Anyone read my cylinder head ?

Discussion

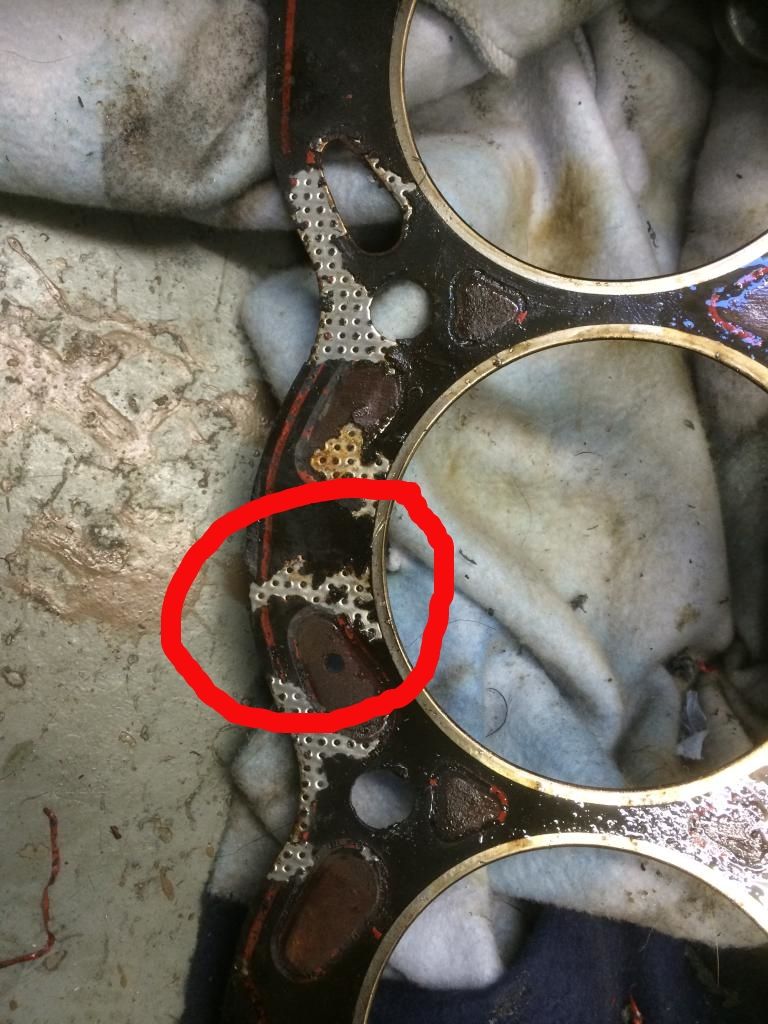

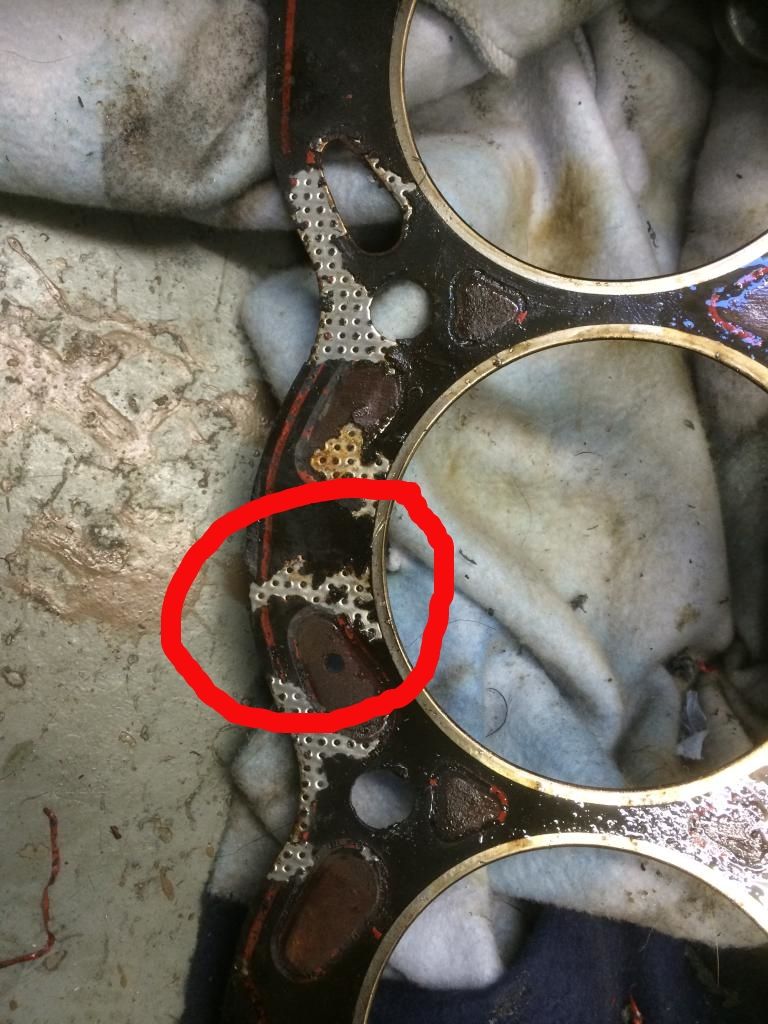

Found a leak literally coming out of the head at the weekend and pulled it apart but can't see any det or deformation of the fire ring . Cleaned the head and marked roughly where the weep was . The marks around the fire ring look a bit darker but I'm stumped as it's on studs and the head was faced .

It's a Saab 234 and knock control is pretty good on the trionic system . The only change was fitting enem 268 cams but afr was still good .

It's been weeping for a little while but not enough to stain the block lower down where it's easier to see

Had plenty of failures on stretch bolts but usually obvious 50 p shaped gaskets , this one looks perfect ??

It's a Saab 234 and knock control is pretty good on the trionic system . The only change was fitting enem 268 cams but afr was still good .

It's been weeping for a little while but not enough to stain the block lower down where it's easier to see

Had plenty of failures on stretch bolts but usually obvious 50 p shaped gaskets , this one looks perfect ??

Hmmm, not sure what you're after there, so your head was leaking outwardly in front of your eyes and you want us to tell you how, why and where?

Is there a prize?

Do we get a set amount of questions?

I'll have first go, was it here:

?

Have you pressure tested the head?

Do any of the studs on the outside go through into the water passages?

Was it leaking hot, cold or both?

Is there a prize?

Do we get a set amount of questions?

I'll have first go, was it here:

?

Have you pressure tested the head?

Do any of the studs on the outside go through into the water passages?

Was it leaking hot, cold or both?

The dull grey patina on parts of the fire ring area of the head indicate where the gasket has been leaking combustion gasses, there will be a degree of annealing on that area of the head so I would have the head hardness tested. I would also ensure that the head is completely flat.

The rest of the gasket won't hold up to well once it is subjected to those temperatures and pressures, hence the breach.

Dave

The rest of the gasket won't hold up to well once it is subjected to those temperatures and pressures, hence the breach.

Dave

Edited by DVandrews on Monday 7th July 21:15

You win and your prize is not having to waste any more of your valuable time on this thread , enjoy !

Thanks for that Dave , the above comment wasn't aimed at you . I thought the dull marks on the inlet side were odd il get the head checked

Thanks for that Dave , the above comment wasn't aimed at you . I thought the dull marks on the inlet side were odd il get the head checked

Edited by mighty kitten on Monday 7th July 21:39

Before I put any head back on an iron block I go over the block face with an oilstone (big old 8" x 2" chisel sharpening stone) lubricated with paraffin, light oil or WD40. This immediately shows up any high or low spots and gives a nice finish for gripping gaskets properly as well as removing any traces of gasket or sealant that might have been missed.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff