Serp engines - coolant rail around driver's side rocker box

Discussion

Anyone else curse the bloody awful design of the twin coolant pipes that run alonside the rocker cover. Nightmare everytime the cover has to come off and a nightmare to remove the rail... anyone come up with a silicone hose solution as an alternative? Thinking of routing two runs along the inner wing or even inside the wing void...

I went from pre-serp to serp and didn't fancy the heater pipes down the side of the rocker either.

Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Edited by Ant. on Tuesday 15th September 22:12

Ant. said:

I went from pre-serp to serp and didn't fancy the heater pipes down the side of the rocker either.

Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Cheers Ant, that sounds tidy... don't suppose you have any pics?Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Edited by Ant. on Tuesday 15th September 22:12

You can also swap the serp temp gauge and pipe connector over, but there is still s tight U bend to go back under the valley.

It's also possible to get rid of the connector to the swan neck by drilling / tapping a pipe connector to the top of the water pump return connector - so the heater hose doesn't have to pass the manifolds & belts as well as being nice and handy for the valley routing.

I reckon if you use the valley route, stell pipes aren't necessary, but its well worth tapping the blind holes under the manifold so that you can secure the pipework that runs under there? TBH I've done it, but its a lot easier to use a pre-serp manifold to start with

It's also possible to get rid of the connector to the swan neck by drilling / tapping a pipe connector to the top of the water pump return connector - so the heater hose doesn't have to pass the manifolds & belts as well as being nice and handy for the valley routing.

I reckon if you use the valley route, stell pipes aren't necessary, but its well worth tapping the blind holes under the manifold so that you can secure the pipework that runs under there? TBH I've done it, but its a lot easier to use a pre-serp manifold to start with

Pupp said:

Ant. said:

I went from pre-serp to serp and didn't fancy the heater pipes down the side of the rocker either.

Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Cheers Ant, that sounds tidy... don't suppose you have any pics?Silicon U bend from the outlet on the side of the manifold, onto a 90deg bent SS pipe running under the manifold.

The other heater pipe also has a SS pipe under the manifold, attached to another silicone pipe leading to the rad return pipe below the pump.

Edited by Ant. on Tuesday 15th September 22:12

The pipe is SS domestic plumbing pipe from Wickes.

HTH

Pupp said:

Ant. said:

The pipe is SS domestic plumbing pipe from Wickes.

HTH

You sure it was stainless Ant? I'm struggling to find stainless plumbing pipe...chromed copper, yes.HTH

Edited by Ant. on Sunday 20th September 13:03

Ant. said:

Yes mate, defo SS. It was in one of the DIY places, pretty sure it was Wickes.. or Focus

Couldn't you get a SS cap screw to replace that unsightly stud you left in the timing cover

I may have one or two if you are stuck Ant, as well as the UNF nuts to be able to unscrew the stud

(UNC into casting & UNF at top IIRC?)

(UNC into casting & UNF at top IIRC?)Pupp said:

Ok, done this now and it's a much neater appearance with an added benefit of more room at the rear of the block to get you hand round the back of the plenum etc. Went slightly overboard on the stainless pipe 'though; about 5m left

So you managed to find the pipe I mentioned??

spend said:

Couldn't you get a SS cap screw to replace that unsightly stud you left in the timing cover

I may have one or two if you are stuck Ant, as well as the UNF nuts to be able to unscrew the stud (UNC into casting & UNF at top IIRC?)

(UNC into casting & UNF at top IIRC?)

On my jobs list mate !!

I may have one or two if you are stuck Ant, as well as the UNF nuts to be able to unscrew the stud

(UNC into casting & UNF at top IIRC?)

(UNC into casting & UNF at top IIRC?)

Ant. said:

So you managed to find the pipe I mentioned??

Not from any regular DIY place but sourced some stainless 15mm O/D stuff from a place that plumbs food factories etc... needed a mandrel bender to cope with it but pleased with the results. Think there would be room for two runs of 13mm I/D silicone under the inlet manifold as an alternative.Edited by Pupp on Monday 2nd November 12:59

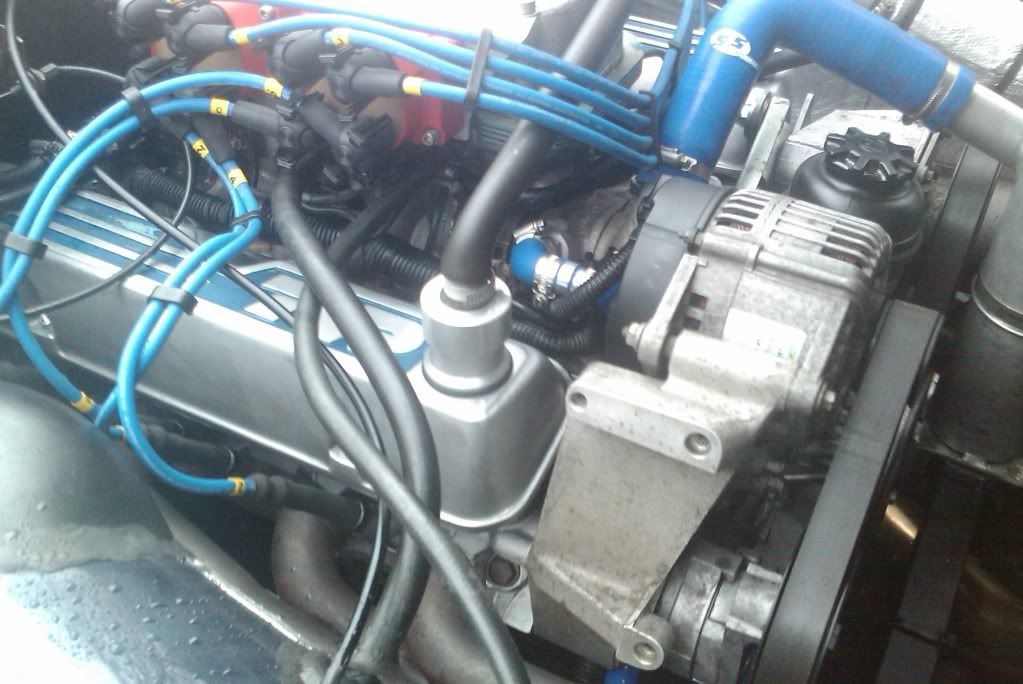

Ok, here's what mine looks like... used a pair of 90deg silicone bends off the manifold with an ally joiner... gets round to the pipe nice and neatly though I guess a 180deg elbow would fit in there with some jiggling (it's tight behind the alternator). Access to the O/S exhaust manifold bolts and rocker cover is much enhanced

Gassing Station | Chimaera | Top of Page | What's New | My Stuff