John sc chimaera upgrades

Discussion

Just a heads up at this stage while the cerb is at the rollcentre nicks chim is coming back in the workshop for some upgrade work namely water injection courtesy of aquamist then fit the intatrim seats properly fit a front brake linelock for the quarter mile stuff and if time before shakey a new flywheel clutch unit,will all be well documented on here with pics to iluustrate the work.

John

John

a start has been made car out off trailer jacked up for work to begin sorted all the water injection stuff just got to fit it all now clutch and flywheel ordered so should all be good for shakey.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickronly got half a day on the chim but progressing nicely with getting the gearbox out, rear arb off, exhaust off, gearbox mounting off, centre console out, gearstick off, slave cylinder off, also got the top off the dash ready for the water injection gauge and wiring and all but the top bellhousing bolts out so out easily in the morning.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on FlickrEdited by Engineer1949 on Wednesday 25th February 18:52

clutch foot pressure will be about the same as standard the real advantage is the triple plates lots of surface area and terrific heat dissipation qualities, below is a pic of the new flywheel looks almost to good to use clutch itself will be here next week but been getting on with refitting the sump with new better quality crucifix seals and starting on the water injection install, i have run the pipe from boot to engine bay although not clipped up yet and sorted how all the wiring will connect and run the line lock turned up pm as well looks a nice unit.

sorry about the missing pics they are there if you click the link anyone got any ideas on a reliable photo host just about had enough of flikr

john

[

sorry about the missing pics they are there if you click the link anyone got any ideas on a reliable photo host just about had enough of flikr

john

[

Edited by Engineer1949 on Tuesday 3rd March 07:40

another day at the tvr mill got the trigger wheel for the speed sensor tiged up had to reduce the slots by half as the dash pro didnt like the multi slot trigger on the prop shaft went a bit mad after 100mph so needed to get that done and repainted ready to go back on monday tuesday , also finally tightened up the sump bolts fitted the flywheel and sorted the clutch need to make a top hat bush for the release bearing carrier to fit the new 40mm i.d. bearing so coming along nicely

n.b. i need a gearbox first motion shaft as the triple plate clutch has to not only be lined up but have all the splines in line as well best route is an old gearbox first motion shaft so anyone got one to lend sell or let me steal???

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

n.b. i need a gearbox first motion shaft as the triple plate clutch has to not only be lined up but have all the splines in line as well best route is an old gearbox first motion shaft so anyone got one to lend sell or let me steal???

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickrgot a fair amount done yesterday turned up a spacer to allow the new release bearing to fit the original carrier then shrunk it on, then built up the water injection valve and fitted that near to the injection point plus drilled and loctited in the nozzle carrier into the feed from intercooler to plenum plus figured out a route for wiring from dash to valve sensors etc and got the bases fitted to the back of the tank for the pump and water tank i also fitted the dash mounted gauge for the system and made some more turrets to mount the tank only came with two seemed a bit wobbly,all in all not a bad day.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickrnot so much on the car today but got my new toy fixed up and running i bought a secondhand DRO for my lathe its off a mill but does the same thing very good so much easier specially with my not quite so good eyes,but managed to get the clutch all nicely located on the flywheel gearbox in tomorrow

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on FlickrDerek as far as i could make out the mc cloud fits to the original flywheel i know you could have a light one built to put the mc cloud on but then it would need sending for balancing etc. But superclutch and ttv work together to supply a complete package and it is very light with little periferal weight so very good pickup faster changes etc. Time will tell but i think it will be good the only down side is as there are no driven plate damping the gearbox will probably rattle at tickover maybe not to everyones liking.

John

John

Gearbox and drivetrain back in plus now sourced the required master and slave cylinders to get the correct throw on the clutch just got to build a clutch stop to make absolutly sure there is no chance off over acting the the clutch spring so a way to go yet but on the right track

John

John

Gearbox and drivetrain back in plus now sourced the required master and slave cylinders to get the correct throw on the clutch just got to build a clutch stop to make absolutly sure there is no chance off over acting the the clutch spring so a way to go yet but on the right track

John

John

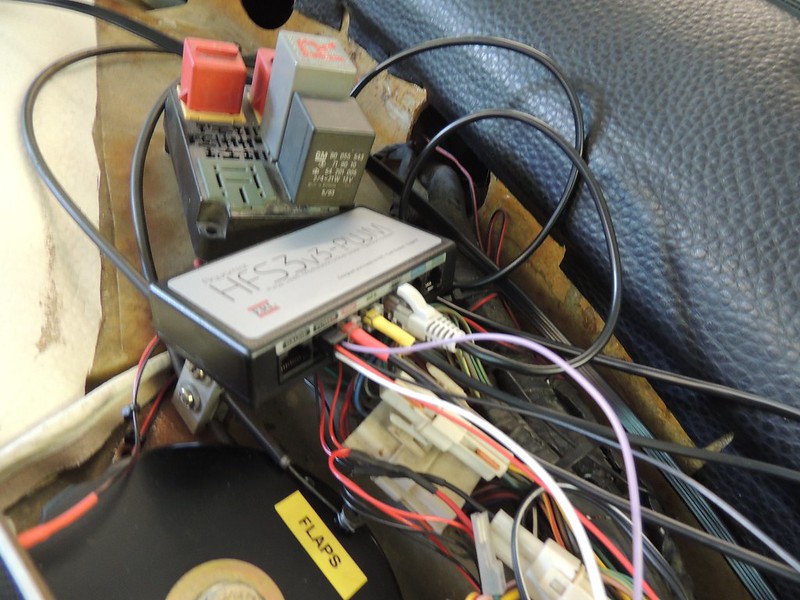

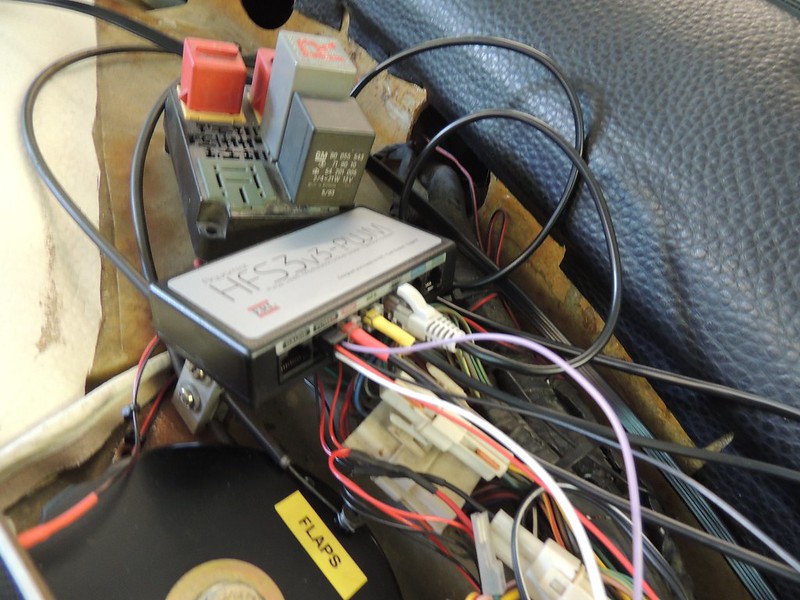

been at the wiring again today got all the wires and multi cores into place some have been fitted into conduit and clipped in place some are waiting for tomorrow to come, the wiring for the line locks is also moused through so lots of terminating to come, i am going to use the button in centre of the door opener for the lock as its the only available place which is easily in reach when clamped tight in the harness unless anyone one has a better idea?.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickrbeen at the wiring again today got all the wires and multi cores into place some have been fitted into conduit and clipped in place some are waiting for tomorrow to come, the wiring for the line locks is also moused through so lots of terminating to come, i am going to use the button in centre of the door opener for the lock as its the only available place which is easily in reach when clamped tight in the harness unless anyone one has a better idea?.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickrbit more done to chim wiring now complete although needs tidying tank and pump in place and plumbed up line lock wiring all in and working the toggle switch is a master override to energise the locks button in door opener operates the locks press and hold to lock release to unlock.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

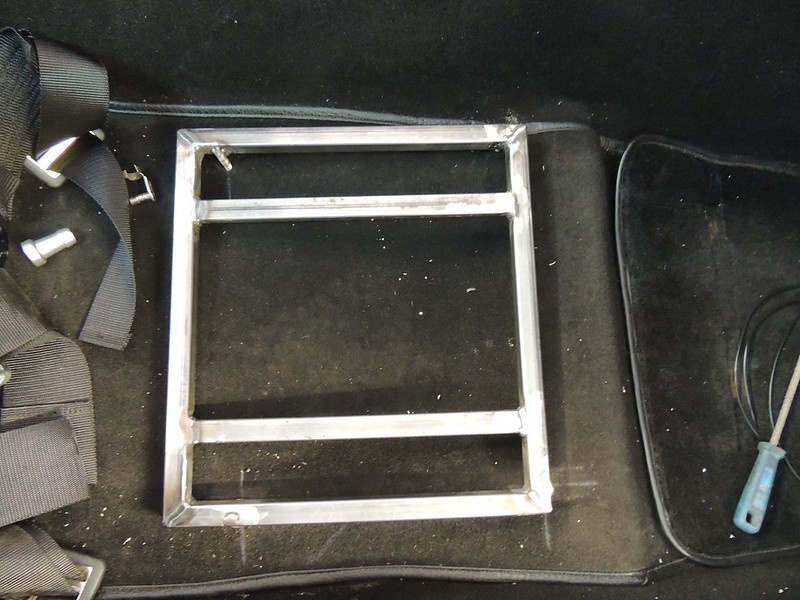

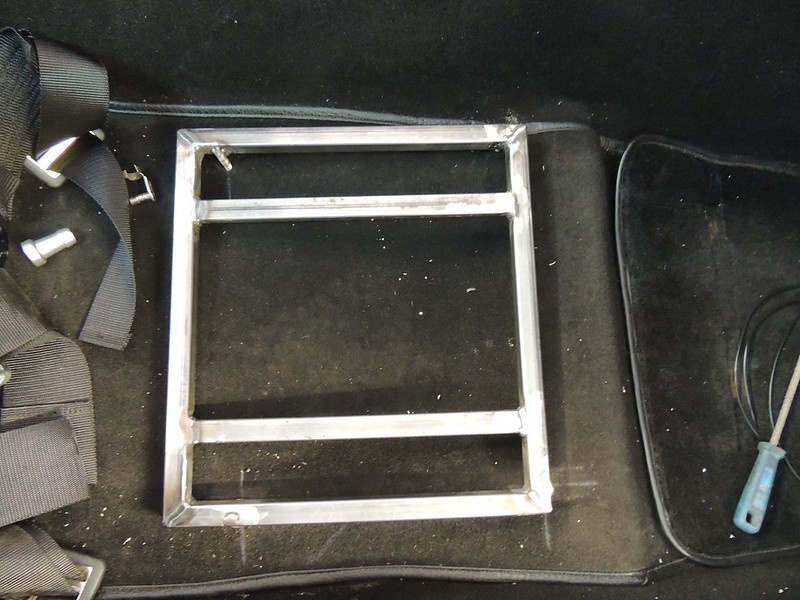

Untitled by brundallmotorsport, on Flickras i am waiting for some parts for the line lock i have been getting on with the seat bases i have made the drivers adjustable the passenger will be fixed but nice light firm base for the bucket seats.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickrclutch all now operational not without a few problems on the way first is the new master cyl is 3/16th pipe and fitting the new slave is still 1/4in but with a unf fitting so i made a little fitting one end 3/16th one end 1/4in then silver soldered the respective pipes into the fitting new swaged ends and hey presto a complete system ,master all fitted fine used the old clevis with a new pin suprising the wear on the old one ,the new master is not integral with the resevoir so a remote resevoir has been fitted on the passengers side and piped across and into the inner wing all looks neat and tidy the action now that i have the correct hydraulic advantage is very smooth and supprisingly light so the rest of the engine is back together run it up tomorrow and set up the water injection.

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

IMG_0527_2 by brundallmotorsport, on Flickr

IMG_0527_2 by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr

john

Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on Flickr IMG_0527_2 by brundallmotorsport, on Flickr

IMG_0527_2 by brundallmotorsport, on Flickr Untitled by brundallmotorsport, on Flickr

Untitled by brundallmotorsport, on FlickrGassing Station | Chimaera | Top of Page | What's New | My Stuff