Discussion

Just discovered this thread.

Did a City and Guilds in Furniture making when I retired, have made quite a bit of furniture and nic nacs. Currently making a bass guitar out of wenge, maple and black walnut.

First thing I made for my own workshop was my bench. Cost me about £6 for the recycled softwood, the fixings cost more! But I am quite tall so it was made to measure so to speak.

Interesting to see what other people are up to.

Re tools, a low angle block plane is indispensable in my view, and they do not cost a great deal unless you go down the Lie Neilsen route.

Did a City and Guilds in Furniture making when I retired, have made quite a bit of furniture and nic nacs. Currently making a bass guitar out of wenge, maple and black walnut.

First thing I made for my own workshop was my bench. Cost me about £6 for the recycled softwood, the fixings cost more! But I am quite tall so it was made to measure so to speak.

Interesting to see what other people are up to.

Re tools, a low angle block plane is indispensable in my view, and they do not cost a great deal unless you go down the Lie Neilsen route.

uncinqsix said:

Depends on your table. Some have universal clamp thingies that can take almost any router, while others have screw holes that you screw the base of the router to. Usually 4 holes in a square at 85mm spacing.

You do lose a little depth, but normally only around 6mm or so. This isn't a problem for the bigger 1/2" routers that normally get used in tables, but might limit what your 1/4" one can do.

It is fairly simple to make your own router table, there are many options out there with different levels of elegance. You do lose a little depth, but normally only around 6mm or so. This isn't a problem for the bigger 1/2" routers that normally get used in tables, but might limit what your 1/4" one can do.

I feel this instance is not the most elegant solution but has some ingenuity being portable and space saving with a good old hillbilly style routalift to make adjustments to bit cutting height somewhat easier. He also mills out some of the thickness of the top to insert the router base, minimising loss of cutter length without losing too much support from a sturdy top. Obviously you do lose the advantage of a close fit to the different size bits a table insert provides, but as a starter it seems pretty innovative.

https://www.youtube.com/watch?v=-xHVPCrR7OU&ap...

SeeFive said:

It is fairly simple to make your own router table, there are many options out there with different levels of elegance.

I feel this instance is not the most elegant solution but has some ingenuity being portable and space saving with a good old hillbilly style routalift to make adjustments to bit cutting height somewhat easier. He also mills out some of the thickness of the top to insert the router base, minimising loss of cutter length without losing too much support from a sturdy top. Obviously you do lose the advantage of a close fit to the different size bits a table insert provides, but as a starter it seems pretty innovative.

https://www.youtube.com/watch?v=-xHVPCrR7OU&ap...

Table inserts are available quite cheaply from Aliexpress as another option. Bit of a dice-roll when it comes to quality, but there are a few on there that look pretty good. I currently have a triton table with the aforementioned clamp thingies, but I'm planning to try one of those inserts at some stage. I feel this instance is not the most elegant solution but has some ingenuity being portable and space saving with a good old hillbilly style routalift to make adjustments to bit cutting height somewhat easier. He also mills out some of the thickness of the top to insert the router base, minimising loss of cutter length without losing too much support from a sturdy top. Obviously you do lose the advantage of a close fit to the different size bits a table insert provides, but as a starter it seems pretty innovative.

https://www.youtube.com/watch?v=-xHVPCrR7OU&ap...

Any tips for getting square cuts? My hand saw seems to leave a curved surface usually so I switched to my cheap circular saw for a project I am making, a ladder type frame held together with dowels. So all the middle pieces needed to be the same length and square. Endless fiddling to get them and a guide clamped, as I find I need a guide to cut straight. Saw body hits clamp. One piece of wood works loose. Etc. Then I cut the bits and it seems the cut is circa 10 degrees off square so in doesn’t fit perfectly. The saw is notionally on the 90 degree marker but clearly not.

I am thinking a table saw would help me chop things consistently and square, or a mitre saw?

Probably mostly a bad work man blaming his cheap tools but I can’t spend a fortune.

Thinking of looking on Facebook marketplace or eBay but I don’t want to get another wonky tool that doesn’t adjust easily for instance.

I am thinking a table saw would help me chop things consistently and square, or a mitre saw?

Probably mostly a bad work man blaming his cheap tools but I can’t spend a fortune.

Thinking of looking on Facebook marketplace or eBay but I don’t want to get another wonky tool that doesn’t adjust easily for instance.

snowman99 said:

I am thinking a table saw would help me chop things consistently and square, or a mitre saw?

If you only have the budget for one power saw then it needs to be a plunge/track saw.The best way to achieve square cuts is with the above and an MFT style table top and some 'dogs' to fit it. You can make your own using the Axminster Tools Parf system but for now it would be cheaper to buy an MFT top from eBay.

Many things can cause you not to get a straight accurate cut. The type of saw used, how sharp it is, have the teeth on one side bin "knocked" out of shape (perhaps when previosley cutting too near concrete or steel) How accurate is your mitre block (if using one) how accurate is your set square. Are you marking the wood accurately. Are you using the saw right.

Regarding the mitre saw depending on the saw it may be able to adjust the angle it cuts but again unless the set square you use isn't correct it won't work.

Regarding the mitre saw depending on the saw it may be able to adjust the angle it cuts but again unless the set square you use isn't correct it won't work.

singlecoil said:

snowman99 said:

I am thinking a table saw would help me chop things consistently and square, or a mitre saw?

If you only have the budget for one power saw then it needs to be a plunge/track saw.The best way to achieve square cuts is with the above and an MFT style table top and some 'dogs' to fit it. You can make your own using the Axminster Tools Parf system but for now it would be cheaper to buy an MFT top from eBay.

Personally I'd be more inclined towards a bandsaw ahead of the track saw, then order sheet goods from somewhere that'll cut to size for you to begin with.

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track

It depends on what you are mainly going to be cutting. For me the most used saw is the mitre saw as I mainly cut planks so once I have set up my Mitre saw I can quickly get many accurate cuts done. A plunge saw is something I use infrequently and that was even before I brought a table saw.Drumroll said:

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track

It depends on what you are mainly going to be cutting. For me the most used saw is the mitre saw as I mainly cut planks so once I have set up my Mitre saw I can quickly get many accurate cuts done. A plunge saw is something I use infrequently and that was even before I brought a table saw.Until he says what he's going to be doing though we are both in the dark.

singlecoil said:

Drumroll said:

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track

It depends on what you are mainly going to be cutting. For me the most used saw is the mitre saw as I mainly cut planks so once I have set up my Mitre saw I can quickly get many accurate cuts done. A plunge saw is something I use infrequently and that was even before I brought a table saw.Until he says what he's going to be doing though we are both in the dark.

snowman99 said:

Any tips for getting square cuts? My hand saw seems to leave a curved surface usually so I switched to my cheap circular saw for a project I am making, a ladder type frame held together with dowels. So all the middle pieces needed to be the same length and square. Endless fiddling to get them and a guide clamped, as I find I need a guide to cut straight. Saw body hits clamp. One piece of wood works loose. Etc. Then I cut the bits and it seems the cut is circa 10 degrees off square so in doesn’t fit perfectly. The saw is notionally on the 90 degree marker but clearly not.

If your handsaw won't cut straight then it's not correctly set - either get a new one or reset it if it's the type that can be reset.Don't trust the gauge on circular saws, it's a guide not an accurate measure. Use a proper square to setup the saw and you should get straight cuts.

Also, I never assume I'm going to get a perfect cut suitable for joining straight off the saw. Cut slightly large and then plane to length and square.

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track saw.

I have three power saws and neither is a plunge or track saw. It really depends on what you want to do with them.XCP said:

Just discovered this thread.

Did a City and Guilds in Furniture making when I retired, have made quite a bit of furniture and nic nacs. Currently making a bass guitar out of wenge, maple and black walnut.

First thing I made for my own workshop was my bench. Cost me about £6 for the recycled softwood, the fixings cost more! But I am quite tall so it was made to measure so to speak.

Interesting to see what other people are up to.

Re tools, a low angle block plane is indispensable in my view, and they do not cost a great deal unless you go down the Lie Neilsen route.

Agreed, a low angled block plane is the most useful of woodworking tools. I use a Lie Neilson 60 1/2 and it's a very nice thing. Did a City and Guilds in Furniture making when I retired, have made quite a bit of furniture and nic nacs. Currently making a bass guitar out of wenge, maple and black walnut.

First thing I made for my own workshop was my bench. Cost me about £6 for the recycled softwood, the fixings cost more! But I am quite tall so it was made to measure so to speak.

Interesting to see what other people are up to.

Re tools, a low angle block plane is indispensable in my view, and they do not cost a great deal unless you go down the Lie Neilsen route.

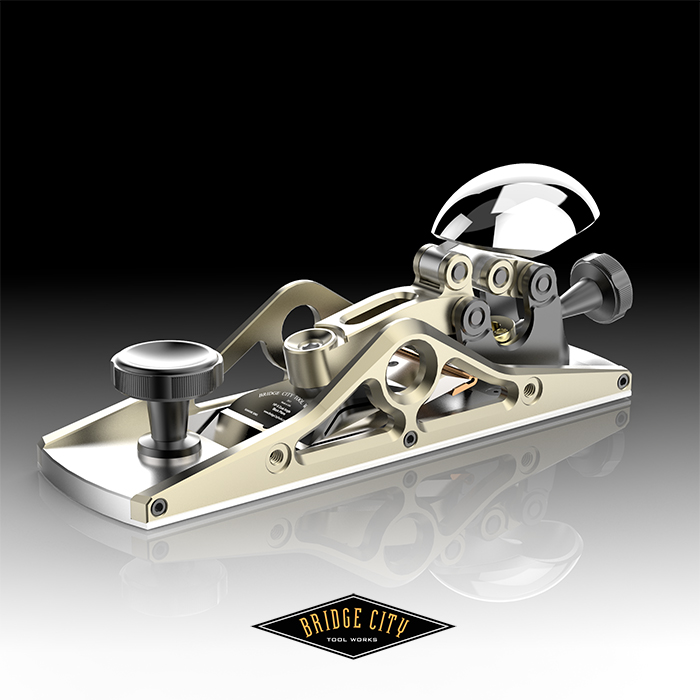

I've always hankered after a Bridge City low angle block plane, they were made as a limited edition and you see them occasionally on ebay..... but maybe they're to beautiful (and expensive) to use. See how the sole is dovetailed into the sides and then infilled with rosewood.

Or maybe a HP9 dual angle.

If however you're feeling flush you could hunt down something by Karl Holtey. i think he's retired now but his planes do come up occasionally... for the price of a nice car.

http://www.holteyplanes.com/gallery.html

singlecoil said:

Flibble said:

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track saw.

I have three power saws and neither is a plunge or track saw. It really depends on what you want to do with them.My power saws in order of use are: Mitre saw: Used for cutting planks and any any other relatively thin pieces (less than 150mm wide)

Table saw: used for wider pieces and sheets of wood, offset angles and channels etc.

Band saw: for smaller pieces (like any band-saw it is limited by it's size) and rounding wood for turning

Oscillating saw: for close to floor etc pieces

Reciprocating saw: for rough cutting.

Mini-Plunge saw: for small nothes etc

Jigsaw: for cutting out pipe holes etc

and lastly although I can't remember using it in over a year is my circular saw.

So please explain why if I could only afford one saw I should get the one I (and others) are going to use least.

It's very subjective, but if you only had one saw, you'd use that the most and the plunge saw has very good range, whereas the other saws don't to the same extent. ie you can rip and cross-cut. Tablesaw comes close for range, but much more expensive and will struggle to accurately cross-cut long lengths.

My view is that cutting 1" x 1" pieces square to length with a plunge saw will quickly have you finding the money for a mitre saw, it would add hours to a job getting that done accurately enough. And usually it's length that's more important as you can work with the other dimensions of a board more easily.

You might argue I can rough-cut to length with a saw and shoot to finished size so that doesn't matter, but I can counter that by pointing out that you can also get your sheet supplier to dimension everything on their panel saw, so you don't need rip cut capability either.

Which I guess leaves the bandsaw as your best option as it'll quickly get your non-sheet stock ready for your hand tools. It would be my first choice for pottering in the shed where I'm making stuff from whatever I've got on the pile, but not for quickly getting through house renovationy sort of jobs where I want to buy the right size sections and quickly cut to length accurately.

So my answer is bandsaw for tinkering in the shed, mitre saw for DIY stuff, but always keep your eye on Gumtree and pick up the good value stuff when ti comes up.

My view is that cutting 1" x 1" pieces square to length with a plunge saw will quickly have you finding the money for a mitre saw, it would add hours to a job getting that done accurately enough. And usually it's length that's more important as you can work with the other dimensions of a board more easily.

You might argue I can rough-cut to length with a saw and shoot to finished size so that doesn't matter, but I can counter that by pointing out that you can also get your sheet supplier to dimension everything on their panel saw, so you don't need rip cut capability either.

Which I guess leaves the bandsaw as your best option as it'll quickly get your non-sheet stock ready for your hand tools. It would be my first choice for pottering in the shed where I'm making stuff from whatever I've got on the pile, but not for quickly getting through house renovationy sort of jobs where I want to buy the right size sections and quickly cut to length accurately.

So my answer is bandsaw for tinkering in the shed, mitre saw for DIY stuff, but always keep your eye on Gumtree and pick up the good value stuff when ti comes up.

Drumroll said:

You're not getting it, are you.

Thank you for schooling me on the use of power saws.If you had looked at my profile you would have realised that it was a subject I am already have some familiarity with.

I have in the past when necessity required made an entire kitchen, for money, with a tracksaw. I have all the other saws listed but I was putting myself in the position of a person with only one saw.

singlecoil said:

Flibble said:

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track saw.

I have three power saws and neither is a plunge or track saw. It really depends on what you want to do with them.I mostly use the bandsaw as it happens.

Flibble said:

singlecoil said:

Flibble said:

singlecoil said:

If you only have the budget for one power saw then it needs to be a plunge/track saw.

I have three power saws and neither is a plunge or track saw. It really depends on what you want to do with them.I mostly use the bandsaw as it happens.

Bandsaws are great at what they do, but the list of what they can't do is longer than the list of what track saws can't do.

Given more than one saw, or ideally a selection, then the track saw might only see occasional use.

So, you’re stuck on a desert island, you’ve got a pile of carcassing timber, plywood, doors, skirtings, worktops, architraves etc. and you need to build yourself a timber frame house: You can have one power saw, what will it be? I’ll side with Singlecoil and make it a plunge saw. Rough sawn timber and second fix stuff can be done no problem with hand saws, if a little slower but ripping ply, worktops with hand saws? Sod that for game of soldiers. What would your single power saw be? Oh, wait, there’s no power on the island, hand saws it is

wolfracesonic said:

So, you’re stuck on a desert island, you’ve got a pile of carcassing timber, plywood, doors, skirtings, worktops, architraves etc. and you need to build yourself a timber frame house: You can have one power saw, what will it be? I’ll side with Singlecoil and make it a plunge saw. Rough sawn timber and second fix stuff can be done no problem with hand saws, if a little slower but ripping ply, worktops with hand saws? Sod that for game of soldiers. What would your single power saw be? Oh, wait, there’s no power on the island, hand saws it is

I'd work on the assumption that I had all the time in the world and would go all Japanese handsaws

. It would be very soothing although it might take five years to finish my shelter.

. It would be very soothing although it might take five years to finish my shelter.I am alarmed at the amount of time I can spend on YouTube watching Japanese craftsmen taking an epoch shaving a small piece of wood...

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff