Hard to get parts

Discussion

Throttle cable - from the house of Bodgit.

If you're really stuck, it's amazing what you can lash together from a length of bicycle brake cable - it's almost exactly the same as most of the classic throttle cables I've seen. There are also 'solderless nipples' (oo-err missus) which are available in different sizes, and at a pinch, these will get you a working pedal....in fact Lucas used this nipple design on a lot of their heater units, with a simple screw tightener on the cable.

I've actually done this on a Scimitar, and used a nipple to repair a broken Triumph cable.

So go have a look in your local bike shop !!

If you're really stuck, it's amazing what you can lash together from a length of bicycle brake cable - it's almost exactly the same as most of the classic throttle cables I've seen. There are also 'solderless nipples' (oo-err missus) which are available in different sizes, and at a pinch, these will get you a working pedal....in fact Lucas used this nipple design on a lot of their heater units, with a simple screw tightener on the cable.

I've actually done this on a Scimitar, and used a nipple to repair a broken Triumph cable.

So go have a look in your local bike shop !!

Hi Andy...Thing is with the V8 throttle cable it has a shackle at the throttle body end..The other can be as you say but the shackle needs to be soldered on..

Here is one for the Chimaera/Griff but it is way too long...I thought about getting one and having it modified to fit..

http://www.google.co.uk/url?sa=t&rct=j&q=&...

But it will cost that agin so works out way too expensive..Although it seems there might be no other choice....

Here is one for the Chimaera/Griff but it is way too long...I thought about getting one and having it modified to fit..

http://www.google.co.uk/url?sa=t&rct=j&q=&...

But it will cost that agin so works out way too expensive..Although it seems there might be no other choice....

Shurely if you are starting from a busted throttle cable you can detach the old shackle, drill out the old cable, and solder the new cable into place. Don't forget to use plenty of plumbers flux on it, or else it will be very tricky getting a good bond.

Now.... where did I put that big box of brand new lattice wheel centres I found at the back of the garage.... ;^)

Now.... where did I put that big box of brand new lattice wheel centres I found at the back of the garage.... ;^)

adam quantrill said:

Shurely if you are starting from a busted throttle cable you can detach the old shackle, drill out the old cable, and solder the new cable into place. Don't forget to use plenty of plumbers flux on it, or else it will be very tricky getting a good bond.

mmm...I might just get myself a cable crimping kit and fittings and modify some that are available for the Chim/Griff..So who wants one for £80 + Postage...Cheap at that price...

I also have a lead on a big box of chocolate blocs from 1980 for that originality touch..Only a fiver each.....Bargain!

mrzigazaga said:

Hi Andy...Thing is with the V8 throttle cable it has a shackle at the throttle body end..The other can be as you say but the shackle needs to be soldered on..

Here is one for the Chimaera/Griff but it is way too long...I thought about getting one and having it modified to fit..

Hmm... looking at that, I see what you mean, but I reckon you could still drill out the old cable and then push it through and use a small nipple at the back - I guess there might not be enough room...Here is one for the Chimaera/Griff but it is way too long...I thought about getting one and having it modified to fit..

BUT - I've seen lots of those shackle types on old carb linkages etc, so I bet there's still a cheap bodge that's functional !!

RCK974X said:

Hmm... looking at that, I see what you mean, but I reckon you could still drill out the old cable and then push it through and use a small nipple at the back - I guess there might not be enough room...

BUT - I've seen lots of those shackle types on old carb linkages etc, so I bet there's still a cheap bodge that's functional !!

BODGE!...BUT - I've seen lots of those shackle types on old carb linkages etc, so I bet there's still a cheap bodge that's functional !!

Sorry mate but that word is forbidden near my Wedge...I don't care how good of a one it is, One thing i have NEVER done and will NEVER do is BODGE ANYTHING on my Wedge....However there are of course alternative solutions but i will always try to replace like for like....

Sorry mate but that word is forbidden near my Wedge...I don't care how good of a one it is, One thing i have NEVER done and will NEVER do is BODGE ANYTHING on my Wedge....However there are of course alternative solutions but i will always try to replace like for like....

Sireatalot said:

ok. let me have a play and I'll see what I can come up with...

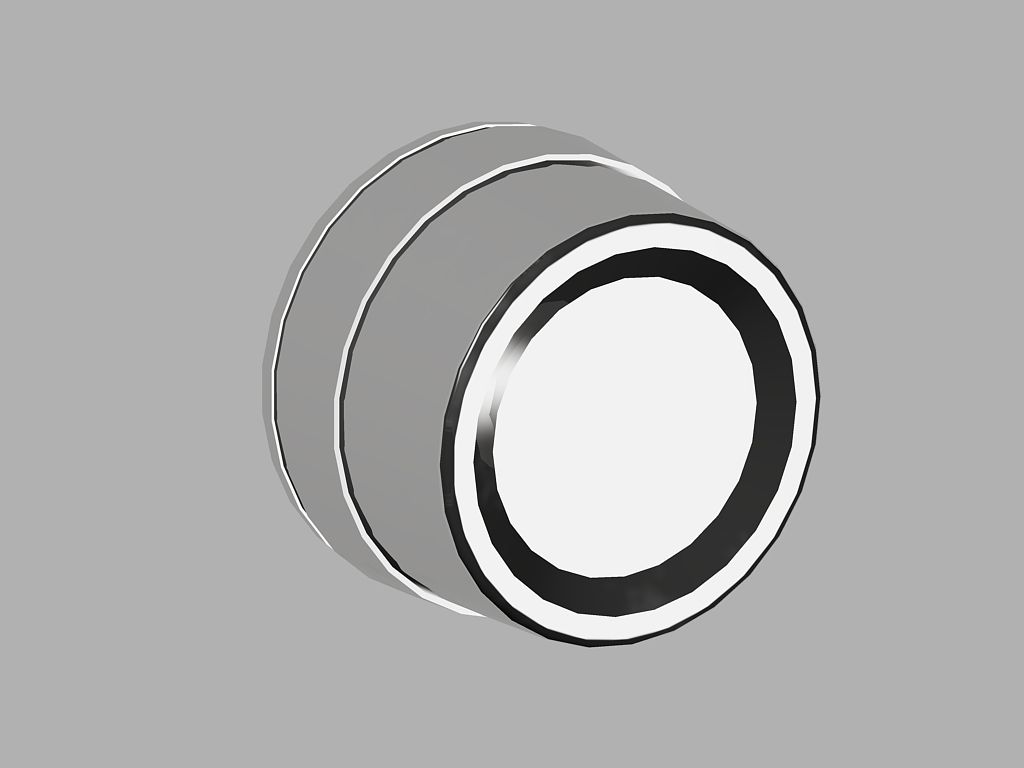

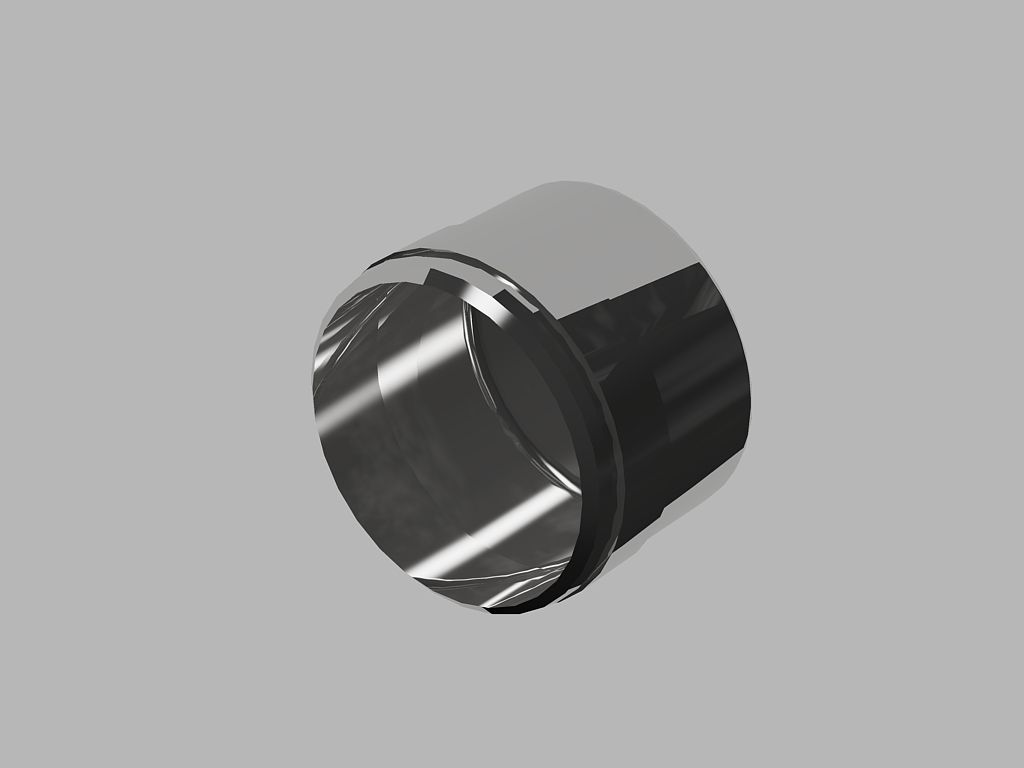

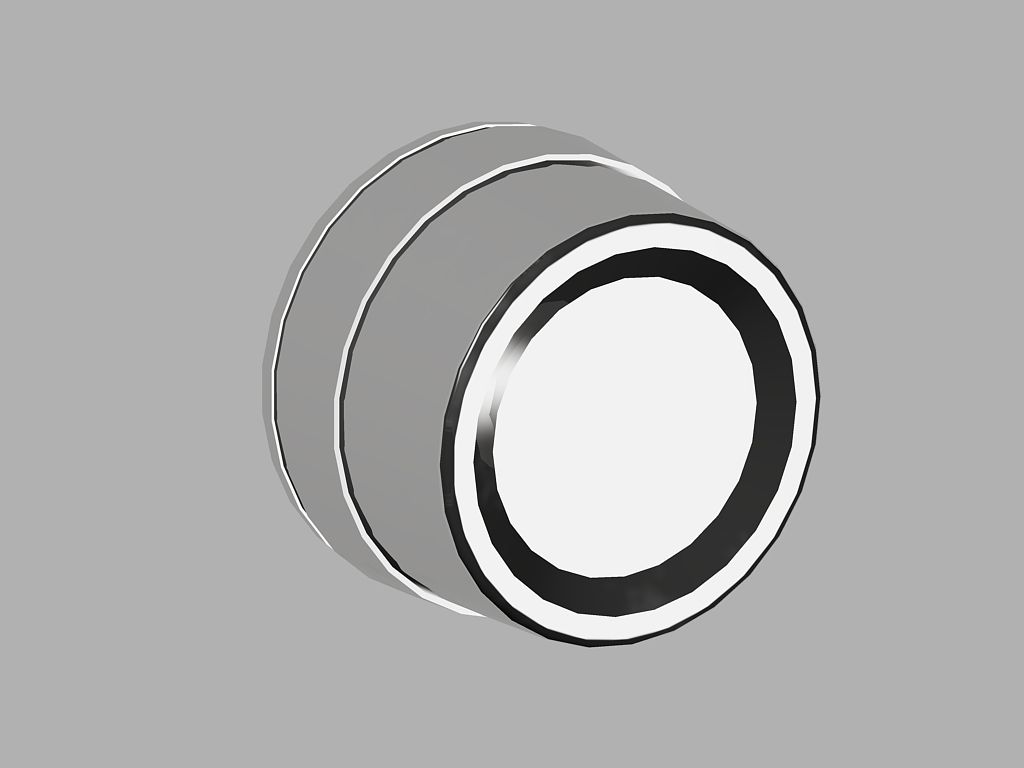

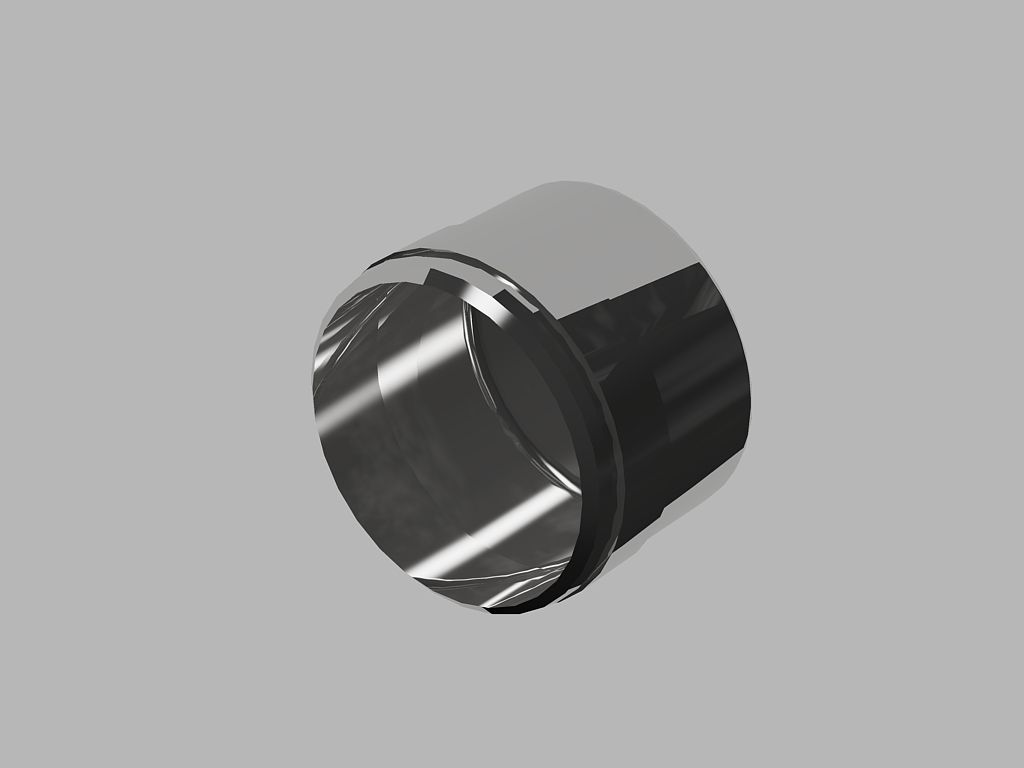

Cool. had a little play last night and I've come up with something...What do you all think.. this model was created from one of my 14" 280i centre caps..

I was having trouble modelling the 5 flanges that 'grip' the wheel but after a bit more tweaking, i'm sure I'll have mastered it.

Hi Dom...Looks good mate...Can this be fed straight into a 3D printer as a file?....Be interesting to see....It would be great if amongst us we can get some if not all of the hens teeth parts re-manufactured/Custom made at a reasonable cost..The future of the Wedge is in our hands...Cool...Ziga

Bobby Shaftoe said:

I made a mould and produced some repros (in plastic) of the cap for the 15" OZ's for a few people a year back or so. I could potentially do the same for the 14" if there is a demand. I don't know what you'd do regarding the chrome finish as pretty much every chrome spray paint is utter crap, Chrome vehicle wrap worked well on the 15" but they're pretty flat shape wise.

Could you then make a two-part mould for the domed wheel centres?...I was thinking maybe cold metal casting in alloy powder...The finish can be buffed and polished although its not as straightforward as buffing real metal..You have to be careful and only use the edge of a polishing wheel not the flat surface.Chromium plating might be better but a tad more expensive..Around £20-30 each..Could be cheaper with a job lot i should imagine...I have a good contact for that...Ziga

Sireatalot said:

Cool. had a little play last night and I've come up with something...

What do you all think.. this model was created from one of my 14" 280i centre caps..

I was having trouble modelling the 5 flanges that 'grip' the wheel but after a bit more tweaking, i'm sure I'll have mastered it.

Dom, model looks fantastic - fingers crossed it works okay on a 3D printer. What do you all think.. this model was created from one of my 14" 280i centre caps..

I was having trouble modelling the 5 flanges that 'grip' the wheel but after a bit more tweaking, i'm sure I'll have mastered it.

Hi guys.

Slight delay in sending model through, needed to redo as I found out previous model with posted pics wasnt solid .. am still having issues modelling those 5 flanges so this test will be a proof of concept. Will keep on playing with it until complete.

.. am still having issues modelling those 5 flanges so this test will be a proof of concept. Will keep on playing with it until complete.

Hope ok.. looking forward to see what happens however..

Is there anything else that could be printed ?

Dom.

Slight delay in sending model through, needed to redo as I found out previous model with posted pics wasnt solid

.. am still having issues modelling those 5 flanges so this test will be a proof of concept. Will keep on playing with it until complete.

.. am still having issues modelling those 5 flanges so this test will be a proof of concept. Will keep on playing with it until complete.Hope ok.. looking forward to see what happens however..

Is there anything else that could be printed ?

Dom.

I could machine the roof lugs out of Aluminium and anodise them if you want, although I'd also be interested to see how they come out of the 3d printer. "Additive Manufacture" as the corporates call it is really catching on. Powder metallurgy (another buzzword) conrods have been about for years. All has its origins in sintering.

The main tricky bit with the roof lugs is probably getting the screws out cleanly? Mine were a bit crumbly...

The main tricky bit with the roof lugs is probably getting the screws out cleanly? Mine were a bit crumbly...

Gassing Station | Wedges | Top of Page | What's New | My Stuff

......

......