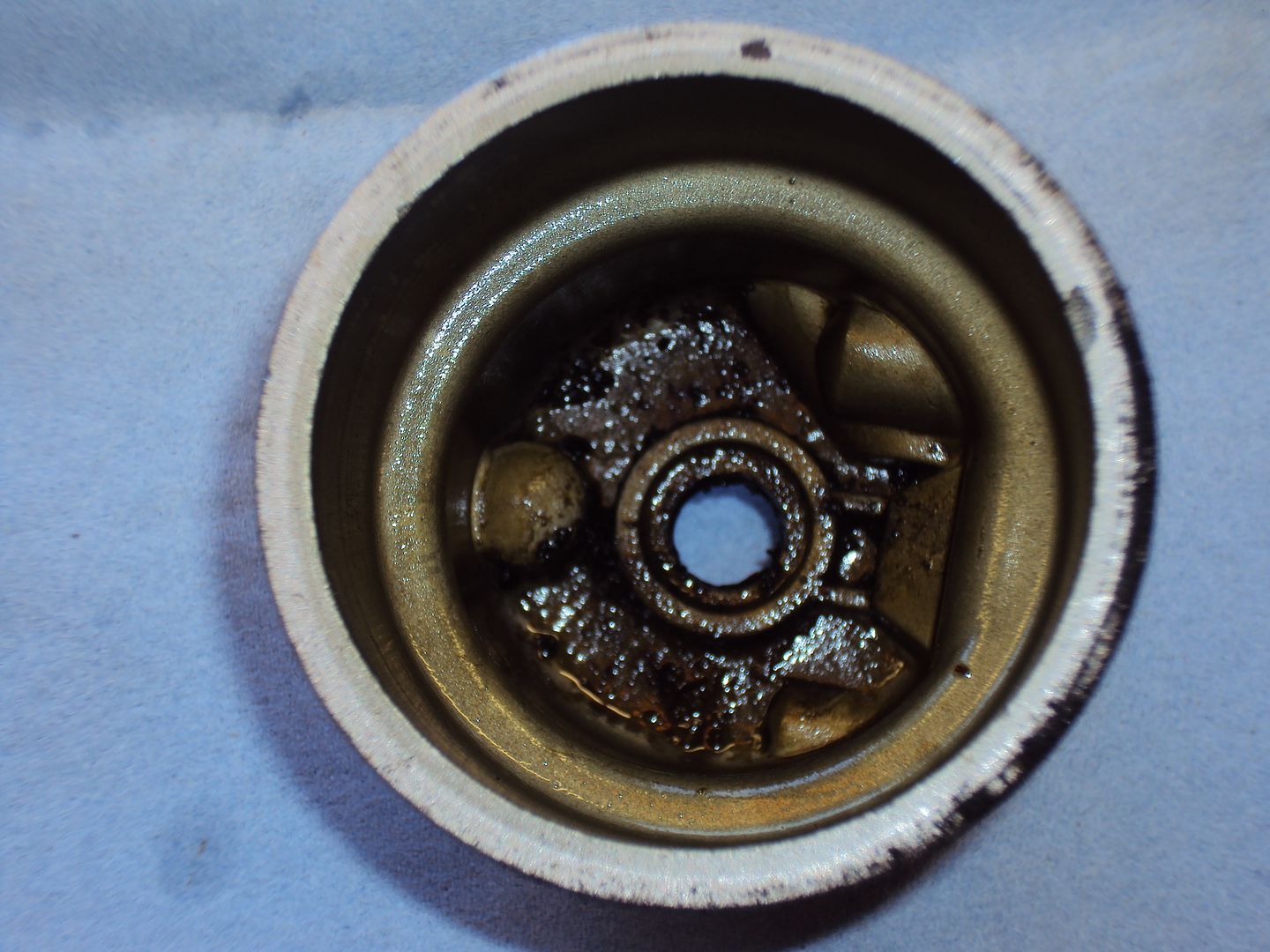

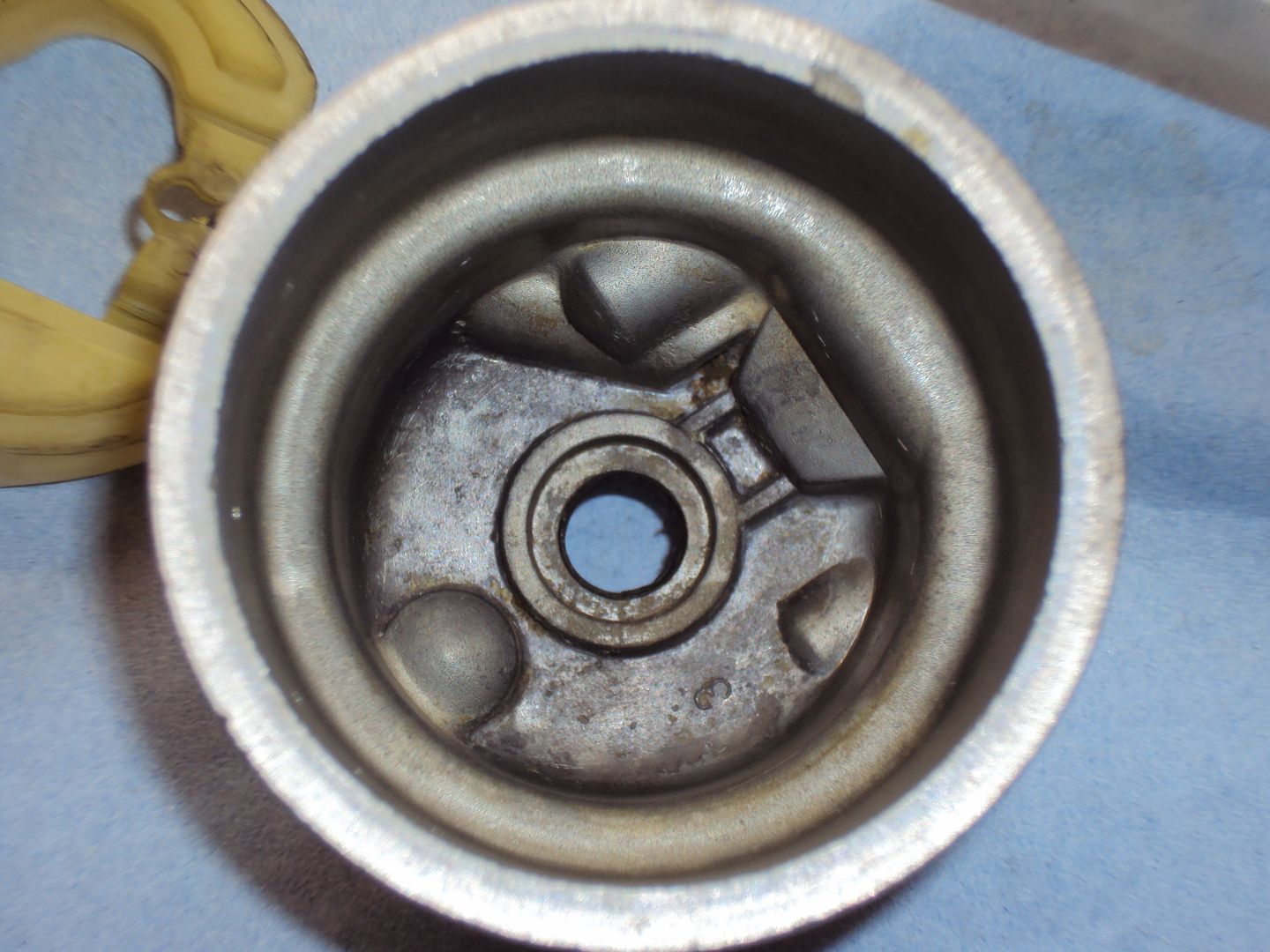

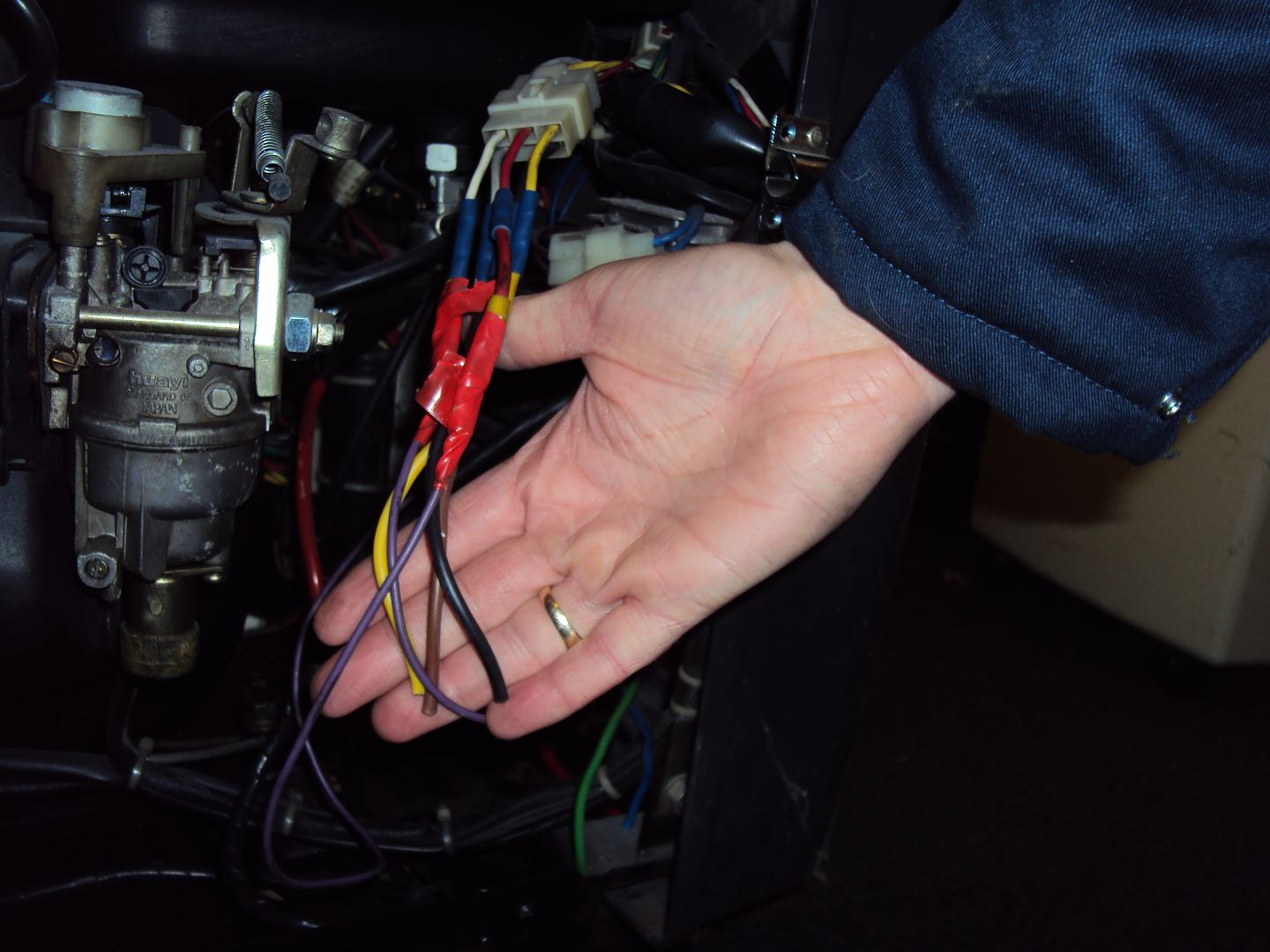

After getting it all wired up, the engine wouldn’t start so checked the carburettor, the fuel that came out didn’t look quite right, also found the fuel cut off valve was stuck.

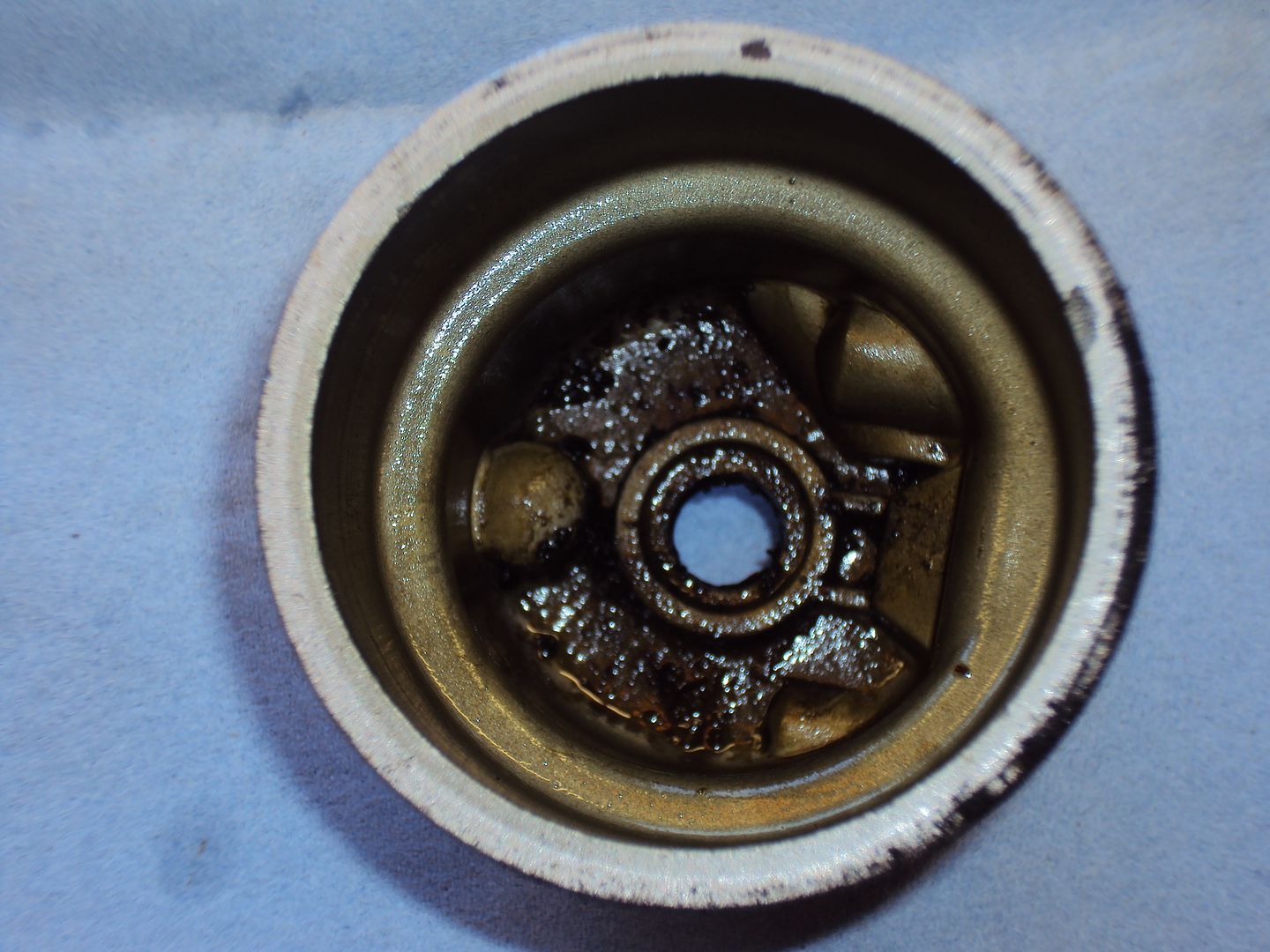

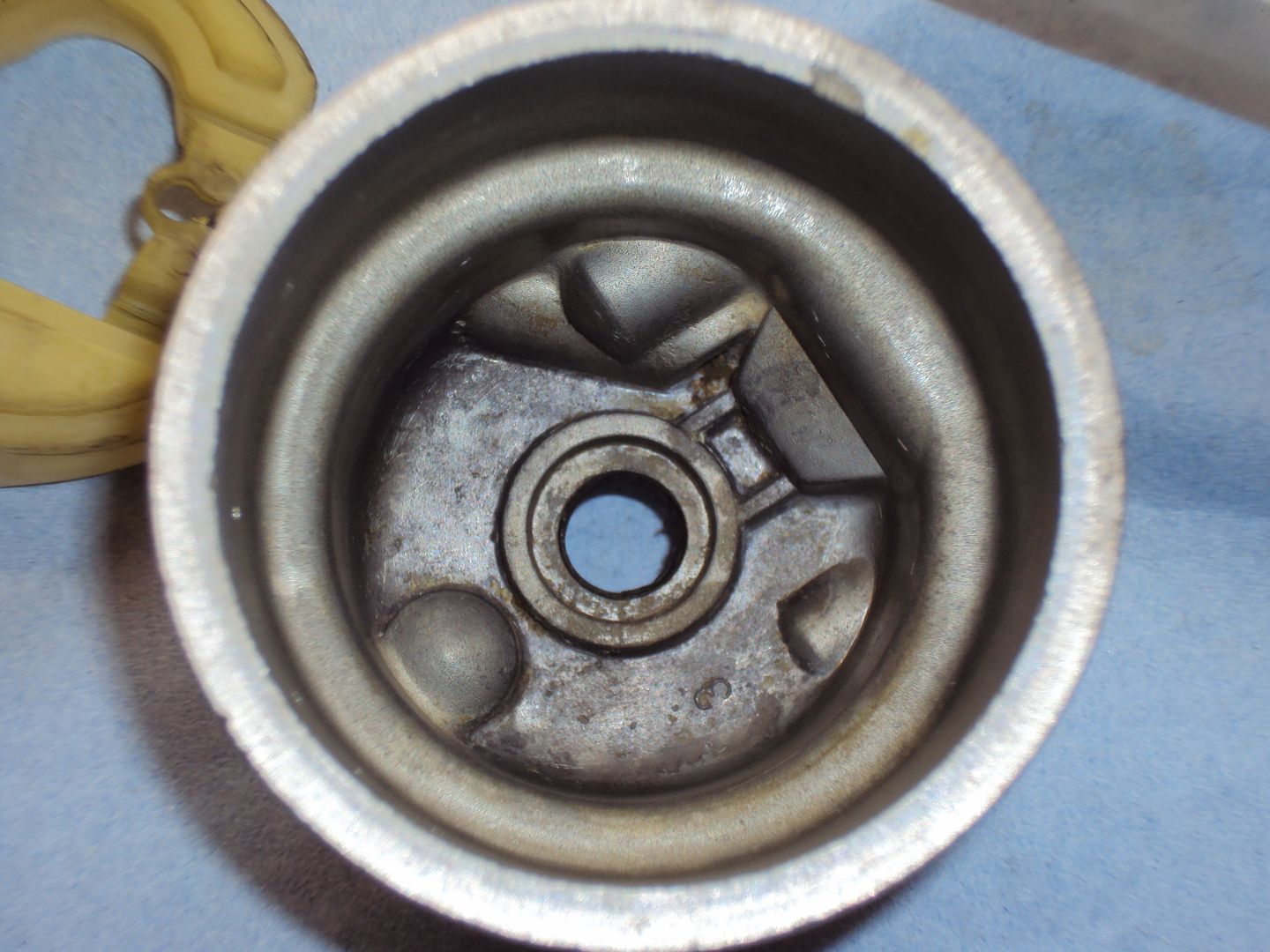

Got the valve freed up and stripped the rest of the carb, the main jet was in a poor state along with a lot of gunge in the bowl.

After a clean the bits were looking better,

Once reassembled, the engine spluttered into life but wasn’t running very well so I need to strip the carb down again .

.

A Kipor 6kVA Inverter generator, this one had been removed from a race support truck.

The problem was that the ignition key switch was relocated to the truck cab, unfortunately when removed a record wasn’t kept of where wires went

so it won’t start or run.

so it won’t start or run.

Fortunately the seller gave me a new ignition key switch when I collected it

The only problem was that the connector on the new switch (right) is different to the original (left)

So armed with the wiring diagram

I figured out how it needed to be connected.

I figured out how it needed to be connected.

After getting it all wired up, the engine wouldn’t start so checked the carburettor, the fuel that came out didn’t look quite right, also found the fuel cut off valve was stuck.

Got the valve freed up and stripped the rest of the carb, the main jet was in a poor state along with a lot of gunge in the bowl.

After a clean the bits were looking better,

Once reassembled, the engine spluttered into life but wasn’t running very well so I need to strip the carb down again

.

. After reading this thread though I am inspired and addicted.

So, when I decided I needed a small backup generator for our camper I went hunting on eBay. Not finding anything of quality I ended up winning a horrible Chinese 1500w beast that had been returned as it didn't work but was brand new..

Found a unconnected capacitor straight away but its a job for another night to get this thing working.

However, for 53€ i hope it will be a bargain

So, when I decided I needed a small backup generator for our camper I went hunting on eBay. Not finding anything of quality I ended up winning a horrible Chinese 1500w beast that had been returned as it didn't work but was brand new..

Found a unconnected capacitor straight away but its a job for another night to get this thing working.

However, for 53€ i hope it will be a bargain

Edited by Lord  on Thursday 12th February 18:33

on Thursday 12th February 18:33

on Thursday 12th February 18:33

on Thursday 12th February 18:33Very good material here from like-minded tinkerers who get enormous satisfaction from getting machinery going again.

I have 4 inverter generators, including two Chinese XG-SF1000's. I bought one new and soon I will post the litany of fixes for it. The other was almost new, but not running. Needed a new vacuum pulse fuel pump and fuel hoses.

This second one gives readings of 50hz but 280 volts, and will not run any portable 240v fans. They hum and spin slowly.

The first (bought new) one runs fans and everything else, with AC voltage of 228, but the cycle hz are off the kill-a-watt-type meter scale, possibly around 150hz. (An electric clock plugged in to the generator will have minutes ticking by in seconds).

The tops of capacitors sticking out above the bed of epoxy in the inverter units look OK, no obvious bulges.

The stepper motors respond to changing loads and the engines run sweetly for hours on end charging batteries and running a small fridge.

But since discovering their peculiarities I am reluctant to deploy them further in case the cycle rate or voltages damage charger, fridges, televisions and anything else.

Any ideas on likely causes?

I have 4 inverter generators, including two Chinese XG-SF1000's. I bought one new and soon I will post the litany of fixes for it. The other was almost new, but not running. Needed a new vacuum pulse fuel pump and fuel hoses.

This second one gives readings of 50hz but 280 volts, and will not run any portable 240v fans. They hum and spin slowly.

The first (bought new) one runs fans and everything else, with AC voltage of 228, but the cycle hz are off the kill-a-watt-type meter scale, possibly around 150hz. (An electric clock plugged in to the generator will have minutes ticking by in seconds).

The tops of capacitors sticking out above the bed of epoxy in the inverter units look OK, no obvious bulges.

The stepper motors respond to changing loads and the engines run sweetly for hours on end charging batteries and running a small fridge.

But since discovering their peculiarities I am reluctant to deploy them further in case the cycle rate or voltages damage charger, fridges, televisions and anything else.

Any ideas on likely causes?

Hopefully someone on this thread can shed some light on this for me....

My dad has just bought a small 1.8Kw generator - can't remember the make, but it's four letters and Chinese. As usual he has ignored my "buy cheap, buy twice advice".

Besides the fact that it's so load that no caravan place in Christendom would let them use it (nor do they need it) there is a very strange issue....

Start it up, no worries.

Plug in, say, an electric sander or a toaster or a battery charger. They work. That's a variety of appliances with different current draws etc.

Plug in a table lamp from the house with a normal tungsten 60W bulb.

It doesn't light. At all. Go back in the house, plug it into the mains and it works.

What on earth is going on?

My dad has just bought a small 1.8Kw generator - can't remember the make, but it's four letters and Chinese. As usual he has ignored my "buy cheap, buy twice advice".

Besides the fact that it's so load that no caravan place in Christendom would let them use it (nor do they need it) there is a very strange issue....

Start it up, no worries.

Plug in, say, an electric sander or a toaster or a battery charger. They work. That's a variety of appliances with different current draws etc.

Plug in a table lamp from the house with a normal tungsten 60W bulb.

It doesn't light. At all. Go back in the house, plug it into the mains and it works.

What on earth is going on?

If it is an AVR controlled generator, modified sinewave, it may be that at idle it is not supplying enough power to run that low-wattage light globe, whereas the tools load it up sufficiently. Try connecting a power board, then plug with one of the tools that work, plus the light globe, and see if, switching on the tool, the light also lights up.

Thanks Larry - I forgot to say that I've tried that - it still doesn't light. *HOWEVER* I did this by plugging the toaster into socket 1 and the light into socket 2 on the generator.

I'll get my dad (as I'm abroad now) to try it with a multiplug with two items on.

The idle on the thing under no load is awful too - hunts up and down. As I said "buy cheap, buy twice". <sigh>

I'll get my dad (as I'm abroad now) to try it with a multiplug with two items on.

The idle on the thing under no load is awful too - hunts up and down. As I said "buy cheap, buy twice". <sigh>

OK, my tale of woe with the SF 1000 generator.

I bought this on Ebay in 2009 mainly to run a few small tools while restoring my boat. The ad boasted that it was based on Yamaha technology, and indeed looked like it at least.

At 14 kg it's light to heave on and off the boat, and produces 1000 watt peak, 900w rated output.

It was rather louder than I expected, more than the Ebay advert led me to believe. The seller agreed to take it back. But then I changed my mind. At least it produced a pure sinewave and was not as smelly as the exhaust from the two-stroke 850 watt modified sinewave job it was replacing.

Weeks later, the litany of problems began. Despite plenty of petrol in the tank, it always cut out at the 1/3 remaining mark. Strange.

The first of dozens of tear-aparts began. Knowing nothing about these machines, I deduced which gadget was the fuel pump. Luckily it was the repairable kind with bolts---not a one-piece plastic.

After opening it up, noticed gobs of resin-like material clogging the various pulse pump ports. What were they? And why were they there? Poor Chinese quality control, that's what and why. I cleaned out the gunk, and that solved the problem. Genny would now run happily up to 6 hours on the 2+ litre tank.

Sometime later, the bout of happiness ended. It hunted badly and then shut down. After much working in the darkness of my ignorance of inverter-generators, I noticed the stepper motor which automatically matches engine speed to load, was bouncing about. Quality control again. The factory assembler hadn't tightened its two small securing bolts.

Sometime later, after running pretty well for weeks, I pulled the recoil starter rope, and it broke. One end disappeared inside the nether regions faster than a startled rabbit down a burrow.

Off came the side two-piece cases. But when I went to remove the three bolts by which the starter housing was attached to the plastic engine cover...they just turned and turned. The nuts turned with the bolts. And they were inaccessible inside the plastic cover. That cover had to come off, so more dismantling.

I held on to the nuts while unbolting. Then, having freed the recoil starter, I put adhesive on to the nuts to stop them free-turning in future.

Back to the recoiler. The centre bolt holding the bobbin with spring and rope would not unscrew, under any amount of force with my Phillips head screwdriver. So I had to take it to a lawn mower place. They installed a new rope, and away we went again for a few months.

When it started with a few pulls, happiness. Economical, ran the tools to fix the boat, and on the boat it ran the TV, charged the batteries when the solar panels couldn't cope with overcast skies.

But often--and I mean often---you could tug on that starter rope until your arms dropped before it sprang to life.

Finally, on another trip, nothing. No starting. Checked the plug---no spark. A new plug. No spark.

Sent away to China for a new coil and spark plug lead. This fixed the problem, but only for a while.

Again, after hours of arm-wrenching pulls, it gave up again. No spark.

This time, the dismantle involved not just removal of side covers, but the engine itself, and the inverter. Draining the oil out and checking the low-oil shutoff switch. It worked. The spark trigger. Seemed OK. Traced every wire for continuity. OK. Stripped the carburettor, cleaned it thoroughly.

After days of diagnosing I guessed it was the spark control module, so sent away to China for a new one. The module was probably the guilty party in the first place. The new coil only temporarily appeared to fix the problem while the module's intermittent ill temperament behaved itself.

Instant fix.

Sometime later, another thorn in the bed of roses. The rope snapped again--from all that pulling. I became quite adept at dismantling and assembly. And worked out a neat way of winding the recoil spring inside its holder with ease. While on the subject, the bent inner end of the spring, what latches onto a stationary post while it recoils...broke. Several times. You can't just take some pliers and bend spring steel into a hook, because it snaps.

So I heated it red hot over the boat LPG burner, and bent it. That worked, for a few months, before it would break again. So far, 3 ropes have also broken and been replaced.

Sometime later....the little blue genny started hunting badly. It didn't sound like a fuel starvation problem. I looked intuitively at the stepper motor. It was bopping around like a cork in a sea. One of its two little ears through which tiny bolts hold it down, had snapped off. They are so flimsy.

So, I got some tinfoil and fashioned an upside down U-shaped bracket to hold it down. It's still doing its job.

That's about the end of the physical problems. And probably the generator, too. You see, it works, runs well....But after measuring its output with a kill-a-watt type device recently, it read 228V AC. Pretty good compared to the household supply which read 254 V AC.

More worrying was the cycles. No reading. Occasionally from 0hz, 50hz flashed up for under a second, then back to 0. Yet tools run well. An electric clock, however, sped up so that a minute ticked by in about 3 seconds.

I tried a multimeter, and it's showing something like 150hz. Not good.

This is probably a fault of the inverter. But inverters in all these generators are encased in a hard epoxy resin-like substance and there is no tinkering possible. I have not been able to source a new one, and for the likes of Hondas, Yamahas, Kipors, they are around the $400 mark. More than the $300 the entire genny cost.

And that's where the saga ends. For now.

I bought this on Ebay in 2009 mainly to run a few small tools while restoring my boat. The ad boasted that it was based on Yamaha technology, and indeed looked like it at least.

At 14 kg it's light to heave on and off the boat, and produces 1000 watt peak, 900w rated output.

It was rather louder than I expected, more than the Ebay advert led me to believe. The seller agreed to take it back. But then I changed my mind. At least it produced a pure sinewave and was not as smelly as the exhaust from the two-stroke 850 watt modified sinewave job it was replacing.

Weeks later, the litany of problems began. Despite plenty of petrol in the tank, it always cut out at the 1/3 remaining mark. Strange.

The first of dozens of tear-aparts began. Knowing nothing about these machines, I deduced which gadget was the fuel pump. Luckily it was the repairable kind with bolts---not a one-piece plastic.

After opening it up, noticed gobs of resin-like material clogging the various pulse pump ports. What were they? And why were they there? Poor Chinese quality control, that's what and why. I cleaned out the gunk, and that solved the problem. Genny would now run happily up to 6 hours on the 2+ litre tank.

Sometime later, the bout of happiness ended. It hunted badly and then shut down. After much working in the darkness of my ignorance of inverter-generators, I noticed the stepper motor which automatically matches engine speed to load, was bouncing about. Quality control again. The factory assembler hadn't tightened its two small securing bolts.

Sometime later, after running pretty well for weeks, I pulled the recoil starter rope, and it broke. One end disappeared inside the nether regions faster than a startled rabbit down a burrow.

Off came the side two-piece cases. But when I went to remove the three bolts by which the starter housing was attached to the plastic engine cover...they just turned and turned. The nuts turned with the bolts. And they were inaccessible inside the plastic cover. That cover had to come off, so more dismantling.

I held on to the nuts while unbolting. Then, having freed the recoil starter, I put adhesive on to the nuts to stop them free-turning in future.

Back to the recoiler. The centre bolt holding the bobbin with spring and rope would not unscrew, under any amount of force with my Phillips head screwdriver. So I had to take it to a lawn mower place. They installed a new rope, and away we went again for a few months.

When it started with a few pulls, happiness. Economical, ran the tools to fix the boat, and on the boat it ran the TV, charged the batteries when the solar panels couldn't cope with overcast skies.

But often--and I mean often---you could tug on that starter rope until your arms dropped before it sprang to life.

Finally, on another trip, nothing. No starting. Checked the plug---no spark. A new plug. No spark.

Sent away to China for a new coil and spark plug lead. This fixed the problem, but only for a while.

Again, after hours of arm-wrenching pulls, it gave up again. No spark.

This time, the dismantle involved not just removal of side covers, but the engine itself, and the inverter. Draining the oil out and checking the low-oil shutoff switch. It worked. The spark trigger. Seemed OK. Traced every wire for continuity. OK. Stripped the carburettor, cleaned it thoroughly.

After days of diagnosing I guessed it was the spark control module, so sent away to China for a new one. The module was probably the guilty party in the first place. The new coil only temporarily appeared to fix the problem while the module's intermittent ill temperament behaved itself.

Instant fix.

Sometime later, another thorn in the bed of roses. The rope snapped again--from all that pulling. I became quite adept at dismantling and assembly. And worked out a neat way of winding the recoil spring inside its holder with ease. While on the subject, the bent inner end of the spring, what latches onto a stationary post while it recoils...broke. Several times. You can't just take some pliers and bend spring steel into a hook, because it snaps.

So I heated it red hot over the boat LPG burner, and bent it. That worked, for a few months, before it would break again. So far, 3 ropes have also broken and been replaced.

Sometime later....the little blue genny started hunting badly. It didn't sound like a fuel starvation problem. I looked intuitively at the stepper motor. It was bopping around like a cork in a sea. One of its two little ears through which tiny bolts hold it down, had snapped off. They are so flimsy.

So, I got some tinfoil and fashioned an upside down U-shaped bracket to hold it down. It's still doing its job.

That's about the end of the physical problems. And probably the generator, too. You see, it works, runs well....But after measuring its output with a kill-a-watt type device recently, it read 228V AC. Pretty good compared to the household supply which read 254 V AC.

More worrying was the cycles. No reading. Occasionally from 0hz, 50hz flashed up for under a second, then back to 0. Yet tools run well. An electric clock, however, sped up so that a minute ticked by in about 3 seconds.

I tried a multimeter, and it's showing something like 150hz. Not good.

This is probably a fault of the inverter. But inverters in all these generators are encased in a hard epoxy resin-like substance and there is no tinkering possible. I have not been able to source a new one, and for the likes of Hondas, Yamahas, Kipors, they are around the $400 mark. More than the $300 the entire genny cost.

And that's where the saga ends. For now.

larrypinter said:

OK, my tale of woe with the SF 1000 generator.

I bought this on Ebay in 2009 mainly to run a few small tools while restoring my boat. The ad boasted that it was based on Yamaha technology, and indeed looked like it at least.

At 14 kg it's light to heave on and off the boat, and produces 1000 watt peak, 900w rated output.

It was rather louder than I expected, more than the Ebay advert led me to believe. The seller agreed to take it back. But then I changed my mind. At least it produced a pure sinewave and was not as smelly as the exhaust from the two-stroke 850 watt modified sinewave job it was replacing.

Weeks later, the litany of problems began. Despite plenty of petrol in the tank, it always cut out at the 1/3 remaining mark. Strange.

Sounds to me, like it's time for a burial at sea

The first of dozens of tear-aparts began. Knowing nothing about these machines, I deduced which gadget was the fuel pump. Luckily it was the repairable kind with bolts---not a one-piece plastic.

After opening it up, noticed gobs of resin-like material clogging the various pulse pump ports. What were they? And why were they there? Poor Chinese quality control, that's what and why. I cleaned out the gunk, and that solved the problem. Genny would now run happily up to 6 hours on the 2+ litre tank.

Sometime later, the bout of happiness ended. It hunted badly and then shut down. After much working in the darkness of my ignorance of inverter-generators, I noticed the stepper motor which automatically matches engine speed to load, was bouncing about. Quality control again. The factory assembler hadn't tightened its two small securing bolts.

Sometime later, after running pretty well for weeks, I pulled the recoil starter rope, and it broke. One end disappeared inside the nether regions faster than a startled rabbit down a burrow.

Off came the side two-piece cases. But when I went to remove the three bolts by which the starter housing was attached to the plastic engine cover...they just turned and turned. The nuts turned with the bolts. And they were inaccessible inside the plastic cover. That cover had to come off, so more dismantling.

I held on to the nuts while unbolting. Then, having freed the recoil starter, I put adhesive on to the nuts to stop them free-turning in future.

Back to the recoiler. The centre bolt holding the bobbin with spring and rope would not unscrew, under any amount of force with my Phillips head screwdriver. So I had to take it to a lawn mower place. They installed a new rope, and away we went again for a few months.

When it started with a few pulls, happiness. Economical, ran the tools to fix the boat, and on the boat it ran the TV, charged the batteries when the solar panels couldn't cope with overcast skies.

But often--and I mean often---you could tug on that starter rope until your arms dropped before it sprang to life.

Finally, on another trip, nothing. No starting. Checked the plug---no spark. A new plug. No spark.

Sent away to China for a new coil and spark plug lead. This fixed the problem, but only for a while.

Again, after hours of arm-wrenching pulls, it gave up again. No spark.

This time, the dismantle involved not just removal of side covers, but the engine itself, and the inverter. Draining the oil out and checking the low-oil shutoff switch. It worked. The spark trigger. Seemed OK. Traced every wire for continuity. OK. Stripped the carburettor, cleaned it thoroughly.

After days of diagnosing I guessed it was the spark control module, so sent away to China for a new one. The module was probably the guilty party in the first place. The new coil only temporarily appeared to fix the problem while the module's intermittent ill temperament behaved itself.

Instant fix.

Sometime later, another thorn in the bed of roses. The rope snapped again--from all that pulling. I became quite adept at dismantling and assembly. And worked out a neat way of winding the recoil spring inside its holder with ease. While on the subject, the bent inner end of the spring, what latches onto a stationary post while it recoils...broke. Several times. You can't just take some pliers and bend spring steel into a hook, because it snaps.

So I heated it red hot over the boat LPG burner, and bent it. That worked, for a few months, before it would break again. So far, 3 ropes have also broken and been replaced.

Sometime later....the little blue genny started hunting badly. It didn't sound like a fuel starvation problem. I looked intuitively at the stepper motor. It was bopping around like a cork in a sea. One of its two little ears through which tiny bolts hold it down, had snapped off. They are so flimsy.

So, I got some tinfoil and fashioned an upside down U-shaped bracket to hold it down. It's still doing its job.

That's about the end of the physical problems. And probably the generator, too. You see, it works, runs well....But after measuring its output with a kill-a-watt type device recently, it read 228V AC. Pretty good compared to the household supply which read 254 V AC.

More worrying was the cycles. No reading. Occasionally from 0hz, 50hz flashed up for under a second, then back to 0. Yet tools run well. An electric clock, however, sped up so that a minute ticked by in about 3 seconds.

I tried a multimeter, and it's showing something like 150hz. Not good.

This is probably a fault of the inverter. But inverters in all these generators are encased in a hard epoxy resin-like substance and there is no tinkering possible. I have not been able to source a new one, and for the likes of Hondas, Yamahas, Kipors, they are around the $400 mark. More than the $300 the entire genny cost.

And that's where the saga ends. For now.

I bought this on Ebay in 2009 mainly to run a few small tools while restoring my boat. The ad boasted that it was based on Yamaha technology, and indeed looked like it at least.

At 14 kg it's light to heave on and off the boat, and produces 1000 watt peak, 900w rated output.

It was rather louder than I expected, more than the Ebay advert led me to believe. The seller agreed to take it back. But then I changed my mind. At least it produced a pure sinewave and was not as smelly as the exhaust from the two-stroke 850 watt modified sinewave job it was replacing.

Weeks later, the litany of problems began. Despite plenty of petrol in the tank, it always cut out at the 1/3 remaining mark. Strange.

Sounds to me, like it's time for a burial at sea

The first of dozens of tear-aparts began. Knowing nothing about these machines, I deduced which gadget was the fuel pump. Luckily it was the repairable kind with bolts---not a one-piece plastic.

After opening it up, noticed gobs of resin-like material clogging the various pulse pump ports. What were they? And why were they there? Poor Chinese quality control, that's what and why. I cleaned out the gunk, and that solved the problem. Genny would now run happily up to 6 hours on the 2+ litre tank.

Sometime later, the bout of happiness ended. It hunted badly and then shut down. After much working in the darkness of my ignorance of inverter-generators, I noticed the stepper motor which automatically matches engine speed to load, was bouncing about. Quality control again. The factory assembler hadn't tightened its two small securing bolts.

Sometime later, after running pretty well for weeks, I pulled the recoil starter rope, and it broke. One end disappeared inside the nether regions faster than a startled rabbit down a burrow.

Off came the side two-piece cases. But when I went to remove the three bolts by which the starter housing was attached to the plastic engine cover...they just turned and turned. The nuts turned with the bolts. And they were inaccessible inside the plastic cover. That cover had to come off, so more dismantling.

I held on to the nuts while unbolting. Then, having freed the recoil starter, I put adhesive on to the nuts to stop them free-turning in future.

Back to the recoiler. The centre bolt holding the bobbin with spring and rope would not unscrew, under any amount of force with my Phillips head screwdriver. So I had to take it to a lawn mower place. They installed a new rope, and away we went again for a few months.

When it started with a few pulls, happiness. Economical, ran the tools to fix the boat, and on the boat it ran the TV, charged the batteries when the solar panels couldn't cope with overcast skies.

But often--and I mean often---you could tug on that starter rope until your arms dropped before it sprang to life.

Finally, on another trip, nothing. No starting. Checked the plug---no spark. A new plug. No spark.

Sent away to China for a new coil and spark plug lead. This fixed the problem, but only for a while.

Again, after hours of arm-wrenching pulls, it gave up again. No spark.

This time, the dismantle involved not just removal of side covers, but the engine itself, and the inverter. Draining the oil out and checking the low-oil shutoff switch. It worked. The spark trigger. Seemed OK. Traced every wire for continuity. OK. Stripped the carburettor, cleaned it thoroughly.

After days of diagnosing I guessed it was the spark control module, so sent away to China for a new one. The module was probably the guilty party in the first place. The new coil only temporarily appeared to fix the problem while the module's intermittent ill temperament behaved itself.

Instant fix.

Sometime later, another thorn in the bed of roses. The rope snapped again--from all that pulling. I became quite adept at dismantling and assembly. And worked out a neat way of winding the recoil spring inside its holder with ease. While on the subject, the bent inner end of the spring, what latches onto a stationary post while it recoils...broke. Several times. You can't just take some pliers and bend spring steel into a hook, because it snaps.

So I heated it red hot over the boat LPG burner, and bent it. That worked, for a few months, before it would break again. So far, 3 ropes have also broken and been replaced.

Sometime later....the little blue genny started hunting badly. It didn't sound like a fuel starvation problem. I looked intuitively at the stepper motor. It was bopping around like a cork in a sea. One of its two little ears through which tiny bolts hold it down, had snapped off. They are so flimsy.

So, I got some tinfoil and fashioned an upside down U-shaped bracket to hold it down. It's still doing its job.

That's about the end of the physical problems. And probably the generator, too. You see, it works, runs well....But after measuring its output with a kill-a-watt type device recently, it read 228V AC. Pretty good compared to the household supply which read 254 V AC.

More worrying was the cycles. No reading. Occasionally from 0hz, 50hz flashed up for under a second, then back to 0. Yet tools run well. An electric clock, however, sped up so that a minute ticked by in about 3 seconds.

I tried a multimeter, and it's showing something like 150hz. Not good.

This is probably a fault of the inverter. But inverters in all these generators are encased in a hard epoxy resin-like substance and there is no tinkering possible. I have not been able to source a new one, and for the likes of Hondas, Yamahas, Kipors, they are around the $400 mark. More than the $300 the entire genny cost.

And that's where the saga ends. For now.

creationracing said:

Good write up, and top notch determination. I'd have skipped it by now!

Don't fret about the multimeter readings, your meter is probably measuring the waveform harmonics, as has been mentioned earlier in this thread. If you can blag a shot of a scope then that's how to verify your frequency properly.

What he said; an oscilloscope is necessary to get a good idea of what frequency and waveform you're getting.Don't fret about the multimeter readings, your meter is probably measuring the waveform harmonics, as has been mentioned earlier in this thread. If you can blag a shot of a scope then that's how to verify your frequency properly.

Yes, an oscilloscope would provide a definitive answer. Problem is I cannot access one, and an RMS Fluke multimeter for AC voltage costs more than the generator is worth. I suppose I could plug in the electric clock again and count precisely how many second it takes for a minute to tick by, and convert it to actual Hz versus 50 Hz clock cycles.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff