Rover P4 - Stored in garage for over 20 years.

Discussion

Evening all,

First post I think, I signed up years ago but pretty certain I never posted before. So, Hi!

I'm in need of some technical knowledge so hope this is the correct place to ask?

To cut a long story short I've been asked to help a friend get his late grandfathers Rover P4 80 back on the road, it's been in storage since at least 1980, possibly longer.

I'm a bikes guy myself, I don't even have a car licence, but, I'm handy with a set of spanners and I've got a decent chunk of knowledge I've picked up over the years working on two wheelers, so I agreed to help, I figured an engine is an engine, brakes are brakes etc... and those bits that are only relevant to cars I'll learn as I go.

We've come across two major issues to start with.

1) The car wont move! The tyres are like upside down anvils and the brakes are seized solid. We've very limited access around the car but have hatched a plan which in essence involved changing the front tyres and sticking the rear end on skates to allow us to roll the car out of the garage. From there we can stick some round tyres on the back and should hopefully have something we can move around the yard a bit to allow better access. We've made a slight start on this by getting the front up on axle stands and removing the wheels and callipers.

2) The engine wont budge with the crank handle. This is something I've come across with bikes and so have left it with diesel down the bores to try and release any seized rings. Failing that I'm into slightly newer territory. I've never worked on a pushrod engine, and never worked on an engine where the barrels don't come away from the crank cases. I'm told it is possible to remove a car's sump and gain access to the bottom of the con rods? I've had the sump off of an engine before but being a bike there was a gearbox in the way of access to the crank. Is removing the sump the best next step? What else might be causing the seizing? Any other advice for a n00b to car engines?

Thanks for reading and sorry for the essay!

A couple of pictures for your perusal, I didn't take many so don't get too excited:

First post I think, I signed up years ago but pretty certain I never posted before. So, Hi!

I'm in need of some technical knowledge so hope this is the correct place to ask?

To cut a long story short I've been asked to help a friend get his late grandfathers Rover P4 80 back on the road, it's been in storage since at least 1980, possibly longer.

I'm a bikes guy myself, I don't even have a car licence, but, I'm handy with a set of spanners and I've got a decent chunk of knowledge I've picked up over the years working on two wheelers, so I agreed to help, I figured an engine is an engine, brakes are brakes etc... and those bits that are only relevant to cars I'll learn as I go.

We've come across two major issues to start with.

1) The car wont move! The tyres are like upside down anvils and the brakes are seized solid. We've very limited access around the car but have hatched a plan which in essence involved changing the front tyres and sticking the rear end on skates to allow us to roll the car out of the garage. From there we can stick some round tyres on the back and should hopefully have something we can move around the yard a bit to allow better access. We've made a slight start on this by getting the front up on axle stands and removing the wheels and callipers.

2) The engine wont budge with the crank handle. This is something I've come across with bikes and so have left it with diesel down the bores to try and release any seized rings. Failing that I'm into slightly newer territory. I've never worked on a pushrod engine, and never worked on an engine where the barrels don't come away from the crank cases. I'm told it is possible to remove a car's sump and gain access to the bottom of the con rods? I've had the sump off of an engine before but being a bike there was a gearbox in the way of access to the crank. Is removing the sump the best next step? What else might be causing the seizing? Any other advice for a n00b to car engines?

Thanks for reading and sorry for the essay!

A couple of pictures for your perusal, I didn't take many so don't get too excited:

conan said:

2) The engine wont budge with the crank handle. This is something I've come across with bikes and so have left it with diesel down the bores to try and release any seized rings. Failing that I'm into slightly newer territory. I've never worked on a pushrod engine, and never worked on an engine where the barrels don't come away from the crank cases. I'm told it is possible to remove a car's sump and gain access to the bottom of the con rods? I've had the sump off of an engine before but being a bike there was a gearbox in the way of access to the crank. Is removing the sump the best next step? What else might be causing the seizing? Any other advice for a n00b to car engines?

I'm sure you've already checked this, but make sure the car isn't in gear. If the brakes are seized on, you'll never get it to turn over.Diesel down the bores is a good shout though. But if that won't unlock it, i doubt anything will so removing the sump is going to be pointless.

Lovely.

Yes if the brakes are seized then its worth using skates to move the car around. Just remember its still a heavy car, so moving it will be hard. The servo can stick, forcing the brakes on. Might be worth disconnecting this. Air in tyres is also useful!! Try putting air in first and see if they will hold air. I wouldn't drive on tyres so old, but they will be ok to move around.

Engine could be many things. Yes is it in gear? And obviously leave the plugs out when turning over, to get it free. However the crank start wont give you much purchase. It would be worth getting a big socket onto the end of the crank pulley, then use a big bar up through the engine bay (think between engine and radiator) and try to turn it that way.

Failing that, the engine is the same as many land rovers, so a complete engine swap is very possible with cheap parts.

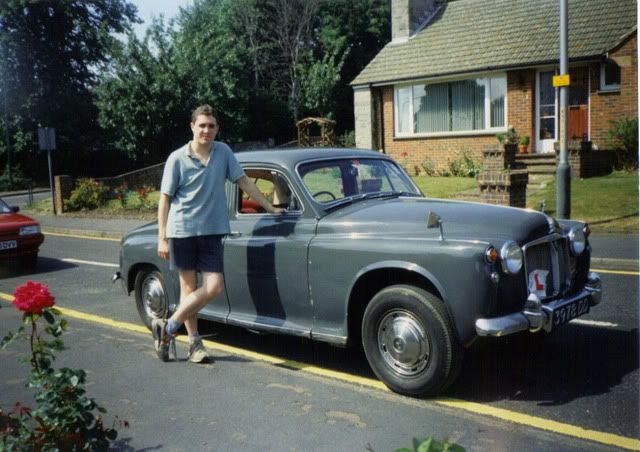

Finally, the 80 was my first car. Here is me and it in 1995.

Yes if the brakes are seized then its worth using skates to move the car around. Just remember its still a heavy car, so moving it will be hard. The servo can stick, forcing the brakes on. Might be worth disconnecting this. Air in tyres is also useful!! Try putting air in first and see if they will hold air. I wouldn't drive on tyres so old, but they will be ok to move around.

Engine could be many things. Yes is it in gear? And obviously leave the plugs out when turning over, to get it free. However the crank start wont give you much purchase. It would be worth getting a big socket onto the end of the crank pulley, then use a big bar up through the engine bay (think between engine and radiator) and try to turn it that way.

Failing that, the engine is the same as many land rovers, so a complete engine swap is very possible with cheap parts.

Finally, the 80 was my first car. Here is me and it in 1995.

The storage must have been nice and dry - the suspension and brake disk show a pleasant lack of rust.

Regarding disassembly :

A car sump is usually just pressed tin, sometimes alloy. Remove it, and you are looking at the crank and big-end bearings.

If the pistons are siezed, you will probably have to undo the main caps and big ends, then remove the crank so you can try to knock the pistons out from the top with a hammer and block of wood.

Good luck : the diesel soak may do the trick.

Regarding disassembly :

A car sump is usually just pressed tin, sometimes alloy. Remove it, and you are looking at the crank and big-end bearings.

If the pistons are siezed, you will probably have to undo the main caps and big ends, then remove the crank so you can try to knock the pistons out from the top with a hammer and block of wood.

Good luck : the diesel soak may do the trick.

Tyres are long beyond holding air! We did have a good go with a compressor but to be honest even if they'd seated I don't think they'd be airtight.

Sparks were taken out but still no luck with turning the engine over. I've never used a crank handle before so I'm unsure how easy it should be to turn over or how much force I can risk putting through the drive?

When we can get the car out of the garage I reckon we'll pop the head off and see what condition everything is in.

The sump thing, from what I gathered I could remove the conrod caps and tap the bottom of the pistons using a wooden drift to remove the pistons from the block if I can't free them with the diesel and crank handle. Would this not work?

Sparks were taken out but still no luck with turning the engine over. I've never used a crank handle before so I'm unsure how easy it should be to turn over or how much force I can risk putting through the drive?

When we can get the car out of the garage I reckon we'll pop the head off and see what condition everything is in.

The sump thing, from what I gathered I could remove the conrod caps and tap the bottom of the pistons using a wooden drift to remove the pistons from the block if I can't free them with the diesel and crank handle. Would this not work?

You may be able to just undo the conrod bearings as you say, it just depends on how much access there is with the crank still in. It's worth a try without removing the crank, but removing it may make life easier.

I have only glanced at that age rover engines, so cannot be more specific.

I have only glanced at that age rover engines, so cannot be more specific.

AW111 said:

The storage must have been nice and dry - the suspension and brake disk show a pleasant lack of rust.

Sorry, managed to completely miss this post.Will the rust on the disks come off alright under normal usage or will it wreck the pads? I could remove them and skim them at work if it's necessary. All of my bikes have had stainless disks so I've not had to deal with much more than light surface rust at the most in the past.

cdug said:

Sorry, managed to completely miss this post.

Will the rust on the disks come off alright under normal usage or will it wreck the pads? I could remove them and skim them at work if it's necessary. All of my bikes have had stainless disks so I've not had to deal with much more than light surface rust at the most in the past.

I would wire brush them to remove any loose rust, that should do. I have a boat trailer and the disks often look like that at the end of winter. They seem to clean up ok in use, although I tend to go easy on the brakes when towing.Will the rust on the disks come off alright under normal usage or will it wreck the pads? I could remove them and skim them at work if it's necessary. All of my bikes have had stainless disks so I've not had to deal with much more than light surface rust at the most in the past.

I assume you will have the hubs off and replace the wheel bearings anyway?

What a fantastic project. I'm sure you are aware of this but being a Rover 80 it has the same engine as a Series 2 Land Rover so engine parts are no problem. I'd take the plugs out and pour some diesel down the bores and leave it for a few days. If that doesn't free it off you will need to take the head off to tap the pistons gently with a piece of wood and hammer. They usually free off with diesel though.

I have seen car skates somewhere that can be used under the wheels of an immovable car.

I have seen car skates somewhere that can be used under the wheels of an immovable car.

I'm lucky to have an engineering workshop at my disposal so I've borrowed a pair of 2 tonne skates for the weekend, hopefully there won't be any issues.

On the wheel bearing front, I wasn't really sure how necessary it was? I've given the hubs a good wiggle and there doesn't seem to be any untoward movement, but again I'm used to bike wheels and I'm unsure what needs checking in which directions?

On the wheel bearing front, I wasn't really sure how necessary it was? I've given the hubs a good wiggle and there doesn't seem to be any untoward movement, but again I'm used to bike wheels and I'm unsure what needs checking in which directions?

c_dug said:

I'm lucky to have an engineering workshop at my disposal so I've borrowed a pair of 2 tonne skates for the weekend, hopefully there won't be any issues.

On the wheel bearing front, I wasn't really sure how necessary it was? I've given the hubs a good wiggle and there doesn't seem to be any untoward movement, but again I'm used to bike wheels and I'm unsure what needs checking in which directions?

They are probably ok, but after 20 years sitting I would probably replace them. This is more for the possibility of micro-corrosion than anything. On the wheel bearing front, I wasn't really sure how necessary it was? I've given the hubs a good wiggle and there doesn't seem to be any untoward movement, but again I'm used to bike wheels and I'm unsure what needs checking in which directions?

I assume it's a simple tapered roller set : if so they should be cheap as chips and take about 15 mins a side.

The problem with this attitude, of course, is that there are heaps of quick, cheap jobs in a renovation like yours, and if you do them all the net result is neither cheap nor quick

I check wheel bearing play by taking the weight off the wheel and rocking top to bottom. There should only be a tiny bit of play, if any.

before you strip anything off the engine, its really worth taking the plugs out and pouring some diesel fuel down the bores, leave it for a week or so and top up as required.

then, as suggested above, get a big spanner / socket and bar on the front pulley nut and just start to 'rock' the engine back and forth tiny amounts, this will work the pistons in the bores and should 'shrug' any corrosion off - it will probably only take a little amount of time to free them off.

if it doesn't work, you can then try putting the car in gear and either rocking it back and forth, or very gently tugging it with a tow rope and another car (as its such a big car it might be to heavy to push!)

once its turning, spin it over on the starter with no plugs in it until the oil pressure light goes out / gauge moves and then, all been well, it will start.

old stuff is big and chunky, so is very resilient to been stood, particularly in fairly dry storage - there are no timing belts to snap, or stuff like that!

it it is so jammed that you feel that you need to take the sump off, I would just tug the motor out and strip it in comfort - laying on your back under a filthy black dripping mess is no fun!

then, as suggested above, get a big spanner / socket and bar on the front pulley nut and just start to 'rock' the engine back and forth tiny amounts, this will work the pistons in the bores and should 'shrug' any corrosion off - it will probably only take a little amount of time to free them off.

if it doesn't work, you can then try putting the car in gear and either rocking it back and forth, or very gently tugging it with a tow rope and another car (as its such a big car it might be to heavy to push!)

once its turning, spin it over on the starter with no plugs in it until the oil pressure light goes out / gauge moves and then, all been well, it will start.

old stuff is big and chunky, so is very resilient to been stood, particularly in fairly dry storage - there are no timing belts to snap, or stuff like that!

it it is so jammed that you feel that you need to take the sump off, I would just tug the motor out and strip it in comfort - laying on your back under a filthy black dripping mess is no fun!

A very productive day!

Possibly a little much diesel but the plan is to change the oil before running it anyway so not fussed about it being watered down by the diesel if it passes the rings.

There was no major rust visible on the tops of the pistons, and nothing major in the bores but with a thin feeler gauge you can dislodge rust from down the side of the piston and feel a lumpiness along the line of the ring so I reckon that's what's causing the issue. That said there has been zero movement at all with the crank handle which is slightly concerning. It's going to be left as it is for another week or two before we resort to other methods for freeing the engine.

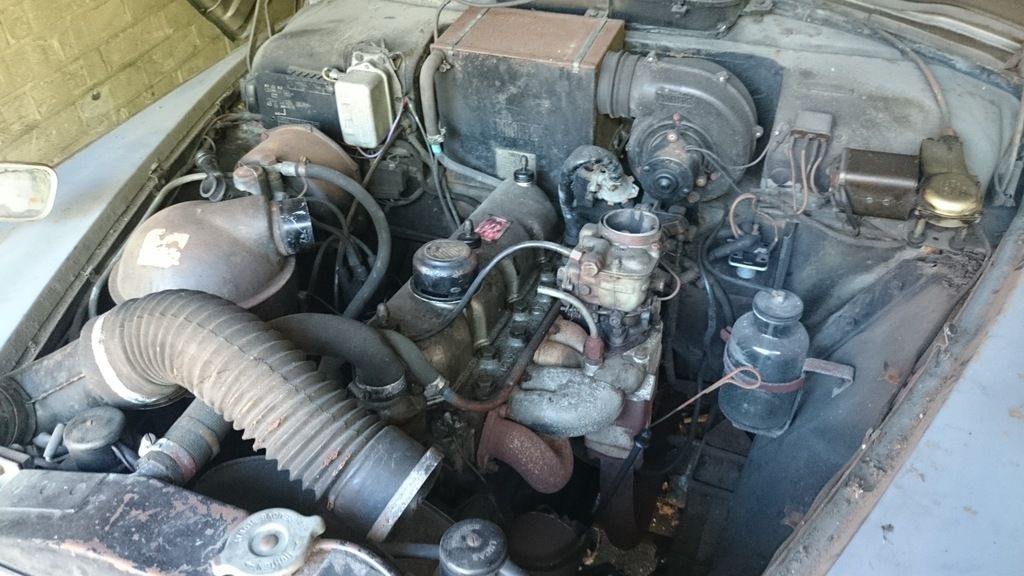

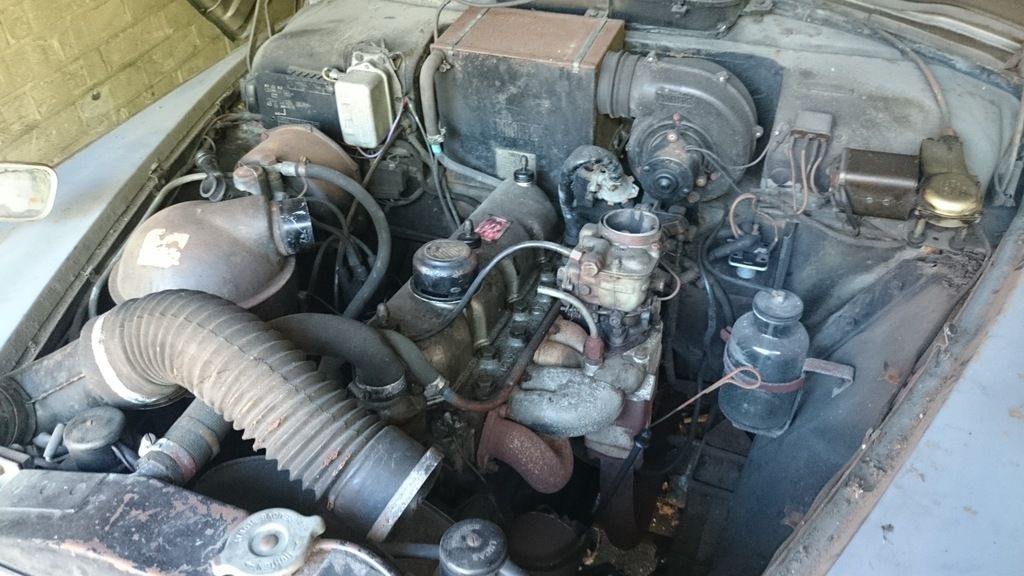

The cooling system appears to be mostly made of rust and corrosion, as can be seen here:

I opened up the radiator tap and about half a litre of rusty water came out, there didn't appear to be much more than that left in the system. Could something like the cooling system pump be gummed up enough to prevent the engine turning? Also given the state of the visible bits I presume I'll need to flush a few gallons of water through the cooling system before this goes on the road?

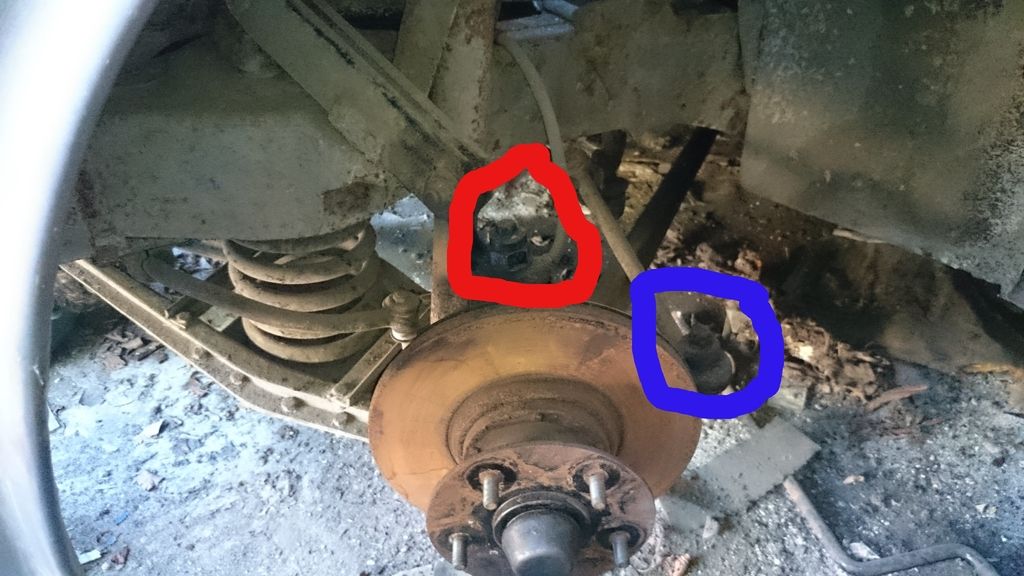

Lastly, with the rear wheel popped off, and also while opening the radiator tap I spotted a fair bit of rust. The exhaust is a gonner, I'm unsure how rusty the leaf springs can be? They're fairly crusty but I reckon it's mostly surface rust, would that pass an MOT? Pictures below:

Possibly a little much diesel but the plan is to change the oil before running it anyway so not fussed about it being watered down by the diesel if it passes the rings.

There was no major rust visible on the tops of the pistons, and nothing major in the bores but with a thin feeler gauge you can dislodge rust from down the side of the piston and feel a lumpiness along the line of the ring so I reckon that's what's causing the issue. That said there has been zero movement at all with the crank handle which is slightly concerning. It's going to be left as it is for another week or two before we resort to other methods for freeing the engine.

The cooling system appears to be mostly made of rust and corrosion, as can be seen here:

I opened up the radiator tap and about half a litre of rusty water came out, there didn't appear to be much more than that left in the system. Could something like the cooling system pump be gummed up enough to prevent the engine turning? Also given the state of the visible bits I presume I'll need to flush a few gallons of water through the cooling system before this goes on the road?

Lastly, with the rear wheel popped off, and also while opening the radiator tap I spotted a fair bit of rust. The exhaust is a gonner, I'm unsure how rusty the leaf springs can be? They're fairly crusty but I reckon it's mostly surface rust, would that pass an MOT? Pictures below:

Theres a lot of crud stuck to these springs but the leaves dont appear to be blown and distorted through corrossion so there probably ok. Going by the state of that thermostat housing its quite possible the water pump is seized solid, it would only take a minute to take the fan belt off and see if engine would turn then.

Gassing Station | Classic Cars and Yesterday's Heroes | Top of Page | What's New | My Stuff