X overthrottle Boddies

Discussion

Hi Matthew,

have been told by a couple of people that the air delaminates from the wall of the induction tube if fitted direct onto the collector box as in Clive's set up. I can't go through the bonnet as in the second picture as regulations don't allow but that would have been favourite I think.

have been told by a couple of people that the air delaminates from the wall of the induction tube if fitted direct onto the collector box as in Clive's set up. I can't go through the bonnet as in the second picture as regulations don't allow but that would have been favourite I think.

roseytvr said:

https://matthewpoxon.files.wordpress.com/2013/07/i...

Yep that's mine with the JE TBs and flat panel filters. The original idea was a twin outlet air box to fit in the nose of the car over the original filter and I have an air box made up that fits. However I found the flat panels work fine even on the track and the car doesn't seem to suffer with hot air being inducted once I'm on the move. I have no holes in the bonnet but I think there's enough fresh air flying around that it's not an issue.

That said I will watch this with interest to see if you come up with any bright ideas I have bought a spare bonnet to hack up for the track but haven't got round to it yet!

I have bought a spare bonnet to hack up for the track but haven't got round to it yet!

I would have thought that under bonnet temps even in a road car would effect the air charge, especially sitting above the manifolds all beit they are coated. I will be taking air from a cold source, that's a must in my book but as I have the free use of rollers I will try both ways to have a look see, I may be talking dribble again. I will post up the results of my set up once it's up and running.Yep that's mine with the JE TBs and flat panel filters. The original idea was a twin outlet air box to fit in the nose of the car over the original filter and I have an air box made up that fits. However I found the flat panels work fine even on the track and the car doesn't seem to suffer with hot air being inducted once I'm on the move. I have no holes in the bonnet but I think there's enough fresh air flying around that it's not an issue.

That said I will watch this with interest to see if you come up with any bright ideas

I have bought a spare bonnet to hack up for the track but haven't got round to it yet!

I have bought a spare bonnet to hack up for the track but haven't got round to it yet!Edited by roseytvr on Monday 30th November 22:00

MPoxon said:

Originally I was thinking early 2016 with an ECU upgrade but just had to pay for the camshaft and clutch to be replaced this month.... probably looking winter 2016 now. The throttle bodies are around 3k and one of Dom's MBE ECUs is 3k fitted so not a cheap endeavour at around 6k.

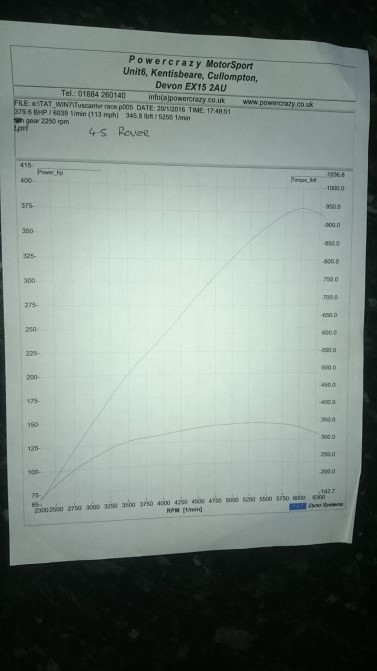

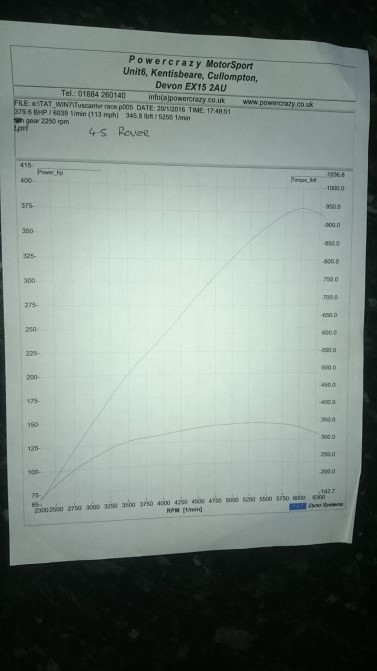

I am going to use Omex 710 ECU as I have used them on all my race cars for years now and can't fault them as a bit of kit or a company. The garage I use to fit them would fit and set up a complete system for a lot less than that 3k you been quoted. The car would have to come to Sunny Devon though for a few days. Still worse places to drink a cold Thatchers Gold or two.Ok , Sorry its taking a little time to get sorted Xmas , new year and life in general have got in the way but I had a dyno run done yesterday to see what we were starting from to see what difference the new build will give us. This engine is a challenge engine 4.5lt, still with dizzy and 48 Quad Delorto Carbs, heavily ported head, old school as it was in 1989. It looks to be spot on and a strong engine. we are building a 4.8lt new build engine to put the cross over throttle bodies on and are just about to blend / match the manifold to the heads before we put the heads on the new engine. It took an age to get crank back from tuffriding. I will update a little later once engine is in the car, saying that hopefully before first race on April 17th fingers crossed.

379.6BHP and 345.8lbft

DSC_0726 by flat chat, on Flickr

DSC_0726 by flat chat, on Flickr

379.6BHP and 345.8lbft

DSC_0726 by flat chat, on Flickr

DSC_0726 by flat chat, on FlickrEdited by 77racing on Friday 31st March 19:21

MPoxon said:

The torque was the main reason for me asking, it has a lovely flat torque band which normally means tame cam but clearly not tame with those figures!

What is it about those challenge engines that allows them to develop so much power and torque? Looks like a really sweet engine that.

Very interested to see how the 4.8 goes. I was thinking of an Eales 5.2 engine with H234 cam and those throttle bodies, I think your challenge engine is pushing out more power though

Could you use the 4.5 Challenge engine on the road or is the drivability and MPG to prohibitive?

Good Morning M,What is it about those challenge engines that allows them to develop so much power and torque? Looks like a really sweet engine that.

Very interested to see how the 4.8 goes. I was thinking of an Eales 5.2 engine with H234 cam and those throttle bodies, I think your challenge engine is pushing out more power though

Could you use the 4.5 Challenge engine on the road or is the drivability and MPG to prohibitive?

A very good question that is not that easy to answer. "The sum of all parts" springs to mind as to how a challenge Rover Tuscan gets to be a quick car, not forgetting a very talented driver to steer it

.As it is the engine you are concerned with I will try not to waffle off subject. Seams like a lot of things TVR, there is a Vail of mysterious mist hanging over the challenge engine. It is just a Rover V8 after all and nothing too complicated about it. Saying that. I'm no engine builder, that's why I take my idea's to a chap down my way who is not very respected on here by a lot of people, but who I think is the most talented engineer I have met. So point one is if you don't have the skill, a very good engine builder (If only to build in reliability) is a must, he or she don't have to be TVR specific, none specific means cheaper labour rates I find.

.As it is the engine you are concerned with I will try not to waffle off subject. Seams like a lot of things TVR, there is a Vail of mysterious mist hanging over the challenge engine. It is just a Rover V8 after all and nothing too complicated about it. Saying that. I'm no engine builder, that's why I take my idea's to a chap down my way who is not very respected on here by a lot of people, but who I think is the most talented engineer I have met. So point one is if you don't have the skill, a very good engine builder (If only to build in reliability) is a must, he or she don't have to be TVR specific, none specific means cheaper labour rates I find.So to the engine and these are only my thoughts on my challenge engine. Take a Range Rover HSE cross bolted block, add top hat liners, Tuffride the crank, Take the heads to a mate of mine and spend £650 getting them ported to within an inch of there life, Get him to Top and tail the valves at the same time or use stainless wasted valves, add roller rockers, (I am looking at Chevy ones at the moment, could be cheaper than the usual) double vented rocker cover both sides, Put on a good matched to head manifold and throttle bodies of your choice or my favourite Quad Delorto 48 Carburettors, put in a M248 cam which is a competition cam but not the full race M256 which might have been the one of choice in the day. You wouldn't want a M256 in a road engine all power at top end but would be better for the pub sketch

Tell my engine builder you want his cam timing added for torque.Breathing to the bodies or carbs is a personnel take and how much room you have, but as a start a cold air flow into a box or boxes is a good start, this bit is worth taking thought and time to think about where to take cold air from (hint) I prefer to take mine from a high pressure area most people don't mind where it comes from. Breathing is very important I think. I would get my exhaust chap to make up the manifolds adding in a spike but any half decent exhaust fabricator would know what to do. Again this manifold and indeed the rest of the exhaust is important. Exiting into low pressure air would be favourite I recon. So I would take the built engine and ancillaries in the car to my friend in my village who will then breath all over the package and set it all up on his rollers. He is the best setup/mapper I have ever met and luckily he lives three doors away from me. He also prepares my race cars and is very successful at it, although he specialises in rally cars with the Vauxhall red top in them. As you are probably thinking there has been a lot of thought gone into the parts of the whole, not just an off the shelf answer but it is only a Rover V8 you should see my chevy

Tell my engine builder you want his cam timing added for torque.Breathing to the bodies or carbs is a personnel take and how much room you have, but as a start a cold air flow into a box or boxes is a good start, this bit is worth taking thought and time to think about where to take cold air from (hint) I prefer to take mine from a high pressure area most people don't mind where it comes from. Breathing is very important I think. I would get my exhaust chap to make up the manifolds adding in a spike but any half decent exhaust fabricator would know what to do. Again this manifold and indeed the rest of the exhaust is important. Exiting into low pressure air would be favourite I recon. So I would take the built engine and ancillaries in the car to my friend in my village who will then breath all over the package and set it all up on his rollers. He is the best setup/mapper I have ever met and luckily he lives three doors away from me. He also prepares my race cars and is very successful at it, although he specialises in rally cars with the Vauxhall red top in them. As you are probably thinking there has been a lot of thought gone into the parts of the whole, not just an off the shelf answer but it is only a Rover V8 you should see my chevy  .

.forgot to say, My engine would be great in a road car, it uses 1.1 litres of vpower a minute does that make it thirsty mpg?

Edited by 77racing on Saturday 23 January 10:46

if you are interested in the JE 5.2 bottom end. I can post up the graph from my griff 5.2 which I used to use on the road and trackdays. just had one done as I plan on getting it back on the road in the next few weeks.Phazed will tell u how it goes, as he spent three years trying to get past it on track LOL

Morning Mathew,5.2 JE short engine with 5.0lt standard heads, ACT triple throttle body plenum and large AFM , h218 cam, rest standard 5.0lt stuff in my griff. 300BHP with 340.3lb/ft @ 3675rpm. I could get a lot more BHP and a bit more torque if I had the heads done, but to be honest this is a cracking car to drive as is.

Just a little update , I have been struggling to match the manifold to heads. We have had a lot of work to match up and we are having to dowel the manifold to heads so they go back on to the matched position when it is refitted as they will be off and on, no dought a fair amount. The bolt holes to heads have a lot of clearance hence the need for dowels. I was expecting some work but this is a fair bit more than I thought. Not sure this casting part suits itself to DIY. Still it is a one size fits all casting, so no complaints. Has anyone had to dowel their set up ? or indeed come up against this straight off. Just wondering if it varies casting to casting.

I am going to go 256 race/competition cam for that bit more power as I think torque will be well looked after.

I am going to go 256 race/competition cam for that bit more power as I think torque will be well looked after.

Edited by 77racing on Thursday 18th February 09:42

Not much progress but the thinking is almost done .Thought been " measure twice, cut once" The bolt holes are not uniform so inserts are not possible as suggested to stop the front to back movement, so we have decided to put a small 4mm bolt tapped in each corner avoiding the water way allowing the manifold to be correctly repositioned every time. we are going to a lot of trouble to get the ports to match up with the least amount of restrictive overlap as possible. Hoping to maximise the flow benefits, after all I am chasing the top step of the podium at Spa Summer Classic later on in the year, no mean feat.

So Finally got the locating bolts done and on Monday I can drop heads off at Devon Racing for Chris to finish of and assemble the engine. As you can see I have a fair amount to take out of the casting to get it all matched up right. Looks like one side of tunnel more than the other that just needs a tickle. The four mil bolts you can see are my mounting bolts tapped into the casings but of course they go in from the other side on assembly. They are just in the wrong side at present to hold the template in place for the porting.

Yep they needed quite a bit of work to get the best from them but I have a good feeling they are going to bring quite a bit to the party. On reflection i'm now not surprised they needed a fair amount of work to get everything to line up we are talking a Rover engine after all  hopefully I can get the car a bit further on soon else the race season will be over before I know it. Only 12 weeks to Spa where I need what the set up will bring, fingers crossed.

hopefully I can get the car a bit further on soon else the race season will be over before I know it. Only 12 weeks to Spa where I need what the set up will bring, fingers crossed.

hopefully I can get the car a bit further on soon else the race season will be over before I know it. Only 12 weeks to Spa where I need what the set up will bring, fingers crossed.

hopefully I can get the car a bit further on soon else the race season will be over before I know it. Only 12 weeks to Spa where I need what the set up will bring, fingers crossed. Gassing Station | TVR Major Mods | Top of Page | What's New | My Stuff

If they get me outa Dodge that bit quicker.

If they get me outa Dodge that bit quicker.

eeerrrr except that lap then.

eeerrrr except that lap then.