here we go again

Discussion

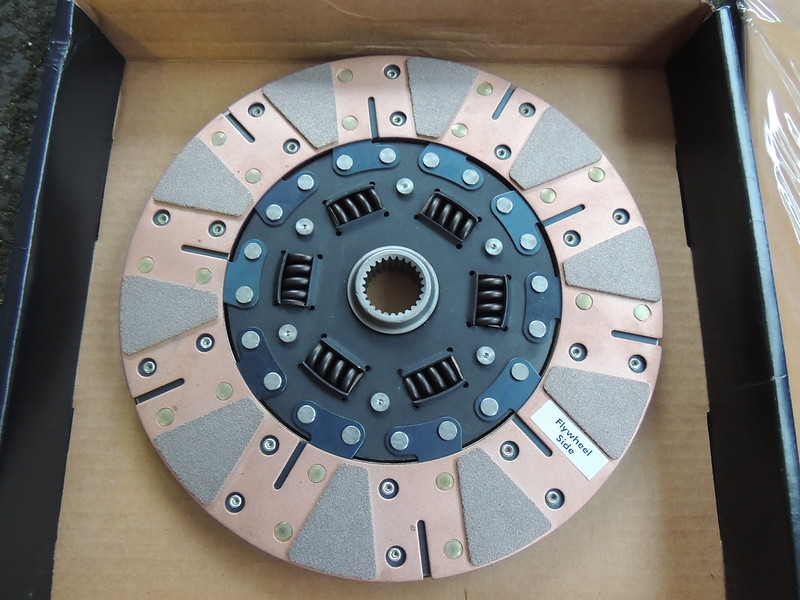

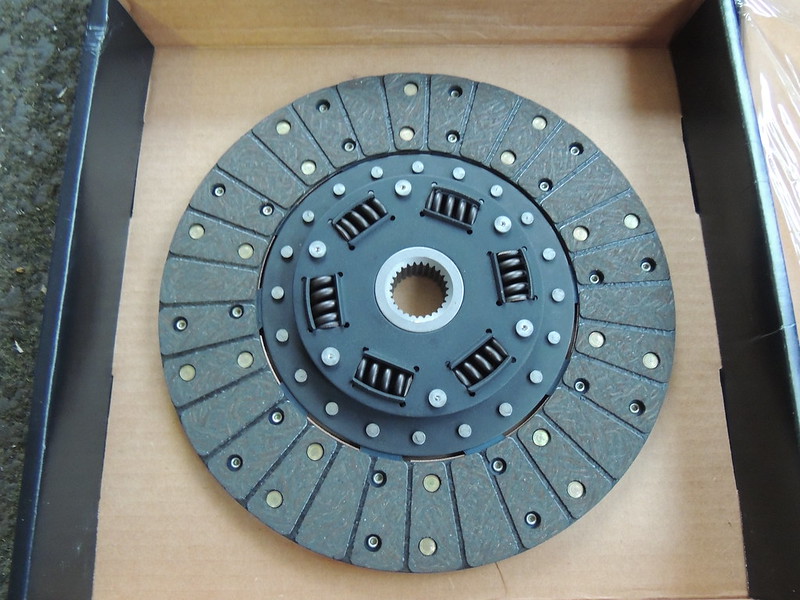

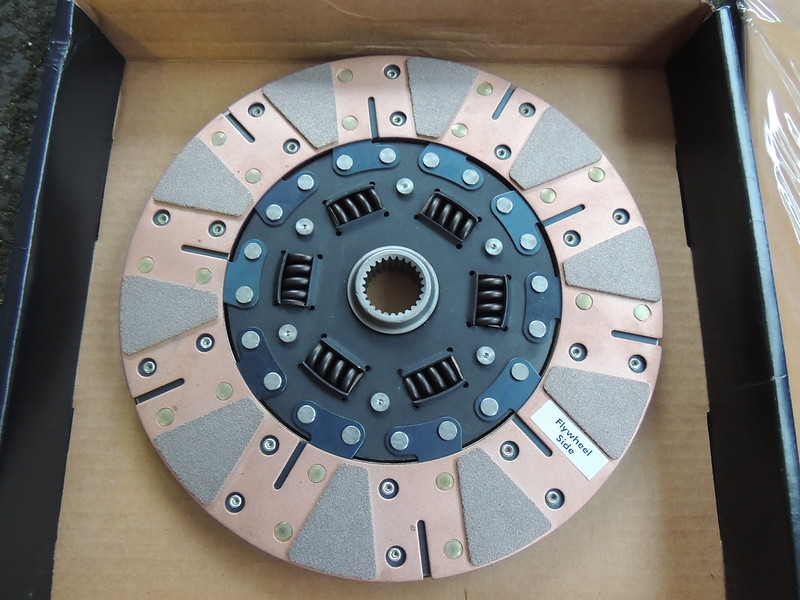

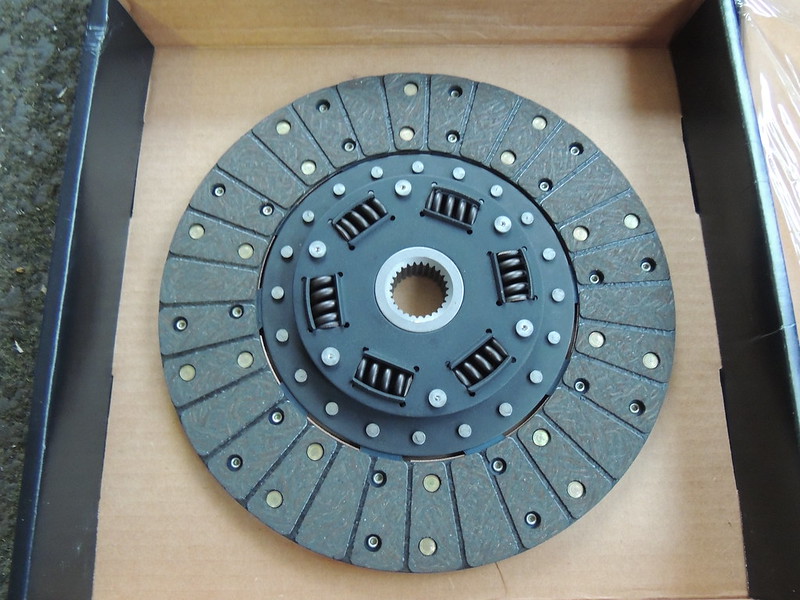

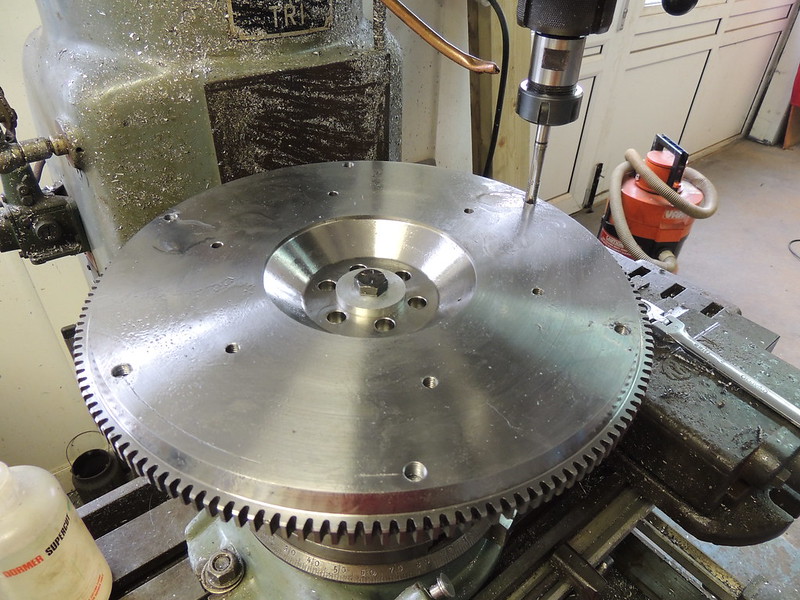

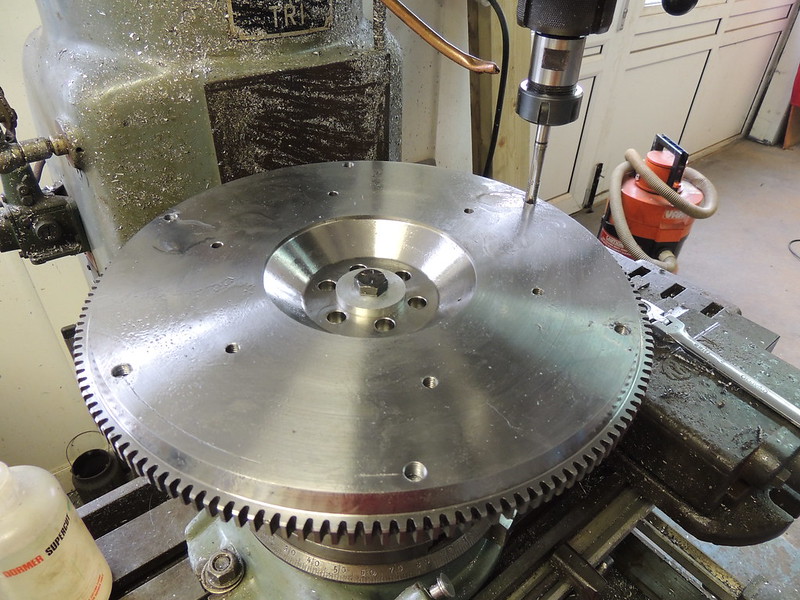

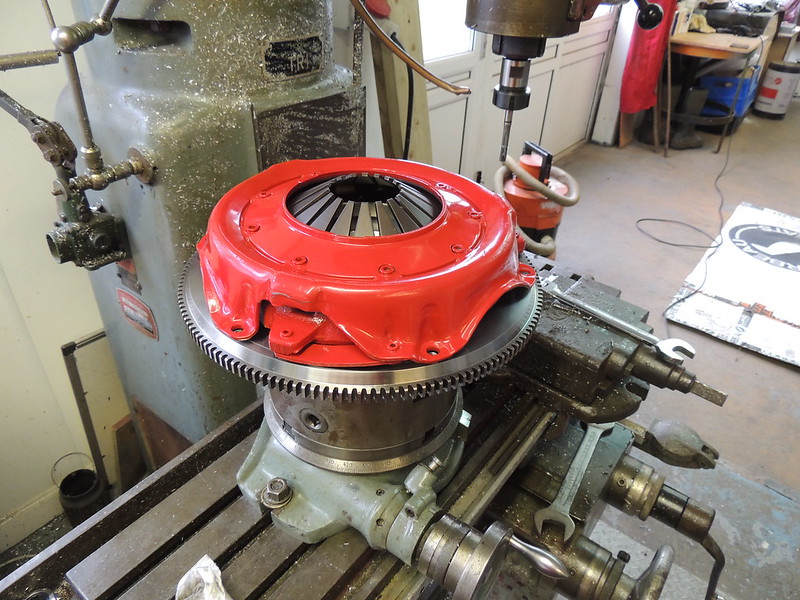

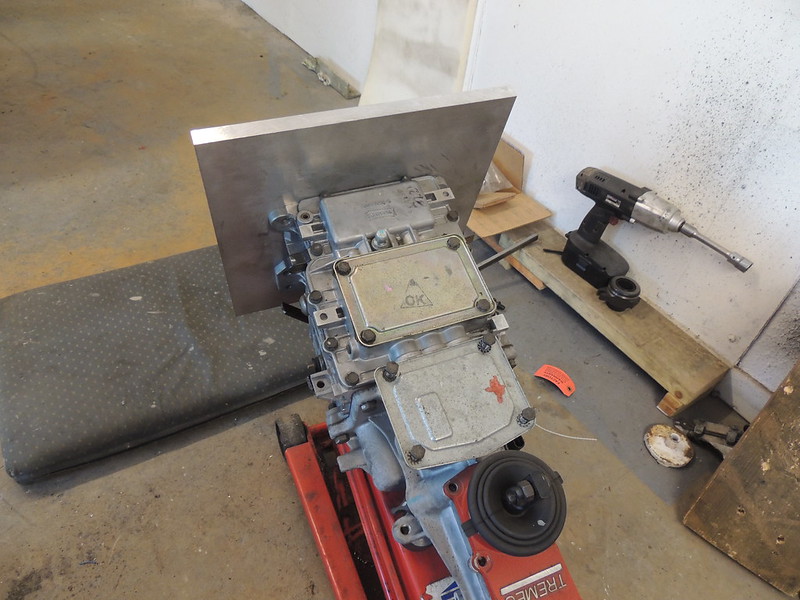

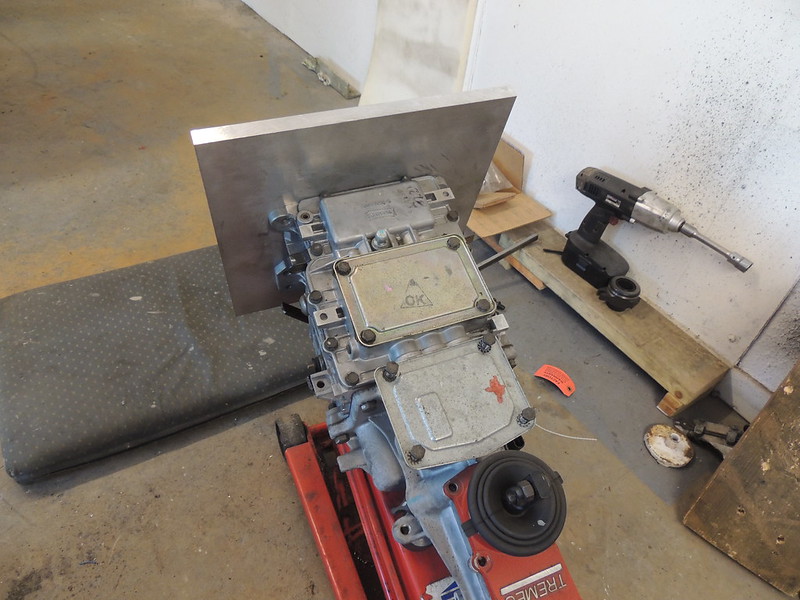

as if theres not enough going on now embarked on another upgrade and alteration of the chim out with the lt77 in with a tremec tko600 steel flywheel 10.5in mcloed clutch centre push release bearing then take the suspension spring rates back to standard still on the ohlins fit road tyres so making a fast gt cruiser be great to get her out on the road again in company with the wedge,as usual lots of pics of the doings.

john

john

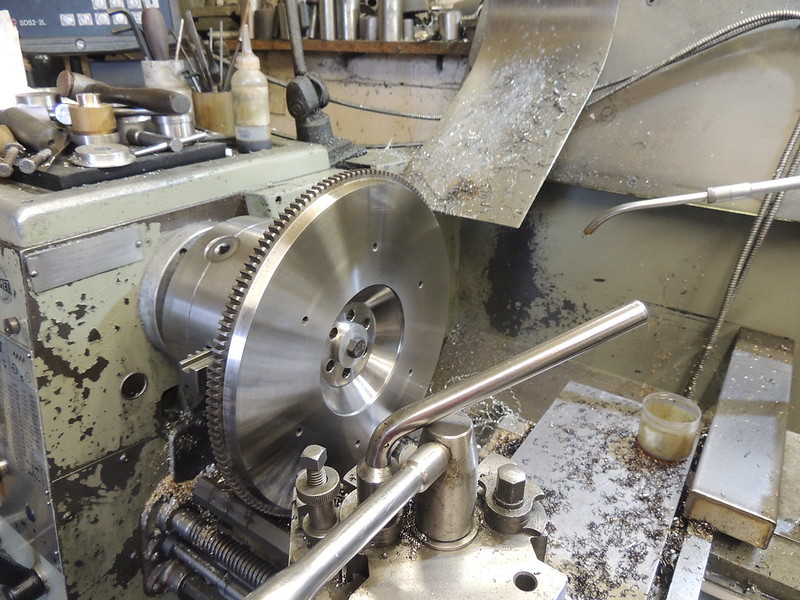

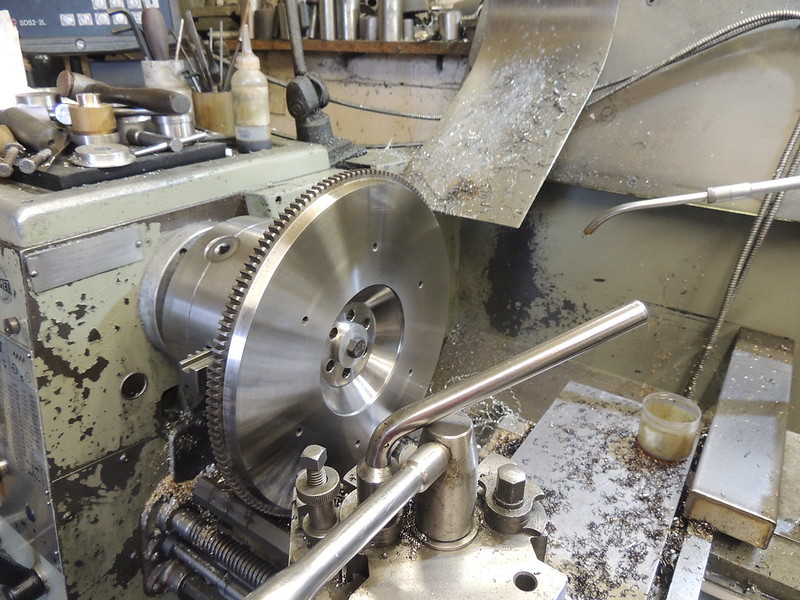

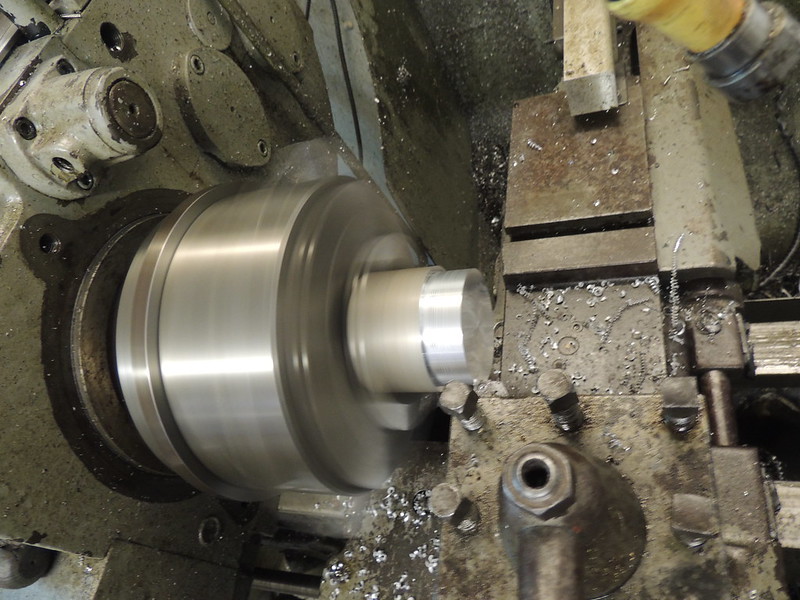

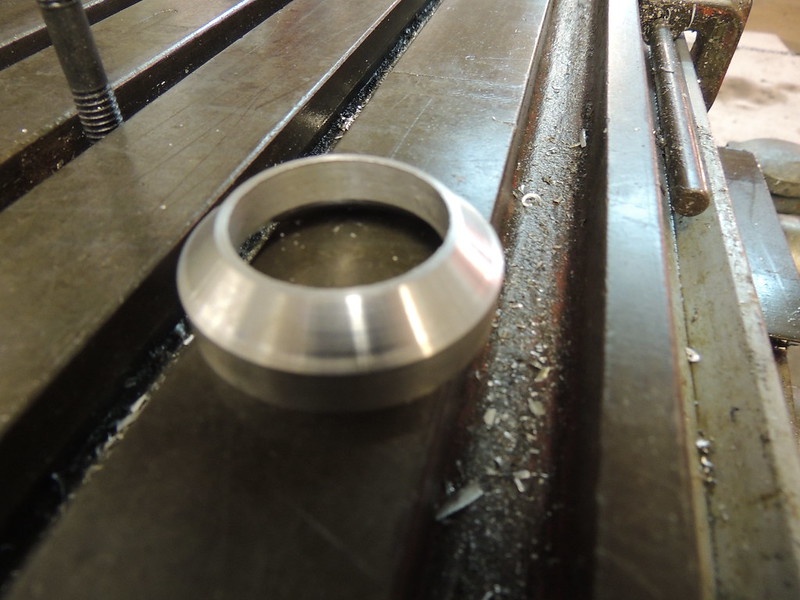

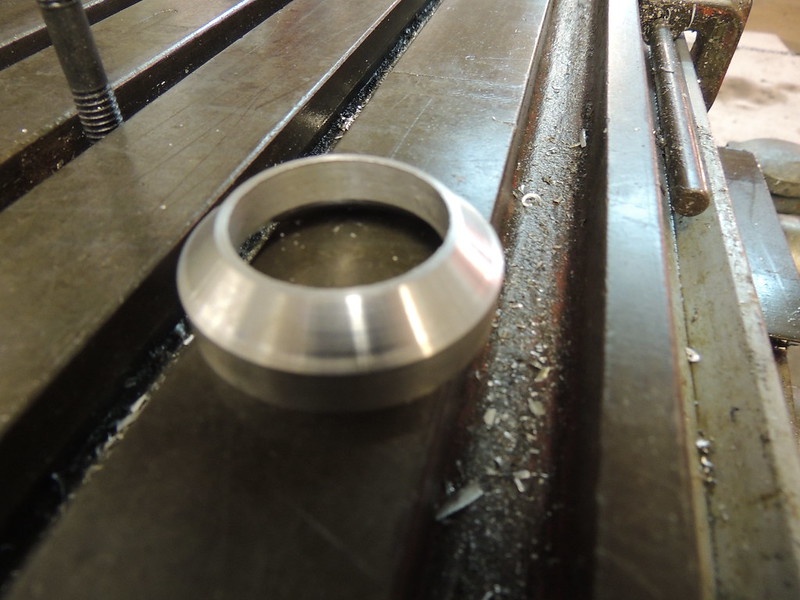

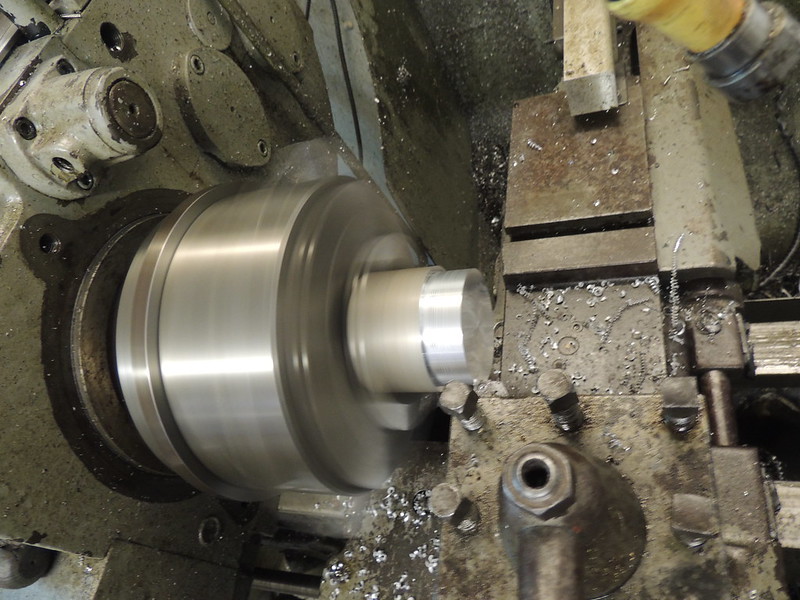

daz cant realy give you a price as not done it yet problem with using this box on the rover is no bellhousings available so i am having to heavily modify the existing lt77 one will be starting that next week so watch this space but as to the job box is out flywheel and clutch off and have had the tko600 mocked up in place looks tight but doable i have ordered the centre shift kit and the new clutch and have machined the flywheel just the fixings to do today on the rotary table.

john

DSCN2397 by Brundall Motorsport, on Flickr

DSCN2397 by Brundall Motorsport, on Flickr

DSCN2398 by Brundall Motorsport, on Flickr

DSCN2398 by Brundall Motorsport, on Flickr

DSCN2399 by Brundall Motorsport, on Flickr

DSCN2399 by Brundall Motorsport, on Flickr

DSCN2401 by Brundall Motorsport, on Flickr

DSCN2401 by Brundall Motorsport, on Flickr

DSCN2400 by Brundall Motorsport, on Flickr

DSCN2400 by Brundall Motorsport, on Flickr

DSCN2402 by Brundall Motorsport, on Flickr

DSCN2402 by Brundall Motorsport, on Flickr

DSCN2403 by Brundall Motorsport, on Flickr

DSCN2403 by Brundall Motorsport, on Flickr

DSCN2405 by Brundall Motorsport, on Flickr

DSCN2405 by Brundall Motorsport, on Flickr

john

DSCN2397 by Brundall Motorsport, on Flickr

DSCN2397 by Brundall Motorsport, on Flickr DSCN2398 by Brundall Motorsport, on Flickr

DSCN2398 by Brundall Motorsport, on Flickr DSCN2399 by Brundall Motorsport, on Flickr

DSCN2399 by Brundall Motorsport, on Flickr DSCN2401 by Brundall Motorsport, on Flickr

DSCN2401 by Brundall Motorsport, on Flickr DSCN2400 by Brundall Motorsport, on Flickr

DSCN2400 by Brundall Motorsport, on Flickr DSCN2402 by Brundall Motorsport, on Flickr

DSCN2402 by Brundall Motorsport, on Flickr DSCN2403 by Brundall Motorsport, on Flickr

DSCN2403 by Brundall Motorsport, on Flickr DSCN2405 by Brundall Motorsport, on Flickr

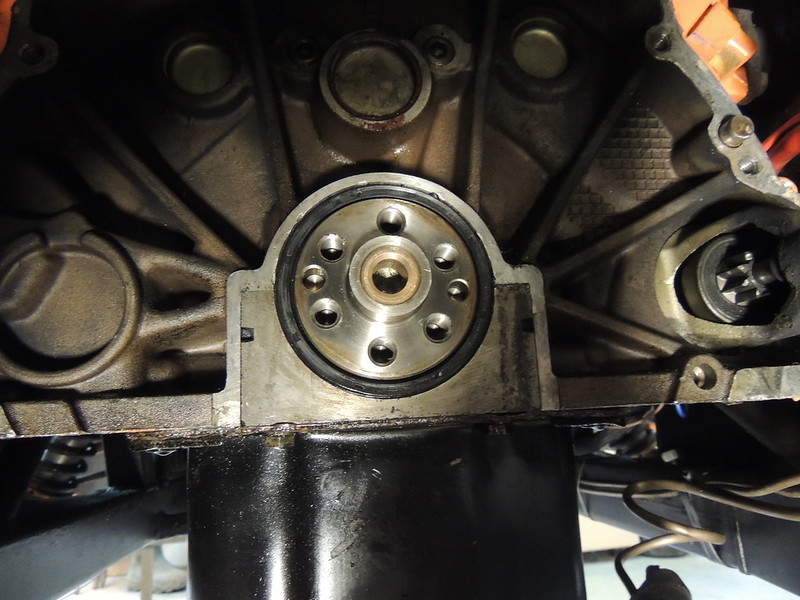

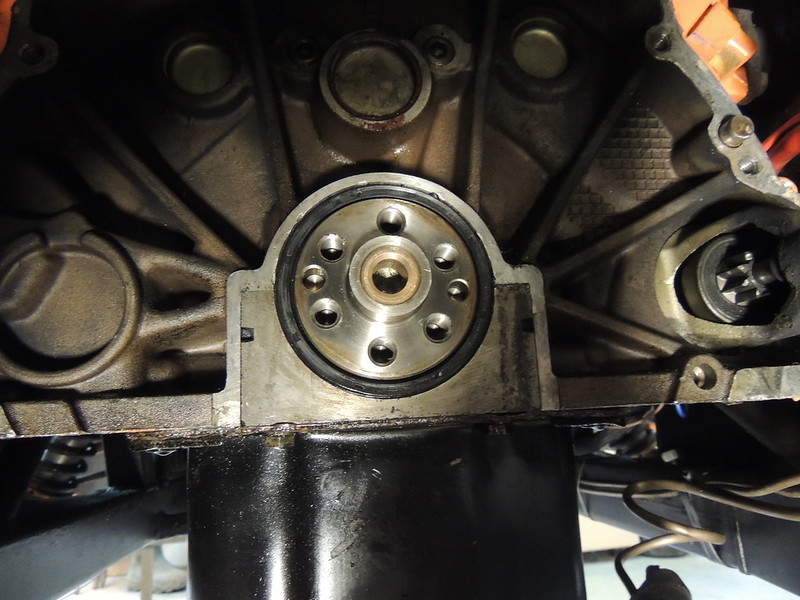

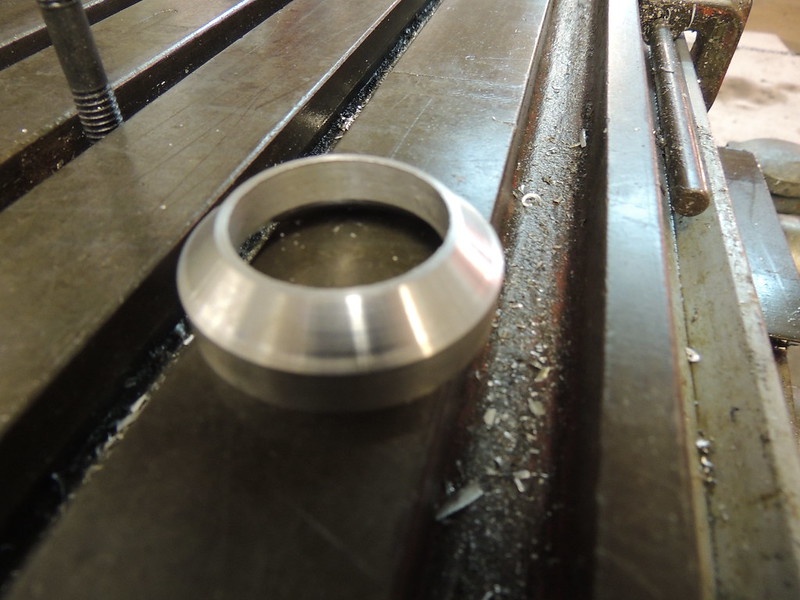

DSCN2405 by Brundall Motorsport, on Flickrfair bit got done today finished the machining on the flywheel all looks good picking up some cap heads to fix it on with tomorrow also got the pilot bush out and machined it out for the tko input shaft and started measuring up ready to start the bellhousing mods.

john

DSCN2412 by Brundall Motorsport, on Flickr

DSCN2412 by Brundall Motorsport, on Flickr

DSCN2413 by Brundall Motorsport, on Flickr

DSCN2413 by Brundall Motorsport, on Flickr

DSCN2414 by Brundall Motorsport, on Flickr

DSCN2414 by Brundall Motorsport, on Flickr

DSCN2415 by Brundall Motorsport, on Flickr

DSCN2415 by Brundall Motorsport, on Flickr

DSCN2416 by Brundall Motorsport, on Flickr

DSCN2416 by Brundall Motorsport, on Flickr

DSCN2417 by Brundall Motorsport, on Flickr

DSCN2417 by Brundall Motorsport, on Flickr

john

DSCN2412 by Brundall Motorsport, on Flickr

DSCN2412 by Brundall Motorsport, on Flickr DSCN2413 by Brundall Motorsport, on Flickr

DSCN2413 by Brundall Motorsport, on Flickr DSCN2414 by Brundall Motorsport, on Flickr

DSCN2414 by Brundall Motorsport, on Flickr DSCN2415 by Brundall Motorsport, on Flickr

DSCN2415 by Brundall Motorsport, on Flickr DSCN2416 by Brundall Motorsport, on Flickr

DSCN2416 by Brundall Motorsport, on Flickr DSCN2417 by Brundall Motorsport, on Flickr

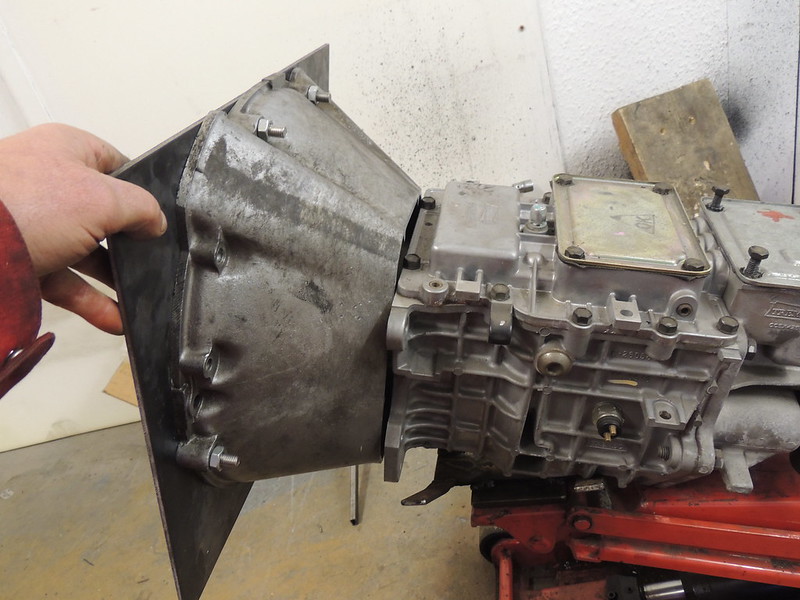

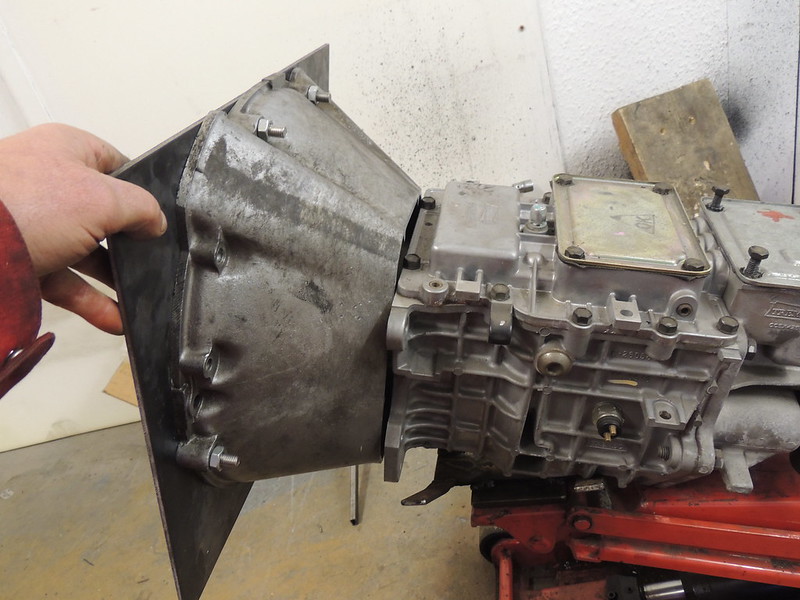

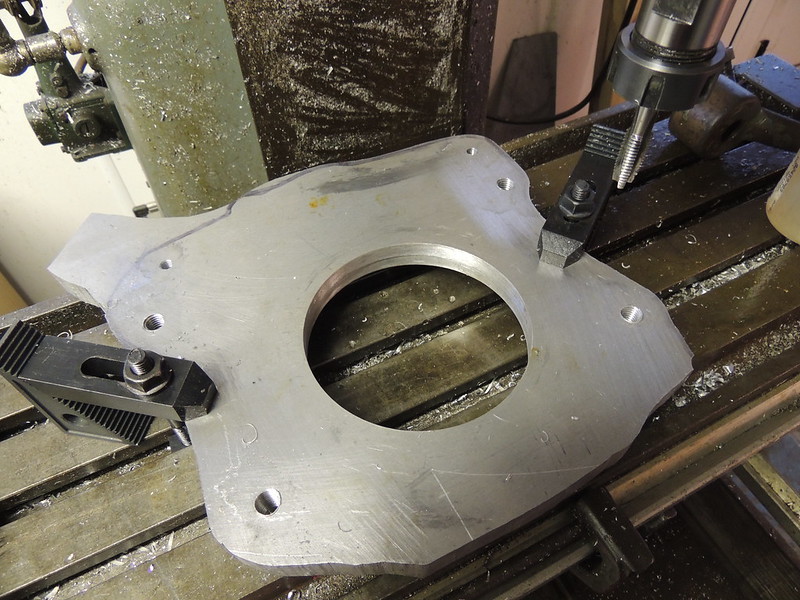

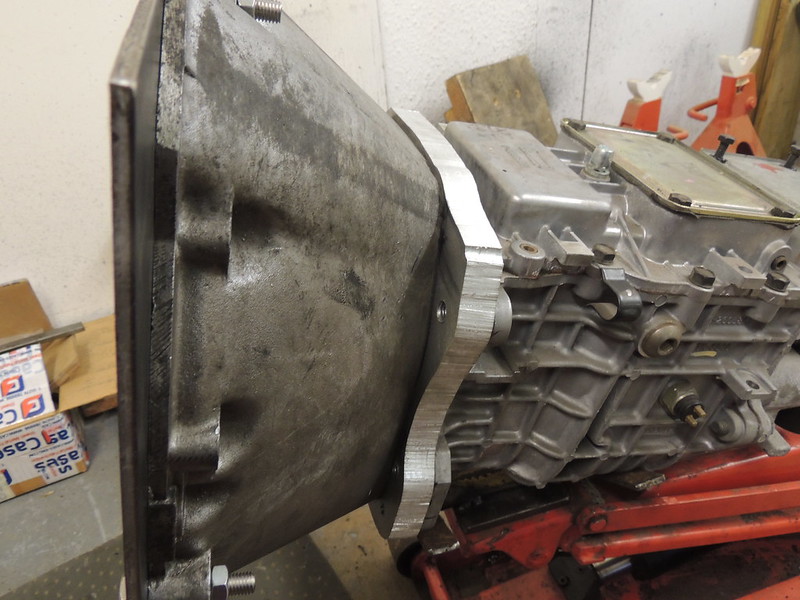

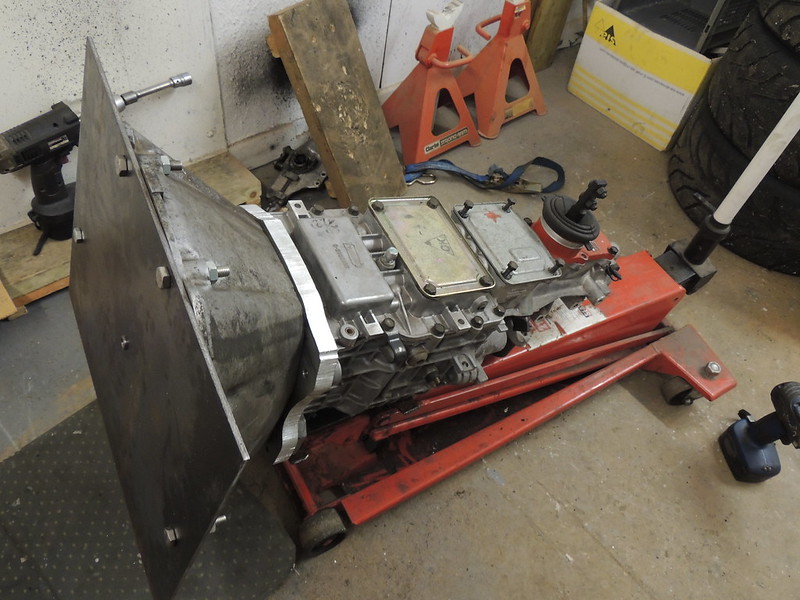

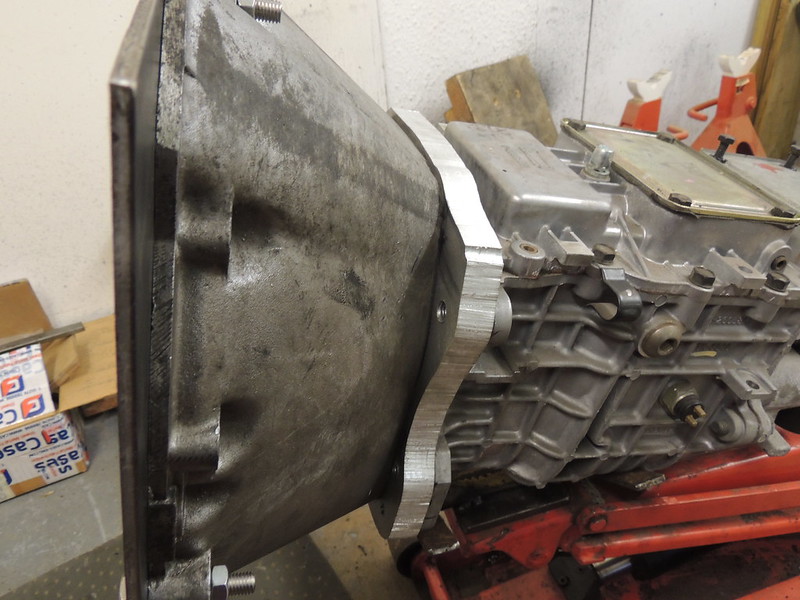

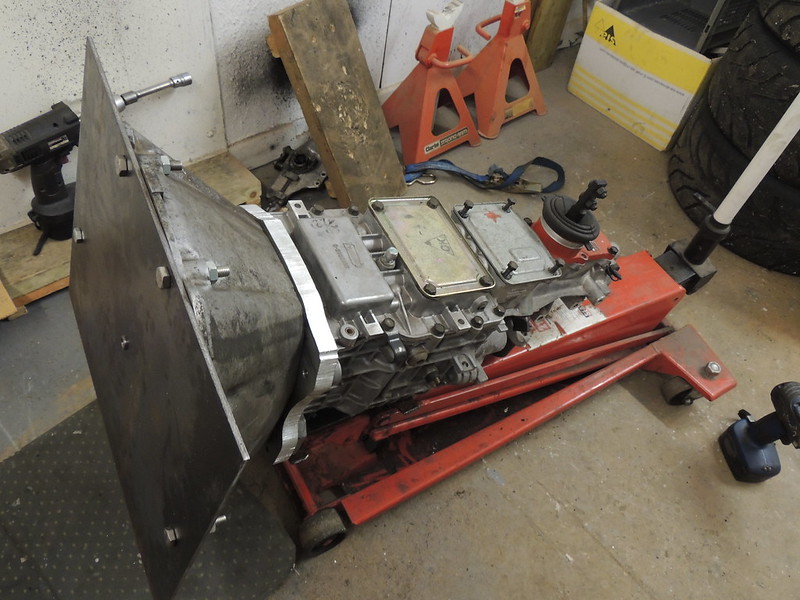

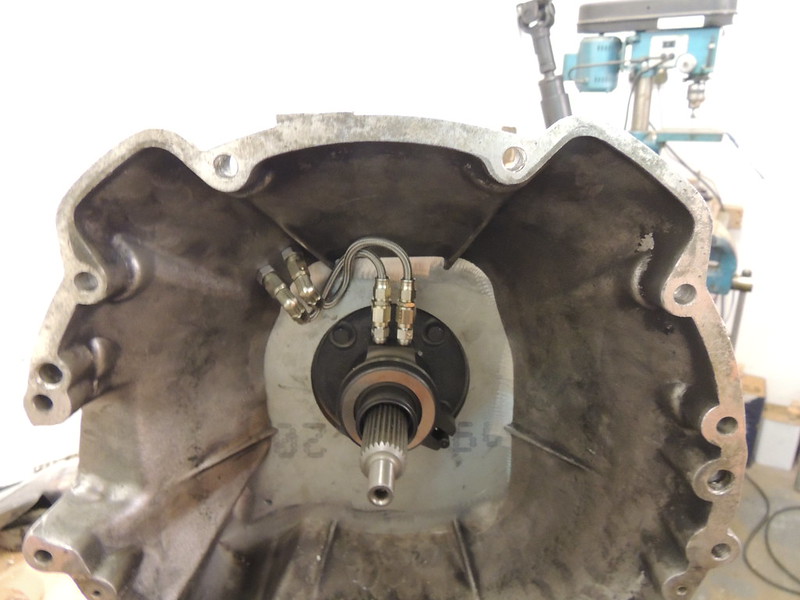

DSCN2417 by Brundall Motorsport, on Flickrlots of maching not quite there yet but well on the way made a register plate to centralise the new gearbox when mating the two parts of the new bellhousing prior to welding then cut the required amount off the bellhousing to bring the spigot forward to fit into the crank spigot bush then started maching the register hole for the tko600, next draw the outline and cut the plate on a band saw prior to welding together.

john

DSCN2418 by Brundall Motorsport, on Flickr

DSCN2418 by Brundall Motorsport, on Flickr

DSCN2419 by Brundall Motorsport, on Flickr

DSCN2419 by Brundall Motorsport, on Flickr

DSCN2420 by Brundall Motorsport, on Flickr

DSCN2420 by Brundall Motorsport, on Flickr

DSCN2421 by Brundall Motorsport, on Flickr

DSCN2421 by Brundall Motorsport, on Flickr

DSCN2422 by Brundall Motorsport, on Flickr

DSCN2422 by Brundall Motorsport, on Flickr

DSCN2423 by Brundall Motorsport, on Flickr

DSCN2423 by Brundall Motorsport, on Flickr

DSCN2424 by Brundall Motorsport, on Flickr

DSCN2424 by Brundall Motorsport, on Flickr

DSCN2425 by Brundall Motorsport, on Flickr

DSCN2425 by Brundall Motorsport, on Flickr

DSCN2426 by Brundall Motorsport, on Flickr

DSCN2426 by Brundall Motorsport, on Flickr

DSCN2427 by Brundall Motorsport, on Flickr

DSCN2427 by Brundall Motorsport, on Flickr

DSCN2428 by Brundall Motorsport, on Flickr

DSCN2428 by Brundall Motorsport, on Flickr

john

DSCN2418 by Brundall Motorsport, on Flickr

DSCN2418 by Brundall Motorsport, on Flickr DSCN2419 by Brundall Motorsport, on Flickr

DSCN2419 by Brundall Motorsport, on Flickr DSCN2420 by Brundall Motorsport, on Flickr

DSCN2420 by Brundall Motorsport, on Flickr DSCN2421 by Brundall Motorsport, on Flickr

DSCN2421 by Brundall Motorsport, on Flickr DSCN2422 by Brundall Motorsport, on Flickr

DSCN2422 by Brundall Motorsport, on Flickr DSCN2423 by Brundall Motorsport, on Flickr

DSCN2423 by Brundall Motorsport, on Flickr DSCN2424 by Brundall Motorsport, on Flickr

DSCN2424 by Brundall Motorsport, on Flickr DSCN2425 by Brundall Motorsport, on Flickr

DSCN2425 by Brundall Motorsport, on Flickr DSCN2426 by Brundall Motorsport, on Flickr

DSCN2426 by Brundall Motorsport, on Flickr DSCN2427 by Brundall Motorsport, on Flickr

DSCN2427 by Brundall Motorsport, on Flickr DSCN2428 by Brundall Motorsport, on Flickr

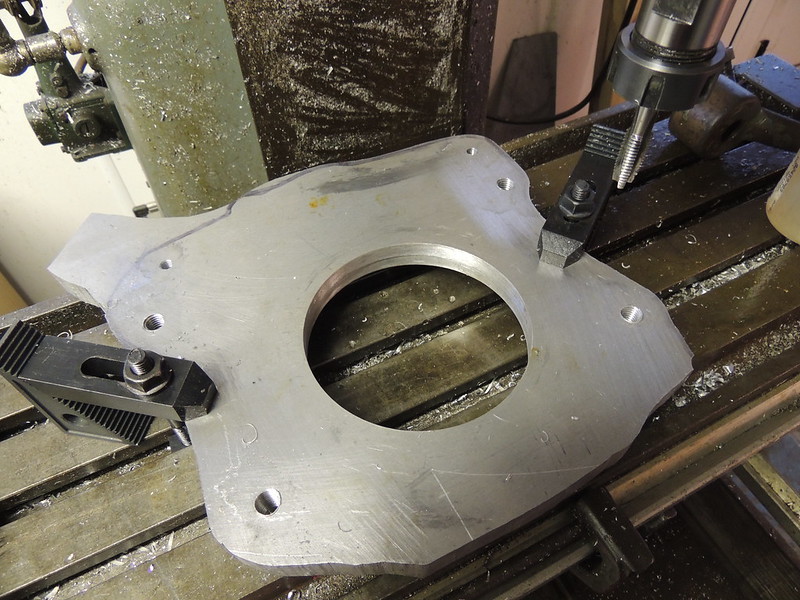

DSCN2428 by Brundall Motorsport, on Flickrthanks mathew glad you like them,had another day of machining finished the register hole in the 20mm ally plate much twiddling of the rotary table handle then marked out the basic shape to cut it into to allow both bellhousing and gearbox to fit snugly, couldnt find anyone to lend me there band saw so cut it with a jigsaw took over 3 hours was i glad when that was finished then marked out the fixing holes and drilled and tapped them on the mill so all nice and square.

john

DSCN2429 by Brundall Motorsport, on Flickr

DSCN2429 by Brundall Motorsport, on Flickr

DSCN2430 by Brundall Motorsport, on Flickr

DSCN2430 by Brundall Motorsport, on Flickr

DSCN2431 by Brundall Motorsport, on Flickr

DSCN2431 by Brundall Motorsport, on Flickr

DSCN2432 by Brundall Motorsport, on Flickr

DSCN2432 by Brundall Motorsport, on Flickr

DSCN2433 by Brundall Motorsport, on Flickr

DSCN2433 by Brundall Motorsport, on Flickr

DSCN2434 by Brundall Motorsport, on Flickr

DSCN2434 by Brundall Motorsport, on Flickr

DSCN2435 by Brundall Motorsport, on Flickr

DSCN2435 by Brundall Motorsport, on Flickr

john

DSCN2429 by Brundall Motorsport, on Flickr

DSCN2429 by Brundall Motorsport, on Flickr DSCN2430 by Brundall Motorsport, on Flickr

DSCN2430 by Brundall Motorsport, on Flickr DSCN2431 by Brundall Motorsport, on Flickr

DSCN2431 by Brundall Motorsport, on Flickr DSCN2432 by Brundall Motorsport, on Flickr

DSCN2432 by Brundall Motorsport, on Flickr DSCN2433 by Brundall Motorsport, on Flickr

DSCN2433 by Brundall Motorsport, on Flickr DSCN2434 by Brundall Motorsport, on Flickr

DSCN2434 by Brundall Motorsport, on Flickr DSCN2435 by Brundall Motorsport, on Flickr

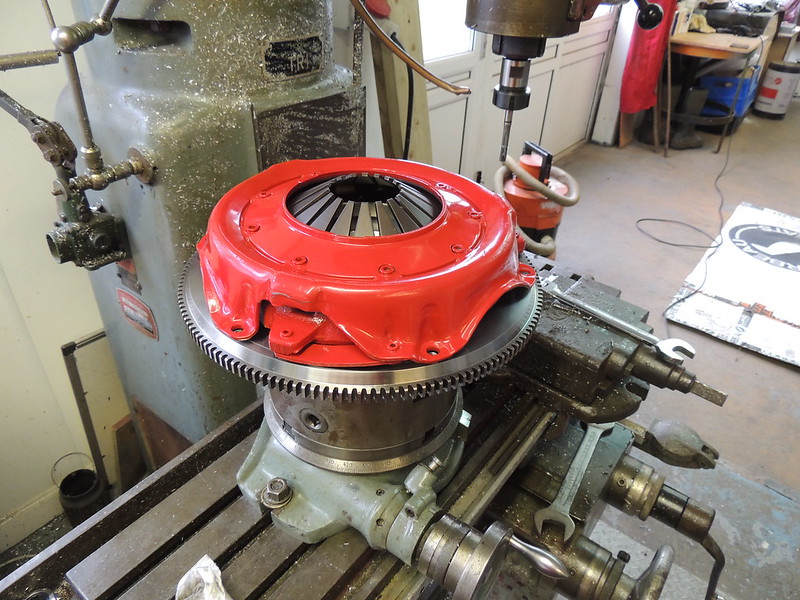

DSCN2435 by Brundall Motorsport, on Flickrstarted putting things together flywheel on and clutch but not before turning up a clutch centring tool for the mcloed clutch all looks good, then stripped off the shocks and started cleaning them and then removed the heavy weight springs from the nitrons and removed the standard springs from the original bilstiens and built the rears up with the standard springs and refitted them, the teflon liner also arrived for the mig so much welding today then skim the faces to make sure they are square.

john

DSCN2436 by Brundall Motorsport, on Flickr

DSCN2436 by Brundall Motorsport, on Flickr

DSCN2438 by Brundall Motorsport, on Flickr

DSCN2438 by Brundall Motorsport, on Flickr

DSCN2445 by Brundall Motorsport, on Flickr

DSCN2445 by Brundall Motorsport, on Flickr

DSCN2447 by Brundall Motorsport, on Flickr

DSCN2447 by Brundall Motorsport, on Flickr

DSCN2439 by Brundall Motorsport, on Flickr

DSCN2439 by Brundall Motorsport, on Flickr

DSCN2441 by Brundall Motorsport, on Flickr

DSCN2441 by Brundall Motorsport, on Flickr

DSCN2442 by Brundall Motorsport, on Flickr

DSCN2442 by Brundall Motorsport, on Flickr

DSCN2443 by Brundall Motorsport, on Flickr

DSCN2443 by Brundall Motorsport, on Flickr

DSCN2444 by Brundall Motorsport, on Flickr

DSCN2444 by Brundall Motorsport, on Flickr

john

DSCN2436 by Brundall Motorsport, on Flickr

DSCN2436 by Brundall Motorsport, on Flickr DSCN2438 by Brundall Motorsport, on Flickr

DSCN2438 by Brundall Motorsport, on Flickr DSCN2445 by Brundall Motorsport, on Flickr

DSCN2445 by Brundall Motorsport, on Flickr DSCN2447 by Brundall Motorsport, on Flickr

DSCN2447 by Brundall Motorsport, on Flickr DSCN2439 by Brundall Motorsport, on Flickr

DSCN2439 by Brundall Motorsport, on Flickr DSCN2441 by Brundall Motorsport, on Flickr

DSCN2441 by Brundall Motorsport, on Flickr DSCN2442 by Brundall Motorsport, on Flickr

DSCN2442 by Brundall Motorsport, on Flickr DSCN2443 by Brundall Motorsport, on Flickr

DSCN2443 by Brundall Motorsport, on Flickr DSCN2444 by Brundall Motorsport, on Flickr

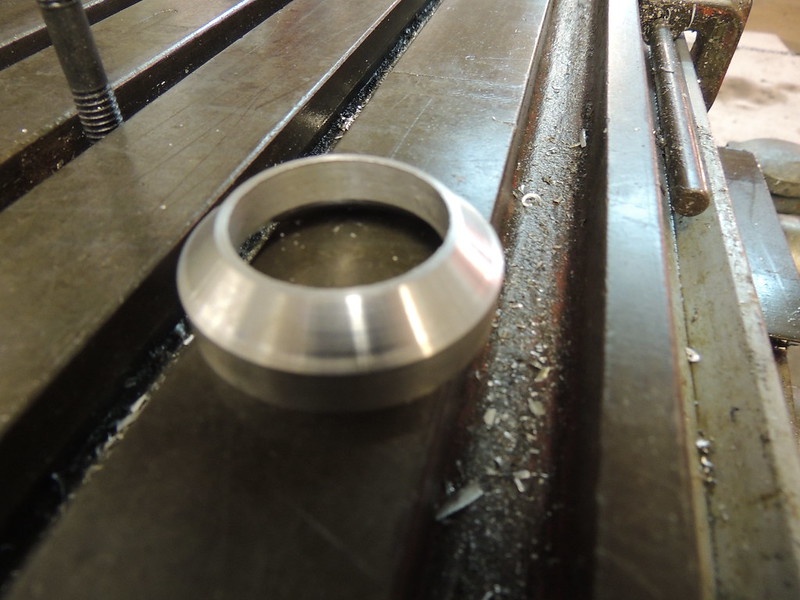

DSCN2444 by Brundall Motorsport, on Flickrwell all went well today got the bellhousing all lined up and tacked it to the mounting plate then fully welded the two together, after it was properly cooled i mounted it on the mill table to skim the plate where it meets the gearbox to assure a level mating surface it had warped about 15thou after welding so with that done i mounted it all on the gearbox and refitted the register plate to be sure everything was spot on, then fitted the bellhousing to the engine to get the measurements for the fitting of the centre push release bearing.

john

DSCN2448 by Brundall Motorsport, on Flickr

DSCN2448 by Brundall Motorsport, on Flickr

DSCN2449 by Brundall Motorsport, on Flickr

DSCN2449 by Brundall Motorsport, on Flickr

DSCN2450 by Brundall Motorsport, on Flickr

DSCN2450 by Brundall Motorsport, on Flickr

DSCN2451 by Brundall Motorsport, on Flickr

DSCN2451 by Brundall Motorsport, on Flickr

DSCN2452 by Brundall Motorsport, on Flickr

DSCN2452 by Brundall Motorsport, on Flickr

DSCN2453 by Brundall Motorsport, on Flickr

DSCN2453 by Brundall Motorsport, on Flickr

DSCN2454 by Brundall Motorsport, on Flickr

DSCN2454 by Brundall Motorsport, on Flickr

DSCN2456 by Brundall Motorsport, on Flickr

DSCN2456 by Brundall Motorsport, on Flickr

DSCN2457 by Brundall Motorsport, on Flickr

DSCN2457 by Brundall Motorsport, on Flickr

DSCN2458 by Brundall Motorsport, on Flickr

DSCN2458 by Brundall Motorsport, on Flickr

DSCN2459 by Brundall Motorsport, on Flickr

DSCN2459 by Brundall Motorsport, on Flickr

john

DSCN2448 by Brundall Motorsport, on Flickr

DSCN2448 by Brundall Motorsport, on Flickr DSCN2449 by Brundall Motorsport, on Flickr

DSCN2449 by Brundall Motorsport, on Flickr DSCN2450 by Brundall Motorsport, on Flickr

DSCN2450 by Brundall Motorsport, on Flickr DSCN2451 by Brundall Motorsport, on Flickr

DSCN2451 by Brundall Motorsport, on Flickr DSCN2452 by Brundall Motorsport, on Flickr

DSCN2452 by Brundall Motorsport, on Flickr DSCN2453 by Brundall Motorsport, on Flickr

DSCN2453 by Brundall Motorsport, on Flickr DSCN2454 by Brundall Motorsport, on Flickr

DSCN2454 by Brundall Motorsport, on Flickr DSCN2456 by Brundall Motorsport, on Flickr

DSCN2456 by Brundall Motorsport, on Flickr DSCN2457 by Brundall Motorsport, on Flickr

DSCN2457 by Brundall Motorsport, on Flickr DSCN2458 by Brundall Motorsport, on Flickr

DSCN2458 by Brundall Motorsport, on Flickr DSCN2459 by Brundall Motorsport, on Flickr

DSCN2459 by Brundall Motorsport, on Flickrback in the workshop had a great break but glad to be back, got the remaining shocks sorted with the standard springs and refitted then stripped the tko 600 and fitted the centre stick conversion all went well apart from having to turn up a drift for the roll pins securing the selectors.

john

DSCN2471 by Brundall Motorsport, on Flickr

DSCN2471 by Brundall Motorsport, on Flickr

DSCN2472 by Brundall Motorsport, on Flickr

DSCN2472 by Brundall Motorsport, on Flickr

DSCN2473 by Brundall Motorsport, on Flickr

DSCN2473 by Brundall Motorsport, on Flickr

DSCN2474 by Brundall Motorsport, on Flickr

DSCN2474 by Brundall Motorsport, on Flickr

DSCN2475 by Brundall Motorsport, on Flickr

DSCN2475 by Brundall Motorsport, on Flickr

DSCN2476 by Brundall Motorsport, on Flickr

DSCN2476 by Brundall Motorsport, on Flickr

DSCN2477 by Brundall Motorsport, on Flickr

DSCN2477 by Brundall Motorsport, on Flickr

DSCN2478 by Brundall Motorsport, on Flickr

DSCN2478 by Brundall Motorsport, on Flickr

john

DSCN2471 by Brundall Motorsport, on Flickr

DSCN2471 by Brundall Motorsport, on Flickr DSCN2472 by Brundall Motorsport, on Flickr

DSCN2472 by Brundall Motorsport, on Flickr DSCN2473 by Brundall Motorsport, on Flickr

DSCN2473 by Brundall Motorsport, on Flickr DSCN2474 by Brundall Motorsport, on Flickr

DSCN2474 by Brundall Motorsport, on Flickr DSCN2475 by Brundall Motorsport, on Flickr

DSCN2475 by Brundall Motorsport, on Flickr DSCN2476 by Brundall Motorsport, on Flickr

DSCN2476 by Brundall Motorsport, on Flickr DSCN2477 by Brundall Motorsport, on Flickr

DSCN2477 by Brundall Motorsport, on Flickr DSCN2478 by Brundall Motorsport, on Flickr

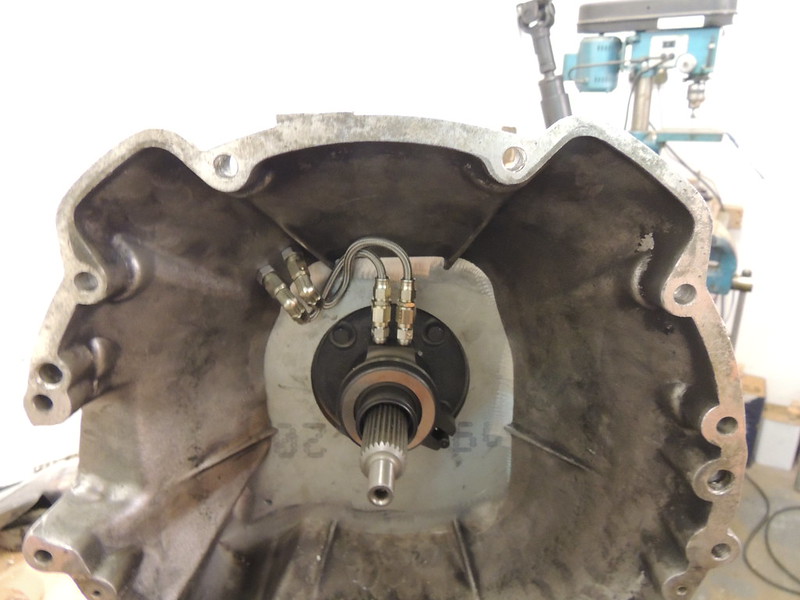

DSCN2478 by Brundall Motorsport, on Flickrlast major obsticle overcome sorting out the throw on the centre push release bearing much measuring and then turned up a spacer with the same mating taper as the box and bearing so go for box fitting next to check all good then sort the pipework from master to centre push and centre push to bleed nipple

john

DSCN2479 by Brundall Motorsport, on Flickr

DSCN2479 by Brundall Motorsport, on Flickr

DSCN2480 by Brundall Motorsport, on Flickr

DSCN2480 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr

DSCN2483 by Brundall Motorsport, on Flickr

DSCN2483 by Brundall Motorsport, on Flickr

john

DSCN2479 by Brundall Motorsport, on Flickr

DSCN2479 by Brundall Motorsport, on Flickr DSCN2480 by Brundall Motorsport, on Flickr

DSCN2480 by Brundall Motorsport, on Flickr DSCN2481 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr DSCN2481 by Brundall Motorsport, on Flickr

DSCN2481 by Brundall Motorsport, on Flickr DSCN2483 by Brundall Motorsport, on Flickr

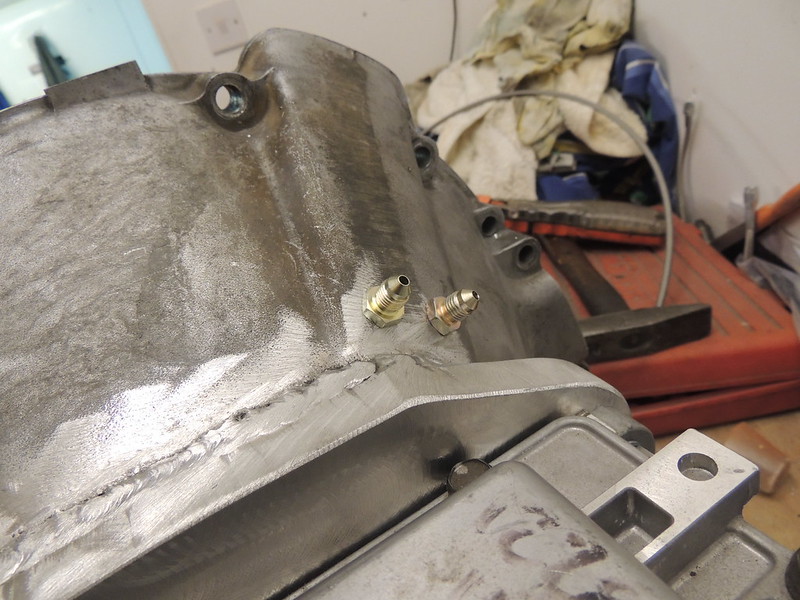

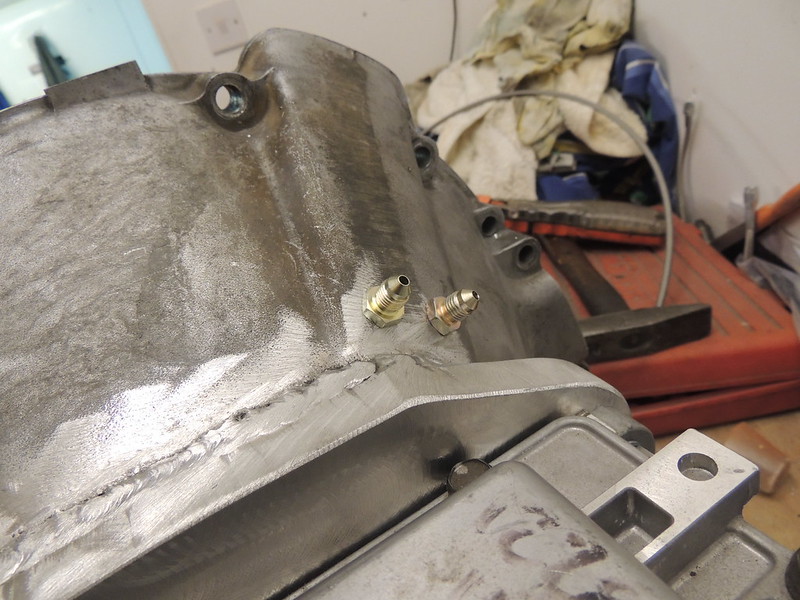

DSCN2483 by Brundall Motorsport, on Flickrbit more done stripped the wiring from the map sensor and the no.8 injector as the water injection had packed up seems the flux i used when soldering the joints has attacked the wires and turned them to dust hence the lack of injection so got a new map sensor plug and will invest in some new fluxed core solder before rewiring fitted the bellhousing and started on the plumbing for the clutch slave doing it all in 600 series aeroquip so had to silver solder up an adaptor from 1/4 brake pipe to jic-3 got the bellhousing sorted with two bulkhead fittings and plumbed up inside the bellhousing so coming along nicely.

john

DSCN2485 by Brundall Motorsport, on Flickr

DSCN2485 by Brundall Motorsport, on Flickr

DSCN2488 by Brundall Motorsport, on Flickr

DSCN2488 by Brundall Motorsport, on Flickr

DSCN2486 by Brundall Motorsport, on Flickr

DSCN2486 by Brundall Motorsport, on Flickr

DSCN2489 by Brundall Motorsport, on Flickr

DSCN2489 by Brundall Motorsport, on Flickr

DSCN2490 by Brundall Motorsport, on Flickr

DSCN2490 by Brundall Motorsport, on Flickr

DSCN2491 by Brundall Motorsport, on Flickr

DSCN2491 by Brundall Motorsport, on Flickr

DSCN2487 by Brundall Motorsport, on Flickr

DSCN2487 by Brundall Motorsport, on Flickr

john

DSCN2485 by Brundall Motorsport, on Flickr

DSCN2485 by Brundall Motorsport, on Flickr DSCN2488 by Brundall Motorsport, on Flickr

DSCN2488 by Brundall Motorsport, on Flickr DSCN2486 by Brundall Motorsport, on Flickr

DSCN2486 by Brundall Motorsport, on Flickr DSCN2489 by Brundall Motorsport, on Flickr

DSCN2489 by Brundall Motorsport, on Flickr DSCN2490 by Brundall Motorsport, on Flickr

DSCN2490 by Brundall Motorsport, on Flickr DSCN2491 by Brundall Motorsport, on Flickr

DSCN2491 by Brundall Motorsport, on Flickr DSCN2487 by Brundall Motorsport, on Flickr

DSCN2487 by Brundall Motorsport, on Flickrbit of an update after the autosport show i have removed the master cylinder that goes with the triple plate clutch and installed a 3/4in one for the centre push bearing thoes two bolts are a nightmare on your own must sort a better method then finished the plumbing to and from the slave one pipe ends in a bleed nipple right next to the remote resevoir then i have removed the seats and harnesses and sorted the drivers side lap and diagonal seat belt works better than i thought considering the seat type so gearbox install monday all being well

john

DSCN2503 by Brundall Motorsport, on Flickr

DSCN2503 by Brundall Motorsport, on Flickr

DSCN2504 by Brundall Motorsport, on Flickr

DSCN2504 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr

DSCN2495 by Brundall Motorsport, on Flickr

DSCN2495 by Brundall Motorsport, on Flickr

DSCN2496 by Brundall Motorsport, on Flickr

DSCN2496 by Brundall Motorsport, on Flickr

DSCN2497 by Brundall Motorsport, on Flickr

DSCN2497 by Brundall Motorsport, on Flickr

DSCN2498 by Brundall Motorsport, on Flickr

DSCN2498 by Brundall Motorsport, on Flickr

DSCN2499 by Brundall Motorsport, on Flickr

DSCN2499 by Brundall Motorsport, on Flickr

DSCN2501 by Brundall Motorsport, on Flickr

DSCN2501 by Brundall Motorsport, on Flickr

DSCN2502 by Brundall Motorsport, on Flickr

DSCN2502 by Brundall Motorsport, on Flickr

john

DSCN2503 by Brundall Motorsport, on Flickr

DSCN2503 by Brundall Motorsport, on Flickr DSCN2504 by Brundall Motorsport, on Flickr

DSCN2504 by Brundall Motorsport, on Flickr DSCN2492 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr DSCN2492 by Brundall Motorsport, on Flickr

DSCN2492 by Brundall Motorsport, on Flickr DSCN2495 by Brundall Motorsport, on Flickr

DSCN2495 by Brundall Motorsport, on Flickr DSCN2496 by Brundall Motorsport, on Flickr

DSCN2496 by Brundall Motorsport, on Flickr DSCN2497 by Brundall Motorsport, on Flickr

DSCN2497 by Brundall Motorsport, on Flickr DSCN2498 by Brundall Motorsport, on Flickr

DSCN2498 by Brundall Motorsport, on Flickr DSCN2499 by Brundall Motorsport, on Flickr

DSCN2499 by Brundall Motorsport, on Flickr DSCN2501 by Brundall Motorsport, on Flickr

DSCN2501 by Brundall Motorsport, on Flickr DSCN2502 by Brundall Motorsport, on Flickr

DSCN2502 by Brundall Motorsport, on Flickranother good couple of days, fitted the passenger seat belt and replaced the seat then the biggy to install the gearbox had to go in complete so meant angling it up and to one side to get the bellhousing inbetween the chassis rails but all went well and it was soon bolted up, next fabricate a new gearbox mount which wasent to bad uses the existing holes in the chassis but a little different as the mounting are perpendicular not angled ,then connected up the master cylinder and fitted the bleed nipple and bled out the clutch all seems to work well and smooth so onto the interior made a closure for the cutout where the new gearstick goes made a new gearstick and fitted that then refitted the rubber gaiter modified the cover to the door opener and then refiited the centre upholstery and finally screwed the gear knob and door opener on and now the gear knob decals are actually correct,then made a blank for the lower bellhousing cover welded that in place and refitted the cover,then rebuilt the left hand side of the engine that was dissmantled to get access to the clutch pipes etc. finally measured up for the new propshaft boxed up the relevant parts and sent them off so all in all not a bad couple of days.and also a purely graturious pic of the engine bay i do love that thing.

john

DSCN2505 by Brundall Motorsport, on Flickr

DSCN2505 by Brundall Motorsport, on Flickr

DSCN2513 by Brundall Motorsport, on Flickr

DSCN2513 by Brundall Motorsport, on Flickr

DSCN2506 by Brundall Motorsport, on Flickr

DSCN2506 by Brundall Motorsport, on Flickr

DSCN2507 by Brundall Motorsport, on Flickr

DSCN2507 by Brundall Motorsport, on Flickr

DSCN2508 by Brundall Motorsport, on Flickr

DSCN2508 by Brundall Motorsport, on Flickr

DSCN2509 by Brundall Motorsport, on Flickr

DSCN2509 by Brundall Motorsport, on Flickr

DSCN2510 by Brundall Motorsport, on Flickr

DSCN2510 by Brundall Motorsport, on Flickr

DSCN2511 by Brundall Motorsport, on Flickr

DSCN2511 by Brundall Motorsport, on Flickr

DSCN2512 by Brundall Motorsport, on Flickr

DSCN2512 by Brundall Motorsport, on Flickr

DSCN2515 by Brundall Motorsport, on Flickr

DSCN2515 by Brundall Motorsport, on Flickr

DSCN2517 by Brundall Motorsport, on Flickr

DSCN2517 by Brundall Motorsport, on Flickr

DSCN2516 by Brundall Motorsport, on Flickr

DSCN2516 by Brundall Motorsport, on Flickr

john

DSCN2505 by Brundall Motorsport, on Flickr

DSCN2505 by Brundall Motorsport, on Flickr DSCN2513 by Brundall Motorsport, on Flickr

DSCN2513 by Brundall Motorsport, on Flickr DSCN2506 by Brundall Motorsport, on Flickr

DSCN2506 by Brundall Motorsport, on Flickr DSCN2507 by Brundall Motorsport, on Flickr

DSCN2507 by Brundall Motorsport, on Flickr DSCN2508 by Brundall Motorsport, on Flickr

DSCN2508 by Brundall Motorsport, on Flickr DSCN2509 by Brundall Motorsport, on Flickr

DSCN2509 by Brundall Motorsport, on Flickr DSCN2510 by Brundall Motorsport, on Flickr

DSCN2510 by Brundall Motorsport, on Flickr DSCN2511 by Brundall Motorsport, on Flickr

DSCN2511 by Brundall Motorsport, on Flickr DSCN2512 by Brundall Motorsport, on Flickr

DSCN2512 by Brundall Motorsport, on Flickr DSCN2515 by Brundall Motorsport, on Flickr

DSCN2515 by Brundall Motorsport, on Flickr DSCN2517 by Brundall Motorsport, on Flickr

DSCN2517 by Brundall Motorsport, on Flickr DSCN2516 by Brundall Motorsport, on Flickr

DSCN2516 by Brundall Motorsport, on Flickranother update car is now up and running gearbox is very crisp clutch not to bad weight wise and passed mot with no advisories so all good then decided to sort the paint several years of track days etc. have certainly taken a toll lots of stone chips so attending to that and a couple of stress cracks also sent the steering wheel off and had it recovered in alcantara which has given it a amazing feel new 17in wheels sourced but 5 weeks delivery time being shod with michelin pilot sports 4 rubber

john

DSCN2530 by Brundall Motorsport, on Flickr

DSCN2530 by Brundall Motorsport, on Flickr

DSCN2532 by Brundall Motorsport, on Flickr

DSCN2532 by Brundall Motorsport, on Flickr

DSCN2533 by Brundall Motorsport, on Flickr

DSCN2533 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr

DSCN2536 by Brundall Motorsport, on Flickr

DSCN2536 by Brundall Motorsport, on Flickr

DSCN2537 by Brundall Motorsport, on Flickr

DSCN2537 by Brundall Motorsport, on Flickr

DSCN2538 by Brundall Motorsport, on Flickr

DSCN2538 by Brundall Motorsport, on Flickr

john

DSCN2530 by Brundall Motorsport, on Flickr

DSCN2530 by Brundall Motorsport, on Flickr DSCN2532 by Brundall Motorsport, on Flickr

DSCN2532 by Brundall Motorsport, on Flickr DSCN2533 by Brundall Motorsport, on Flickr

DSCN2533 by Brundall Motorsport, on Flickr DSCN2534 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr DSCN2534 by Brundall Motorsport, on Flickr

DSCN2534 by Brundall Motorsport, on Flickr DSCN2536 by Brundall Motorsport, on Flickr

DSCN2536 by Brundall Motorsport, on Flickr DSCN2537 by Brundall Motorsport, on Flickr

DSCN2537 by Brundall Motorsport, on Flickr DSCN2538 by Brundall Motorsport, on Flickr

DSCN2538 by Brundall Motorsport, on FlickrGassing Station | Chimaera | Top of Page | What's New | My Stuff