What Engine for 500BHP

Discussion

Its a 3.2L Engine.

I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

Edited by turbonutter on Friday 3rd July 00:24

turbonutter said:

Its a 3.2L Engine.

I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

The V-band housings are usually based on T3 sizing. Given the size of the engine, larger would probably make a lot of sense, although it's bound to spool very fast as it is ?I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

Edited by turbonutter on Friday 3rd July 00:24

stevieturbo said:

turbonutter said:

Its a 3.2L Engine.

I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

The V-band housings are usually based on T3 sizing. Given the size of the engine, larger would probably make a lot of sense, although it's bound to spool very fast as it is ?I assume the Housing is a T3, but I am using a tial one: http://www.tialsport.com/index.php/tial-products/t...

Edited by turbonutter on Friday 3rd July 00:24

Power wise this turbo makes much more that I need in the stratos, 1bar boost will see 500BHP, which was the initial plan.

All the turbo Suppliers in the UK recommended this turbo, but I think I might be able to get more useable power with something smaller?

My last mapping session was at Ric Wood Motorsport & talking to him about the turbo, he suggested going down a frame size with the turbo, to get it to spool earlier, but obviously with a suitable turbine housing - This is based on him getting 1200BHP out of his skyline engine with a pair of 28 turbo's.

Obviously some reasearch is needed here, & I did contact Owen Developments last year when the engine blew up and they told me they could rebuild this turbo with the bigger AR housing (1.02) and a more upto date compressor, which would spool earlier & give more at the top end.... More at the top end I dont need, so Probably a suitably speced GT30 would be better all round.

In a recent thread on PassionFord, there were a lot of graphs with GT30's that were less than inspiring.

I've only used a couple of GT30's, on a 2.0 and 2.5 but both performed very well.

The 2.5 when first built was making close to 2 bar boost by about 3500rpm, that car would have been around 500hp, maybe a little more.

But it was just a standard engine with bolt on mods. 8 years later spool had deteriorated slightly, but otherwise it was still going superbly until a little whoops when racing saw the car expire.

I'd think a GT30 would be on the small side for what you want though. It would still make power, but you'd push it harder to do so.

I've had good luck with Precisions BB turbos again on engines around 2.3 range, a 6266CEA on paper is a lot larger than the GT35, even that on a 2.35 will make 2bar boost around 4800rpm

I'd hope that would be an easy 1000-1500rpm earlier on a 3.2

Obviously with a lower boost target it would hit it sooner again.

It almost looks like yours isnt making full boost until 4k ? with what is a relatively small turbo for a 3.2 engine, certainly as far as turbine size goes anyway.

What is EGBP like vs MAP throughout the rpm range ?

Even graphs I seen some time ago for a 2.7 GTR Skylne with a GT4094 which is huge compared to the GT35...spool with it didnt look much worse than yours.

What is being used for boost control ? What w/g springs ?

I've only used a couple of GT30's, on a 2.0 and 2.5 but both performed very well.

The 2.5 when first built was making close to 2 bar boost by about 3500rpm, that car would have been around 500hp, maybe a little more.

But it was just a standard engine with bolt on mods. 8 years later spool had deteriorated slightly, but otherwise it was still going superbly until a little whoops when racing saw the car expire.

I'd think a GT30 would be on the small side for what you want though. It would still make power, but you'd push it harder to do so.

I've had good luck with Precisions BB turbos again on engines around 2.3 range, a 6266CEA on paper is a lot larger than the GT35, even that on a 2.35 will make 2bar boost around 4800rpm

I'd hope that would be an easy 1000-1500rpm earlier on a 3.2

Obviously with a lower boost target it would hit it sooner again.

It almost looks like yours isnt making full boost until 4k ? with what is a relatively small turbo for a 3.2 engine, certainly as far as turbine size goes anyway.

What is EGBP like vs MAP throughout the rpm range ?

Even graphs I seen some time ago for a 2.7 GTR Skylne with a GT4094 which is huge compared to the GT35...spool with it didnt look much worse than yours.

What is being used for boost control ? What w/g springs ?

See below a couple of graphs from the Data logging, showing MAP & EBP and Engine speed. The one including AAP1 is on the road, the other is on the Rolling road...

In the Power/boost graph above the wastegate spring was 1bar, but this was swapped for a 0.4 bar spring when we did the mapping this time, as I wanted to be able to get less than 1 bar.

Boost Control:

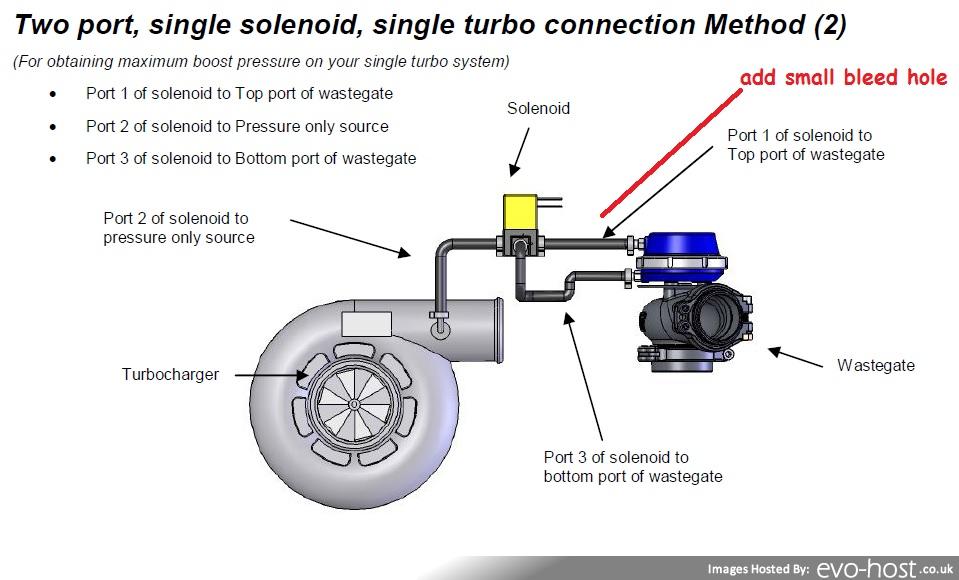

I have a boost signal piped direct to the bottom of the wastegate & the opening is controlled by the ecu driving a solenoid (PWM signal) that puts boost on top of the wastegate diaphragm.

As shown below, only the boost supply I am using is taken from after the intercooler & not from the compressor outlet...

In the Power/boost graph above the wastegate spring was 1bar, but this was swapped for a 0.4 bar spring when we did the mapping this time, as I wanted to be able to get less than 1 bar.

Boost Control:

I have a boost signal piped direct to the bottom of the wastegate & the opening is controlled by the ecu driving a solenoid (PWM signal) that puts boost on top of the wastegate diaphragm.

As shown below, only the boost supply I am using is taken from after the intercooler & not from the compressor outlet...

All looks reasonable, EGBP doesnt look anything to be concerned about. It's getting a little higher than 1:1, but there are many setups out there pushing a lot more with no problems.

One I tested a few years back, 2.3 close to 600hp, precision 6262, was around 58psi EGBP vs 35psi Boost pressure.

It ran like that for a long time. Eventually changed to a 6266CEA, and it made a huge improvement. More power, same spool, EGBP still higher than 1:1, but not much.

All the one's I'm referring to were on T4 flange turbines though, circa 0.68 if I recall right. That's probably still bigger than a T3 at 0.8 plus the turbine wheels themselves larger hence better flowing.

Does the engine have standard cams, or uprated ?

One I tested a few years back, 2.3 close to 600hp, precision 6262, was around 58psi EGBP vs 35psi Boost pressure.

It ran like that for a long time. Eventually changed to a 6266CEA, and it made a huge improvement. More power, same spool, EGBP still higher than 1:1, but not much.

All the one's I'm referring to were on T4 flange turbines though, circa 0.68 if I recall right. That's probably still bigger than a T3 at 0.8 plus the turbine wheels themselves larger hence better flowing.

Does the engine have standard cams, or uprated ?

If I put more boost into the engine, then I would have thought that with a bit more boost, the EGBP would be further above the MAP, at least there is room for improvement - the main thing if I swap turbo's would be to get it to spool earlier....

We did try to get a little more boost, to get the 500BHP, but with the 0.4 bar spring in the wastegate it wasnt possible & with a bigger 0.6 spring, it wasnt possible to get the boost lower than 0.5 bar, which I also wanted - so maybe I need to modify the way the boost control is done. Would having 2 solenoids, one controlling the supply to the top of the waste gate & one to the bottom work to give a larger range of control.

The engine has the stock Alfa 147 GTA cams.

We did try to get a little more boost, to get the 500BHP, but with the 0.4 bar spring in the wastegate it wasnt possible & with a bigger 0.6 spring, it wasnt possible to get the boost lower than 0.5 bar, which I also wanted - so maybe I need to modify the way the boost control is done. Would having 2 solenoids, one controlling the supply to the top of the waste gate & one to the bottom work to give a larger range of control.

The engine has the stock Alfa 147 GTA cams.

The Ultima was 3.7 with forged pistons. My guess is a drop in compression to give the extra boost somewhere to go. She was making 600-ish if the wheels would stay on the rollers. As for cam's didn't the 159 3.2 JTS Q4 had a longer exhaust cam' duration to allow extra torque for the four wheel drive? Longer exhaust would give better low down boost in theory.

Liquid Knight said:

The Ultima was 3.7 with forged pistons. My guess is a drop in compression to give the extra boost somewhere to go. She was making 600-ish if the wheels would stay on the rollers. As for cam's didn't the 159 3.2 JTS Q4 had a longer exhaust cam' duration to allow extra torque for the four wheel drive? Longer exhaust would give better low down boost in theory.

The 3.7 is from a bigger bore, dropping compression does just that, it dosent increace capacity. I had close on 600 with higher boost if I had given it 1.5 bar it would have had 600, but what I am looking for here is more lower down - to get better driveability I dont need more than 500 at the wheels & could hapily sacrifice some at the top for more lower down..Not sure on the cams for the Q4 - I thought all the GTA cams were the same, but I have never checked it out....

turbonutter said:

If I put more boost into the engine, then I would have thought that with a bit more boost, the EGBP would be further above the MAP, at least there is room for improvement - the main thing if I swap turbo's would be to get it to spool earlier....

We did try to get a little more boost, to get the 500BHP, but with the 0.4 bar spring in the wastegate it wasnt possible & with a bigger 0.6 spring, it wasnt possible to get the boost lower than 0.5 bar, which I also wanted - so maybe I need to modify the way the boost control is done. Would having 2 solenoids, one controlling the supply to the top of the waste gate & one to the bottom work to give a larger range of control.

The engine has the stock Alfa 147 GTA cams.

I' struggle to believe that in the current configuration you could not achieve more boost at least somewhere in the rpm range. That just sounds wrong even with the EGBP figures and the soft spring.We did try to get a little more boost, to get the 500BHP, but with the 0.4 bar spring in the wastegate it wasnt possible & with a bigger 0.6 spring, it wasnt possible to get the boost lower than 0.5 bar, which I also wanted - so maybe I need to modify the way the boost control is done. Would having 2 solenoids, one controlling the supply to the top of the waste gate & one to the bottom work to give a larger range of control.

The engine has the stock Alfa 147 GTA cams.

What sort of duty cycles are being applied at present to achieve current boost ?

Whilst you can use two solenoids, you do not need two solenoids. The same can be achieved with one.

If you configure like this, this will give the widest range of boost possible with a single solenoid. It's basically doing the same job as either a 4 port or two solenoids ( almost )

I would suggest you add a small bleed hole somewhere on the top chamber line. It could even be a hole drilled in the chamber itself. A small hole, say 0.6-0.8mm for starters.

With no air vent, boost control can get quite tricky as small amounts of duty can have a large effect on boost. It will ultimately reduce max boost achievable as some pressure is always being bled off the top chamber, but not much.

With the set up as is, it just wouldnt make more boost - I think it did once, but it wouldnt do it again...

This is the boost control as it is in the ECU after mapping - we capped the boost at .9bar, as it hadent been mapped higher - intrestingly if you look at the data logs it was running 1bar on the road....

The suggestion pictured above for how to connect the 3 port solenoid looks good

I have just googled 4 port solenoids & I think that would be my preference over drilling a hole somewhere (mind you the wastegate has some blank plugs , that could be drilled & easily replaced if it didnt work.

I guess having 2 independently controlled solenoids (2 pwm signals) would be the same as a 4 port??

I think the next step is to play with the boost control method and see if that makes any difference.

This is the boost control as it is in the ECU after mapping - we capped the boost at .9bar, as it hadent been mapped higher - intrestingly if you look at the data logs it was running 1bar on the road....

The suggestion pictured above for how to connect the 3 port solenoid looks good

I have just googled 4 port solenoids & I think that would be my preference over drilling a hole somewhere (mind you the wastegate has some blank plugs , that could be drilled & easily replaced if it didnt work.

I guess having 2 independently controlled solenoids (2 pwm signals) would be the same as a 4 port??

I think the next step is to play with the boost control method and see if that makes any difference.

Stick a tee piece in the line and shove a 0.6mm MIG tip up it for the vent, or 0.8mm, or place a small section of hardline in the middle and drill a small hole in it.

Tee and MIG tip might be more practical if you dont have small drill bits.

4 port solenoids operate slower than 3 ports.

And given the duties in that table are still relatively low...and oddly 210kpa lower than 200kpa, it makes little sense that more boost was not achievable.

Without knowing whether closed loop is in operation or what other tables may be present, or any final duties being applied, that base table does look a bit odd. Just depends how the boost control setup is actually using that table. If open loop he's maybe trying to use the 210kpa line as some sort of overboost protection.

Tee and MIG tip might be more practical if you dont have small drill bits.

4 port solenoids operate slower than 3 ports.

And given the duties in that table are still relatively low...and oddly 210kpa lower than 200kpa, it makes little sense that more boost was not achievable.

Without knowing whether closed loop is in operation or what other tables may be present, or any final duties being applied, that base table does look a bit odd. Just depends how the boost control setup is actually using that table. If open loop he's maybe trying to use the 210kpa line as some sort of overboost protection.

stevieturbo said:

Stick a tee piece in the line and shove a 0.6mm MIG tip up it for the vent, or 0.8mm, or place a small section of hardline in the middle and drill a small hole in it.

Tee and MIG tip might be more practical if you dont have small drill bits.

4 port solenoids operate slower than 3 ports.

And given the duties in that table are still relatively low...and oddly 210kpa lower than 200kpa, it makes little sense that more boost was not achievable.

Without knowing whether closed loop is in operation or what other tables may be present, or any final duties being applied, that base table does look a bit odd. Just depends how the boost control setup is actually using that table. If open loop he's maybe trying to use the 210kpa line as some sort of overboost protection.

If 4 ports are slower, then I guess an ultimate solution would be 2 x 3 port valves, but I guess not necessary for the level of boost I need. Small drills are not a problem - its not brealing them that's the problem!Tee and MIG tip might be more practical if you dont have small drill bits.

4 port solenoids operate slower than 3 ports.

And given the duties in that table are still relatively low...and oddly 210kpa lower than 200kpa, it makes little sense that more boost was not achievable.

Without knowing whether closed loop is in operation or what other tables may be present, or any final duties being applied, that base table does look a bit odd. Just depends how the boost control setup is actually using that table. If open loop he's maybe trying to use the 210kpa line as some sort of overboost protection.

We did try the whole table above .5 bar with a high duty cycle to see if higher boost was possible, but on the rollers 0.9 was the max.

The 210 line is probably as you guessed, to try and stop overboost, as the map isnt checked there. Its been tried both open and closed loop neither got any higher boost with the 0.4bar spring.

The only other table I can see is the PWM duty table for the Solenoid

Little bit of a strange way to have tables, but that follows with AEM, everything they do is strange lol

That's just determining valve duty with respect to the boost duty table. ie whether the valve operates in a n/o or n/c type setup without changing the physical plumbing.

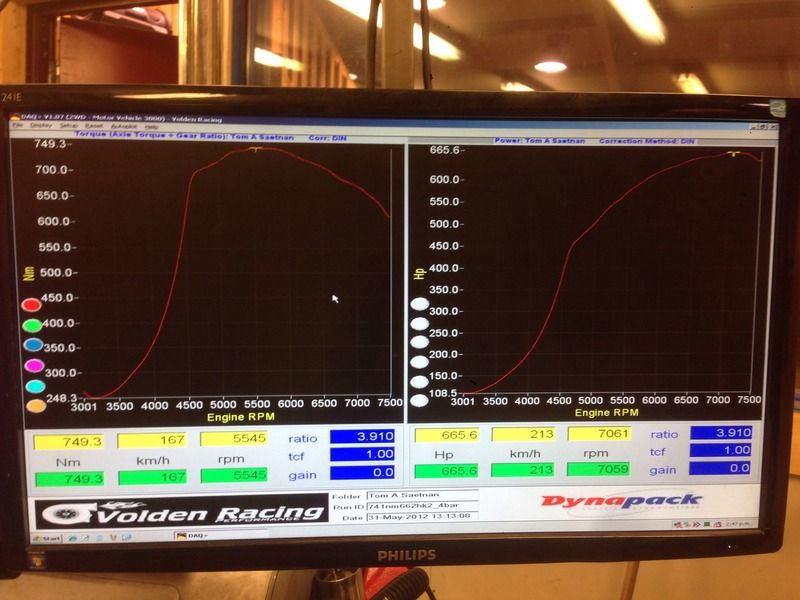

Here's an example that popped up on PF just last night, post #237

GT35 same as yours, except he's using a larger turbine housing and presumably it's only a 2.0 being a Cosworth. It would appear to be making full boost around 4500rpm based on the torque output

Quite a few graphs in there.

http://passionford.com/forum/general-car-related-d...

[QUOTE=SierraCos2wd;6603792]This is what my new engine did with gt3582r t4 1.06ar 2bar boost 750nm 665hk @wheels

[/QUOTE]

[/QUOTE]

That's just determining valve duty with respect to the boost duty table. ie whether the valve operates in a n/o or n/c type setup without changing the physical plumbing.

Here's an example that popped up on PF just last night, post #237

GT35 same as yours, except he's using a larger turbine housing and presumably it's only a 2.0 being a Cosworth. It would appear to be making full boost around 4500rpm based on the torque output

Quite a few graphs in there.

http://passionford.com/forum/general-car-related-d...

[QUOTE=SierraCos2wd;6603792]This is what my new engine did with gt3582r t4 1.06ar 2bar boost 750nm 665hk @wheels

[/QUOTE]

[/QUOTE]stevieturbo said:

In a recent thread on PassionFord, there were a lot of graphs with GT30's that were less than inspiring.

I've only used a couple of GT30's, on a 2.0 and 2.5 but both performed very well.

The 2.5 when first built was making close to 2 bar boost by about 3500rpm, that car would have been around 500hp, maybe a little more.

But it was just a standard engine with bolt on mods. 8 years later spool had deteriorated slightly, but otherwise it was still going superbly until a little whoops when racing saw the car expire.

I'd think a GT30 would be on the small side for what you want though. It would still make power, but you'd push it harder to do so.

I agree, one GT30 is too small for a 3.2 engine, it would cause even more back pressure problems.I've only used a couple of GT30's, on a 2.0 and 2.5 but both performed very well.

The 2.5 when first built was making close to 2 bar boost by about 3500rpm, that car would have been around 500hp, maybe a little more.

But it was just a standard engine with bolt on mods. 8 years later spool had deteriorated slightly, but otherwise it was still going superbly until a little whoops when racing saw the car expire.

I'd think a GT30 would be on the small side for what you want though. It would still make power, but you'd push it harder to do so.

I've read the thread on PF and regarding your post on there, the cynic in me wonders what else the guy doing to make the EFR turbo spool up so well, in order to improve sales he could well be altering the cam timings at the same time. This (and in particular overlap) can change things quite markedly.

Evoluzione said:

I agree, one GT30 is too small for a 3.2 engine, it would cause even more back pressure problems.

I've read the thread on PF and regarding your post on there, the cynic in me wonders what else the guy doing to make the EFR turbo spool up so well, in order to improve sales he could well be altering the cam timings at the same time. This (and in particular overlap) can change things quite markedly.

I dont see anything that suggests the EFR's spool up so well. What I see on some graphs is that their GT30's spool diabolically bad, which makes no sense. So in that respect the EFR's do perform a lot better. But why are their GT30's so bad that they are comparing the EFR's to ?I've read the thread on PF and regarding your post on there, the cynic in me wonders what else the guy doing to make the EFR turbo spool up so well, in order to improve sales he could well be altering the cam timings at the same time. This (and in particular overlap) can change things quite markedly.

Even some of the GT35 graphs appear to spool better than the GT30's

There's a certain big name car out there that did a lot of testing with turbos. Garrett's, EFR's and some Precision, 2-3 sizes of each turbo to meet their power goals. Money was not an object with this vehicle. They ended up with a Precision 6466 on a 2.0 engine and it makes just under 800hp.

I've no doubt the EFR's are very good, but a lot of graphs would almost suggest they're just very good compared to Garrett's, which simply arent as good as they should be.

I'm sure there is no more profit from selling EFR's against any other turbo, so can't see any motive to fudge numbers. Clearly those using them are happy with the performance. I just dont understand why what they're using as comparisons are so bad.

Just had a look at the Comparison between the GT & the EFR on PF...... I also would have to ask wht the GT is so bad at spooling.. the comparison has the EFR streets ahead, but I find it hard to believe that nothing else has changed...

Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

turbonutter said:

Just had a look at the Comparison between the GT & the EFR on PF...... I also would have to ask wht the GT is so bad at spooling.. the comparison has the EFR streets ahead, but I find it hard to believe that nothing else has changed...

Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

A simple test would be to leave the plumbing as is, but simply disconnect the signal to the solenoid from the boost source.Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

ie so there is no boost control at all. Obviously have an ecu cut at say 230kpa so you dont damage anything. I'd be shocked if you dont hit the boost cut, which would indicate you do have more scope for boost on the current plumbing

But using the 3port as I say will give you the widest range possible without actually changing or buying any parts other than re-working some pipes and is how I use it on my own car.

stevieturbo said:

turbonutter said:

Just had a look at the Comparison between the GT & the EFR on PF...... I also would have to ask wht the GT is so bad at spooling.. the comparison has the EFR streets ahead, but I find it hard to believe that nothing else has changed...

Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

A simple test would be to leave the plumbing as is, but simply disconnect the signal to the solenoid from the boost source.Thanks for the input here, re my set up, I think the first thing to do is change my boost control solenoid plumbing, to make sure the wastegate stays shut untill i want it to open, then get some more data logged and take it from there.

ie so there is no boost control at all. Obviously have an ecu cut at say 230kpa so you dont damage anything. I'd be shocked if you dont hit the boost cut, which would indicate you do have more scope for boost on the current plumbing

But using the 3port as I say will give you the widest range possible without actually changing or buying any parts other than re-working some pipes and is how I use it on my own car.

turbonutter said:

If i do that wouldnt i just get the spring pressure boost? I have boost under the diaphragm & the solenoid adds the boost signal to the top to increase boost - no signal to the solenoid = no pressure on top of the waste gate - so spring pressure boost - or have i got something wrong there.....

With no signal going to the gate, you would be relying on EGBP to push against the poppet valve and w/g spring.This will take a lot more EGBP to open this than the base spring pressure suggests.

Normal basic w/g operation is with boost applied to open the gate against the spring pressure, so usually 4psi boost would start to open against your 4psi spring and so on.

Obviously the reality is it is 4psi boost + force of EGBP trying to open the gate, but then once the gate/poppet valve opens the force from EGBP would lessen slightly because the valve is now open and pressure isnt acting against it the same way

Your current setup has boost always applied to lower port blowing it open, and in theory at 100% duty should have this same pressure in the top chamber. So effectively it is 100% reliant on mechanical spring pressure only to fight EGBP.

With a small valve it will take a lot more effort from EGBP to open the valve than say a large valve. Force/area and all that crap.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff