AWD Civic Coupe Turbo Build

Discussion

Good evening all

Ive been lurking around here for ages, but i thought i might post the build..

My car isnt blessed with the cosworth / RWD pedigree, so its handling is (and will be) a little different. More akin to a tuned golf R32 / Audi. Where the car is FWD, with a little to the rear, until slip is detected and power is routed further to the rear. Hence it will handle more like a FWD.. Sorry- dont hit me.. If it wasnt for having spent alot of money on my engine, and it rotating backwards compared with most other engines, i would be running an MT75, but alas, im not..

I think pictures speak a thousand words so..

I started my Civic turbo build in 2008, it briefly saw the road before the engine (a stock B16a2) gave up.

I decided at that point to do what i always wanted to do and build a B20VTEC turbo, AWD, time attack inspired EJ2. Hopefully ill be able to compete when the setting up is done.

Those pics were taken as the car saw the road with its turbo running. The bonnet was changed for a new seibon OEM item which has oxidised within an inch of its life- i need to restore it soon..

Ill cut out alot of the boring stuff from my other build thread, its a bit tedious..

I removed all the rear subframe, for the rear drive parts;

For the trailing arms i used civic RTSi ones, modified them to shorten them, boxed them in for strength and modified them to fit the crv wheel bearings.

Had to angle the rear strut tops as the struts will now sit slightly angled to the rear suspension

Made brackets for the rear diff

Installed the radiator and cut open the boot floor to make way for the fuel cell;

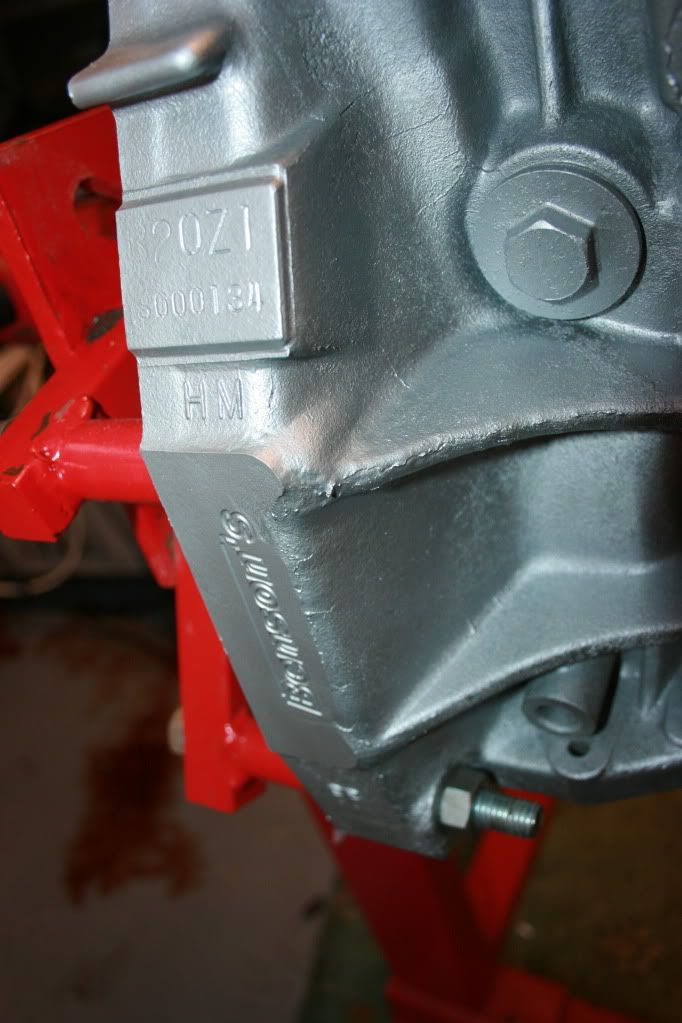

Here is the engine, built by laskey racing in the states in late 2010;

Here is teh B16 head, ported to hell.. its a work of art.. even stamped with the portflow ident..

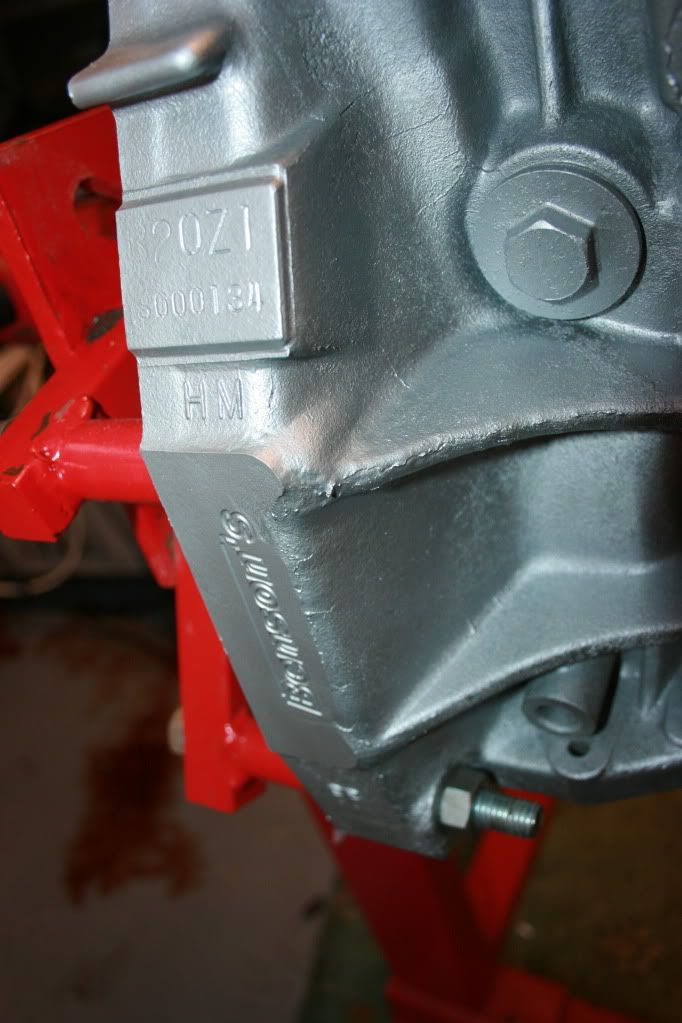

And now for the block;

Thought id stick the dry sump on, unfortunately needed to modify it to fit past the main girdle;

And finally the new driveshafts

Installed the front coolers;

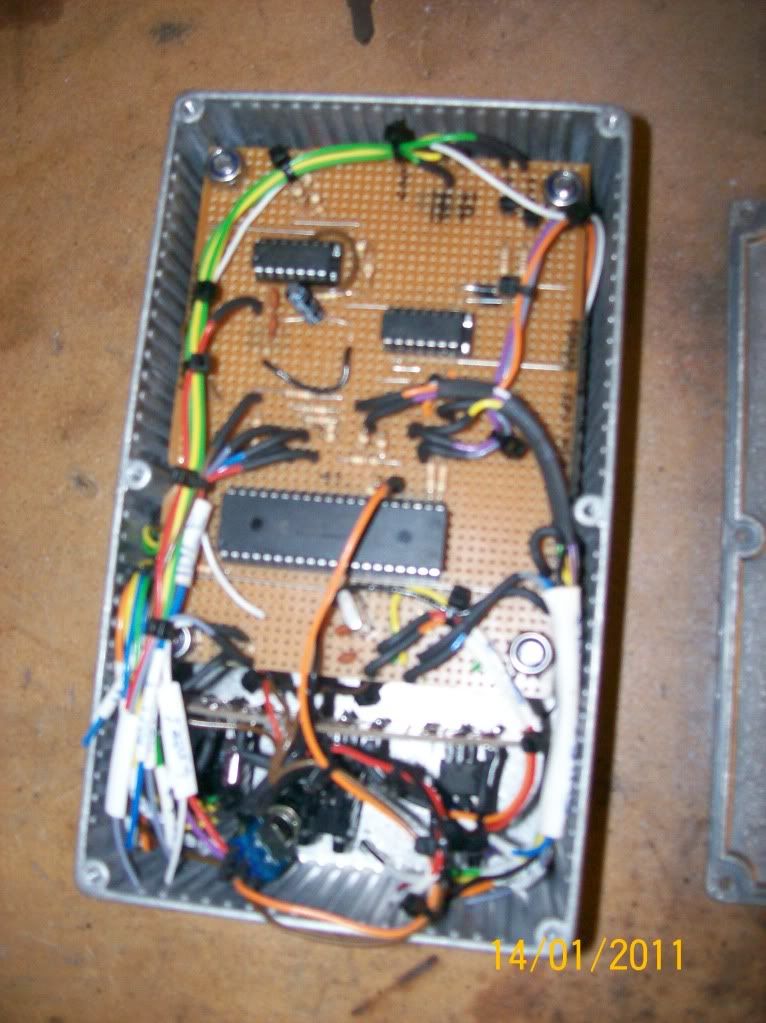

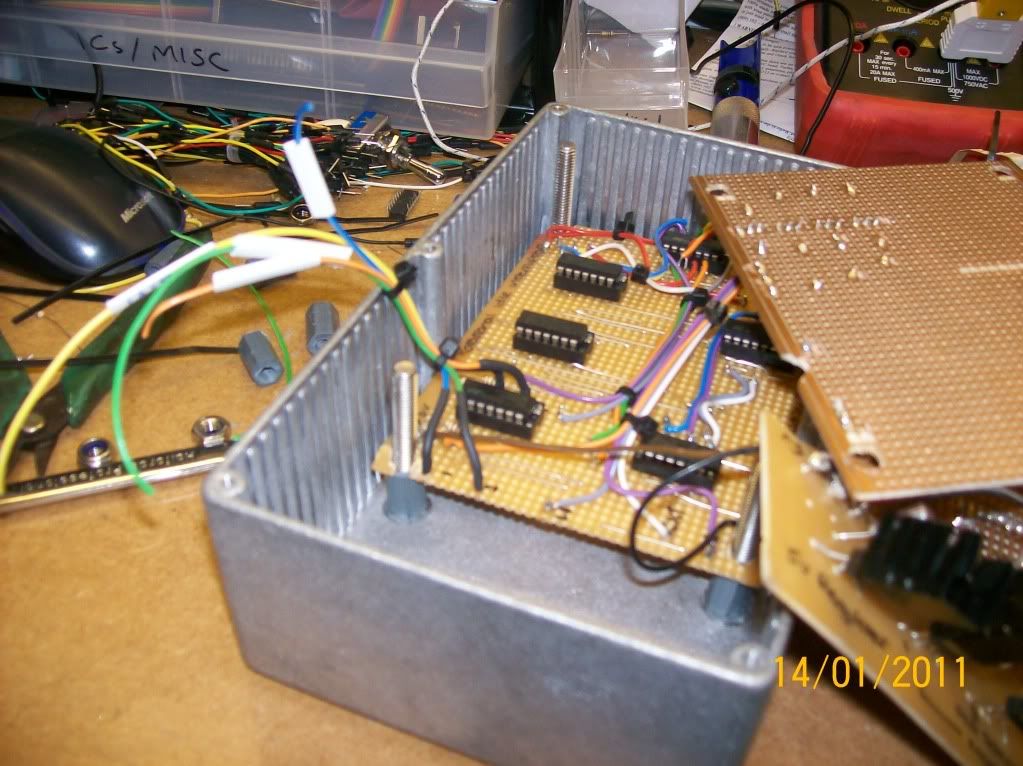

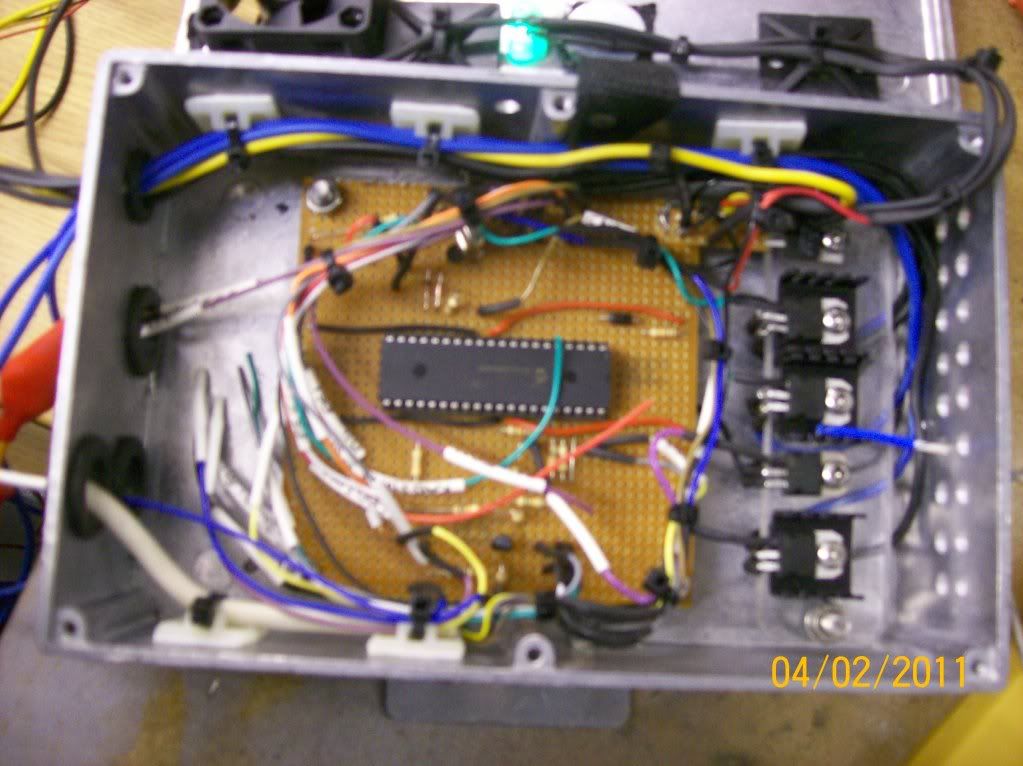

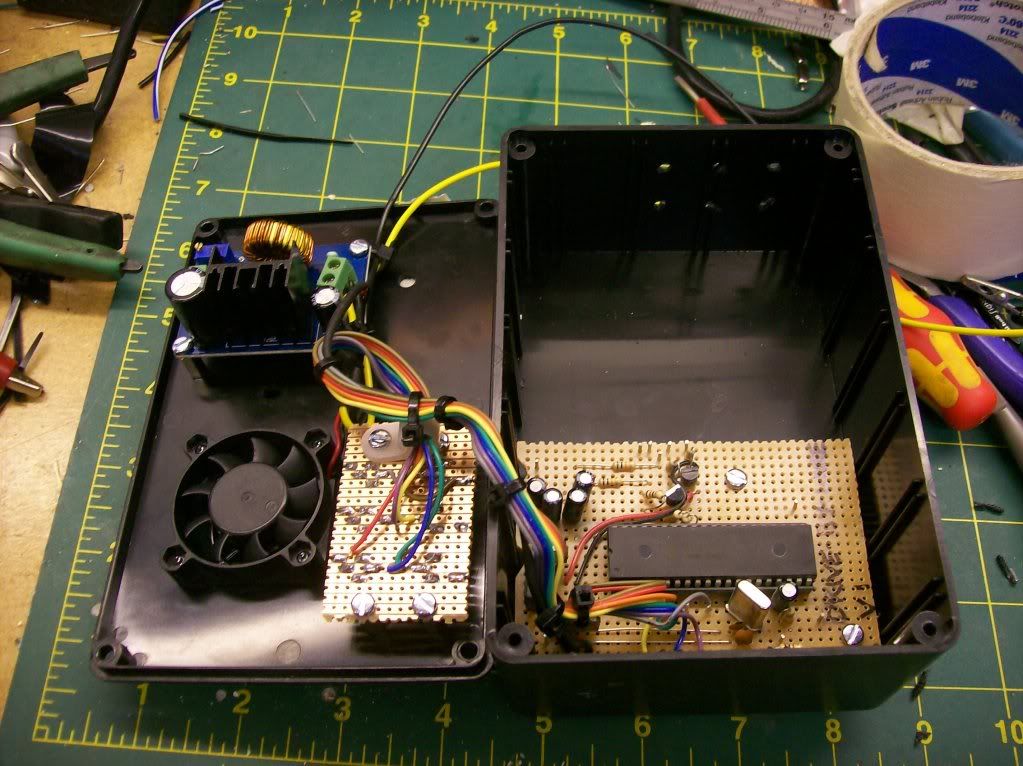

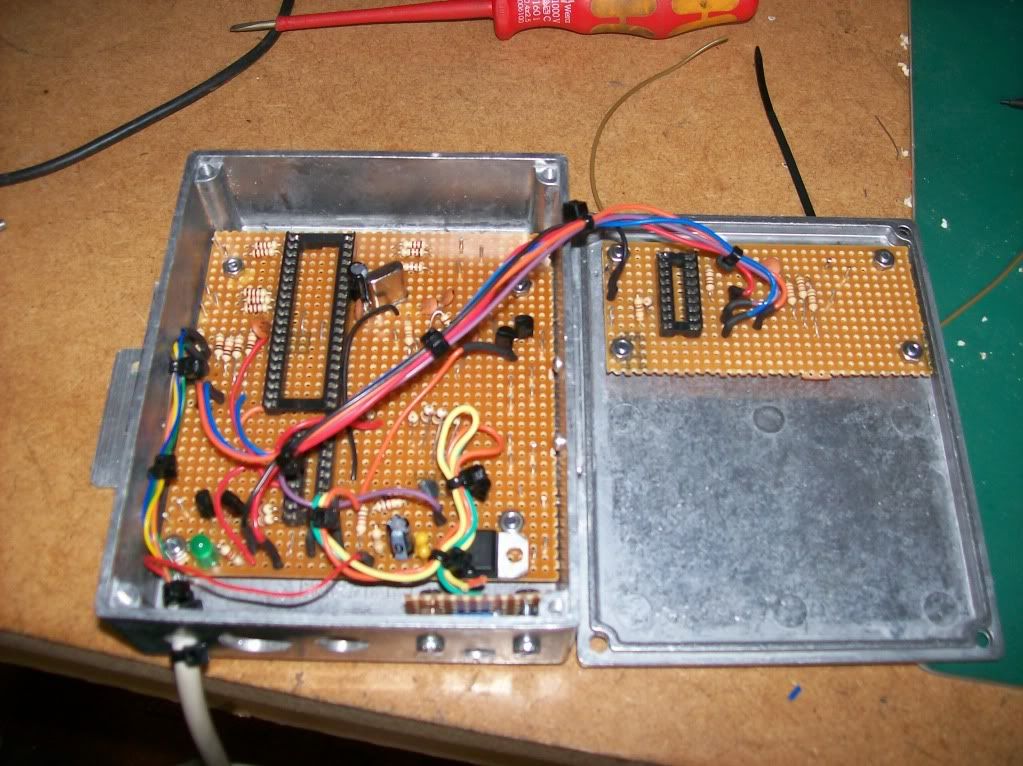

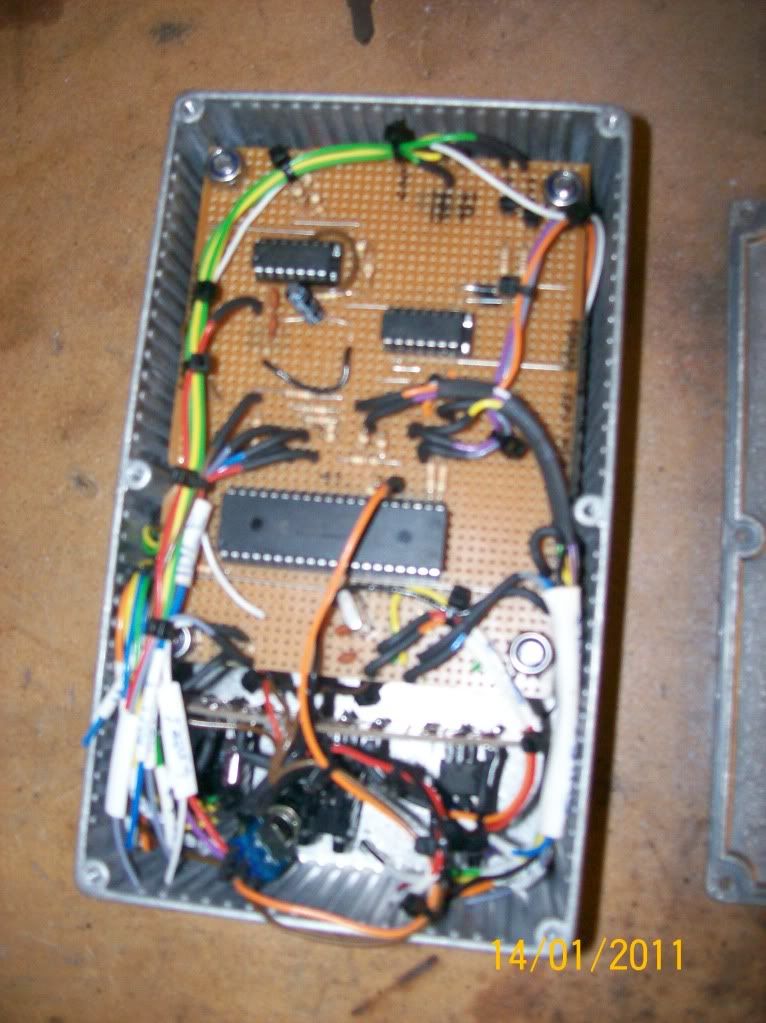

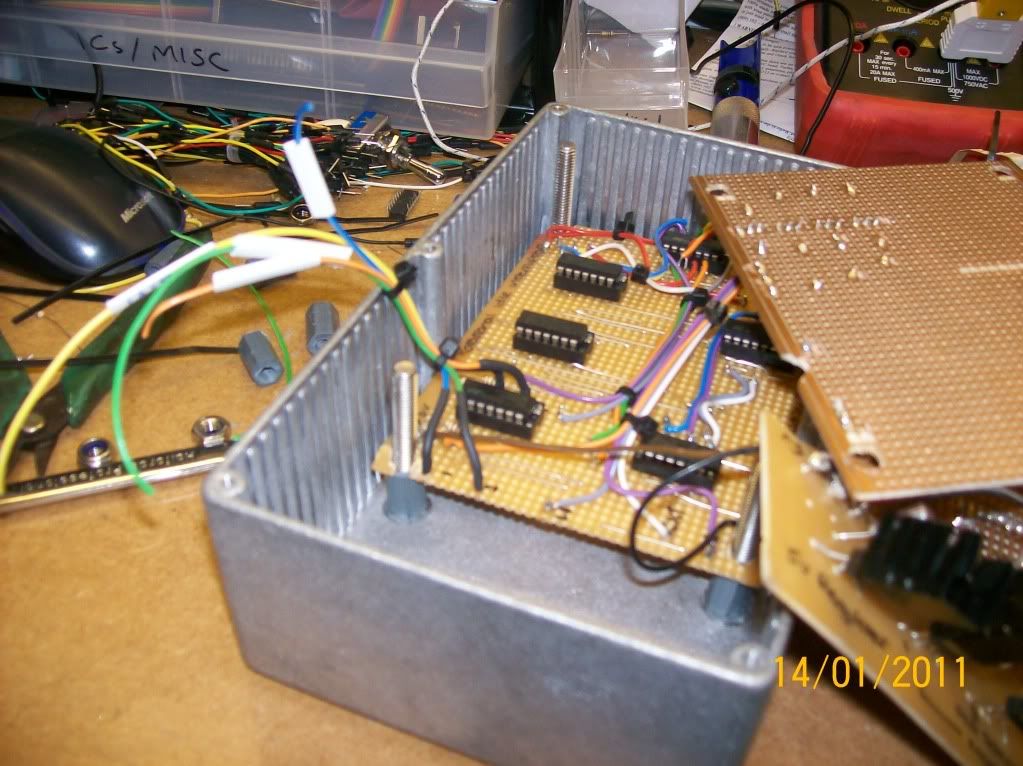

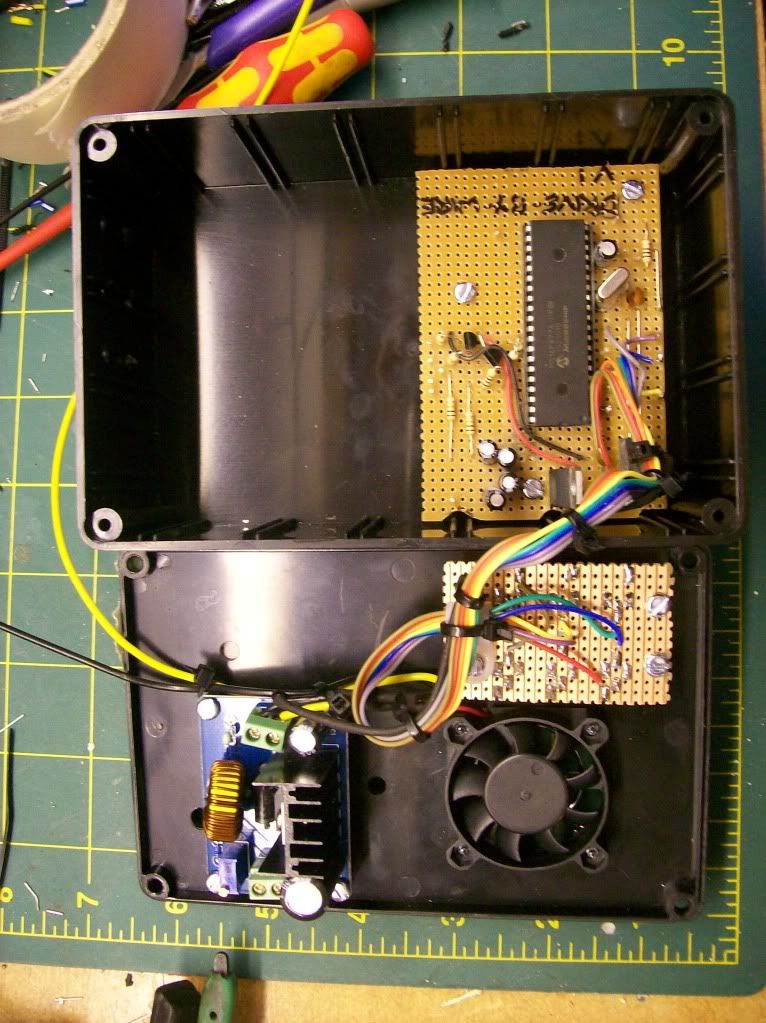

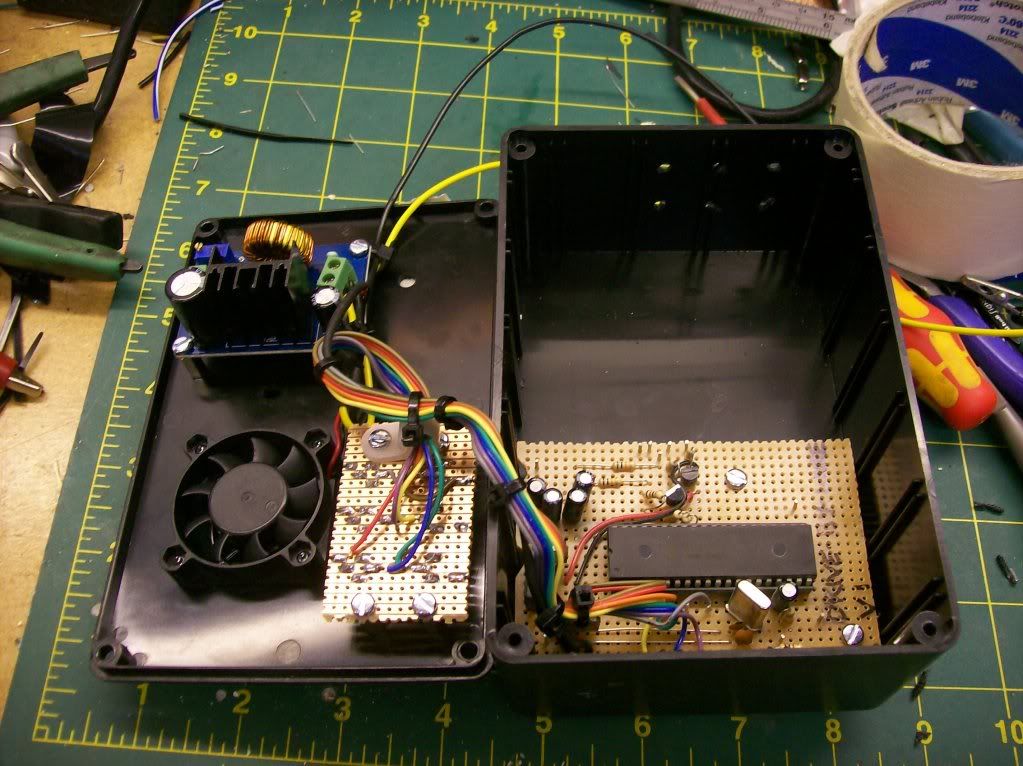

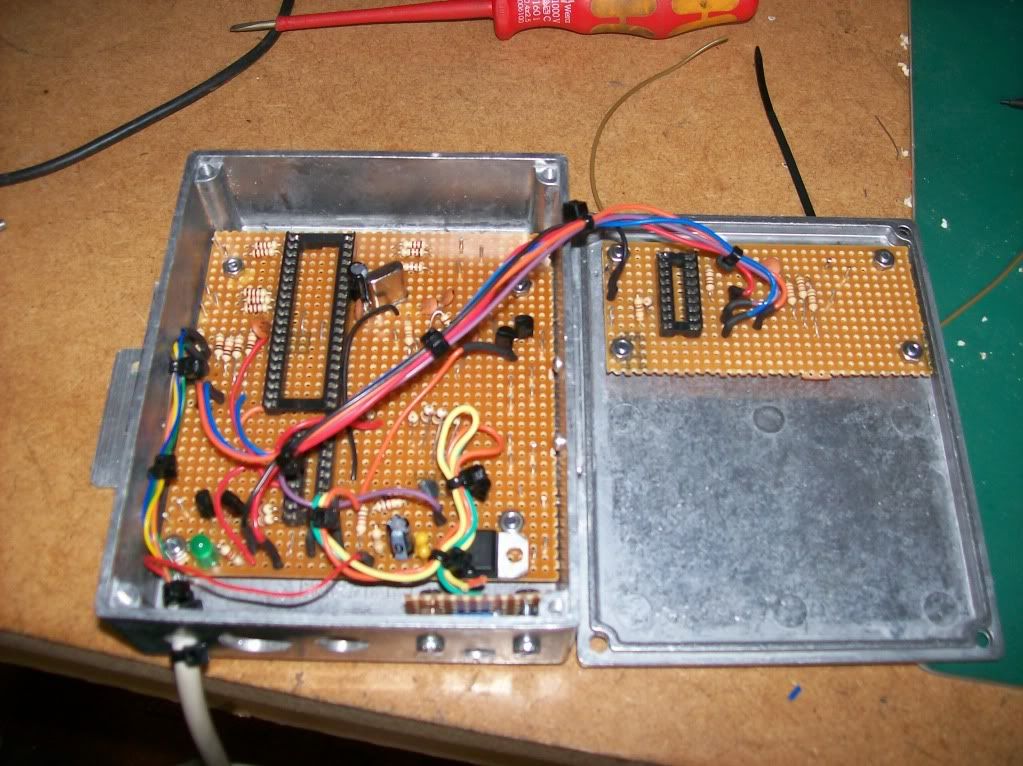

Since i was doing an engineering degree on day release, i got them to let me do my own project. I decided to research turbo lag and build an anti lag system, similar to the proper rally ones;

(the new version is alot better and smaller than this but i had to dumb it down for uni...)

My dog "Garrett" helping me put the engine together;

Got ahold of the electric power folding mirrors, but i had to make a controller for it. I wanted it to properly interface with the alarm .etc

I added some puddle lights to the mirrors as well (just hyper bright 10mm white LEDs);

Crap but it shows in the dark lol

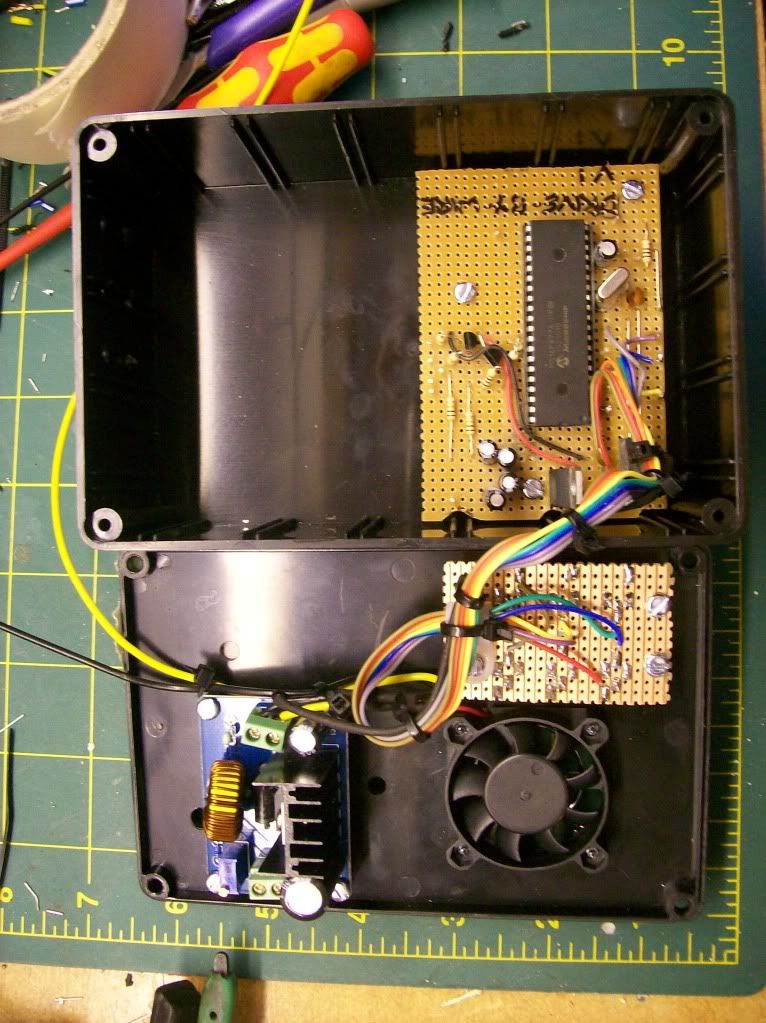

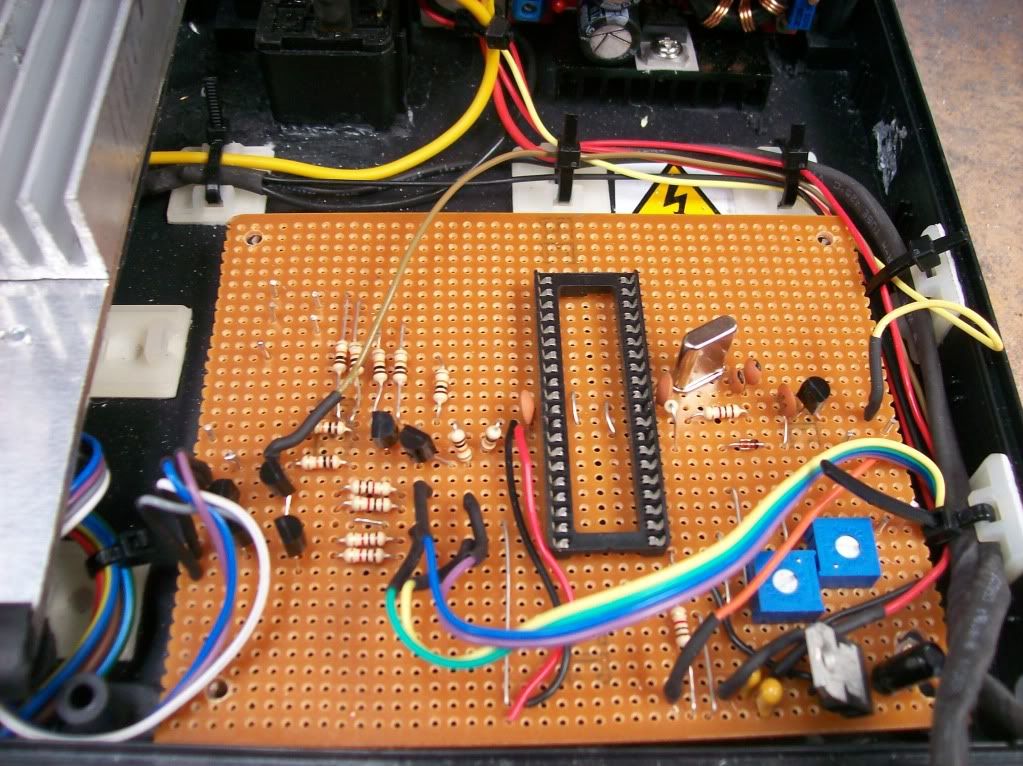

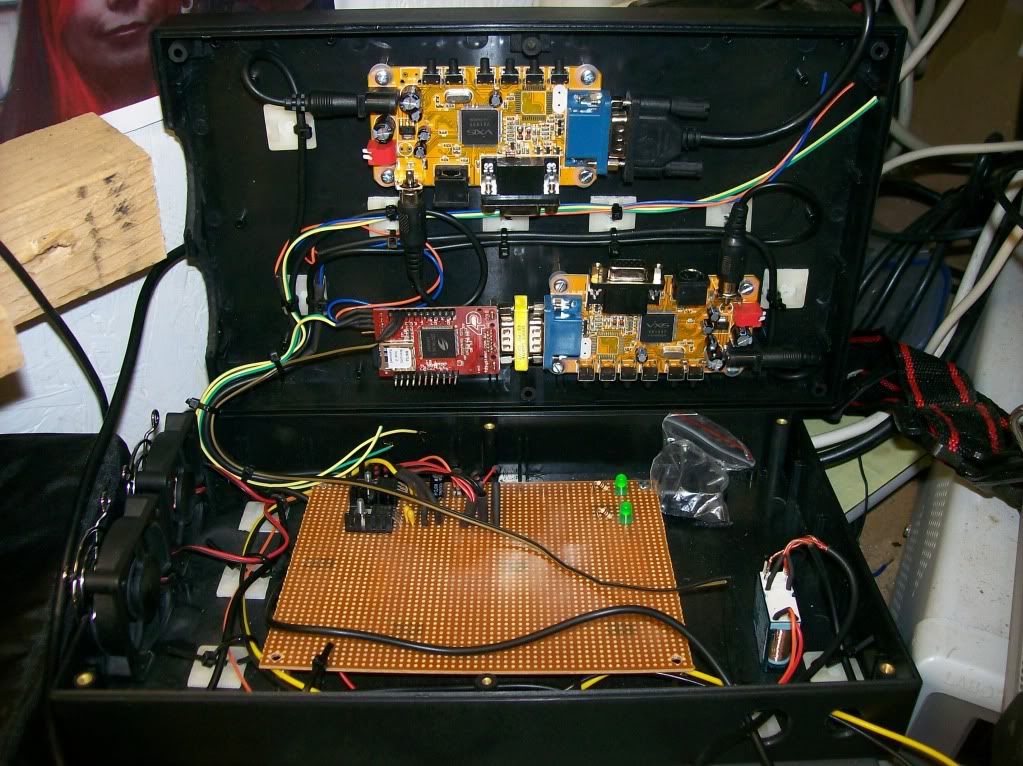

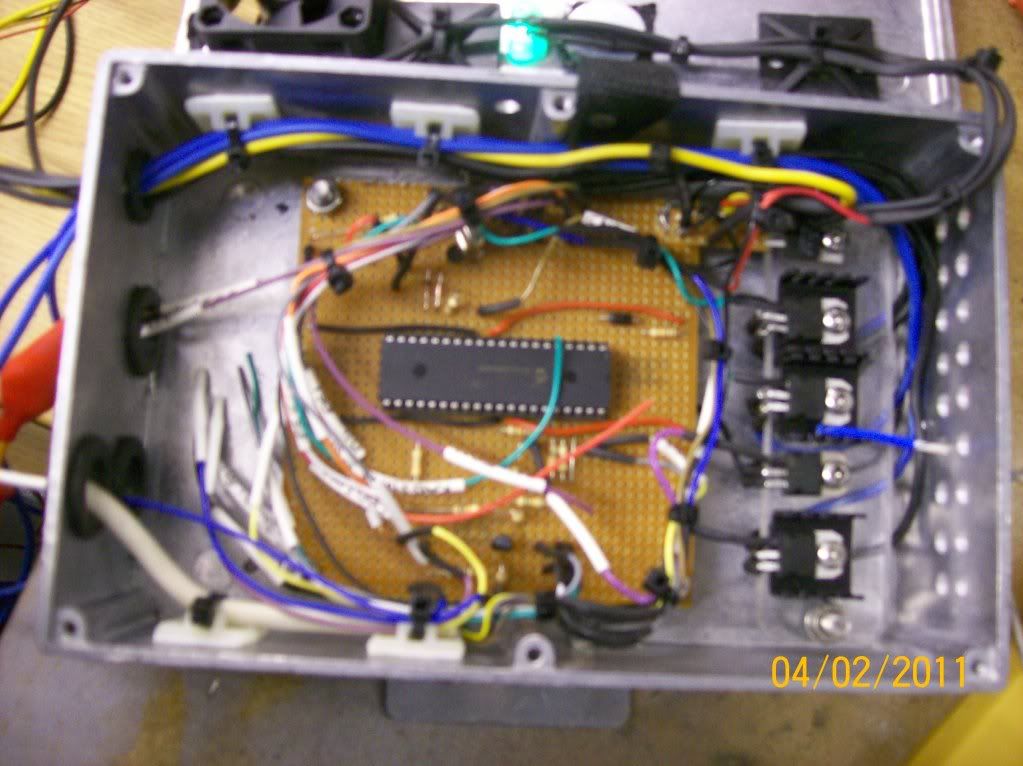

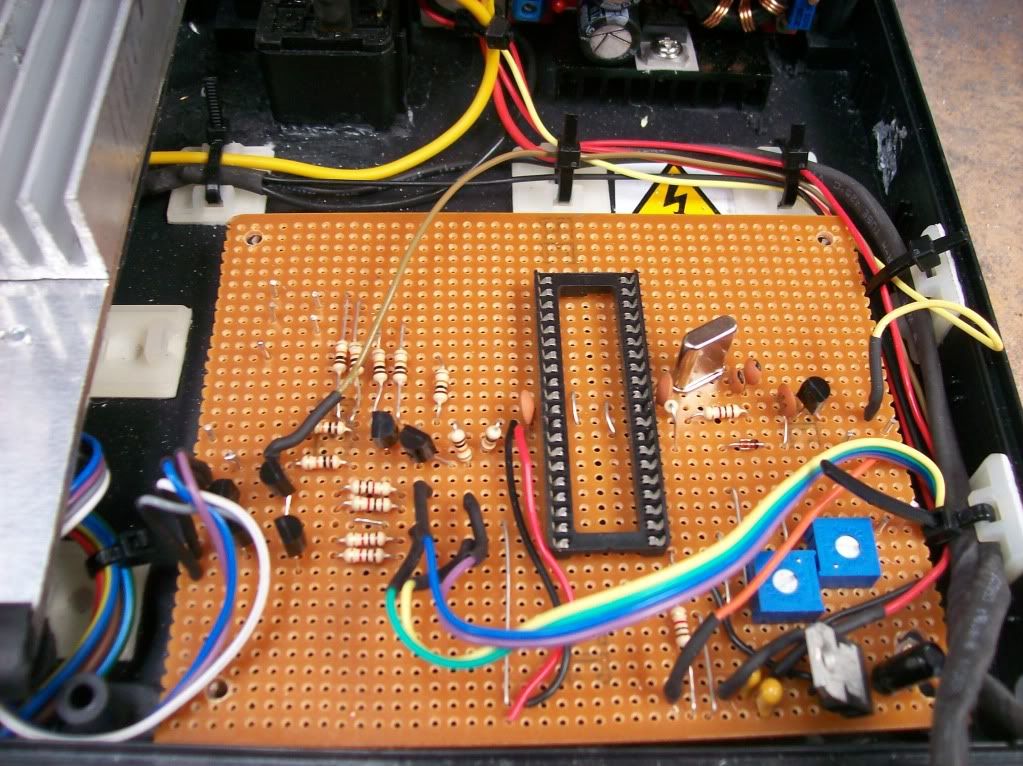

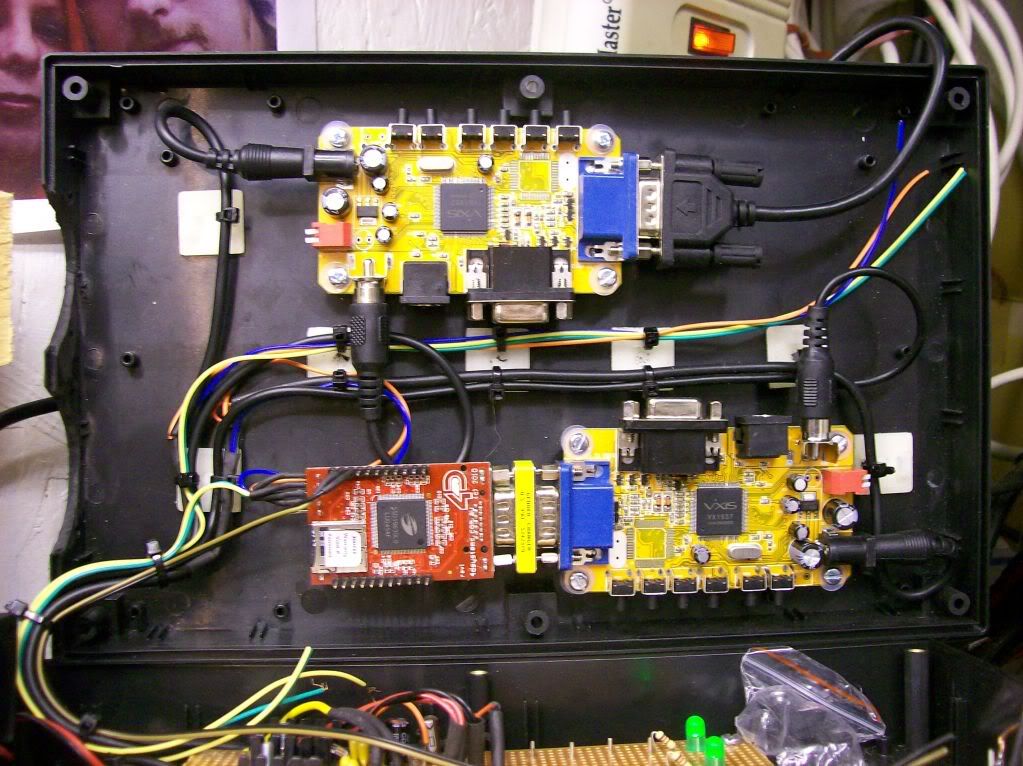

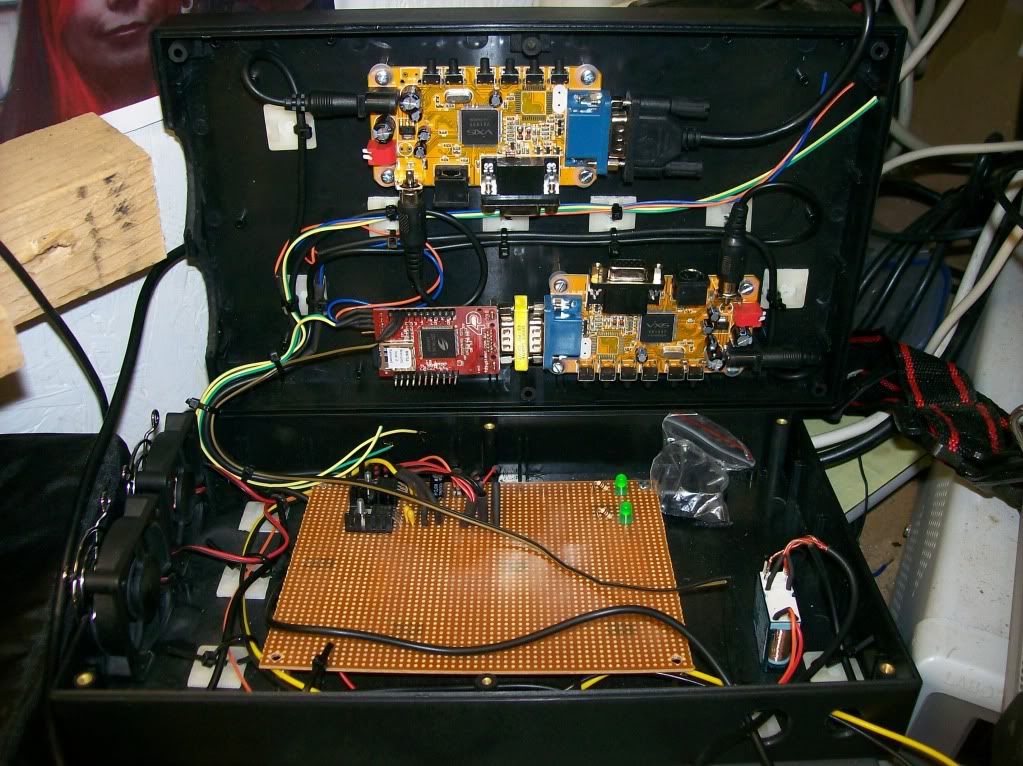

I made a computer to monitor, control and report warnings for all temperatures and pressures in the car. As the radiator is in the boot, fed by small NACA ducts in the sides, at low speeds there is no airflow. THis unit will run the radiator fans at increasing speeds as the car slows to a halt, to ensure the airflow is maintained. This is also done for oil and intercooler fans (intercooler due to anti lag).

Here is the most boring video ever..

I had some projector units knocking around from my wifes trike, so i decided to modify my headlights a little. THose familiar with the escort cosworths will see i quite like the quads with the innter lights removed lol

Made a battery tray for the boot;

and from underneath the car

Seam welded the engine bay, the rest is done but not pictured for some reason;

Cut the holes for the side exit exhausts...

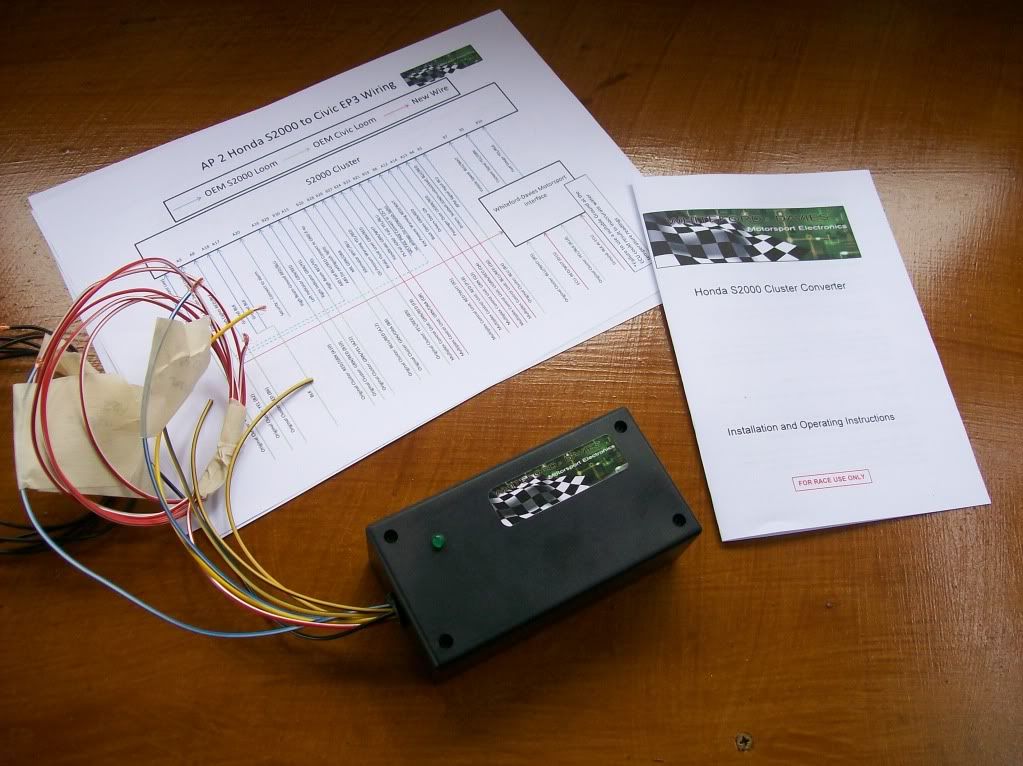

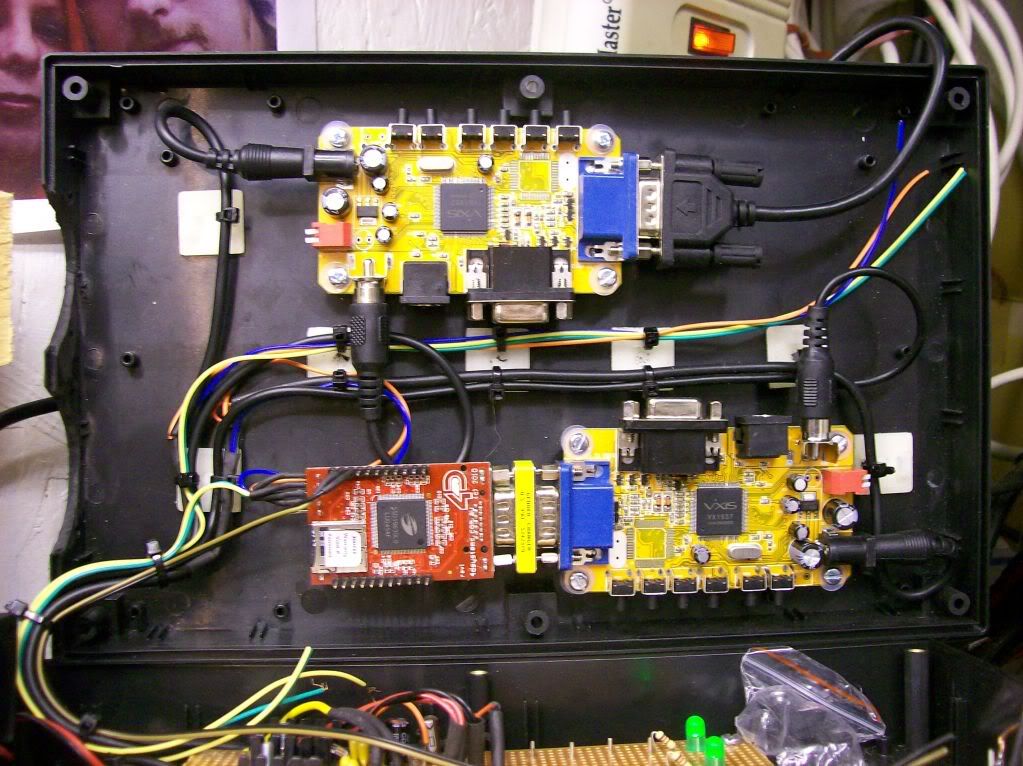

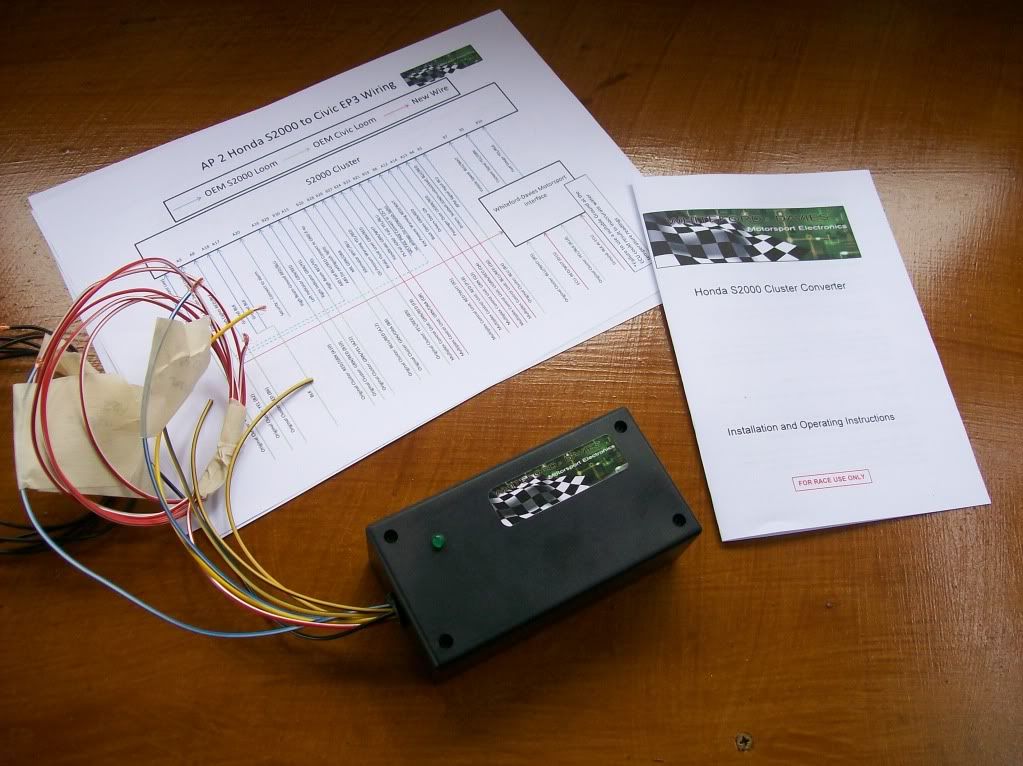

Started making an S2000 cluster converter for all hondas to try and fund my build lol.

Made the fuel computer, this will determine the speed to run the twin aeromotive a1000s, to increase their lifespan and reduce noise;

It has built in fault finding and redundancy

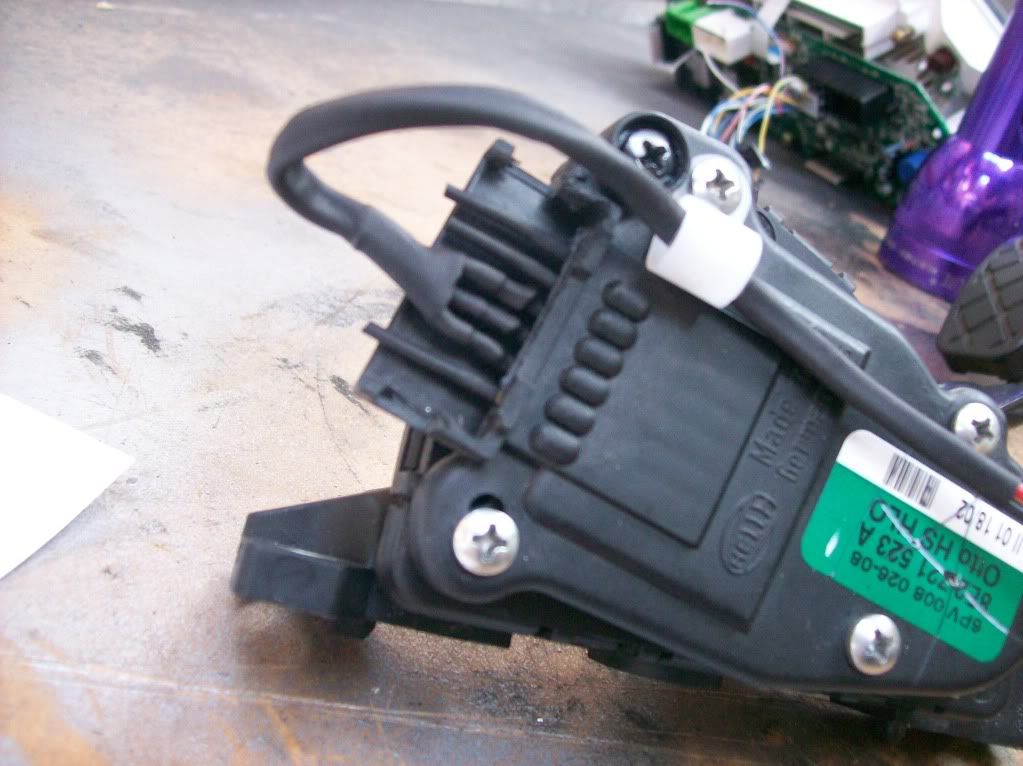

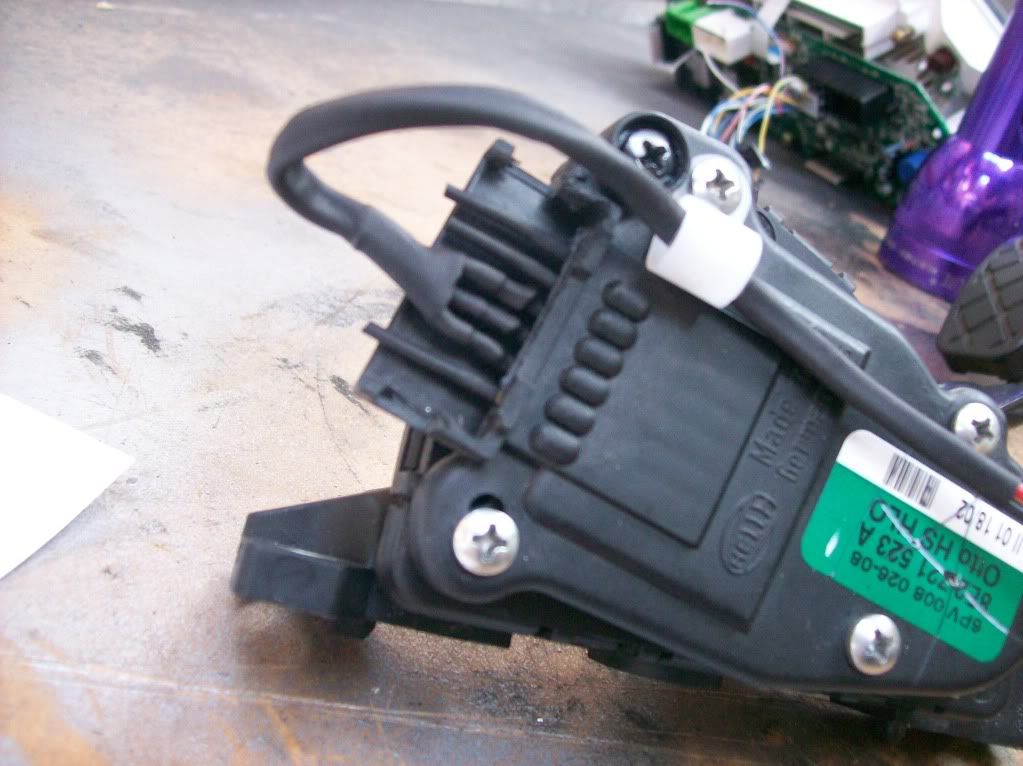

In order to tie in the ALS in the most effective way, do away with the archaic thermo valve, and allow easy adjustment of idle, i made drive by wire for it- which also allowed me to give it cruise control lol

I used an audi throttle pedal for the system;

I also made a computer controlled rear wing. Which can raise and tilt automatically. this will vary the rear downforce and add massive amounts of drag during heavy braking- very much like the bugatti veyron wing.

Not finished yet but here is some deveopment with the drive by wire actuator;

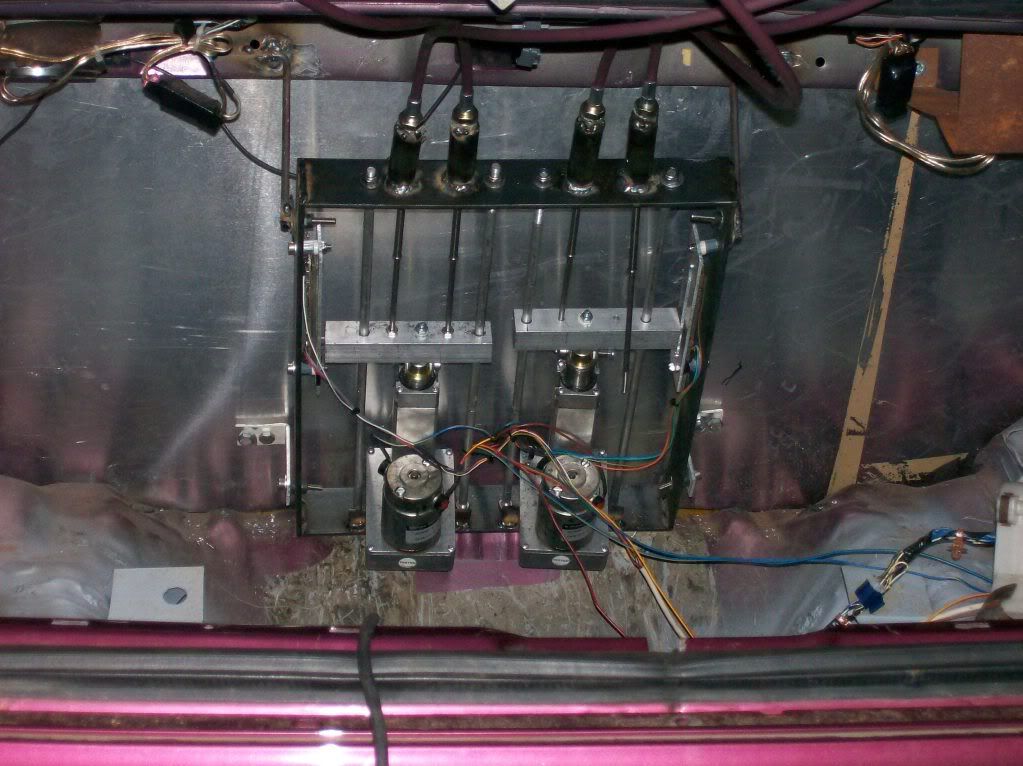

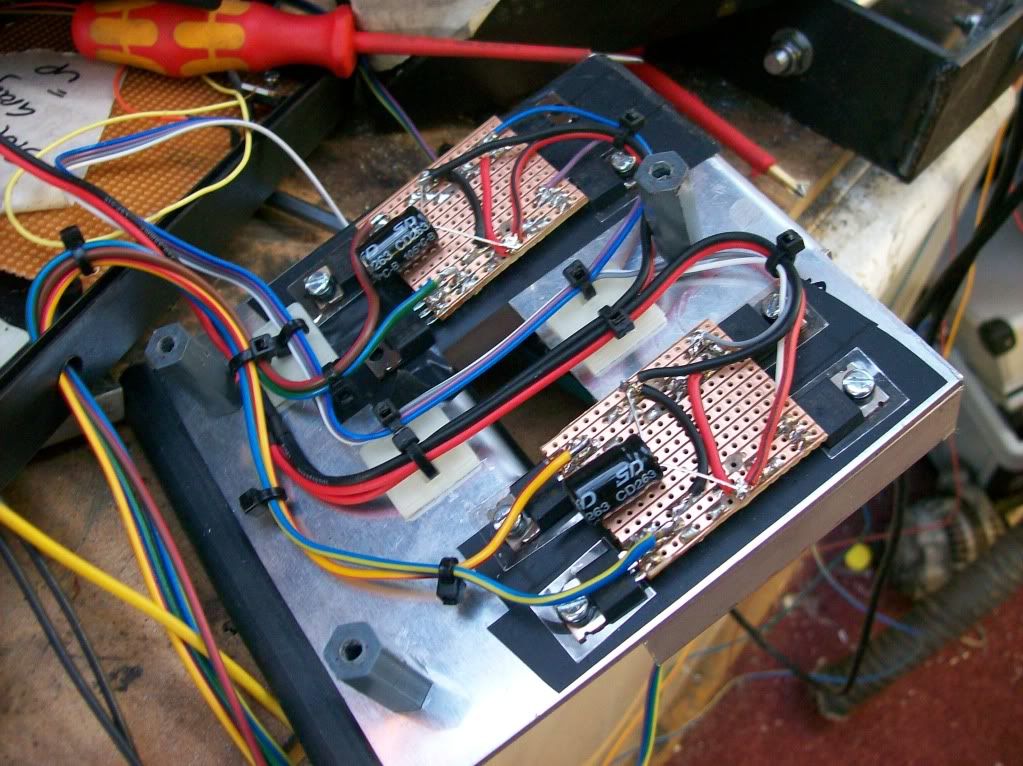

Some stuff on the rear wing actuator computer;

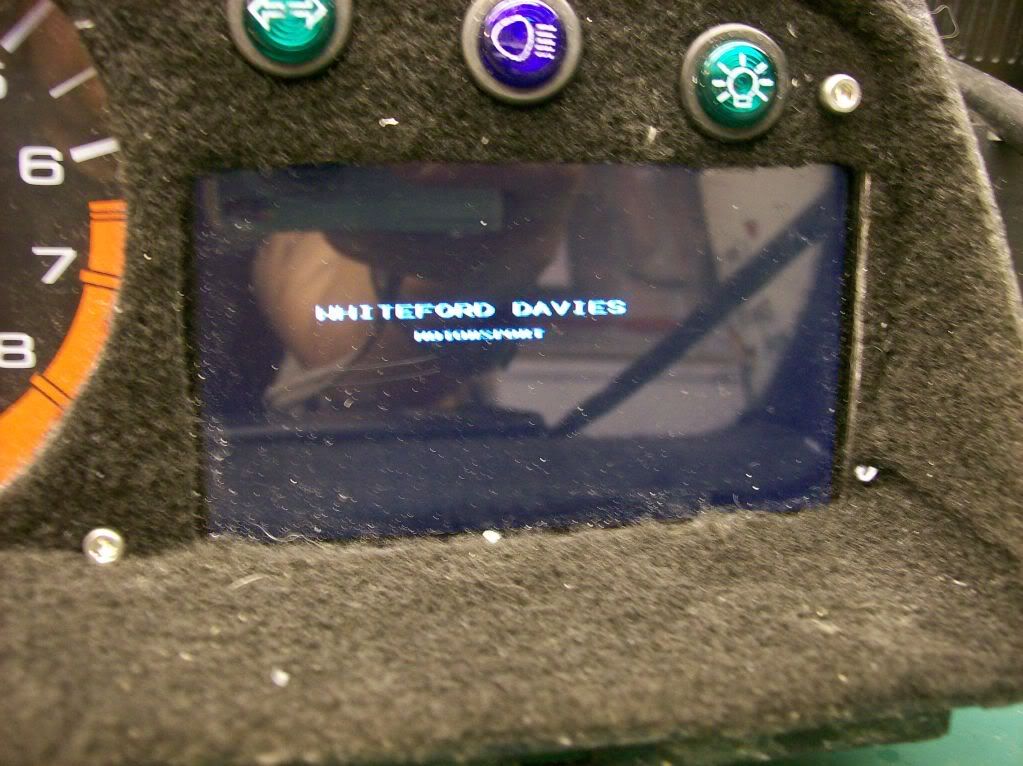

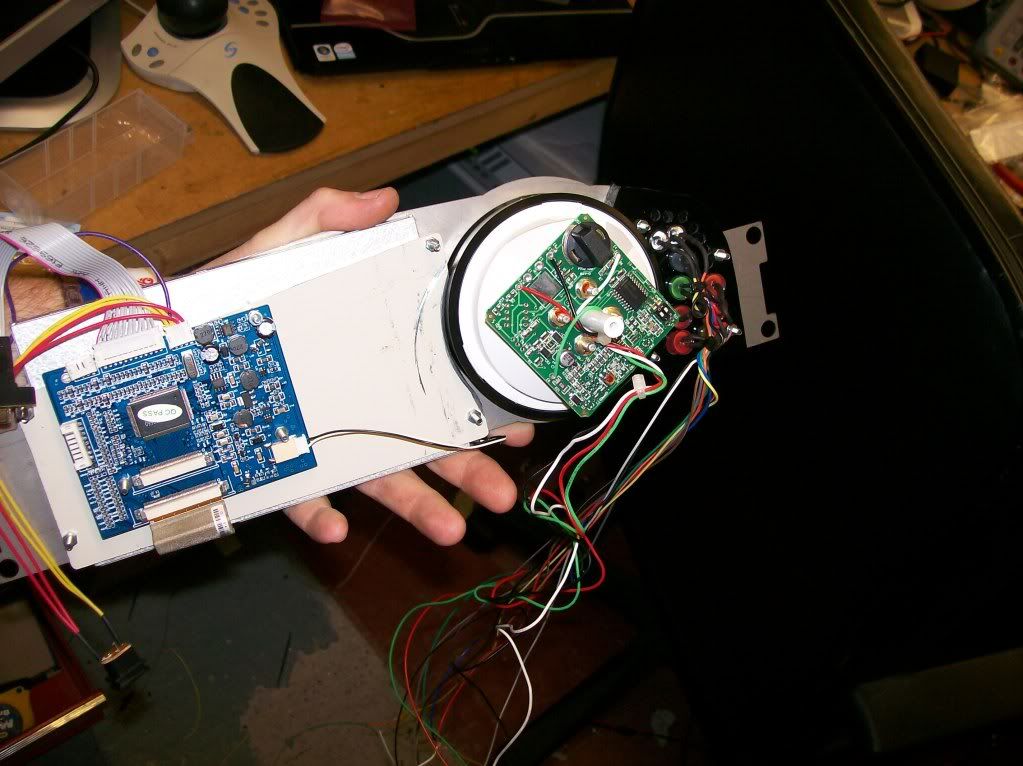

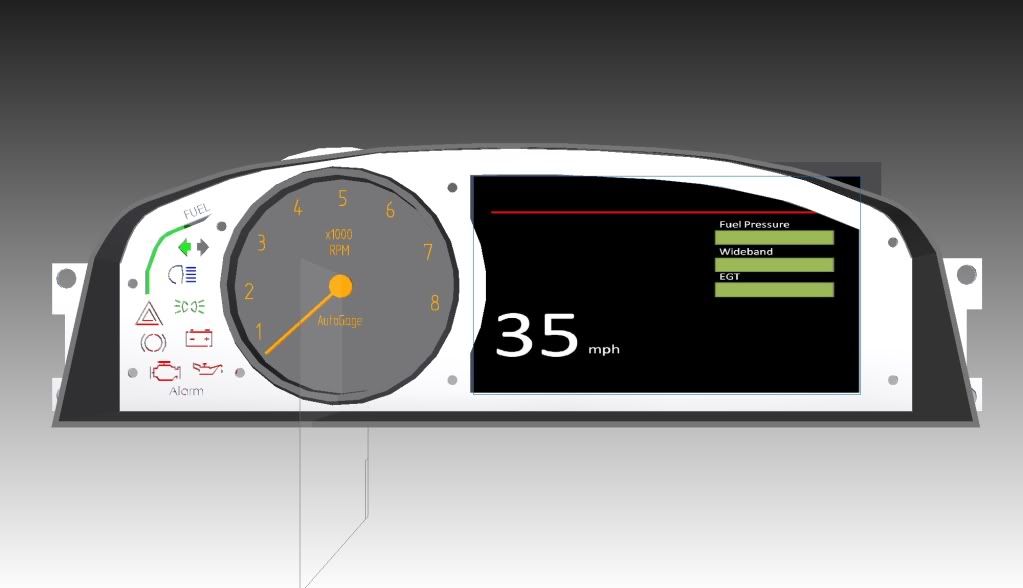

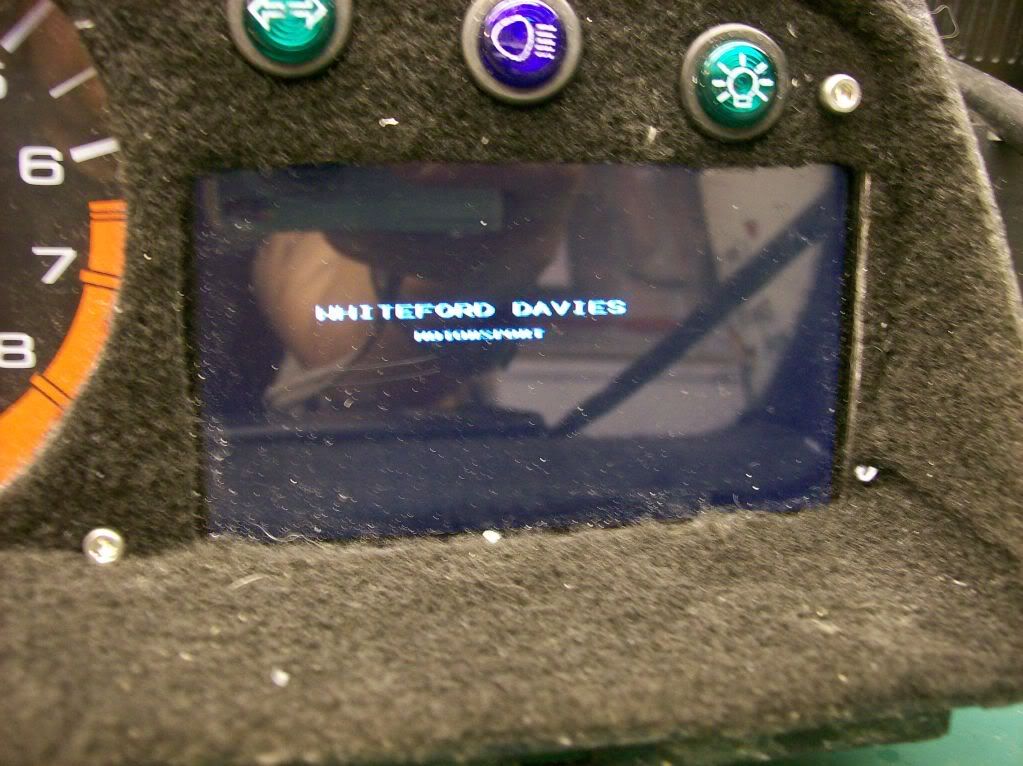

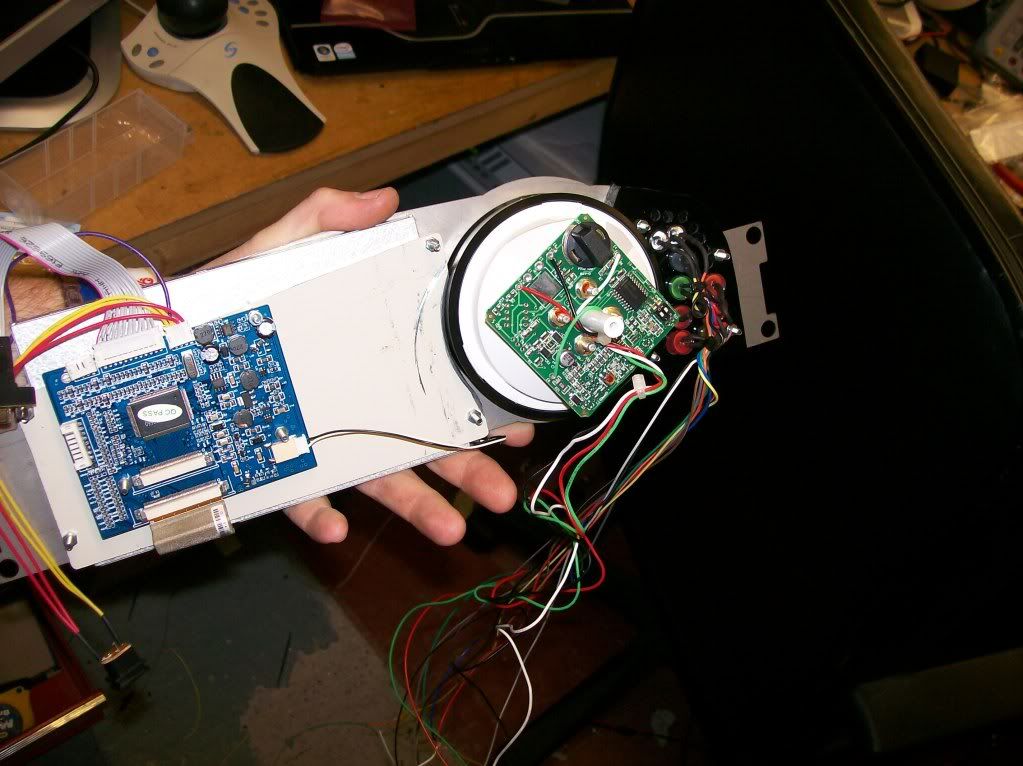

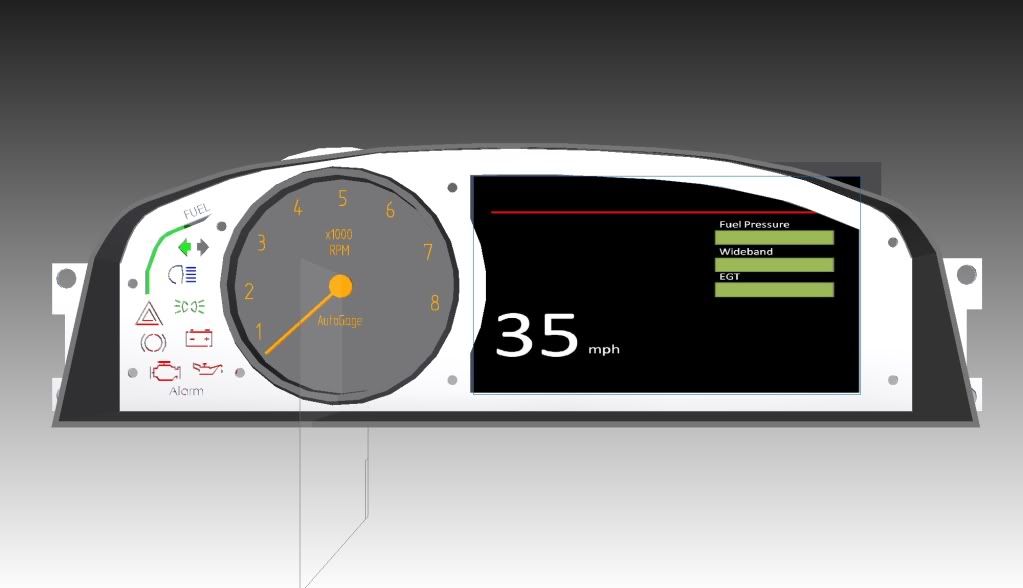

I decided to make my own cluster, using my original rev counter (looks tacky so ill be getting rid) and 2 LCD screens. This will show data on all systems of the car, fuel, cooling, anti lag, wing angles, 4wd .etc

Here is a little video of it testing. Just getting it to speak. The system i designed has voice warings, which will play through the stereo and alert me to anything wrong.

This is on the back burner for the moment as im busy with a few other things.. I can do this when im not doing anything else. Its all software writing so it needs focus..

Made my own steering wheel controls;

As i had to get rid of the Power steering pump to place the turbo, i obtained an MR2 electrohydraulic pump. My first system was manually controlled, but i designed a system to control it and put it in standby when necessary. To do it properly i made and intalled my own steering position sensor using a 10 turn pot and a toothed belt drive;

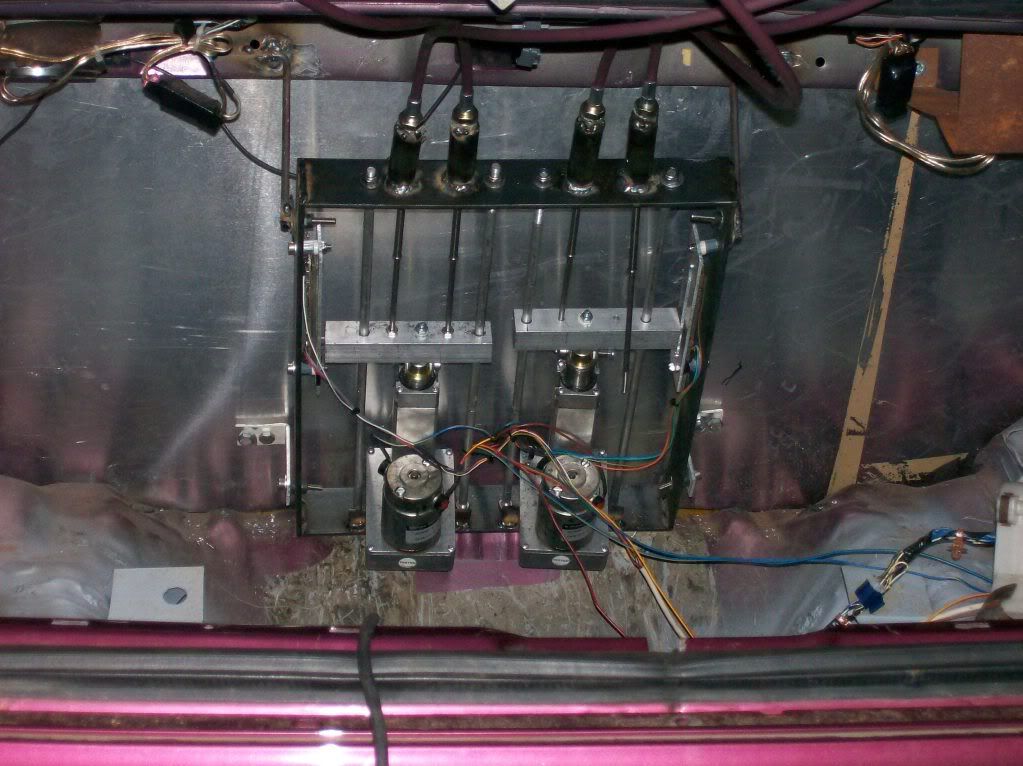

Finished and assembled the rear wing actuator system;

The mounts are currently at the chromer's (for protective coating- not bling lol)

fitted the actuator to the rear firewall.. Wanted to do it before i painted the actuator itself..

Latest engine pics- sorry ive missed a few boring stages;

the toothed wheel is the new timing system. Ive made a converter that allows hondata to use a more accurate 36/1 timing wheel, ive also made another controller that allows any standard (or hondata) ecu to run coil packs. Im using 4 audi 1.8t coil on plugs, which are awesome!

and recently the new and improved anti lag computer. Ive also added a speed limiter system for track days.

To bring the whole build upto date,

Here are some of the pics of testing the rear wing. Under manual control (no computer)

This is the view from the front, shows how much of a restriction the wing will cause when it is in airbrake mode;

I really never wanted to show my ugly mug on my build thread, but unfortunately there isnt any other way..

The latest job;

This is the new dash- to replace the old one- pictured above. I really hated how it came out.. Thanks to my dad for having my design laser cut..

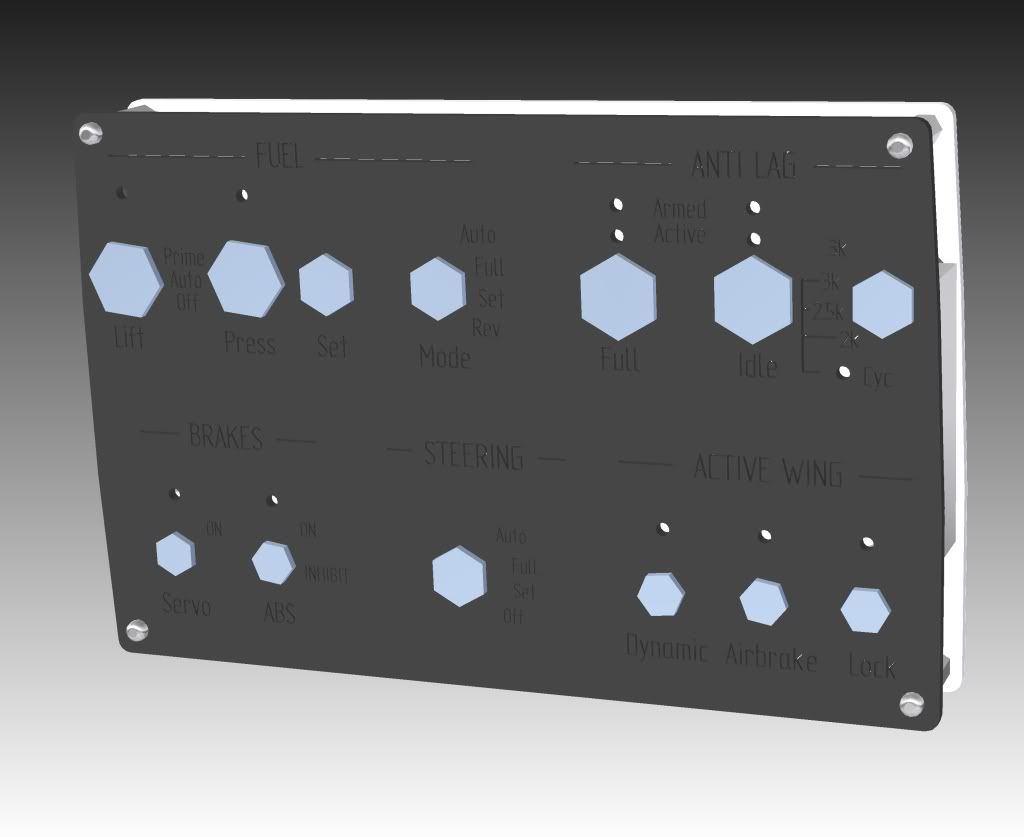

and just for comparison (my original CAD drawing)

At the moment im just tidying a few thngs up, sorting out the custom dash upper panel to move the stereo up (7" screen) closer to the eyeline as the system im making relies on putting essential information on the cluster, but non-essential information on a "paged" display on the stereo..

Recently have managed to finish off a few jobs, but pictures speek a thousand words lol;

Finished the rear wing;

and a small video of me simulating the car speeding up and slowing.. The long pause at the end shows how the fans and PSU turn off after a period when no adjustments are being made..

I am building a computer and using the Skyline R32 ATTESA pump a rather extensive modification of my rear diff clutch actuator, ill be able to precisely control the bias of torque to the rear wheels, i can tie into the ABS sensors, the G sensor (for the rear wing) .etc to finely tune and develop it.. Here is a it of testing on the ATTESA unit;

I know an old civic isnt going to be everyones cup of tea, but I like it lol...

Ive been lurking around here for ages, but i thought i might post the build..

My car isnt blessed with the cosworth / RWD pedigree, so its handling is (and will be) a little different. More akin to a tuned golf R32 / Audi. Where the car is FWD, with a little to the rear, until slip is detected and power is routed further to the rear. Hence it will handle more like a FWD.. Sorry- dont hit me.. If it wasnt for having spent alot of money on my engine, and it rotating backwards compared with most other engines, i would be running an MT75, but alas, im not..

I think pictures speak a thousand words so..

I started my Civic turbo build in 2008, it briefly saw the road before the engine (a stock B16a2) gave up.

I decided at that point to do what i always wanted to do and build a B20VTEC turbo, AWD, time attack inspired EJ2. Hopefully ill be able to compete when the setting up is done.

Those pics were taken as the car saw the road with its turbo running. The bonnet was changed for a new seibon OEM item which has oxidised within an inch of its life- i need to restore it soon..

Ill cut out alot of the boring stuff from my other build thread, its a bit tedious..

I removed all the rear subframe, for the rear drive parts;

For the trailing arms i used civic RTSi ones, modified them to shorten them, boxed them in for strength and modified them to fit the crv wheel bearings.

Had to angle the rear strut tops as the struts will now sit slightly angled to the rear suspension

Made brackets for the rear diff

Installed the radiator and cut open the boot floor to make way for the fuel cell;

Here is the engine, built by laskey racing in the states in late 2010;

Here is teh B16 head, ported to hell.. its a work of art.. even stamped with the portflow ident..

And now for the block;

Thought id stick the dry sump on, unfortunately needed to modify it to fit past the main girdle;

And finally the new driveshafts

Installed the front coolers;

Since i was doing an engineering degree on day release, i got them to let me do my own project. I decided to research turbo lag and build an anti lag system, similar to the proper rally ones;

(the new version is alot better and smaller than this but i had to dumb it down for uni...)

My dog "Garrett" helping me put the engine together;

Got ahold of the electric power folding mirrors, but i had to make a controller for it. I wanted it to properly interface with the alarm .etc

I added some puddle lights to the mirrors as well (just hyper bright 10mm white LEDs);

Crap but it shows in the dark lol

I made a computer to monitor, control and report warnings for all temperatures and pressures in the car. As the radiator is in the boot, fed by small NACA ducts in the sides, at low speeds there is no airflow. THis unit will run the radiator fans at increasing speeds as the car slows to a halt, to ensure the airflow is maintained. This is also done for oil and intercooler fans (intercooler due to anti lag).

Here is the most boring video ever..

I had some projector units knocking around from my wifes trike, so i decided to modify my headlights a little. THose familiar with the escort cosworths will see i quite like the quads with the innter lights removed lol

Made a battery tray for the boot;

and from underneath the car

Seam welded the engine bay, the rest is done but not pictured for some reason;

Cut the holes for the side exit exhausts...

Started making an S2000 cluster converter for all hondas to try and fund my build lol.

Made the fuel computer, this will determine the speed to run the twin aeromotive a1000s, to increase their lifespan and reduce noise;

It has built in fault finding and redundancy

In order to tie in the ALS in the most effective way, do away with the archaic thermo valve, and allow easy adjustment of idle, i made drive by wire for it- which also allowed me to give it cruise control lol

I used an audi throttle pedal for the system;

I also made a computer controlled rear wing. Which can raise and tilt automatically. this will vary the rear downforce and add massive amounts of drag during heavy braking- very much like the bugatti veyron wing.

Not finished yet but here is some deveopment with the drive by wire actuator;

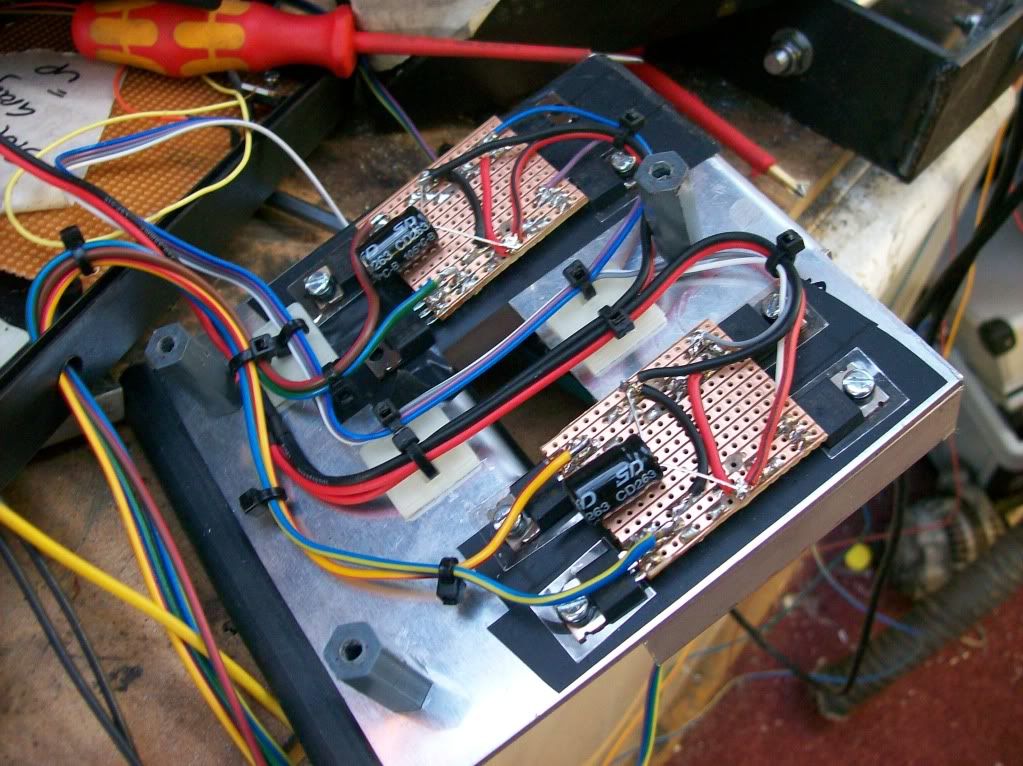

Some stuff on the rear wing actuator computer;

I decided to make my own cluster, using my original rev counter (looks tacky so ill be getting rid) and 2 LCD screens. This will show data on all systems of the car, fuel, cooling, anti lag, wing angles, 4wd .etc

Here is a little video of it testing. Just getting it to speak. The system i designed has voice warings, which will play through the stereo and alert me to anything wrong.

This is on the back burner for the moment as im busy with a few other things.. I can do this when im not doing anything else. Its all software writing so it needs focus..

Made my own steering wheel controls;

As i had to get rid of the Power steering pump to place the turbo, i obtained an MR2 electrohydraulic pump. My first system was manually controlled, but i designed a system to control it and put it in standby when necessary. To do it properly i made and intalled my own steering position sensor using a 10 turn pot and a toothed belt drive;

Finished and assembled the rear wing actuator system;

The mounts are currently at the chromer's (for protective coating- not bling lol)

fitted the actuator to the rear firewall.. Wanted to do it before i painted the actuator itself..

Latest engine pics- sorry ive missed a few boring stages;

the toothed wheel is the new timing system. Ive made a converter that allows hondata to use a more accurate 36/1 timing wheel, ive also made another controller that allows any standard (or hondata) ecu to run coil packs. Im using 4 audi 1.8t coil on plugs, which are awesome!

and recently the new and improved anti lag computer. Ive also added a speed limiter system for track days.

To bring the whole build upto date,

Here are some of the pics of testing the rear wing. Under manual control (no computer)

This is the view from the front, shows how much of a restriction the wing will cause when it is in airbrake mode;

I really never wanted to show my ugly mug on my build thread, but unfortunately there isnt any other way..

The latest job;

This is the new dash- to replace the old one- pictured above. I really hated how it came out.. Thanks to my dad for having my design laser cut..

and just for comparison (my original CAD drawing)

At the moment im just tidying a few thngs up, sorting out the custom dash upper panel to move the stereo up (7" screen) closer to the eyeline as the system im making relies on putting essential information on the cluster, but non-essential information on a "paged" display on the stereo..

Recently have managed to finish off a few jobs, but pictures speek a thousand words lol;

Finished the rear wing;

and a small video of me simulating the car speeding up and slowing.. The long pause at the end shows how the fans and PSU turn off after a period when no adjustments are being made..

I am building a computer and using the Skyline R32 ATTESA pump a rather extensive modification of my rear diff clutch actuator, ill be able to precisely control the bias of torque to the rear wheels, i can tie into the ABS sensors, the G sensor (for the rear wing) .etc to finely tune and develop it.. Here is a it of testing on the ATTESA unit;

I know an old civic isnt going to be everyones cup of tea, but I like it lol...

Wow that was rather positive- thanks very much chaps..

I can see why some wouldnt like the 4wd, to be honest its a weird one.. The handling of the car will be set up as a front wheel drive, as its only part time.. I can also understand the wing, its based on the wing which aeromotions in the states developed.. It should be interesting, especially if i can swap the aerofoil for a more aerodynamically specific one..

The ETC point is actually rather valid. Most of my items have redundancy built in, this however doesnt.. Ill incorporate an override switch onto the lower control console..

Ive been using OTS where possible, the only reason i havnt done it with this is that the throttle and inlet was a prototype from hypertune in OZ, but they never put it into production.. This method saved me having to disrupt the tidy inlet airflow.. It should be pretty bulletproof..

Thanks again chaps!

I can see why some wouldnt like the 4wd, to be honest its a weird one.. The handling of the car will be set up as a front wheel drive, as its only part time.. I can also understand the wing, its based on the wing which aeromotions in the states developed.. It should be interesting, especially if i can swap the aerofoil for a more aerodynamically specific one..

The ETC point is actually rather valid. Most of my items have redundancy built in, this however doesnt.. Ill incorporate an override switch onto the lower control console..

Ive been using OTS where possible, the only reason i havnt done it with this is that the throttle and inlet was a prototype from hypertune in OZ, but they never put it into production.. This method saved me having to disrupt the tidy inlet airflow.. It should be pretty bulletproof..

Thanks again chaps!

Edited by purplecivicturbo on Wednesday 11th January 23:38

Not a chance mate, lol, i love the colour.. Its either that or skyline midnight purple 3..

I know what you mean about the layout, i would also prefer not to see the tree that killed me.. The main reason for the choice is the fact i spent quite alot of time on the engine before the awd idea.. Because the engine runs backwards, im limited by the choice of transmissions..

Day to day i work in military aircraft avionics..

I know what you mean about the layout, i would also prefer not to see the tree that killed me.. The main reason for the choice is the fact i spent quite alot of time on the engine before the awd idea.. Because the engine runs backwards, im limited by the choice of transmissions..

Day to day i work in military aircraft avionics..

neiljohnson said:

Will be a bit mental when its done, have you upgraded the internals of the rear diff?? they fail on stock crv's so i would imagine it wont last long once yours is putting a lot more power through it.

Its going to be a learning curve, as its never been done like this before, so ill just have to wait and see..

snowmuncher said:

awesome stuff dude

I've moved from a 40% front, 60% rear (ford drivetrain), to 50/50 (Peugeot & Subaru), and now on 'variable' 60% front 40% rear (Haldex).

TBH, in its standard format Haldex isn't that good (too slow and unpredictable). A more aggressive Blue controller (engages clutch based on throttle response as well as slip sensors) and front & rear transverse ATB diff's fixed that.

Being a Honda I bet you've got a much better selection of diffs to choose from, including race-proven plate/grippers.

It's now much better at agility/rally style work than my previous cars (95% of its use). Disengagement of power to rear during braking is very handy too, no "torsen oversteer".

Much much better in the snow & ice, particularly on steep descents.

ps

Garrett's a very patient looking hound !

Thats quite interesting information mate.. I can pretty much use any data from the car i want to drive the torque split.. Im going to connect pretty much everything to it, then i have the choice when i program it.. Ill have to see how i can get it to shape up, do you know what the difference is with the upgraded Haldex controller over the standard one..

I've moved from a 40% front, 60% rear (ford drivetrain), to 50/50 (Peugeot & Subaru), and now on 'variable' 60% front 40% rear (Haldex).

TBH, in its standard format Haldex isn't that good (too slow and unpredictable). A more aggressive Blue controller (engages clutch based on throttle response as well as slip sensors) and front & rear transverse ATB diff's fixed that.

Being a Honda I bet you've got a much better selection of diffs to choose from, including race-proven plate/grippers.

It's now much better at agility/rally style work than my previous cars (95% of its use). Disengagement of power to rear during braking is very handy too, no "torsen oversteer".

Much much better in the snow & ice, particularly on steep descents.

ps

Garrett's a very patient looking hound !

Garrett is pretty patient, to a limit.. He isnt afraid of windy drills either which is great..

Thanks Kieran, its been a while coming..

Thanks alot as well chaps.. Its not as bonkers as i wish it could have been.. i was going to put the engine in the back with drive to the front wheels.. Id still love to..

Ahh that is awesome.. At the moment im just using open diffs.. I can deal with the custom / modified diffs when the car is driving..

I havnt seen many people who could tell me either way if spending the money on Helical / ATB diffs actually made a difference.. You sir have just swayed me.. Itll still have to wait but its something i can start looking into..

I havnt seen many people who could tell me either way if spending the money on Helical / ATB diffs actually made a difference.. You sir have just swayed me.. Itll still have to wait but its something i can start looking into..

Thanks chaps..

Nah, i could never do the sleeper look.. Plus, the side exit exhausts are there because the rear driveshafts make it too cramped..

Im going to be installing a front wind splitter and possibly a basic rear diffuser once its done, its going to look more time attack inspired than anything else.. Depending on how it turns out, i may even enter it..

The anti lag is similar to the older anti lag systems. It retards the ignition, increases the fuel and opens the electronic throttle. That will move the combustion out into the manifold area.. I was thinking about the modern systems with direct air injection but it would end up very expensive..

I know it will drastically shorten the life of the turbo but it will hardly be used, and only on track at that..

Nah, i could never do the sleeper look.. Plus, the side exit exhausts are there because the rear driveshafts make it too cramped..

Im going to be installing a front wind splitter and possibly a basic rear diffuser once its done, its going to look more time attack inspired than anything else.. Depending on how it turns out, i may even enter it..

The anti lag is similar to the older anti lag systems. It retards the ignition, increases the fuel and opens the electronic throttle. That will move the combustion out into the manifold area.. I was thinking about the modern systems with direct air injection but it would end up very expensive..

I know it will drastically shorten the life of the turbo but it will hardly be used, and only on track at that..

Not at all mate- constructive criticism is more than welcomed..

I know what youre saying, i believe i have dealt with it all properly..

Some of the pictures ive used dont really show the full story as they were mid-points through the build..

I think its probably better if i answer in bullets...

1. The big caps on the H-bridges. They have all been secured now, there wasnt much point at the early stages as i was changing components regularly.. Now they are firmly attached with the cunning use of sticky backed pads and locking wire..

2. All the additional electronics are mounted (besides the wing controller) on a large ali panel under the passenger carpet. They are on 4 large rubber shock absorbing mounts. That should hopefully take away the damaging high frequency stuff.. All the other heavier components, will be firmly attached, many of them with potting compound. I have no idea if- when i turn it on initially whether it will all work- it most likely wont.. So i dont want to make anything too permanent at this stage..

3. The power steering. I ran the hydraulic / electric power steering system on the car before i took it off the road the first time. It had 6 months of daily use where i was able to work out exactly how to run the pump and when it needed extra juice- such as manoeuvring and emergencies as you said. Im quite confident in this design, especially as the pump itself is out of an MR2, so its simply the electronics which are "new".

4. The power steering system steering position sensor. Youre quite correct that this could be a weak point, i have built in some redundancy.. The belt itself is toothed, so it cant slip. In case of a sensor failure, or other input failure, an error signal is sent to the dashboard computer which will display a warning and announce it with a voice. There are dashboard controls which allow me to select the steering mode between; Auto, Full, Set, OFF, Reversionary- the latter being simply to bypass the control computer by closing a large relay and running the pump at 100%.

5. Use of veroboard.. It isnt something i really wanted to use. Plus as you said about the neatness, i have concerns about adding too many uncessary "jumpers" to move connections to the outside edges as its adding another source of failure.. I do have a PCB etching tank and equipment, when all this is done and the car fires up and i weed out all the bugs, ill be using a single layer PCB to replace ALL the veroboard in the safety critical systems.

6. Every safety critical system (until yesterday with the exception of the electronic throttle) has a backup, or safety mode. This would either be to run it to 100% in the case of fuel pumps, power steering, cooling fans, brake vacuum pump .etc or to shut it off entirely. Centrally, the display and voice warning system will alert me to any fault which doesnt inhibit the CPU in question's ability to flag a discrete error signal (5v direct line). Only in the event of a rare double failure would the system fail to tell me of a fault.

On the mention of the welding, my original work was piss poor- i had only just started out. I revisited the really bad stuff. Most of the rest is simply not as tidy as it should be- but it isnt a safety concern.. I honestly wouldnt be happy with it if i wasnt totally happy it was safe.. And i certainly wouldnt allow my wife or friends .etc into the car until im happy with its shakedowns..

Please, if there are any others with constructive criticism please speak up. I honestly appreciate anything people have to say.. To me thats the best thing about a forum- hundreds of "second pair's of eyes"..

Thanks for all your comments everyone..

I know what youre saying, i believe i have dealt with it all properly..

Some of the pictures ive used dont really show the full story as they were mid-points through the build..

I think its probably better if i answer in bullets...

1. The big caps on the H-bridges. They have all been secured now, there wasnt much point at the early stages as i was changing components regularly.. Now they are firmly attached with the cunning use of sticky backed pads and locking wire..

2. All the additional electronics are mounted (besides the wing controller) on a large ali panel under the passenger carpet. They are on 4 large rubber shock absorbing mounts. That should hopefully take away the damaging high frequency stuff.. All the other heavier components, will be firmly attached, many of them with potting compound. I have no idea if- when i turn it on initially whether it will all work- it most likely wont.. So i dont want to make anything too permanent at this stage..

3. The power steering. I ran the hydraulic / electric power steering system on the car before i took it off the road the first time. It had 6 months of daily use where i was able to work out exactly how to run the pump and when it needed extra juice- such as manoeuvring and emergencies as you said. Im quite confident in this design, especially as the pump itself is out of an MR2, so its simply the electronics which are "new".

4. The power steering system steering position sensor. Youre quite correct that this could be a weak point, i have built in some redundancy.. The belt itself is toothed, so it cant slip. In case of a sensor failure, or other input failure, an error signal is sent to the dashboard computer which will display a warning and announce it with a voice. There are dashboard controls which allow me to select the steering mode between; Auto, Full, Set, OFF, Reversionary- the latter being simply to bypass the control computer by closing a large relay and running the pump at 100%.

5. Use of veroboard.. It isnt something i really wanted to use. Plus as you said about the neatness, i have concerns about adding too many uncessary "jumpers" to move connections to the outside edges as its adding another source of failure.. I do have a PCB etching tank and equipment, when all this is done and the car fires up and i weed out all the bugs, ill be using a single layer PCB to replace ALL the veroboard in the safety critical systems.

6. Every safety critical system (until yesterday with the exception of the electronic throttle) has a backup, or safety mode. This would either be to run it to 100% in the case of fuel pumps, power steering, cooling fans, brake vacuum pump .etc or to shut it off entirely. Centrally, the display and voice warning system will alert me to any fault which doesnt inhibit the CPU in question's ability to flag a discrete error signal (5v direct line). Only in the event of a rare double failure would the system fail to tell me of a fault.

On the mention of the welding, my original work was piss poor- i had only just started out. I revisited the really bad stuff. Most of the rest is simply not as tidy as it should be- but it isnt a safety concern.. I honestly wouldnt be happy with it if i wasnt totally happy it was safe.. And i certainly wouldnt allow my wife or friends .etc into the car until im happy with its shakedowns..

Please, if there are any others with constructive criticism please speak up. I honestly appreciate anything people have to say.. To me thats the best thing about a forum- hundreds of "second pair's of eyes"..

Thanks for all your comments everyone..

PaulG40 said:

It's an awesome project you've got going! But that's a fair amount of control boxes (and extra weight?) you've got, have you thought about making a proper 'green' pcb, smaller components rather than the mass of 'big' wires, etc and with it all integrated into one board. Working in AVionics, you should be able to get hold of the mini components and smaller gauge wire (like raychem 55?) then you should be able to create something fairly compact?

Keep up the good work!

Thanks mate.. The control boxes themselves arent heavy at all.. If you think about it, even a skyline has separate control units for the various functions..Keep up the good work!

This - agreeably has more than it needs.. At the moment that is simply just for prototyping.. Once the car is on the road, ill probably replace it all with a couple of boxes like the one for my new drive by wire.. It is aluminium with slots inside, you can stack boards rather effectively.. Im contemplating combining at least the anti lag and drive by wire into the same box when i sort out PCBs.. I just want to iron out any problems before i go splashing out on either equipment or one-off production (not cheap) of PCBs..

I know the Civic has alot of stigma against it, i suppose that was one of the problems of getting into cars when i did.. Was my 3rd car and before long, i had done too much to stop lol

Thanks again for all the positive comments chaps!

STash07 said:

Love it!!! Great project you have there, can't wait for updates and to see this finished and running

Just out of curiosity how long has it taken to get to this stage?

Me too mate- its been too long since i last drove it.. Its taken 18 months to get to this stage.. The major restriction now is the cost of the respray. Apart from little bits like the wheels, engine mounts, plumbing and the main wiring, there isnt much left to buy..

Just out of curiosity how long has it taken to get to this stage?

If you dont mind me asking mate, what are you driving?? Im hoping to get more than 1k out of the gearbox through..

Ive been contemplating modifying the skyline clutch servo to work.. That will make my twin plate exedy lighter.. But as with you, itll be very very rarely driven on the road..

Ive been contemplating modifying the skyline clutch servo to work.. That will make my twin plate exedy lighter.. But as with you, itll be very very rarely driven on the road..

Thanks mate

I agree- for all out performance, without a doubt, light weight and simple.. But ive done that.. I found i never drove the car lol.. Why drive a noisy fuel guzzling car thats noisy and always damp lol, when you have an audi with heated seats lol..

This time i decided to add some comfort back into it- at least then id be able to justify using more.. Not just for trackdays..

I agree- for all out performance, without a doubt, light weight and simple.. But ive done that.. I found i never drove the car lol.. Why drive a noisy fuel guzzling car thats noisy and always damp lol, when you have an audi with heated seats lol..

This time i decided to add some comfort back into it- at least then id be able to justify using more.. Not just for trackdays..

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff