Ask a plumber/heating ‘engineer’ anything

Discussion

a viesmann 200 30KW combi can do almost 17Lpm dhw and will run 2 showers just fine if you restrict the showers flow rates

the storage combis can provide a hell of alot of flow without having to go stupid on the output

viessmann are expensive though the 222-F 32kw is about 3600 on its own the 111-w is 2200 ish

i do love my viessmann boiler maybe a bit too much

the storage combis can provide a hell of alot of flow without having to go stupid on the output

viessmann are expensive though the 222-F 32kw is about 3600 on its own the 111-w is 2200 ish

i do love my viessmann boiler maybe a bit too much

Edited by Trustmeimadoctor on Friday 12th April 16:25

Was about to change a kitchen tap, new one comes with flexibles that terminate with a female end

and that's fine for the cold pipe which is terminated with an inline pressure adjuster. This is the hot pipe end

Am I best to see if I can get a flexi to fit or to put an adjuster on this pipe as well, thus reversing the gender of the pipe end?

TIA

and that's fine for the cold pipe which is terminated with an inline pressure adjuster. This is the hot pipe end

Am I best to see if I can get a flexi to fit or to put an adjuster on this pipe as well, thus reversing the gender of the pipe end?

TIA

Fingers, toes and everything in between crossed I have hopefully now solved my boiler pressure issues.

When it was first being diagnosed the water in the system was oily black and the plumber said it needed a powerflush. However, as a result of having to refill the system from 0.1bar every day the water in the system appears to be a cloudy grey. My questions are

1. Now that the water looks clean does it still need a powerflush?

2. Assuming it does, I assume it makes sense to put inhibitor in AFTER the system's been flushed and not before?

3. Finally, does the fact that Ive been filling the system with fresh water daily for a month mean that I have possibly caused problems somewhere?

Thanks as always

When it was first being diagnosed the water in the system was oily black and the plumber said it needed a powerflush. However, as a result of having to refill the system from 0.1bar every day the water in the system appears to be a cloudy grey. My questions are

1. Now that the water looks clean does it still need a powerflush?

2. Assuming it does, I assume it makes sense to put inhibitor in AFTER the system's been flushed and not before?

3. Finally, does the fact that Ive been filling the system with fresh water daily for a month mean that I have possibly caused problems somewhere?

Thanks as always

Hi,

My pressurised system is losing pressure, I estimate at about 0.2 bar a week. I've also noticed I am having to bleed a rad at the top of the house fairly regularly.

We've recently had a lot of work done as part of an extension, so I've waited a while for all the air to pass through the system and things to settle down, but the system is still losing pressure over time.

I'm quite worried we have a leak somewhere and will have to tear up recently completed work at great expense. If it's a leak in the underfloor heating I would of course have a significant issue.

Could it be something less concerning or easily diagnosed or is this definitely a leak?

My pressurised system is losing pressure, I estimate at about 0.2 bar a week. I've also noticed I am having to bleed a rad at the top of the house fairly regularly.

We've recently had a lot of work done as part of an extension, so I've waited a while for all the air to pass through the system and things to settle down, but the system is still losing pressure over time.

I'm quite worried we have a leak somewhere and will have to tear up recently completed work at great expense. If it's a leak in the underfloor heating I would of course have a significant issue.

Could it be something less concerning or easily diagnosed or is this definitely a leak?

Hi - DIY'er renovating a small bathroom and getting confused about my wastes.

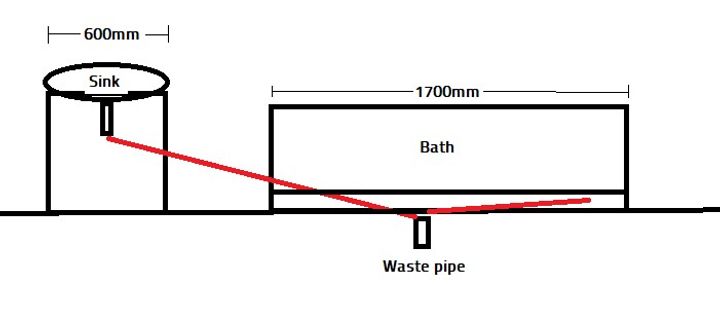

The bath and basin both drain into a waste pipe in the middle of the room. Bad paint image below!

Previously the bath (with a shallow trap) would gurgle and water would come up out of the bath plughole whenever the basin was being drained. I guess this was due to the pressure of water coming from the higher basin pushing the water out of the trap.

Also, if you partially emptied the bath to let some water out and then put the plug back in, the basin would gurgle and the room would smell of sewer. I guess this was due to the suction of the draining water pulling water from the basin trap.

Is this right? I'm not 100% on how to rectify this.

I think I need an anti-syphon trap for the basin and a self-sealing trap for the bath (or are these the same thing?).

Do I also need an air admittance valve somewhere? Is there any harm putting one on the basin side of the pipe anyway?

Would appreciate any recommendations on brands etc.

Cheers

The bath and basin both drain into a waste pipe in the middle of the room. Bad paint image below!

Previously the bath (with a shallow trap) would gurgle and water would come up out of the bath plughole whenever the basin was being drained. I guess this was due to the pressure of water coming from the higher basin pushing the water out of the trap.

Also, if you partially emptied the bath to let some water out and then put the plug back in, the basin would gurgle and the room would smell of sewer. I guess this was due to the suction of the draining water pulling water from the basin trap.

Is this right? I'm not 100% on how to rectify this.

I think I need an anti-syphon trap for the basin and a self-sealing trap for the bath (or are these the same thing?).

Do I also need an air admittance valve somewhere? Is there any harm putting one on the basin side of the pipe anyway?

Would appreciate any recommendations on brands etc.

Cheers

DoubleSix said:

Hi,

My pressurised system is losing pressure, I estimate at about 0.2 bar a week. I've also noticed I am having to bleed a rad at the top of the house fairly regularly.

We've recently had a lot of work done as part of an extension, so I've waited a while for all the air to pass through the system and things to settle down, but the system is still losing pressure over time.

I'm quite worried we have a leak somewhere and will have to tear up recently completed work at great expense. If it's a leak in the underfloor heating I would of course have a significant issue.

Could it be something less concerning or easily diagnosed or is this definitely a leak?

Could be a faulty expansion vessel as they have a lifespan. If that's the case it may be losing the water through the pressure relief valve. Can you see where that exits? Sometimes not easy (mine is high up), but see if you can tell if any water is dripping out of it when system running. How old is it?My pressurised system is losing pressure, I estimate at about 0.2 bar a week. I've also noticed I am having to bleed a rad at the top of the house fairly regularly.

We've recently had a lot of work done as part of an extension, so I've waited a while for all the air to pass through the system and things to settle down, but the system is still losing pressure over time.

I'm quite worried we have a leak somewhere and will have to tear up recently completed work at great expense. If it's a leak in the underfloor heating I would of course have a significant issue.

Could it be something less concerning or easily diagnosed or is this definitely a leak?

We had a faulty heat exchanger in our boiler which caused pressure loss. Less common but possible. The water would be leaving through the condensate pipe in that scenario. Obviously, water is supposed to come out of that pipe when it's condensing so the telltale is it dripping out when the system is off.

I'm tearing my hair out with the people currently working on our system and they're now trying to wash their hands of the situation entirely.

I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

Chucklehead said:

I'm tearing my hair out with the people currently working on our system and they're now trying to wash their hands of the situation entirely.

I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

Sticking my neck out and calling it can only be the diaphragm in the expansion vessel. Either it's a faulty vessel, or it's not been charged properly to 3 Bar.I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

Somebody said:

Sticking my neck out and calling it can only be the diaphragm in the expansion vessel. Either it's a faulty vessel, or it's not been charged properly to 3 Bar.

He has seen out three or four times and every time he just brings in his pump and plays around with the pressure in the tank and then goes down and adjusts the cold feed pressure coming into the house. Either he's not doing it properly, or he also doesn't know what it could be beyond that. My hot water only stays hot for about half an hour.

It’s an invented cylinder, heated by a traditional 45kw boiler.

I suspect that cold water is short-circuiting one of the mixer taps or showers, but with seven bathrooms and toilets many of which have piping inside the shower cubicle walls it’s not obvious how to find out where the issue is.

Any thoughts of a clever way to find out?

It’s an invented cylinder, heated by a traditional 45kw boiler.

I suspect that cold water is short-circuiting one of the mixer taps or showers, but with seven bathrooms and toilets many of which have piping inside the shower cubicle walls it’s not obvious how to find out where the issue is.

Any thoughts of a clever way to find out?

Ken_Code said:

My hot water only stays hot for about half an hour.

It’s an invented cylinder, heated by a traditional 45kw boiler.

I suspect that cold water is short-circuiting one of the mixer taps or showers, but with seven bathrooms and toilets many of which have piping inside the shower cubicle walls it’s not obvious how to find out where the issue is.

Any thoughts of a clever way to find out?

Similar scenario here -watch from 2 mins in It’s an invented cylinder, heated by a traditional 45kw boiler.

I suspect that cold water is short-circuiting one of the mixer taps or showers, but with seven bathrooms and toilets many of which have piping inside the shower cubicle walls it’s not obvious how to find out where the issue is.

Any thoughts of a clever way to find out?

Crumpet said:

I have a question….

We have two mains water supplies supplying two combi boilers. One of the combis is now dead but I’ve linked the working combi into both systems (and turned the stop tap off at one water supply) and it all functions fine. It’s just not great with two showers running.

A plumber has suggested that in order to keep a decent flow of hot water from the remaining combi I could run one mains supply as the cold feed to the whole house and the other mains supply to the combi boiler to provide the hot water to the house. This way I’d have maximum flow for the hot water at all times and flushing a cold-fed toilet wouldn’t affect the shower if you were running it at the same time.

Seems easy enough to do to me but are there any risks doing this with excess pressure on the system or balance issues at the outlets?

Further to my previous question, as quoted above, I went ahead and connected one mains supply to the combi for the hot water and the other supply to the cold. All seems good…..We have two mains water supplies supplying two combi boilers. One of the combis is now dead but I’ve linked the working combi into both systems (and turned the stop tap off at one water supply) and it all functions fine. It’s just not great with two showers running.

A plumber has suggested that in order to keep a decent flow of hot water from the remaining combi I could run one mains supply as the cold feed to the whole house and the other mains supply to the combi boiler to provide the hot water to the house. This way I’d have maximum flow for the hot water at all times and flushing a cold-fed toilet wouldn’t affect the shower if you were running it at the same time.

Seems easy enough to do to me but are there any risks doing this with excess pressure on the system or balance issues at the outlets?

I just want to check; even though the two supplies never meet, other than at the mixer taps, the water pressure would still be the same even if they did? Ie. 3 bar + 3 bar would still equal 3 bar, but the flow would be doubled?

Also, the mixed flow on a couple of the cheaper taps without restrictors is now a bit…..fierce. I assume it’s acceptable to moderate the flow with the isolation valves to the tap?

As for the shower flow…..I hadn’t realised how little you need for an acceptable shower. As a base line our garden taps do 20 litres per minute. Our main en-suite, which I assumed must’ve been chucking out 14+ litres per minute, was actually doing 10 and was a really nice flow. It’s still doing 10lpm with independent hot and cold so I think there’s either a restrictor still in the inlets or the boiler maxes out at around 10lpm.

The other (identical) shower was doing 8lpm and again has always been fine. It still does 8lpm.

Running both showers does still have an effect; the better one drops to 7lpm and the other one drops to 6lpm.

The good thing is that running a cold tap to brush teeth or flush the toilet has no effect whatsoever on the hot flow or shower, so that’s good.

Either way, my experiment is complete. You can run both showers together now and they remain acceptable - you’d notice the reduced flow but they’re usable. I think we’re being limited by the old, not-very-large, combi which doesn’t have particularly impressive DHW output. All the normal hot taps around the house will do 8lpm max. I guess a slightly bigger one would do better.

I need to replace a 18 year old sink tap. It is on copper tails down to a plastic Hep2o screwed connection on to 15mm copper.

The new tap won’t connect onto the existing copper tails as the thread at the tap body is smaller.

The new tap comes with flexible braided tails with a standard threaded connection to tighten on to a regular washing machine connection type of fitment

I would hope I can buy a Hep2o fitting that screws (not push fit) on to the existing hep2o plastic fittings which are inline t shaped bodies.

Issue is everything I search for that is hep2o looks like push fit. Has Hep2o moved on ? Any one know what I can use to join the two ?

Thanks

The new tap won’t connect onto the existing copper tails as the thread at the tap body is smaller.

The new tap comes with flexible braided tails with a standard threaded connection to tighten on to a regular washing machine connection type of fitment

I would hope I can buy a Hep2o fitting that screws (not push fit) on to the existing hep2o plastic fittings which are inline t shaped bodies.

Issue is everything I search for that is hep2o looks like push fit. Has Hep2o moved on ? Any one know what I can use to join the two ?

Thanks

people never listen when i say you dont need huge l/min for a shower

and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

Trustmeimadoctor said:

people never listen when i say you dont need huge l/min for a shower

and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

Totally. And I’m actually quite surprised. One of them is a deluge / rainfall type head and I honestly thought it must be running 14lpm+ as it’s that good. To find out it was doing 10lpm was a surprise. and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

Anyway, I know I’ve diverted the thread somewhat but after having numerous quotes for unvented cylinders, system boilers, storage combis and oversized combis which all came back at £5k+, I’ve decided I’m just going to stick with our crappy 28kwh and forget about it. I think I’ve spent maybe £150 on various fittings and £80 for a service so I’m pleased with that.

Trustmeimadoctor said:

people never listen when i say you dont need huge l/min for a shower

and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

This is encouraging to hear. I've been repeatedly told that 18lpm is too low for an unvented cylinder, as i want to run two showers from it, but it sounds like it should do fine.and you cetainly dont need it for a tap on a sink so get a 3lpm flow reducer in them

my shower is 5.4l/min is absolutely fine one issue is you cant just restrict any shower down and it be fine if its too big or the holes too big you do notice it but a well designed low flow head isnt hugely noticeable

Chucklehead said:

I'm tearing my hair out with the people currently working on our system and they're now trying to wash their hands of the situation entirely.

I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

There may be a small expansion vessel on the cold side somewhere? Check that is working OK.I noticed water dripping from our HW expansion tank one night. The next day someone was out to look at it and said best to replace the vessel. A like for like replacement was ordered because it's a tight fit and he wanted to be sure it'd fit. Some disassembly of the pipes underneath was required to get the old one out and new one in.

Since it was fitted we now get a really loud vibration / comedy fart-type noise coming from the tank. It usually happens in the evening when my wife goes to run herself a bath (having already run a bath for the kids). So i'm guessing it needs a drain/refill/heat cycle to do it. We also noticed the hot water pressure was poor.

They've been out several times to adjust the pressure in the tank, adjust our incoming cold feed pressure - and we either end up with lots of noise and poor pressure or no noise and awful pressure. As i said, they're trying to wash their hands of the situation now and telling me any more visits would be chargeable, but the way i see it the job isn't finished. If they found something else was faulty or needs replaced id pay for it, but they just keeping pumping things up or letting pressure out and saying that we should be fine after that.

I've been reading up about mixer taps and back pressure from cold through hot due to failed cartridges, but it feels like i'm clutching at straws. The engineer called the technical line for the expansion tank manufacturer and he has "already done everything they said it could be".

Any ideas?

If these isn't one, you may need one?

Does the pressure regulator valve do the whole system, hot and cold?

You need to consider the whole system, not just the bit that's been replaced.

Possibly the pressure regulator valve is failing. Does it have a gauge on it? does the gauge stay steady -ish when water is flowing?

This one might be a head scratcher but I'll give it a punt.

4 bedroom 2 storey house on multiple levels (rear rooms are higher than the front rooms).

1 x shower room with toilet

1 x shower room

1 x bathroom

2 x toilet rooms

Because there isn't enough space in the loft for tanks there's a plant / utility room at floor 1 1/4 (the level at the rear of the ground level). The utility room contains a freezer, washing machine, 245 litre unvented hot water tank, a boiler, a water softener, 227 litre cold water tank and a Grundfos Scala II pump which pushes the cold water around the house.

My main issues are as follows:

The Grundfos pump, although it does a great job is bloody noisy.

The 227 litre cold tank is absolutely massive and I'd rather something smaller so I can use the sockets behind it for a tumble dryer or something else.

When I specced it with the plumber I went with no loss of pressure across any of the showers if they are running at the same time. The reality is that I probably went too high on the spec and the plumber delivered a solution which would deliver against that.

So what options are available to either do away with the tank / pump or just the tank?

4 bedroom 2 storey house on multiple levels (rear rooms are higher than the front rooms).

1 x shower room with toilet

1 x shower room

1 x bathroom

2 x toilet rooms

Because there isn't enough space in the loft for tanks there's a plant / utility room at floor 1 1/4 (the level at the rear of the ground level). The utility room contains a freezer, washing machine, 245 litre unvented hot water tank, a boiler, a water softener, 227 litre cold water tank and a Grundfos Scala II pump which pushes the cold water around the house.

My main issues are as follows:

The Grundfos pump, although it does a great job is bloody noisy.

The 227 litre cold tank is absolutely massive and I'd rather something smaller so I can use the sockets behind it for a tumble dryer or something else.

When I specced it with the plumber I went with no loss of pressure across any of the showers if they are running at the same time. The reality is that I probably went too high on the spec and the plumber delivered a solution which would deliver against that.

So what options are available to either do away with the tank / pump or just the tank?

bmwmike said:

This is encouraging to hear. I've been repeatedly told that 18lpm is too low for an unvented cylinder, as i want to run two showers from it, but it sounds like it should do fine.

try a something like this https://www.amazon.co.uk/Restrictor-Reducer-Limite...good quality ones are made by neoperl

i use this in the ensuite https://www.hansgrohe.co.uk/articledetail-vernis-b...

or hand held something like this

https://uk.methven.com/showers/shower-handsets/kir...

Edited by Trustmeimadoctor on Friday 10th May 16:49

RustyMX5 said:

This one might be a head scratcher but I'll give it a punt.

4 bedroom 2 storey house on multiple levels (rear rooms are higher than the front rooms).

1 x shower room with toilet

1 x shower room

1 x bathroom

2 x toilet rooms

Because there isn't enough space in the loft for tanks there's a plant / utility room at floor 1 1/4 (the level at the rear of the ground level). The utility room contains a freezer, washing machine, 245 litre unvented hot water tank, a boiler, a water softener, 227 litre cold water tank and a Grundfos Scala II pump which pushes the cold water around the house.

My main issues are as follows:

The Grundfos pump, although it does a great job is bloody noisy.

The 227 litre cold tank is absolutely massive and I'd rather something smaller so I can use the sockets behind it for a tumble dryer or something else.

When I specced it with the plumber I went with no loss of pressure across any of the showers if they are running at the same time. The reality is that I probably went too high on the spec and the plumber delivered a solution which would deliver against that.

So what options are available to either do away with the tank / pump or just the tank?

do you mean pressure or flow rate, id assume flow rate.4 bedroom 2 storey house on multiple levels (rear rooms are higher than the front rooms).

1 x shower room with toilet

1 x shower room

1 x bathroom

2 x toilet rooms

Because there isn't enough space in the loft for tanks there's a plant / utility room at floor 1 1/4 (the level at the rear of the ground level). The utility room contains a freezer, washing machine, 245 litre unvented hot water tank, a boiler, a water softener, 227 litre cold water tank and a Grundfos Scala II pump which pushes the cold water around the house.

My main issues are as follows:

The Grundfos pump, although it does a great job is bloody noisy.

The 227 litre cold tank is absolutely massive and I'd rather something smaller so I can use the sockets behind it for a tumble dryer or something else.

When I specced it with the plumber I went with no loss of pressure across any of the showers if they are running at the same time. The reality is that I probably went too high on the spec and the plumber delivered a solution which would deliver against that.

So what options are available to either do away with the tank / pump or just the tank?

how much do you want in lpm from each shower

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff