Infiniti's variable compression ratio engine

Infiniti reckons there's still life in the petrol engine; 'Variable Compression-Turbocharged' will debut at Paris

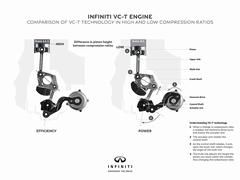

There are more details to follow at Paris but essentially - at least as far as our knowledge extends - an actuator arm (controlled by the 'Harmonic Drive') rotates a control shaft in the combustion chamber. The rotation of that shaft adjusts the angle of certain links, which then limit the height the piston can reach. Ergo, variable compression ratio. And if none of that makes sense, Infiniti has a handy diagram too. PHers with engineering nous, feel free to contribute more insightful knowledge!

Infiniti's president Roland Krueger says the engine is "a revolutionary next step" in optimising combustion engine efficiency. He is promising "the power of a of a high performance 2.0-litre turbo gasoline engine with a high level of efficiency at the same time." The VC-T engine is able to vary its compression ratio from anywhere between 8:1 and 14:1 which, on top of the efficiency benefits, should reduce noise and vibration as well.

That's all that's been detailed so far; expect specifics on numbers and power at Paris. Is this the technology that keeps petrol engines relevant? It should be very interesting to find out.

Which may also mean it could infer benefits where engine capacity is key, such as class Motorsport, taxation classes etc

The diagram seems a little confusing too: surely the "power" setting is the one with the higher compression ratio and the "efficiency" the one with the lower?

And the article states that the control shaft rotates in the combustion chamber - which it doesn't (it appears to be in the crankcase. The combustion chamber is where the combustion takes place).

Happy to be shot down by a better explanation as I'm no engineer.

I stand corrected.

Efficiency = 1 - 1 / (CR ^ (gamma-1))

Where gamma is the specific heat capacity of the fluid in question (straight air is 1.4, air/fuel mix is typically around 1.3).

As a result, the efficiency of an 8:1 engine assuming gamma is 1.3 is ~ 46.5% however at 14:1 it's 54.7%. So an improvement of 9.2%.

That doesn't really give a fair overview of what happens everywhere in the operating map though. For instance, it might be possible to realise all of that benefit at low - medium loads (the region depends a lot on cam profile and supporting technology) however if the higher compression ratio starts to generate knock so that peak combustion pressure is not taking place at the most efficient point of the cycle then the CR should be lower for that point. With VCR - you can do exactly that.

This is the problem that a lot of high CR, high output fixed geometry engines are having now. If CR is high, then along the full load line there is likely to be a significant impact on the knock limit that won't be seen on a much lower compression ratio engine. This leads to an increase in overfuelling (with the associated reductions in efficiency), high demand on the cooling system, high demand on the boosting system etc etc. This is where the likes of "miller" cycle engines come into their own, but they have significant impacts on turbocharger selection. An engine operating "miller" cycle uses a shortened intake cam duration (i.e. it closes some time during the intake stroke, not after BDC as per a traditionally cam'd engine). The benefit of this is that it enables a higher geometric compression ratio to be used which helps increase expansion efficiency (i.e. the amount of work extracted from the expansion of combustion gas is higher than at a lower compression ratio). A side effect is that it also reduces the effective compression ratio (i.e. the amount of compression work done on the gas is reduced because the pressure in the cylinder reduces from intake valve closing to BDC and does not recover until the same point in terms of crank angles (ish) on the compression stroke - a picture paints a thousand words...) which can help with the knock limit somewhat.

How big the benefits are with VCR will depend quite a lot on supporting technology in terms of pumping reduction (i.e. continuously variable valve timing/lift or external EGR). Higher compression ratio typically allows you to get away with dethrottling the engine more to improve the benefit of those technologies.

As long as the combustion efficiency isn't impacted.

A lot of consultancies are developing these systems which are either multi-stage switching or continuously variable.

There is alot I've missed out tbh, I could write a book on all of this stuff...!

Gassing Station | General Gassing | Top of Page | What's New | My Stuff