Posh Shed / Garden Room DIY Build

Discussion

I'm looking to move my workshop which is currently in the cellar to a posh shed in the garden. The cellar would then become a child free zone/cinema/xbox room. Something along the lines of this.....

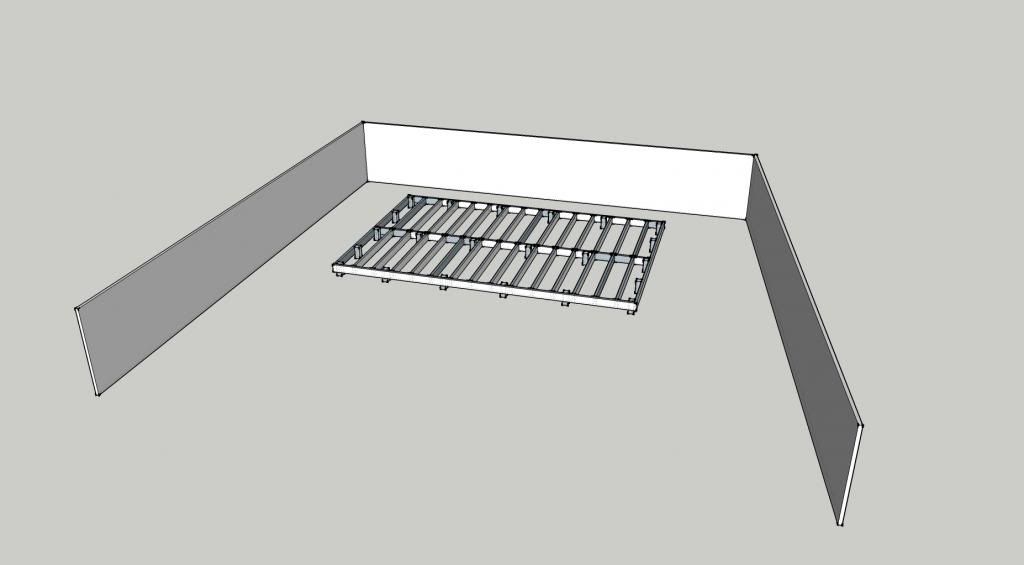

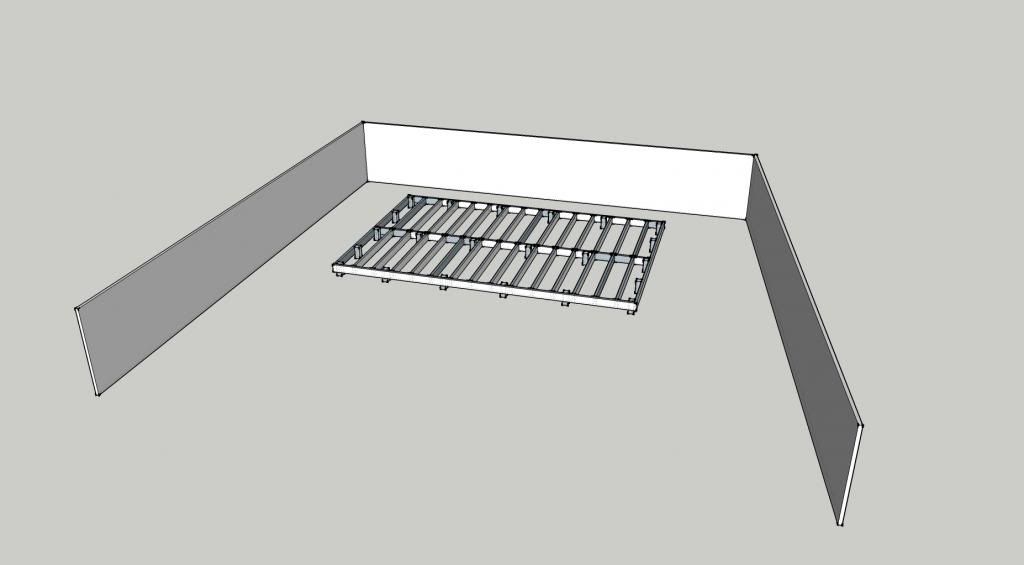

The posh shed would be 6.5 x 4m split into two - 3.5x4m workshop & 3x4m garden room/office. The walls constructed out of 4x2"s at 400mm centres. It needs to be useable all year round so its going to be insulated with Kingspan or similar, clad with cedar & plaster boarded inside. At the moment the base is to be constructed out of 6x2"s at 400mm centres held up on 50mm galvanised steel box section posts. Like this....

If OK, how long should posts be - I'm thinking concreting in 30-40cm should be fine.

Also what's the best way of constructing the frame? Concrete the posts in first then attach the 6x2s or use the squared up frame as a guide for positioning the posts. Posts and frame must be perfectly square and level otherwise the walls and roof will be on the p1ss.

Suggestions gratefully received

Cheers

The posh shed would be 6.5 x 4m split into two - 3.5x4m workshop & 3x4m garden room/office. The walls constructed out of 4x2"s at 400mm centres. It needs to be useable all year round so its going to be insulated with Kingspan or similar, clad with cedar & plaster boarded inside. At the moment the base is to be constructed out of 6x2"s at 400mm centres held up on 50mm galvanised steel box section posts. Like this....

If OK, how long should posts be - I'm thinking concreting in 30-40cm should be fine.

Also what's the best way of constructing the frame? Concrete the posts in first then attach the 6x2s or use the squared up frame as a guide for positioning the posts. Posts and frame must be perfectly square and level otherwise the walls and roof will be on the p1ss.

Suggestions gratefully received

Cheers

Main base frame is now finished......pics to follow.

Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

speedyguy said:

mikees said:

I would REALLY REALLY lay a concrete base. Surely this s only a few hundred quid. Mike

http://www.minimix.co.ukHandy for working bits out and ball park figures if your doing the base yourself.

Any way it's too late - 28 galvanised posts have been concreted in and 6x2 frame bolted to it!

The previous summer house concrete base was wrecked by the nearby tree roots so I discounted the slab.

Most of the garden room suppliers use either timber or steel framed bases so didn't think I would go too far wrong

So....Weed fabric or damp proof membrane?

Just started something very similar, will start a thread of my own once it's been delivered. Ours is strictly for fun so the floor had to be able to support a 7ft slate bed pool table! The suppliers said their floor options would be a bit weak for that so we went with concrete.

Our base is 8 x 5 meters, so got 5 tonnes of mot type 1 delivered, wheel barrowed it all into the area, whacker plated it all, laid a damp proof membrane, made some shuttering and got some cement pumped (150ft) down the garden, tampered it down and now it's ready to be built on.

I think the sub base was £190 for the mot, £40 for a whacker plate. The shuttering I will reuse as decking bearers, the cement was £95 per cubic meter (4), the expensive (but necessary) pump was £350. It was that or 60 wheel barrow loads down the garden!

Total for base is therefore £940. Should out last us and still add value to the house.

Good luck with yours, where's it from? or are you making it yourself? I'm not that brave!

Matt

Our base is 8 x 5 meters, so got 5 tonnes of mot type 1 delivered, wheel barrowed it all into the area, whacker plated it all, laid a damp proof membrane, made some shuttering and got some cement pumped (150ft) down the garden, tampered it down and now it's ready to be built on.

I think the sub base was £190 for the mot, £40 for a whacker plate. The shuttering I will reuse as decking bearers, the cement was £95 per cubic meter (4), the expensive (but necessary) pump was £350. It was that or 60 wheel barrow loads down the garden!

Total for base is therefore £940. Should out last us and still add value to the house.

Good luck with yours, where's it from? or are you making it yourself? I'm not that brave!

Matt

Russ_H said:

Main base frame is now finished......pics to follow.

Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

I'd go for weed fabric, and pea shingle or similar. You don't require a DPC unless the joists are touching the ground, which would be a mistake. I'm assuming you planning to use celotex or similar inbetween joists, then DPC and boarded?Question, what should I be laying underneath the frame?

Weed fabric to control any weeds but allows water to drain

or

Damp proof membrane to stop weeds but also prevents water socking up into the timber base?

Suggestions appreciated - floor joists going down in the next couple of days.

Cheers

You've beat me to it, building one similar in a few weeks. Will be using recycled plastic timber for the supports into the ground. I have the same issue with tree roots, and to be fair, I just nicked the idea from the local log cabin company, they don't install concrete bases anymore due to this very reason.

Planning to build in sheet dimensions to limit cuts and speed build time.....famous last words! Enjoy.

Updated pics........

main framed laid out - levelled and squared & then marked out the hole positions

Holes dug using a petrol post hole borer, a lot easier than digging by hand but still hard work

hard work

Finished frame ready for joists. Doesn't look like its going anywhere, the wife says its over engineered, I say its robust

Next step floor joists and walls.

Was planning to use 18mm WBP plywood for the floor - any cheaper options???

Assume 38x89mm CLS is good for the walls?

Thanks

main framed laid out - levelled and squared & then marked out the hole positions

Holes dug using a petrol post hole borer, a lot easier than digging by hand but still

hard work

hard work

Finished frame ready for joists. Doesn't look like its going anywhere, the wife says its over engineered, I say its robust

Next step floor joists and walls.

Was planning to use 18mm WBP plywood for the floor - any cheaper options???

Assume 38x89mm CLS is good for the walls?

Thanks

Thread resurrection!

There's been a bit of a change of plan following a impulse Ebay purchase

SIP Panels

Seemed cheap for the size of panels, phoned up the guy and the deal was done.

Was only then I considered how was I going to get 2500kg of panels from Huddersfield to Leicester.

Was advised to get a 7.5 ton lorry by the guy selling so I hired & pitched up in a box lorry with a tail lift. Wrong! With hindsight a 7.5 ton flat bed would have been a lot easier. After man-handling 16off 5m & 6m lenghs into the back with the aid of a forklift it dawned on me how the F**k I was going to offload at the other end.

While driving back i was frantically phoning round local buddies to give me a hand but no one was picking up....... managed to rope in a couple of neighbors but it still took 2 hours to unload.

managed to rope in a couple of neighbors but it still took 2 hours to unload.

Anyway - anyone have any experience building a SIPs?? The walls and roof of the garden room / posh will be made out of them.

Doesn't look difficult but could do with some pointers.

Cheers

There's been a bit of a change of plan following a impulse Ebay purchase

SIP Panels

Seemed cheap for the size of panels, phoned up the guy and the deal was done.

Was only then I considered how was I going to get 2500kg of panels from Huddersfield to Leicester.

Was advised to get a 7.5 ton lorry by the guy selling so I hired & pitched up in a box lorry with a tail lift. Wrong! With hindsight a 7.5 ton flat bed would have been a lot easier. After man-handling 16off 5m & 6m lenghs into the back with the aid of a forklift it dawned on me how the F**k I was going to offload at the other end.

While driving back i was frantically phoning round local buddies to give me a hand but no one was picking up.......

managed to rope in a couple of neighbors but it still took 2 hours to unload.

managed to rope in a couple of neighbors but it still took 2 hours to unload.Anyway - anyone have any experience building a SIPs?? The walls and roof of the garden room / posh will be made out of them.

Doesn't look difficult but could do with some pointers.

Cheers

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff

) is going to be building a 4m x 6.5m garage in my garden, a wooden one is still an option, so it is similar to this. I'm interested to see how you get on.

) is going to be building a 4m x 6.5m garage in my garden, a wooden one is still an option, so it is similar to this. I'm interested to see how you get on.