Ethiopian plane crash

Discussion

So in short, does this issue only affect the CFM56-7 that's fitted to the 737NG and not the CFM56-5 that's fitted to the Airbus A318/319/320/321/340?

Also, on the Boeing/de Havilland question, I thought the problem was that BOAC basically became Boeing Only Airways Corporation and that was what finished off both de Havilland and eventually Vickers after the VC10 didn't produce the number of BOAC orders that were expected?

Also, on the Boeing/de Havilland question, I thought the problem was that BOAC basically became Boeing Only Airways Corporation and that was what finished off both de Havilland and eventually Vickers after the VC10 didn't produce the number of BOAC orders that were expected?

alangla said:

So in short, does this issue only affect the CFM56-7 that's fitted to the 737NG and not the CFM56-5 that's fitted to the Airbus A318/319/320/321/340?

Also, on the Boeing/de Havilland question, I thought the problem was that BOAC basically became Boeing Only Airways Corporation and that was what finished off both de Havilland and eventually Vickers after the VC10 didn't produce the number of BOAC orders that were expected?

737 only, the A320 family nacelle is round due much longer landing gear.Also, on the Boeing/de Havilland question, I thought the problem was that BOAC basically became Boeing Only Airways Corporation and that was what finished off both de Havilland and eventually Vickers after the VC10 didn't produce the number of BOAC orders that were expected?

George Smiley said:

How did Boeing kill BOAC? Was it

A. The fitment of round windows

B. The fitment of windows with flattened tops and bottoms?

Boeing jet airliners have never had round windows.A. The fitment of round windows

B. The fitment of windows with flattened tops and bottoms?

In what way did Boeing kill BOAC anyway? BOAC stayed in existence until it merged with BEA and others to form British Airways. And BOAC was a keen supporter of Boeing products. It flew a number of 707 variants and later the 747-100.

alangla said:

Also, on the Boeing/de Havilland question, I thought the problem was that BOAC basically became Boeing Only Airways Corporation and that was what finished off both de Havilland and eventually Vickers after the VC10 didn't produce the number of BOAC orders that were expected?

In 1962 de Havilland became part of the Hawker Siddeley group as part of a forced merger ordered by the UK government. This was due to the UK government wanting the multiple separate airframe manufacturers to rationalise into larger groupings as there was insufficient work to keep 24 separate companies going - especially when the vast bulk of airframe orders were being paid for by the UK taxpayer (either the nationalised airlines - BEA and BOAC - or the military).As for BOAC wanting Boeings, that is indeed true because they were not convinced that the British designs they were being offered were going to be able to compete on a seat per mile basis compared to designs coming out of the US. The two designs they were looking at was the Vickers V1000 and later the Vickers VC-10.

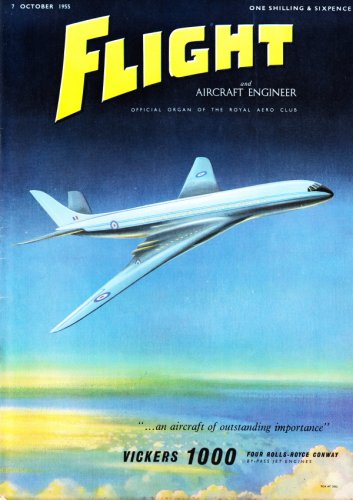

As you can see from the picture of V1000, you can see that its design was already looking a bit dated given that it would be entering service in the early 1960s, slightly behind the 707 and DC-8.

The VC-10 was an excellent aeroplane, but it just could not operate as economically as its rivals - which BOAC realised and therefore only ordered minimal quantities of the type.

The evidence for that is weak; maintenance costs may have been higher because of the engine location but the VC7/V1000 was not optimised for hot and high like the VC10 was. Even allowing that its seat/mile cost was higher, the ability of Boeing and Douglas to meet market demand was not there until the mid-1960s, as evidenced by the fact Convair actually managed to sell airliners; there was enough market demand for pretty much anything that flew for Vickers to sell the VC7 in the low hundreds if it was brought to market as forecast in 59/60, arguably it may have been supplied to airlines much sooner than that as after 1956 there was no longer any need to give the RAF priority. With enough sales to keep Vickers in the black and in the civil aircraft game I'm quite sure George Edwards would have had a redesigned wing with underslung engines and taller undercarriage ready by the mid-60s, with or without BOAC support.

El stovey said:

George Smiley said:

El stovey said:

MartG said:

NoddyonNitrous said:

MartG said:

Read the NTSB article linked above - the blade didn't get as far as the cowling, but the impact of it inside the engine transferred enough energy via the engine casing and engine mountings to damage the cowling

So the engine casing didn't contain the damage as it was supposed to.The reports says.

“The separated fan blade impacted the engine fan case and fractured into multiple fragments.

fan blade’s impact with the fan case caused the fan case to deform locally over a short period of

Some of the fan blade fragments traveled forward of the engine and into the inlet.

. . .

This deformation traveled both around and forward/aft of the fan case. After reaching the airplane structure (the inlet attach ring, which was secured to the engine fan case A1 flange), the deformation generated large loads that resulted in local damage to the inlet. The forward-traveling fan blade fragments and the deformation compromised the structural integrity of the inlet, causing portions of the inlet to depart the airplane.”

We’re discussing whether the engine contained all the parts of the fan blade which it didn’t. Some of them hit the inlet and nacelle. The damage wasn’t just caused by vibration and energy being transferred as stated, it was caused by “forward travelling fan blade fragments”

The deformation is designed to travel with the debris. That’s a feature, not a bug. It takes time & distance to absorb the energy from a loose blade. Our system used a complex combination of a 3d titanium “ring” and Kevlar wrapping. It was designed so the blade would penetrate the ring, but be contained by the Kevlar. As it continued to rotate the failure of the ring absorbed the (tremendous) energy.

Go to 4:31 in this video: https://youtu.be/j973645y5AA - note that the “clever stuff” is not shown on this video but you’ll get an idea and see some of the deformation.

The nacelle should have sufficient internal clearance to allow this to happen.

In the extant case, it seems the containment system failed to contain the fan blade.

Now the report is unclear as to how parts of the blade came free. But if the blade were to break then only the outer portions would be contained by such a ring - inner parts would be free.

You can’t stop that. All you can design for is to prevent axial penetration & hope the blade stays together.

In the current case, it sounds like everything stacked up in an unfortunate way. To me however it seems hard to point a finger of blame; rather, this should be a learning experience. Every blade off event is different; if simply isn’t possible to contain every variation.

hidetheelephants said:

The evidence for that is weak; maintenance costs may have been higher because of the engine location but the VC7/V1000 was not optimised for hot and high like the VC10 was. Even allowing that its seat/mile cost was higher, the ability of Boeing and Douglas to meet market demand was not there until the mid-1960s, as evidenced by the fact Convair actually managed to sell airliners; there was enough market demand for pretty much anything that flew for Vickers to sell the VC7 in the low hundreds if it was brought to market as forecast in 59/60, arguably it may have been supplied to airlines much sooner than that as after 1956 there was no longer any need to give the RAF priority. With enough sales to keep Vickers in the black and in the civil aircraft game I'm quite sure George Edwards would have had a redesigned wing with underslung engines and taller undercarriage ready by the mid-60s, with or without BOAC support.

In other words, a completely new aeroplane

The civil airliner manufacturers in the UK were trying to tailor their designs to suit the perceived needs of the nationalised carriers - BEA and BOAC. The problem was that the market was changing and what an airline thought it might need in 1960 had radically altered by 1965, leaving the British designs a bit high and dry with little or no market.

The American manufacturers boxed a bit more cleverly, although they took big risks too. But they had the capability and capacity to offer multiple versions of each design and (normally) survive any commercial failures.

I think your inclusion of the Convair jets actually shows the gambles that the Americans were prepared to take. The Convair 880 and 990 were absolute commercial flops and more or less bankrupted Convair in what was one of the greatest corporate disasters up to that time.

Lockheed also flopped with their Electra. It shows that it was a tough period for manufacturers as it was not 100% clear how the airline industry would pan out over the next decade or so. Boeing and Douglas got it right with the 707 and DC-8. Others didn't with their designs.

Speed 3 said:

Am I right in thinking a slat track sounds like a rather important piece of the flight control apparatus?Teddy Lop said:

Speed 3 said:

Am I right in thinking a slat track sounds like a rather important piece of the flight control apparatus?scottydoesntknow said:

hutchst said:

Finding and repairing these things is a sign of a system that works

The article says the FAA said Boeing knowingly installed faulty parts.They knew the parts were defective. They knew they had received them. But then they kind of lost track of them.

I'd say they failed to correctly control faulty parts such that they ended up being fitted to planes, when they should not have been.

Munter said:

scottydoesntknow said:

hutchst said:

Finding and repairing these things is a sign of a system that works

The article says the FAA said Boeing knowingly installed faulty parts.They knew the parts were defective. They knew they had received them. But then they kind of lost track of them.

I'd say they failed to correctly control faulty parts such that they ended up being fitted to planes, when they should not have been.

The FAA said

“Boeing failed to maintain its quality system by failing to detect improperly marked slat tracks, installing improperly marked slat tracks in aircraft, and not managing supplier quality,”

Not great but not the same as knowingly installing faulty parts.

Gassing Station | News, Politics & Economics | Top of Page | What's New | My Stuff

ked.

ked.