Anyone interested in home-built sailing dinghies?

Discussion

Huff said:

This looks great fun, and wholly achievable as a home build - wish I had the space! Lovely thread and updates so far, much like.

Thanks for reading, and you're right, I'm loving this. I sincerely hope this isn't my last boat. I only wish the price of wood was much lower!Apparently one of these has been built in only a single car garage but whilst that's where mine is currently kept I do have the 75ft outbuilding where usually the cars live to lay out sheets of plywood and run boards through the planer thicknesser etc. It's a little inconvenient when I have to start up the XJ-S to move it outside left it get covered in saw dust, but I'm in a very fortunate position so I always try to keep a positive view on it.

Work space was a very big factor in choosing where to live and my wife supported that. Whereas so many of my colleagues lost their livelihoods and homes following the oil price crash in 2015 I managed to keep mine even if things have been tight since. I got off lightly!

Brother D said:

Great Build!

I've been following this guy for ages - he does give some excellent tips but you look almost 90% completed already: )

I follow a number of boat channels on YT but have never seen that one - I'll give it a look. Thanks!I've been following this guy for ages - he does give some excellent tips but you look almost 90% completed already: )

As for my own boat, I goofed. I didn't try the tank fill test as it became obvious straight away that I'd missed a seam on top, so today between other household responsibilities which have dominated, I faffed about for a while squeezing glue into the bit I'd missed and filleted it from the inside with my arm inside the access hatch. I did some power sanding of the lower rubbing strips too. They've needed attention for weeks now but it's a very messy job so I moved it outside to do it.

Today's photo shows no obvious progress and a rather dirty Jag that needs a good clean. It's been outside for the past few days since the weather has been nice, but it's ended up covered in crap anyway and may as well have stayed in the big shed where I was industriously hacking marine ply, iroko and softwoods to pieces inside. It wouldn't have ended up much dustier!

[img]

I cut out the vertical bulkheads under the thwarts which will box in the lockers. They haven't been glued in yet.

I also cut the bevel on the stringers which will support each thwart. My more experienced betters will notice that I failed to allow for this properly when I cut the notches in the frames, and because of this I'll need to add little wedges to push the stringer outboard against the hull properly.

I also cut the bevel on the stringers which will support each thwart. My more experienced betters will notice that I failed to allow for this properly when I cut the notches in the frames, and because of this I'll need to add little wedges to push the stringer outboard against the hull properly.

Hi, it's all coming along nicely. From my own experience many years ago after renovating a wrecked Cherub dingy, I would recomend having a look at your trailer and seeing where the rollers and supports will be and reinforcing the areas corresponding to them within the boat. After a race to get the Cherb together, I had two issues on putting the boat in the water that were no immediately apparant until i came to the first tack. No 1 being i had not left enough room between the sheets and the tiller arm to get through. Then once capsised i found out the jouney of 300 plus miles on the trailer had released the bouyancy tank wood and battons from the inner hull wood and we sank stern first! fortunately i had chosen slack tide and a helpful harbour master towed me back to the ramp. The sheet issue was easy to fix as there were two sheet locking positions on the boom and i had chosen the boom end one so moved it to mid boom and that was that solved. then a trip to the chandlers and bought allot of cascamite and expanded the space between the hull and buoyancy tanks filling them up with the cascamite and then afterwards mixing it with sawdust from one of the boat builders trash cans nearby making some enlarged fillets on the inside of the bouyancy tanks to the hull. Two days later back in the water and having fun with a couple of lessons learned carried on to other boats afterwards.

rolster said:

Hi, it's all coming along nicely. From my own experience many years ago after renovating a wrecked Cherub dingy, I would recomend having a look at your trailer and seeing where the rollers and supports will be and reinforcing the areas corresponding to them within the boat. After a race to get the Cherb together, I had two issues on putting the boat in the water that were no immediately apparant until i came to the first tack. No 1 being i had not left enough room between the sheets and the tiller arm to get through. Then once capsised i found out the jouney of 300 plus miles on the trailer had released the bouyancy tank wood and battons from the inner hull wood and we sank stern first! fortunately i had chosen slack tide and a helpful harbour master towed me back to the ramp. The sheet issue was easy to fix as there were two sheet locking positions on the boom and i had chosen the boom end one so moved it to mid boom and that was that solved. then a trip to the chandlers and bought allot of cascamite and expanded the space between the hull and buoyancy tanks filling them up with the cascamite and then afterwards mixing it with sawdust from one of the boat builders trash cans nearby making some enlarged fillets on the inside of the bouyancy tanks to the hull. Two days later back in the water and having fun with a couple of lessons learned carried on to other boats afterwards.

Thanks! That's a very good point actually. I don't have a trailer yet, but I am regularly browsing the classifieds for a second hand one, and the designer of my dinghy certainly has strong views on trailers to avoid the sort of dramas you've experienced.The designer recommends a trailer which can have rollers to help the boat on fine enough but he insists it's better to support the hull from runners lined with carpet or similar under the chines and for a decent length of the hull rather than the weight being point-loaded along the keel as the trailer bounces and crashes through potholes.

To that end, I'm on the lookout for a trailer I can use as a basis to modify to suit my dinghy. I am going to glass tape over the filleted joints that weren't already glass taped before, since I don't really mind the extra weight but do want to have a strong dinghy.

Tangentially related is that I've acquired a decent combination road trailer and launching dolly. It appeared on Facebook market place 3 hours away. The seller was very nice and offered to arrange a family visit to a relative part-way and towed it there to meet me. I'm between cars with a towbar at the moment so my dad loaned me his car to collect it.

It's been a while since I've towed anything but it comes back quickly enough. We made the trip back without event and tried the boat on. As expected, the length suits the Campion Apple 16 well, and also as expected I have some cutting and welding to customise the hull supports to the boat. The designer recommends longer boards with carpet on top under the chines to support the hull over a larger area.

It's been a while since I've towed anything but it comes back quickly enough. We made the trip back without event and tried the boat on. As expected, the length suits the Campion Apple 16 well, and also as expected I have some cutting and welding to customise the hull supports to the boat. The designer recommends longer boards with carpet on top under the chines to support the hull over a larger area.

I'm ashamed to say I haven't touched the boat since my wife was in hospital in July. I've actually done nothing at all other than work and tile a friend's bathroom since summer - I just haven't had, well, I'm not sure what.

Anyway. I had had to defer a lot of leave from work and this meant I finished up on the 19th December. It's taken until yesterday to feel sufficiently motivated to do something practical, although my wife and I have booked ourselves onto a sail making course in Orkney this coming April which is a formal course with an online learning element to do before the practical week there in person. There will be 8 people on the course including us, and we're going to be constructing my two headsails there as the subject. The teacher says that providing I am happy with the odd wonky seam they will be perfectly serviceable, and it'll cost only the materials - about £250. I'm happy with that (and if I'm really not happy to take them I don't have to).

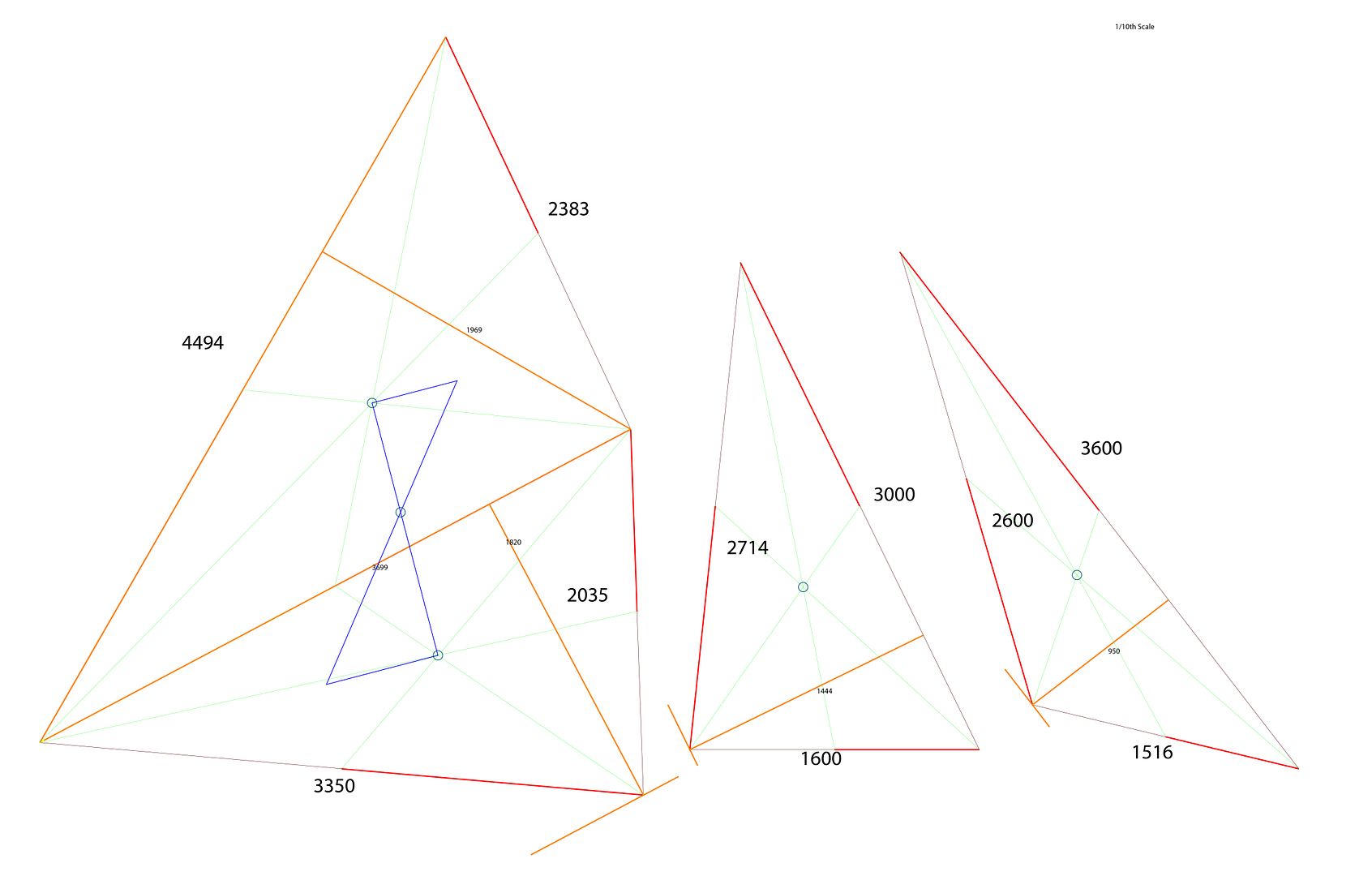

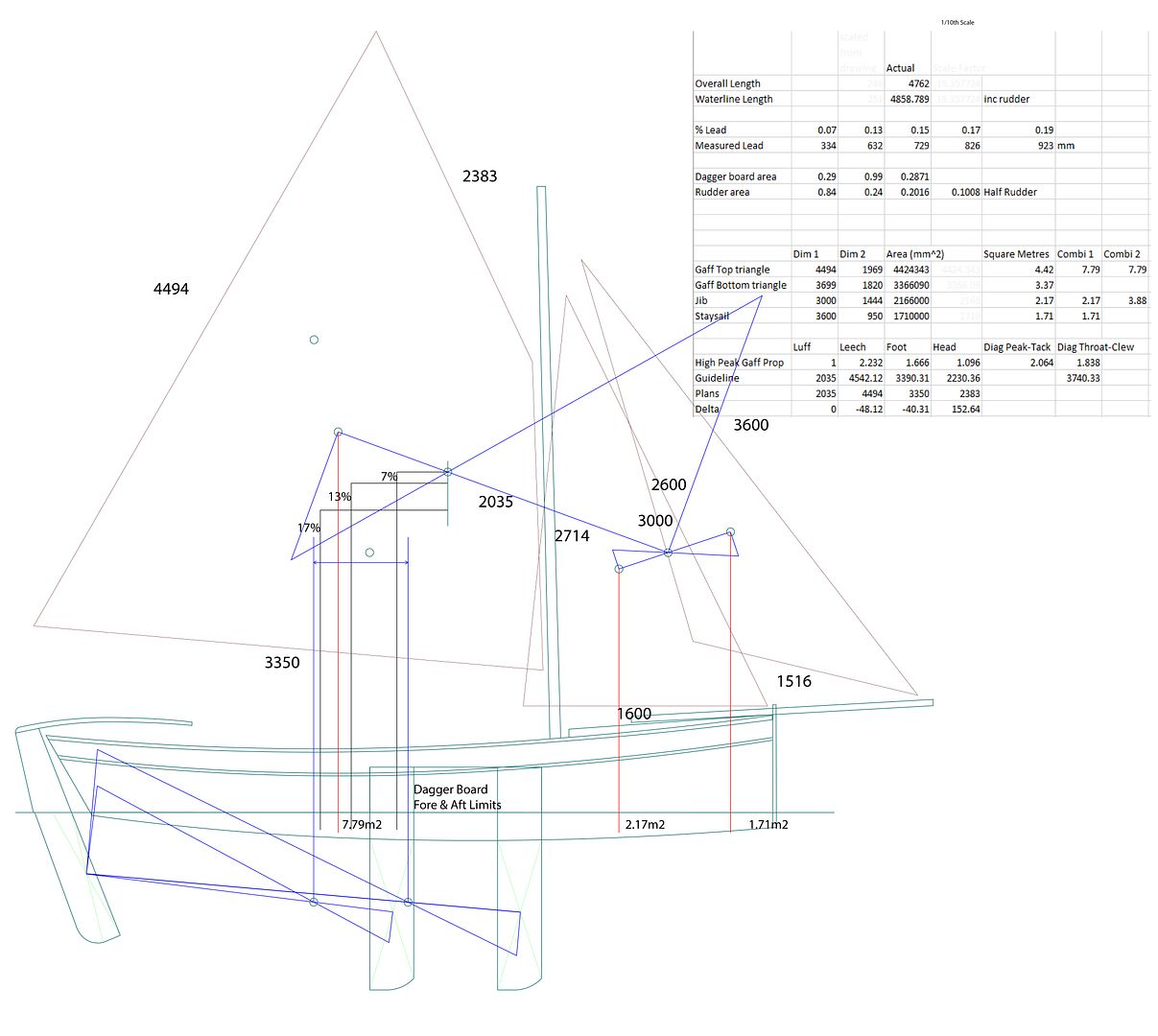

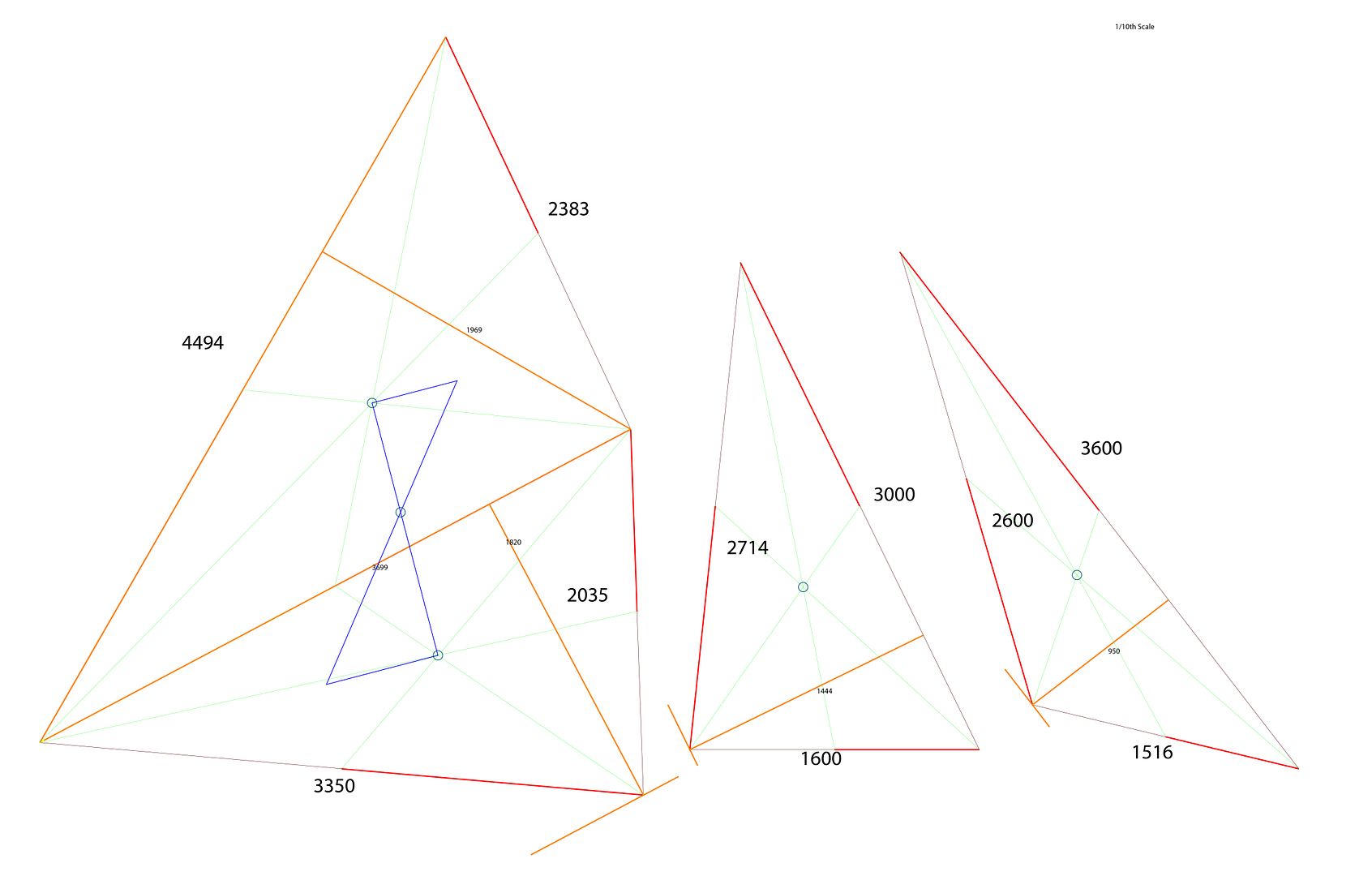

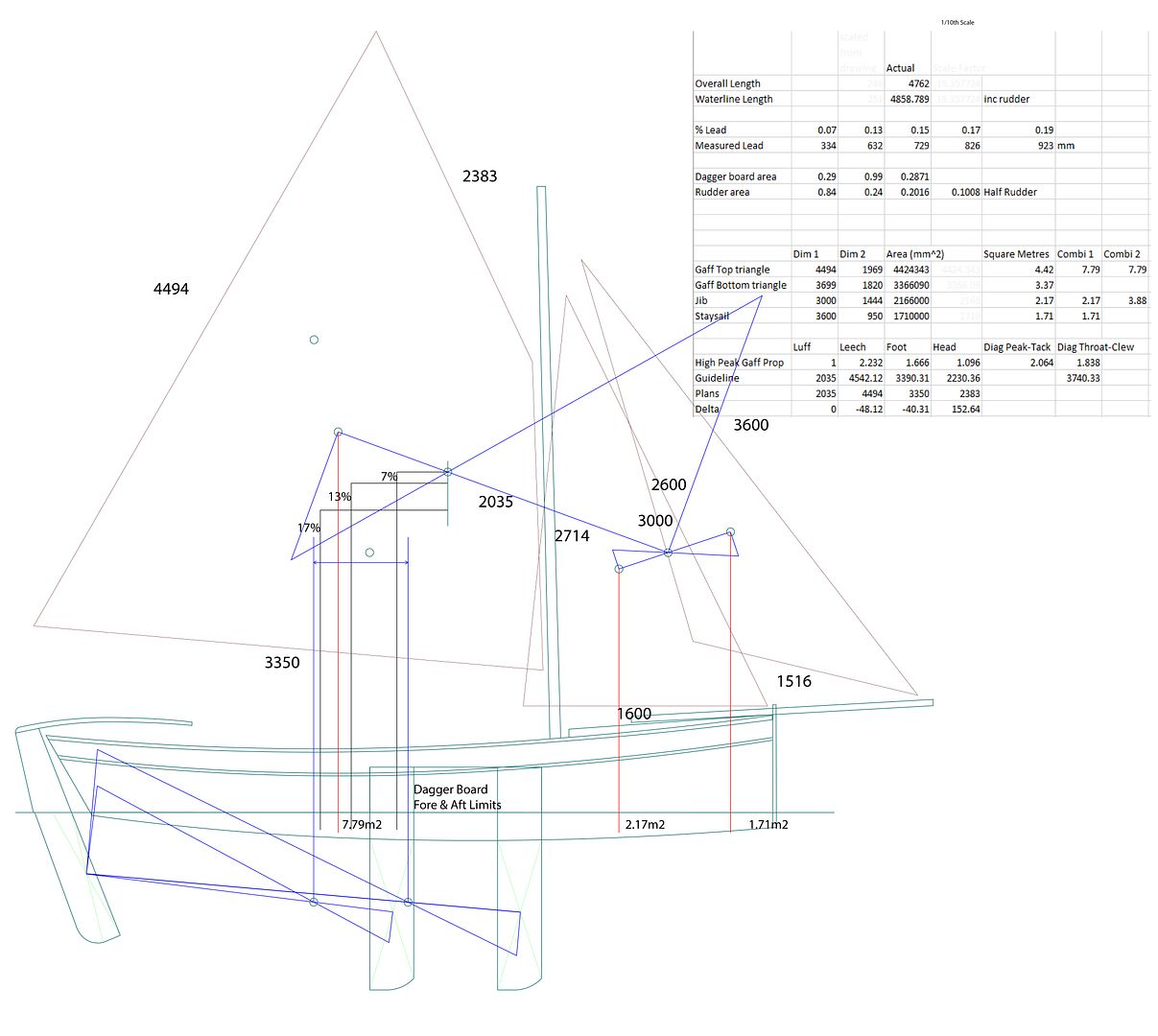

I have started the online learning on Boxing Day, because I really don't enjoy Christmas/New Year and I wanted to do something useful. I've been learning how to calculate my Centre(s) of Lateral Effort and, approximately, Resistance. The designer of the boat obviously already did this but I'm enjoying learning stuff I expect most reading already know.

Practical progress at last though! Yesterday my daughter helped me assess the Douglas Fir I bought some time ago and we were very pleasantly surprised to find it 100mm longer than Melitele's mast. I must have been thinking clearly when I ordered it but since forgot - I had assumed the mast would need scarphed. Happily not. The mast dimensions are 4200mm tall for the keel stepped option and 70mm diameter. There's a taper down to 50 or 55mm along the top 1000 mm. The Fir board was 38~39mm thick, so we sawed it down to two boards 74mm wide. Today she helped me thickness plane them down to 35mm. Melitele has been relegated back to the big unheated shed whence it came as we need the heated garage for some equipment we bought for our business which needs a stable temperature.

All of this has resulted in us gluing Melitele's mast in our living room ??

Anyway. I had had to defer a lot of leave from work and this meant I finished up on the 19th December. It's taken until yesterday to feel sufficiently motivated to do something practical, although my wife and I have booked ourselves onto a sail making course in Orkney this coming April which is a formal course with an online learning element to do before the practical week there in person. There will be 8 people on the course including us, and we're going to be constructing my two headsails there as the subject. The teacher says that providing I am happy with the odd wonky seam they will be perfectly serviceable, and it'll cost only the materials - about £250. I'm happy with that (and if I'm really not happy to take them I don't have to).

I have started the online learning on Boxing Day, because I really don't enjoy Christmas/New Year and I wanted to do something useful. I've been learning how to calculate my Centre(s) of Lateral Effort and, approximately, Resistance. The designer of the boat obviously already did this but I'm enjoying learning stuff I expect most reading already know.

Practical progress at last though! Yesterday my daughter helped me assess the Douglas Fir I bought some time ago and we were very pleasantly surprised to find it 100mm longer than Melitele's mast. I must have been thinking clearly when I ordered it but since forgot - I had assumed the mast would need scarphed. Happily not. The mast dimensions are 4200mm tall for the keel stepped option and 70mm diameter. There's a taper down to 50 or 55mm along the top 1000 mm. The Fir board was 38~39mm thick, so we sawed it down to two boards 74mm wide. Today she helped me thickness plane them down to 35mm. Melitele has been relegated back to the big unheated shed whence it came as we need the heated garage for some equipment we bought for our business which needs a stable temperature.

All of this has resulted in us gluing Melitele's mast in our living room ??

Edited by jamieduff1981 on Thursday 29th December 19:52

jamieduff1981 said:

I'm ashamed to say I haven't touched the boat since my wife was in hospital in July. I've actually done nothing at all other than work and tile a friend's bathroom since summer - I just haven't had, well, I'm not sure what.

I finished up on the 19th December. It's taken until yesterday to feel sufficiently motivated to do something practical,

All of this has resulted in us gluing Melitele's mast in our living room ??

Don't be ashamed. I finished up on the 19th December. It's taken until yesterday to feel sufficiently motivated to do something practical,

All of this has resulted in us gluing Melitele's mast in our living room ??

It's taken me about 6 years to complete and engine swap on the Westfield after the previous engine dropped a valve. Not a direct swap, but the closest alternative 20 year newer model, maybe 10 days work if alone and not pushing yourself.

Life, partners, houses, children, work, mental health, all get in the way and sometimes it's important to let it.

Love the project, love the mast being in the living room.

Daniel

dhutch said:

Don't be ashamed.

It's taken me about 6 years to complete and engine swap on the Westfield after the previous engine dropped a valve. Not a direct swap, but the closest alternative 20 year newer model, maybe 10 days work if alone and not pushing yourself.

Life, partners, houses, children, work, mental health, all get in the way and sometimes it's important to let it.

Love the project, love the mast being in the living room.

Daniel

It's taken me about 6 years to complete and engine swap on the Westfield after the previous engine dropped a valve. Not a direct swap, but the closest alternative 20 year newer model, maybe 10 days work if alone and not pushing yourself.

Life, partners, houses, children, work, mental health, all get in the way and sometimes it's important to let it.

Love the project, love the mast being in the living room.

Daniel

Super post i concur with; all similar stuff as to why my Fisher Fury (for no particular reasons, except mental health vs stress vs then- no time through last 3 yrs, having banished the first two ...) hasn't gone anywhere in nrly 5yrs, at least.

The point is - it will again; soon. I want to make 2023 the season.

Spem in Alium. Hope in All Things.

(abs not in a religious sense at all - just a useful thing to remember.

Oh, and a sublime piece of music in its own right.)

ApOrbital said:

What a great thread hope your wife is better now.

Thank you, she is. She needed a fairly simple surgical procedure but it meant cutting her open and there was a recovery period needed once abdominal muscles have been cut through - similar to that needed after a caesarean section. It all went well but I'd taken the week off work to generally be around and do all the stuff around the house she normally does so between that and while she was sleeping I was able to get a bit done on the boat every day almost which felt great.We got some more done today.

With the glue on the mast cured, my daughter today helped me plane it down to final dimensions (and square!) before marking on the taper at the top 1000mm using a baton. The taper was cut down with a hand-held power planer which is one of my power tools I'm less confident with due to variable results. Practise makes perfect though, apparently, and whilst not actually perfect the mast is close enough and we're happy with it.

The next job is to mark on lines to guide the planer (or me, really) as we turn it from a 4 sided square to an 8 sided octogon cross section. We'll then knock the corners off again to make it 16 sided before changing to the hand planer to make it 32 sided before finishing to the final round shape with a sanding belt.

To aid marking for the first octogon shape we've made a marking gauge from a piece of wood, 2 nails and 2 pencils. They're spaced in a ratio of 7-10-7 which draws on where the new corners will be.

Unfortunately I've had an annoyingly small part break on my old Jag XJ-S which none-the-less renders it undriveable (the end of the gear selector cable has broken off - it left the gearbox in reverse when it failed and yesterday the car tried to take off backwards and would have smashed Melitele had I not been quick on the brakes) meaning the big garage is unavailable for big woodwork so I'm doing this outside. Up here in NE Scotland I'm above 57deg North so daylight is fading and it doesn't seem like a good idea to try planing my mast octagonal in the dark, so that's me done for the night I think.

ApOrbital said:

You are albert einstein AICMFP

Alas not my idea at all - none of these things are - I'm just copying more experienced builders. This little widget worked pretty well though

I started planing the square down to octagon but the very low cost and rather aged power planer gave out shortly after beginning. It still runs but makes funny noises. I think a bearing may have gone. Anyway, I bought one from Screwfix on Click and Collect and drove over to Inverurie to collect it then did the rest after lunch. The light was fading so I haven't attempted the final sanding but the mast is now a 32 sided cylinder ready for that. The part came for the XJ-S too so I'll try to get that fitted tomorrow so it's not in the way any more.

Gassing Station | Boats, Planes & Trains | Top of Page | What's New | My Stuff