Injector sizes

Discussion

Looking at changing the injectors as part of my cam/intake mods. I already completed MSII install with 72mm plenum and 45mm trumpets. I am currently running the standard lucas green belt D1830 injectors whose duty cycle is well into the 90s during hard acceleration.

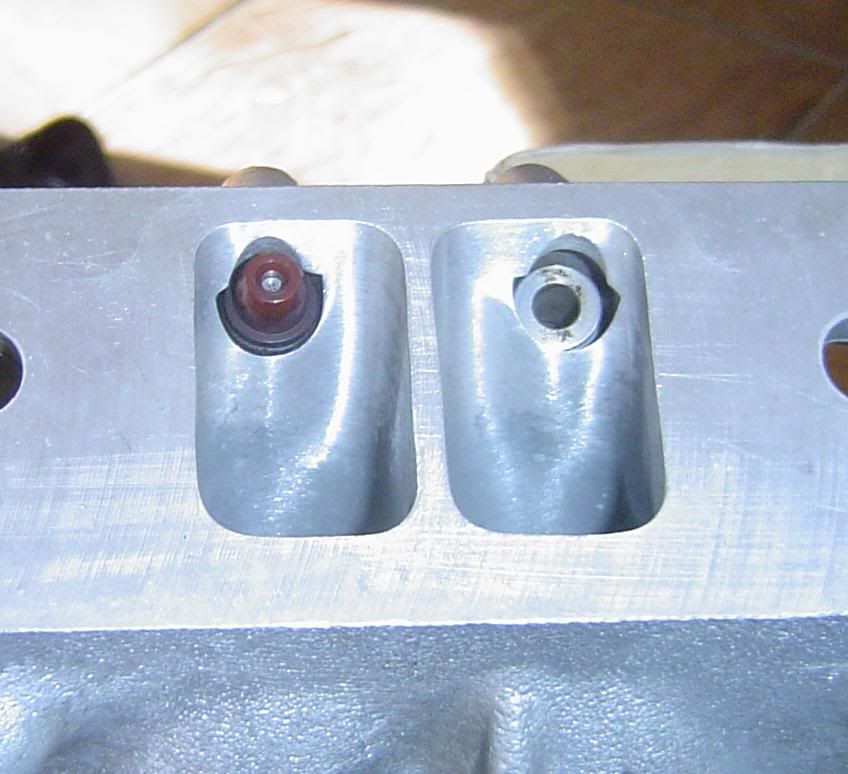

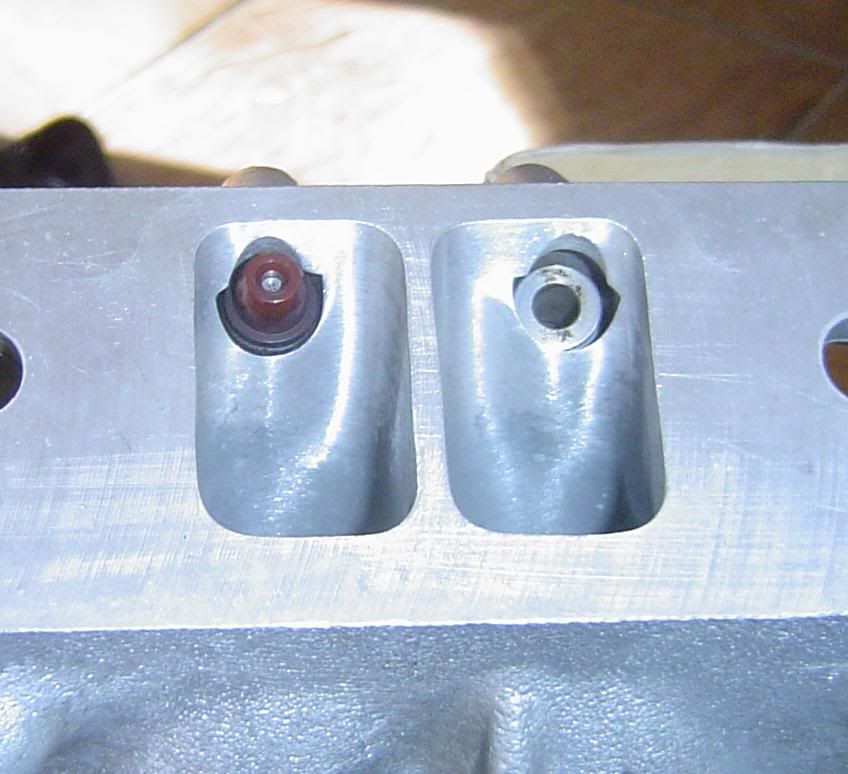

Any tips on which replacement injectors to use is appreciated, I am looking at abt 25lb injectors... however in looking at some candidates, is injector length an issue?? The Lucas injectors (right injector in pic) don't protrude into the air flow and are approx 5mm shorter than the manifold base. Is this an issue if an injector nozzle (left injector in pic)extends into the intake air flow?.

Any tips on which replacement injectors to use is appreciated, I am looking at abt 25lb injectors... however in looking at some candidates, is injector length an issue?? The Lucas injectors (right injector in pic) don't protrude into the air flow and are approx 5mm shorter than the manifold base. Is this an issue if an injector nozzle (left injector in pic)extends into the intake air flow?.

Edited by cinquecento on Monday 8th June 09:26

Most injector installations protrude a little way into the air stream as it's supposed to promote better mixing. I would have said you might lose out very slightly in ultimate airflow but probably not anything you'll notice on the road.

More important to get the right level of flow in there, as an aside I would look at raising the fuel pressure as this tends to promote finer droplets and superior mixing and better combustion.

More important to get the right level of flow in there, as an aside I would look at raising the fuel pressure as this tends to promote finer droplets and superior mixing and better combustion.

The plan was to get injectors that flow approx 22lbs at 2.5 bar..then initially control the Duty cycle with the ECU. Then down the track when cam and inlet manifold are fitted, I can up the psi (if needed) and fine tune the DS again with the ECU.

Currently looking at Bosch 0280150947 injectors...

Currently looking at Bosch 0280150947 injectors...

the griff pump runs at 3 bar, as I just had to change mine for the ajp engine which needs a 5 bar pump, interesting thought on the injectors, Pasco, Spendy and I did some testing at Joo`s last year and found that the bigger red top Bosche injectors gave a significant drop in bhp at the top end when tested against the standard injectors, and thought at the time that this was down to the extra length on the nozzle protruding into the inlet manifold, the standard injectors have given results of up to 350bhp on at least 2 griffs that I know of, as Matt says, just up the pressure on an adjustable regulator.

clive f said:

the griff pump runs at 3 bar, as I just had to change mine for the ajp engine which needs a 5 bar pump, interesting thought on the injectors, Pasco, Spendy and I did some testing at Joo`s last year and found that the bigger red top Bosche injectors gave a significant drop in bhp at the top end when tested against the standard injectors, and thought at the time that this was down to the extra length on the nozzle protruding into the inlet manifold, the standard injectors have given results of up to 350bhp on at least 2 griffs that I know of, as Matt says, just up the pressure on an adjustable regulator.

Sorry to shoot you down Clive, but there are several very significant errors in what you have said. I hope you take this in the same spirit as I would take welding lessons from you, since you are someone who is clearly a master of his craft.Over the years I have done a great deal of research into this matter, in the form of reading and experimentation. I am also privileged to have access to very thorough research on this subject done by major motor manufacturers and component suppliers (e.g. Bosch, Land Rover, etc). Although I cannot pass it on directly, I can at least give you the distilled essence.

The standard RV8 pump is indeed rated at 3.0 Bar, although it is only operated at 2.5 Bar so there is a useful margin available. There are a number of effects of increasing the fuel pressure which must be considered, and the results for the pump and injectors are quite different.

Firstly, increasing the fuel pressure will obviously put more strain on the pump. The flow of fuel through the pump provides it's cooling, and flow drops generally in a non-linear manner with increasing pressure (usually logarithmic).

In general, increasing pressure will improve the atomisation of the injectors for pintle and type II/III designs but not for the Lucas disc type. All fuel injectors are for a specific operating pressure, or pressure range. The effects of increasing the pressure are heavily dependant on the design.

For the Lucas disc design, increasing pressure will increase the flow up to a point. The injector has an upper and lower disc. The lower disc has a hole in the centre (the metering orifice), and the upper disc is lifted by the electro-magnetic solenoid to allow fuel to flow.

It is quite obvious that the higher the pressure, the harder it is to lift the upper disc to allow fuel to flow. This results in a much longer and more unstable opening time for the injector. After 3.3 Bar the fuel flow will actually start to decrease and become more unstable as the electro-magnet struggles to overcome the force of the fuel pressure closing it.

This also requires that the battery voltage compensations in the ECU are adjusted accordingly, since they are dependant on operating pressure.

Additionally the Lucas injector does not produce an atomised spray through the metering orifice. This function is provided by the plastic diffuser underneath, which is supposed to break up the jet into droplets. Quite often there is no atomisation at all.

To show you what really happens I have a couple of pictures for you. Here is a picture of Bosch (left) and Lucas spray patterns side-by-side in the injector cleaning machine at TVR Power:

Now here's another shot done with a faster exposure, using the machine at Shropshire Auto Service. You can clearly see the large droplets in the stream from both the Lucas injectors on the left.

The statement about a power drop with red top injectors couldn't be MORE wrong! You could get to this conclusion if you were not aware of all the factors involved, and consequently only did half the experiment. This would also fly in the face of all the research done by the likes of Bosch and all their clients, not to mention various Formula One teams.

In the simplest terms, fuel droplets burn from the outside in. It follows that the smaller they are the quicker they burn, hence releasing more of the energy contained in the fuel. Ultimately this gives the most efficient use of the fuel, and the cleanest exhaust emissions. There is a minimum size for fuel droplets, but it is not seen outside of Formula One where no engineering effort is spared.

Ever more stringent emissions legislation has driven advances in fuel injector design. Improvements in manufacturing technology have produced some far more effective fuel injectors, with the aim of producing more efficient combustion. Some of the best designs are the Bosch Type II and Type III versions.

Fuel enters the combustion process by two methods for this type of manifold injection system. Firstly there is fuel which is pulled from the manifold walls by the air stream entering the combustion chamber when the inlet valve is open. This fuel is deposited on the manifold walls by the injectors when air is not flowing in the inlet tract. During this time the fuel deposited will evaporate in a warm engine, so the smaller the droplets are the better and faster they evaporate. Some fuel droplets remain in suspension in the air in the inlet tract, and again the smaller they are the better.

During recent testing on standard TVR 5.0 Litre engines, the injectors picked up 8 lb/ft of torque everywhere over a hand picked flow-matched set of brand new Lucas originals. This has been accurately and scientifically tested dozens of times, and is always the case.

Interestingly the improved torque required 2-3 Degrees less ignition advance, denoting improved combustion speed and efficiency. If you simply put in an injector with better atomisation, you will indeed see a drop in power because the ignition timing is now too far advanced for the reasons given above.

When mapping a car and selecting injector sizes, the injectors should run no more than an 80% duty cycle at any point in the map. Obviously the time available for injection decreases with rising RPM. This limit is necessary in order to allow for transient fuelling (sudden throttle opening), and proper response when the engine is cold amongst other factors.

Whilst it is true that the standard Lucas injectors can be operated on motors producing 350BHP, it takes them to 100% opening at pressures well outside the operating envelope. I have asked this before and have never been given an answer - can anyone please tell me what the duty cycle was THEY MEASURED on one of these 350BHP cars? I think not.

A slight protrusion into the inlet air stream is permissible and can help mixture whilst air is flowing in the inlet tract, although injection during this time is undesirable since it can produce a non-homogeneous mixture. However the depth of protrusion can be adjusted, since the legs of the fuel rail are rather bendy!

Mark

At what point in your experience is it better to upgrade injectors? If 350bhp is likely to be 100% duty cycle, what would you consider the sensible upper limit of bhp on standard Lucas injectors?

Is it just a question of 80% duty cycle, or what other factors do you consider when making the decision to upgrade?

At what point in your experience is it better to upgrade injectors? If 350bhp is likely to be 100% duty cycle, what would you consider the sensible upper limit of bhp on standard Lucas injectors?

Is it just a question of 80% duty cycle, or what other factors do you consider when making the decision to upgrade?

Uncle Fester said:

Mark

At what point in your experience is it better to upgrade injectors? If 350bhp is likely to be 100% duty cycle, what would you consider the sensible upper limit of bhp on standard Lucas injectors?

Is it just a question of 80% duty cycle, or what other factors do you consider when making the decision to upgrade?

The moment you upgrade to a 5.3 At what point in your experience is it better to upgrade injectors? If 350bhp is likely to be 100% duty cycle, what would you consider the sensible upper limit of bhp on standard Lucas injectors?

Is it just a question of 80% duty cycle, or what other factors do you consider when making the decision to upgrade?

Uncle Fester said:

Mark - At what point in your experience is it better to upgrade injectors?

If the Bosch injectors give an additional 8 ft lbs extra torque throughout the range then I would have thought it best to just change them? I don't have 350bhp but after a long session with Mark at Austec which included fitting the Bosch injectors we got 300bhp and 325 ft lbs which I was happy with. Also, I still get about 20-22 mpg on fast runs e.g. down to Le Mans which I'm also happy with, I am assuming that a more efficient injector improves fuel economy.Gassing Station | Griffith | Top of Page | What's New | My Stuff

yes do do seem to know a little about this subject Mark

yes do do seem to know a little about this subject Mark