Bloodhound LSR Thread As Requested...

Discussion

Voldemort said:

Why?

Dear me old chap, that's not very British is it?It's for the children, no seriously, it is - http://www.bloodhoundssc.com/education

aka_kerrly said:

Genuinely fascinating stuff!

I went on a training course near Coventry a while back which finished early giving me enough time to go and have a look around the Coventry transport museum which has a rather good display of land speed record vehicles and information.

Standing two feet away from Thrust 2 and Thrust SSC was mind blowing, how anyone can question WHY is beyond me!!

I'm certainly happier for the UK to invest millions in engineering projects like this than continuing to waste millions on projects like Millennium dome and such like.

Going there with the kids over the xmas break, the museum manager has said we can sit in the LSR cars!!!!!I went on a training course near Coventry a while back which finished early giving me enough time to go and have a look around the Coventry transport museum which has a rather good display of land speed record vehicles and information.

Standing two feet away from Thrust 2 and Thrust SSC was mind blowing, how anyone can question WHY is beyond me!!

I'm certainly happier for the UK to invest millions in engineering projects like this than continuing to waste millions on projects like Millennium dome and such like.

Arlie71 said:

IN51GHT, Thanks for an incredible thread.

Can I ask a bit about yourself ? Whats your background and how did you end up working on Bloodhound ?

I always find it fascinating the different way lives end up, and its inspiring to hear the stories of those lucky (and of course talented) enough to be involved in something so special.

Keep the photos and details coming, ignore Voldemort, he obviously doesn't realise the answer to his question is of course "Speed Matters"

Cheers

Andy :-)

Luck had a BIG part to play.Can I ask a bit about yourself ? Whats your background and how did you end up working on Bloodhound ?

I always find it fascinating the different way lives end up, and its inspiring to hear the stories of those lucky (and of course talented) enough to be involved in something so special.

Keep the photos and details coming, ignore Voldemort, he obviously doesn't realise the answer to his question is of course "Speed Matters"

Cheers

Andy :-)

I left school with no qualifications other than a grade C in physics.

Found myself accidentally doing a 3year engineering GCSE at 6th form in a year, whilst doing maths & english re-takes. Failed the Maths & English (got D's) but got an A* in the engineering.

On the back of this I applied for a craft apprenticeship with GKN Westlands, which I started to really enjoy, then moved onto a technician apprenticeship in the same company as I was taking to it really well.

At the end of the 4 year apprenticeship I was offered a position in GKN Westland design services, where I spent 5 years or so doing detail design, until I went to the NEC for the Motorshow in 1998, where we were given a copy of the Telegraph, which we thought would be useful as the Guinea Pigs needed cleaning out & we had run out of news paper to line the hutch with.

Whilst cleaning out the aforementioned Guinea Pigs the news paper fell open at the jobs page, where Williams F1 were advertising for detail design engineers, I applied, got the job & spent until 2005 there. Started doing detail design, worked my way up to the point where I was doing concept assy design & detailing, at which point I needed to spend some time with the family, so took a job designing railway signalling equipment, until Bloodhound came knocking in 2011.

I'm convinced if I didn't end up at sixth form doing the engineering GSCE I'd be staking shelves in my local supermarket now, I got lucky & accidentally found something I actually enjoyed doing.

Edited by IN51GHT on Friday 22 November 14:58

One last pic before the weekend, weekend away from the office rapidly approaching, eldest daughter has a national gymnastics competition.

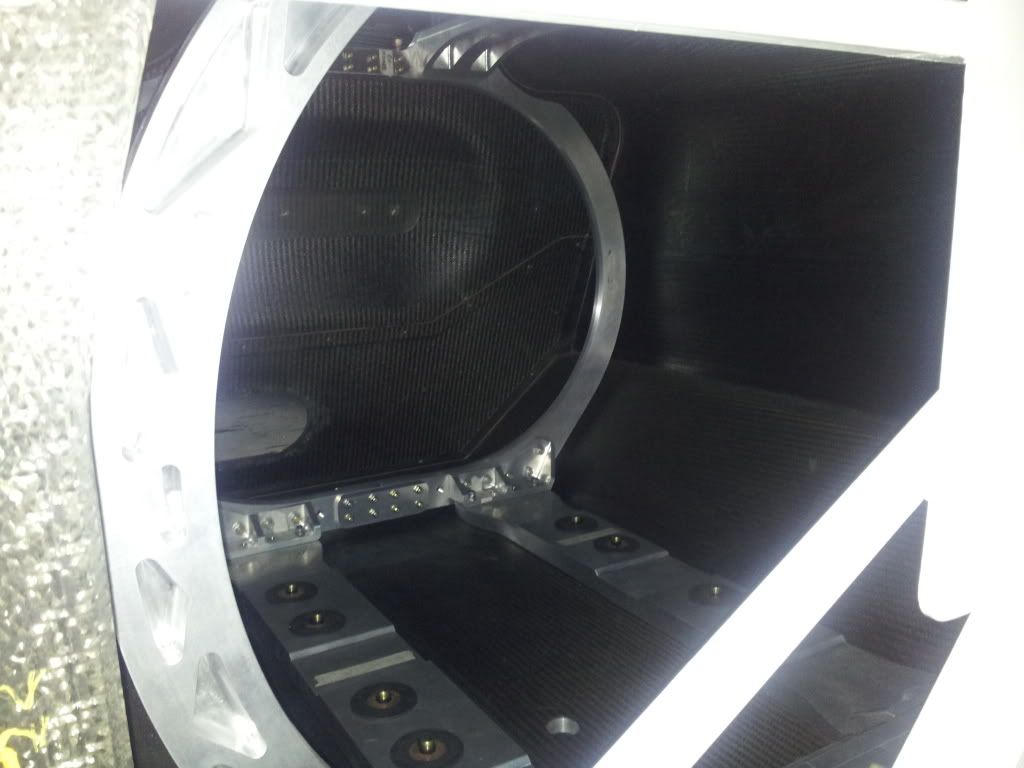

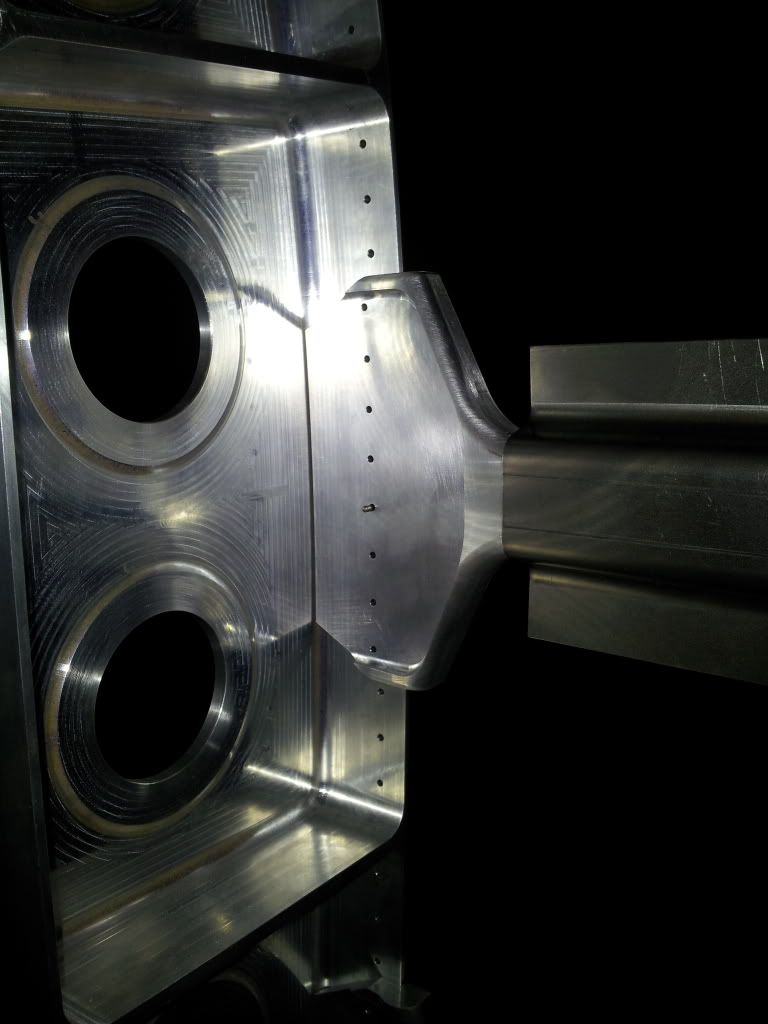

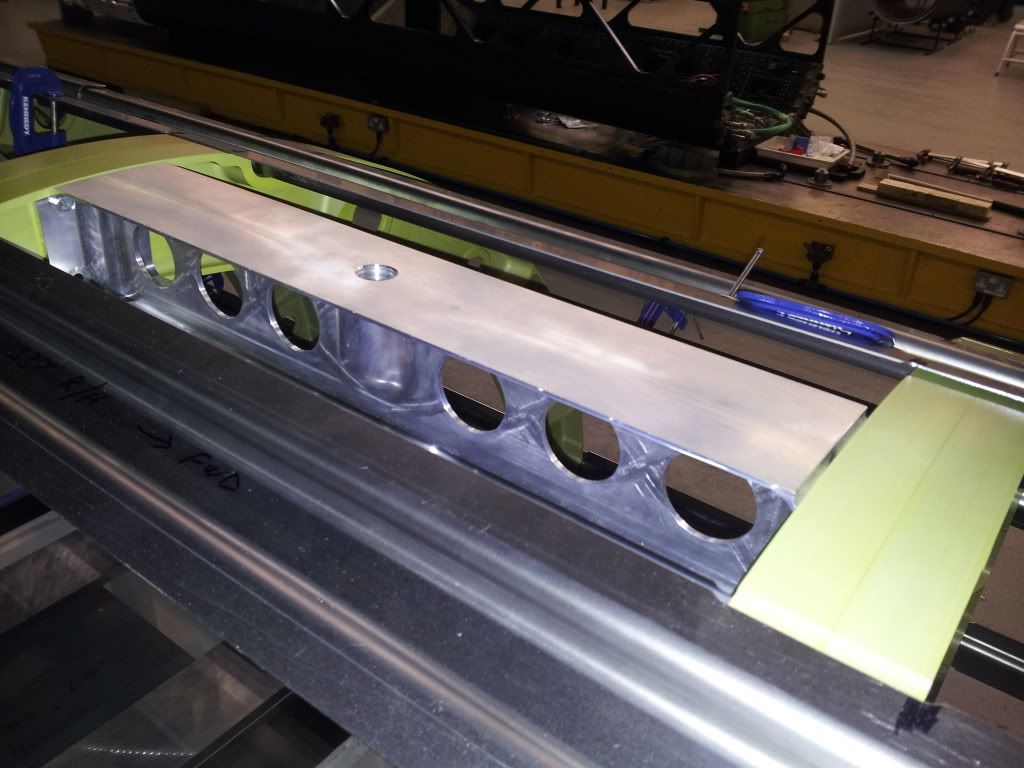

This is the 'cradle' that will restrain the 1000 litre H2O2 tank, located inside the rear end on the carbon monocoque. Designed to withstand a 9g "arrival" when full. I can't claim this as one of my parts, Johnny submarine designed it.

This is the 'cradle' that will restrain the 1000 litre H2O2 tank, located inside the rear end on the carbon monocoque. Designed to withstand a 9g "arrival" when full. I can't claim this as one of my parts, Johnny submarine designed it.

Edited by IN51GHT on Friday 22 November 15:57

Here we are another week closer to run date.

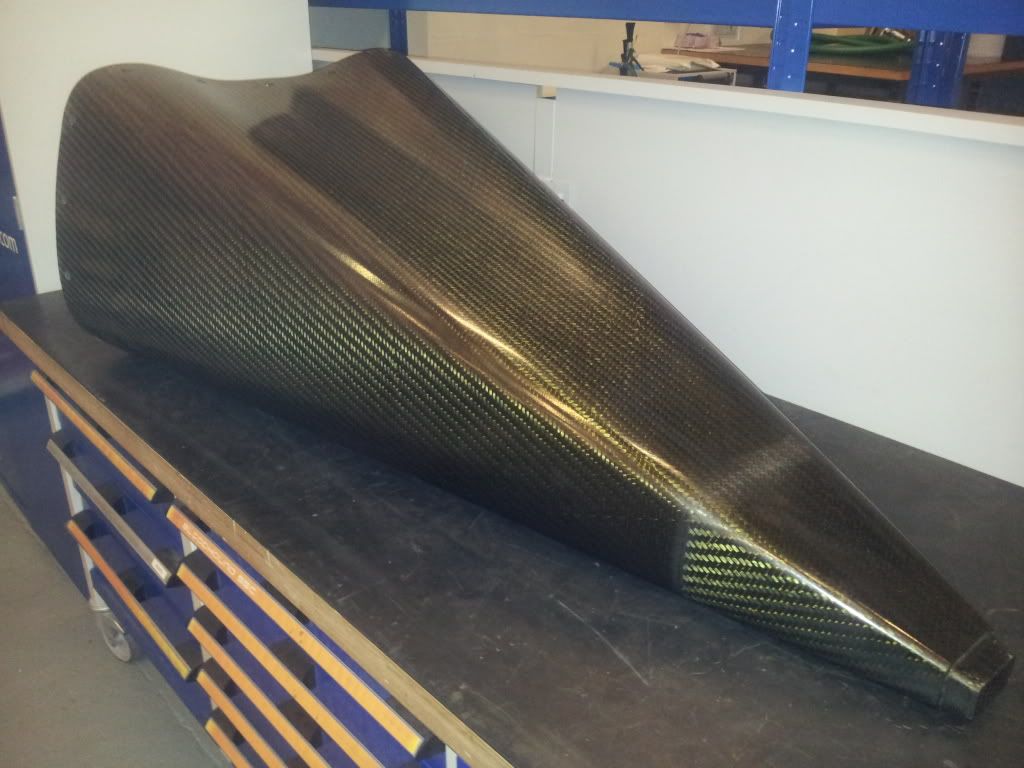

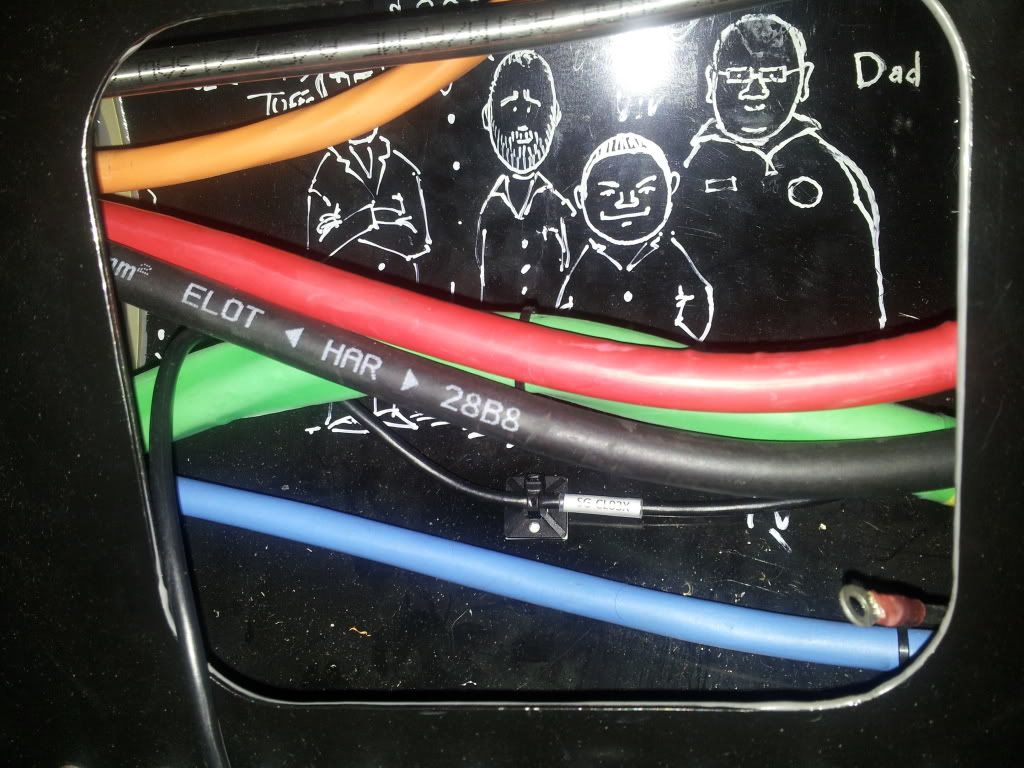

These will become the cockpit switch panel, one of our REME girls is making up the loom for them.

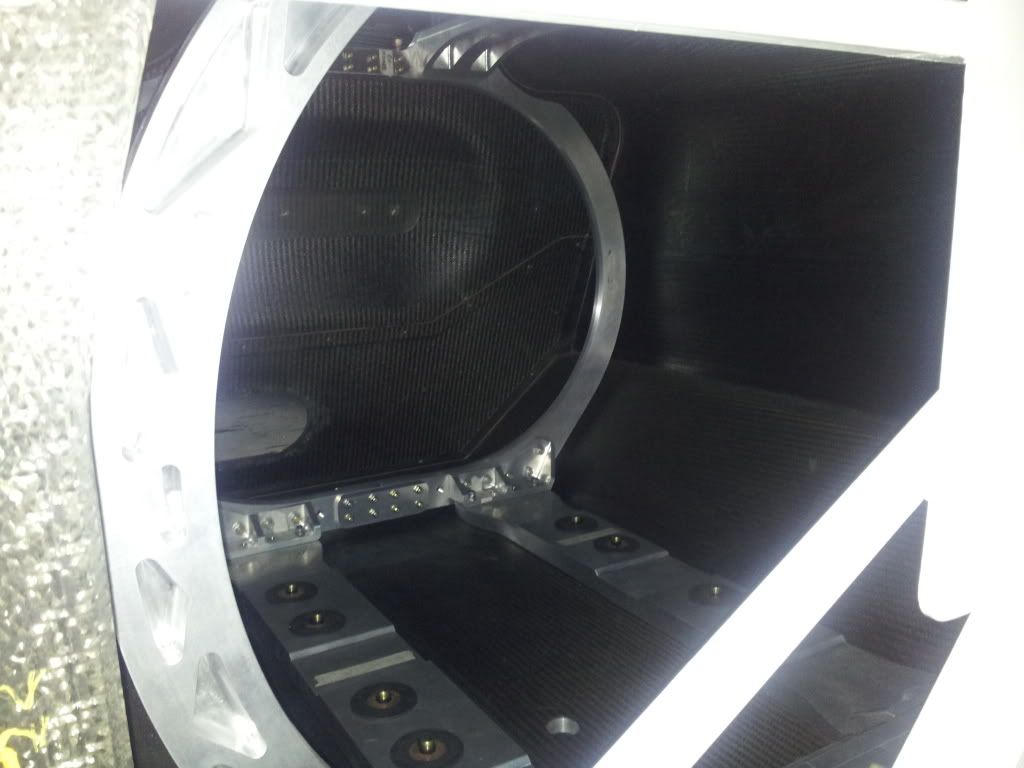

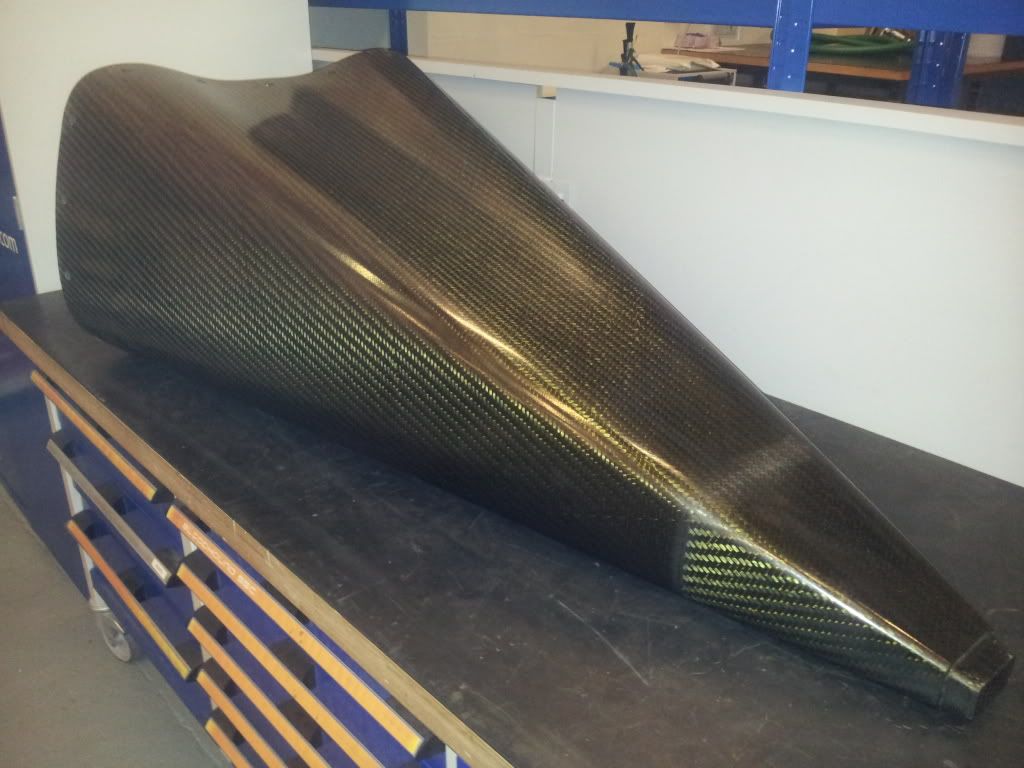

Pretty obvious what this is, the nose of the car, the To grown tip will be bonded on later.

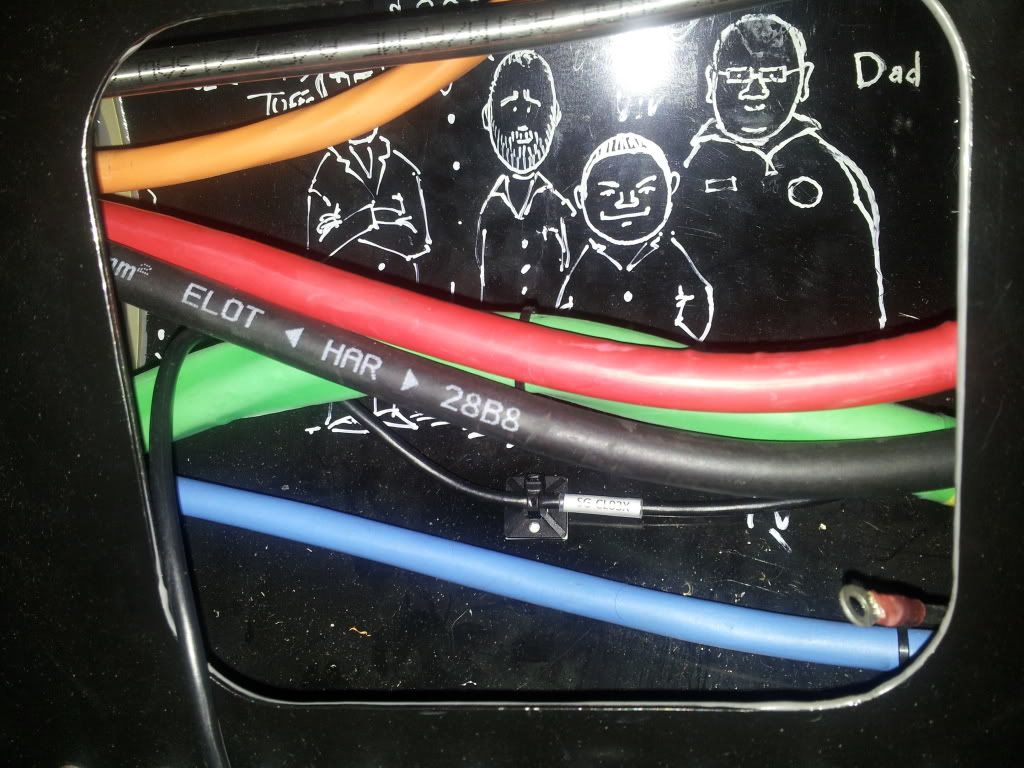

Or film & graphics guy Stefan Marjoram did this little drawing of the lower chassis build team befor it was bonded & cooked. It's inside the lower sill section on the L/H side.

These will become the cockpit switch panel, one of our REME girls is making up the loom for them.

Pretty obvious what this is, the nose of the car, the To grown tip will be bonded on later.

Or film & graphics guy Stefan Marjoram did this little drawing of the lower chassis build team befor it was bonded & cooked. It's inside the lower sill section on the L/H side.

Few more images for you to look at.

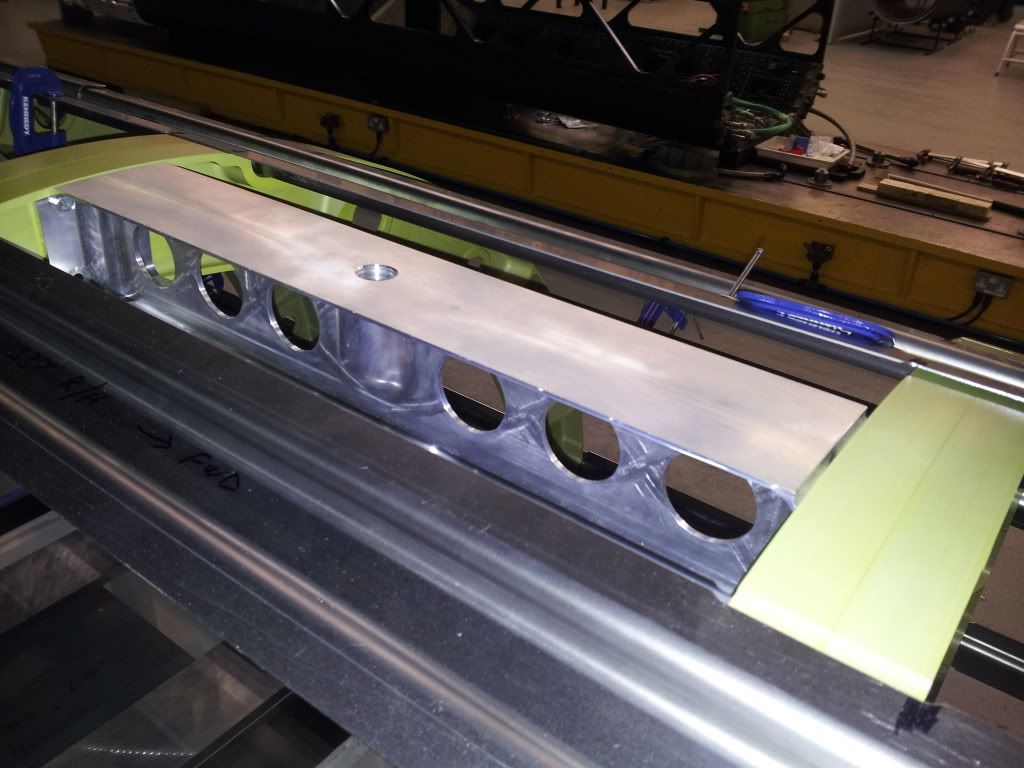

This is the "Stringer Finger". It transmits the load from the stringer & skin into the flange on the chassis rib.

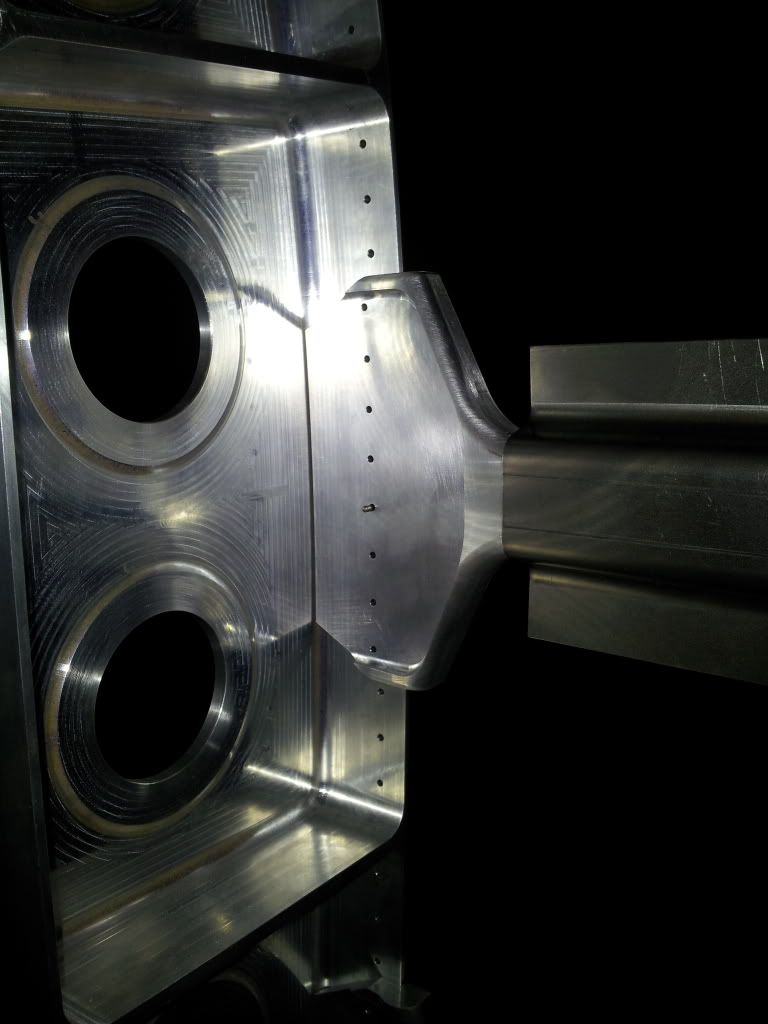

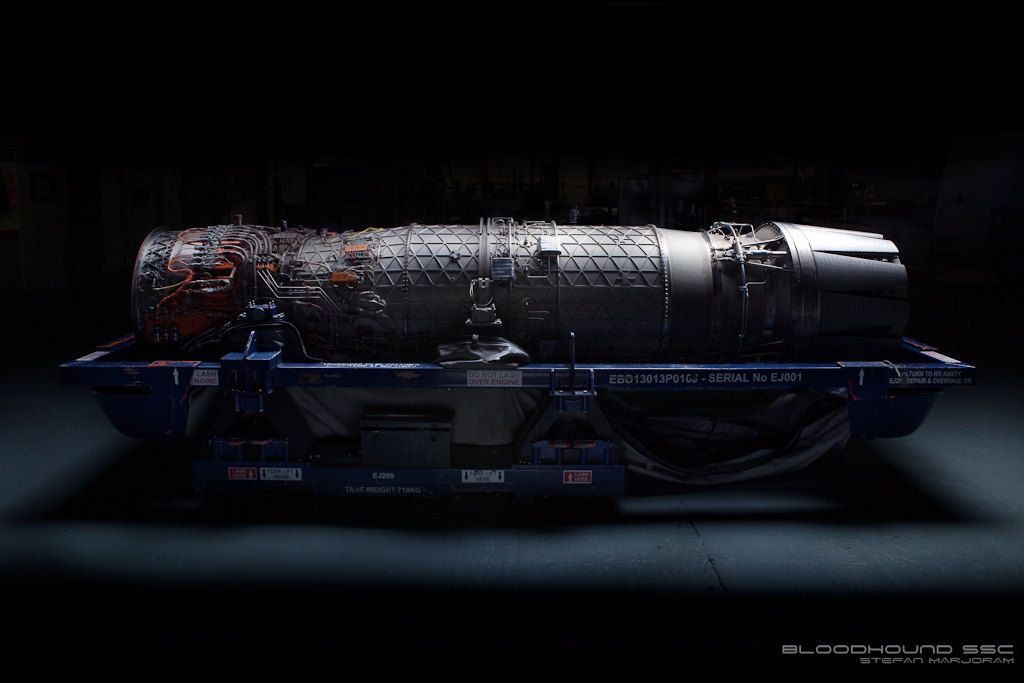

This is where the EJ200 thrust trunnion fitting will live, the trunnion is made from S155 steel to prevent damage to the aluminium rib.

This is where the EJ200 rear hanger will live, it takes the weight of the rear of the engine.

The fwd lifting bracket for the upper chassis. In the event of an EJ200 needing replacing we'll lift the upper chassis from the car, this is where the fwd lifting strop will go, we simply screw in a steel lifting eye.

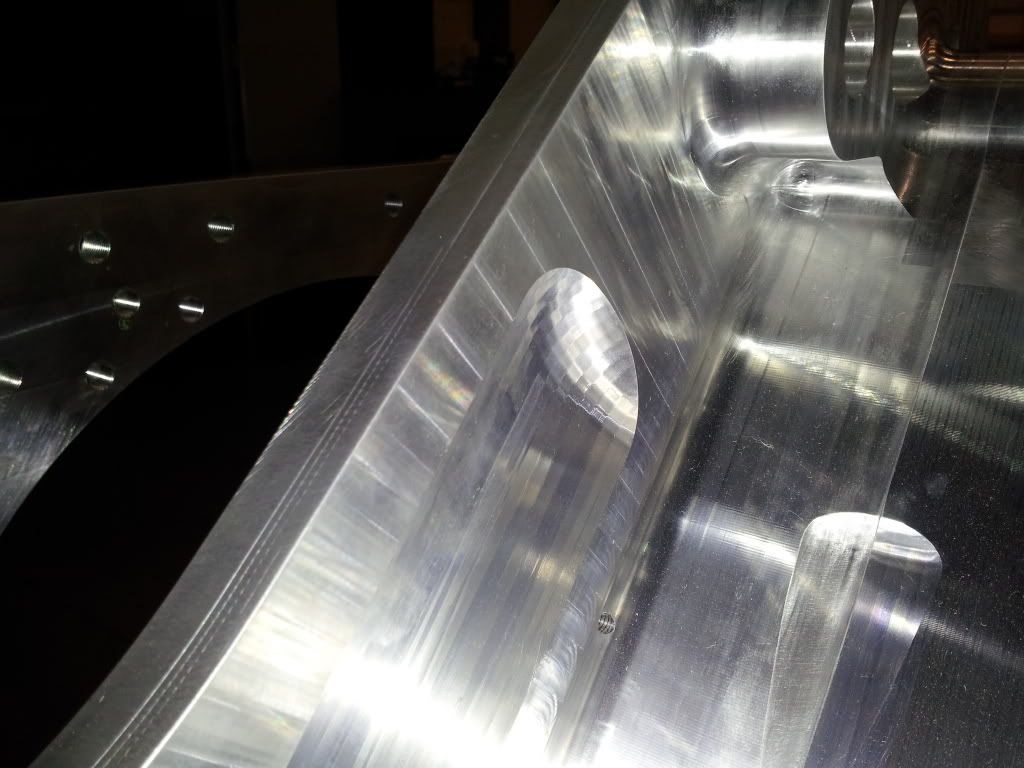

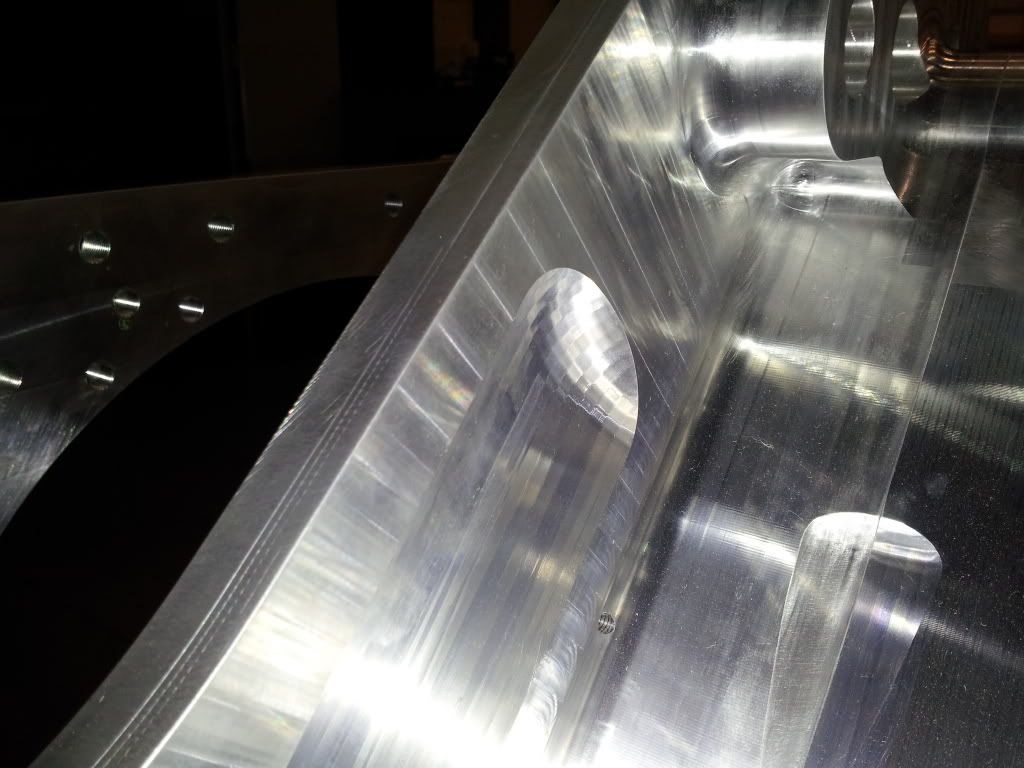

Finally, I just like this photo, it shows the cutout on one of the rear suspension bulkheads to clear the damper, looks kind of mirror ball in appearance.

This is the "Stringer Finger". It transmits the load from the stringer & skin into the flange on the chassis rib.

This is where the EJ200 thrust trunnion fitting will live, the trunnion is made from S155 steel to prevent damage to the aluminium rib.

This is where the EJ200 rear hanger will live, it takes the weight of the rear of the engine.

The fwd lifting bracket for the upper chassis. In the event of an EJ200 needing replacing we'll lift the upper chassis from the car, this is where the fwd lifting strop will go, we simply screw in a steel lifting eye.

Finally, I just like this photo, it shows the cutout on one of the rear suspension bulkheads to clear the damper, looks kind of mirror ball in appearance.

Edited by IN51GHT on Friday 29th November 06:41

Gassing Station | General Gassing | Top of Page | What's New | My Stuff

"Get your logo on that"

"Get your logo on that"