Butchering a Bertone

Discussion

Started life as this

Then stripped of all dignity:

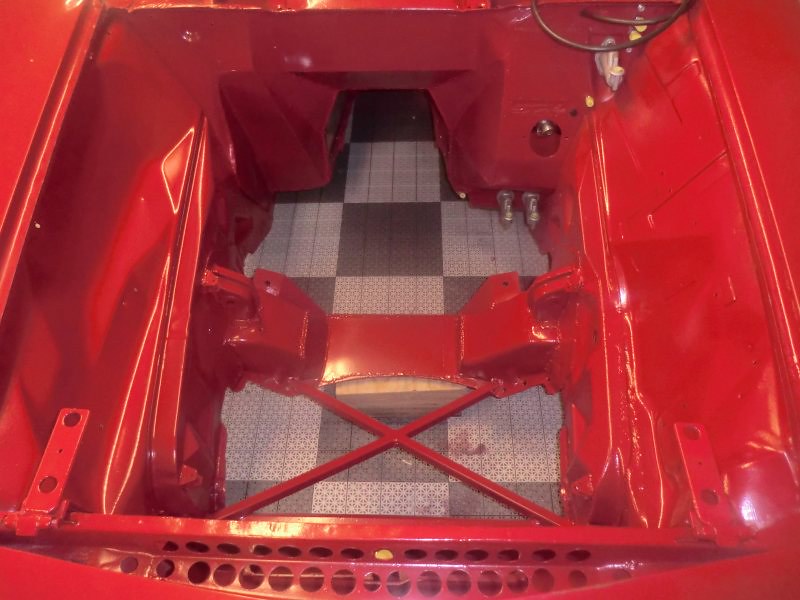

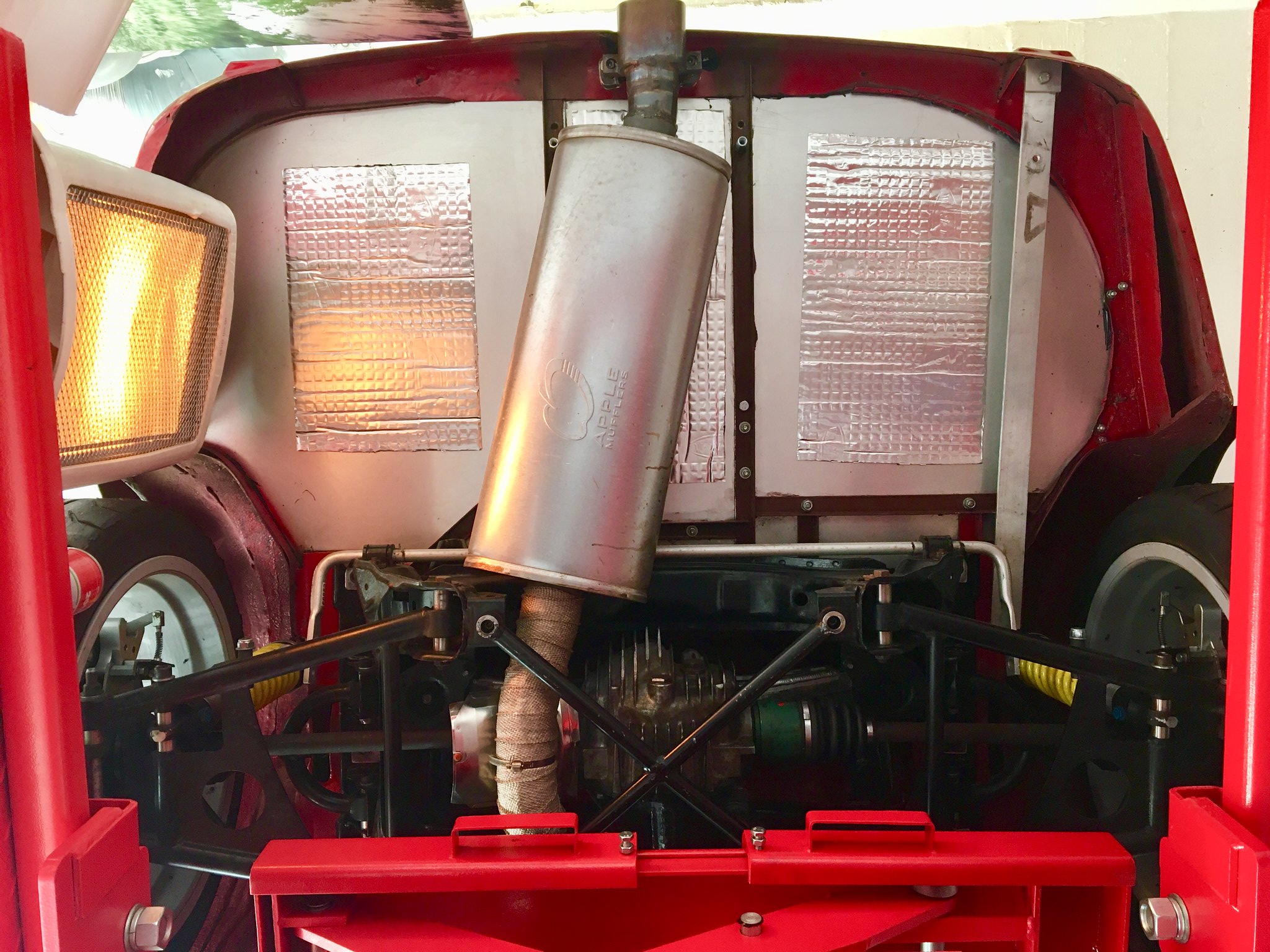

Once finished getting mashed up and ended up like this:

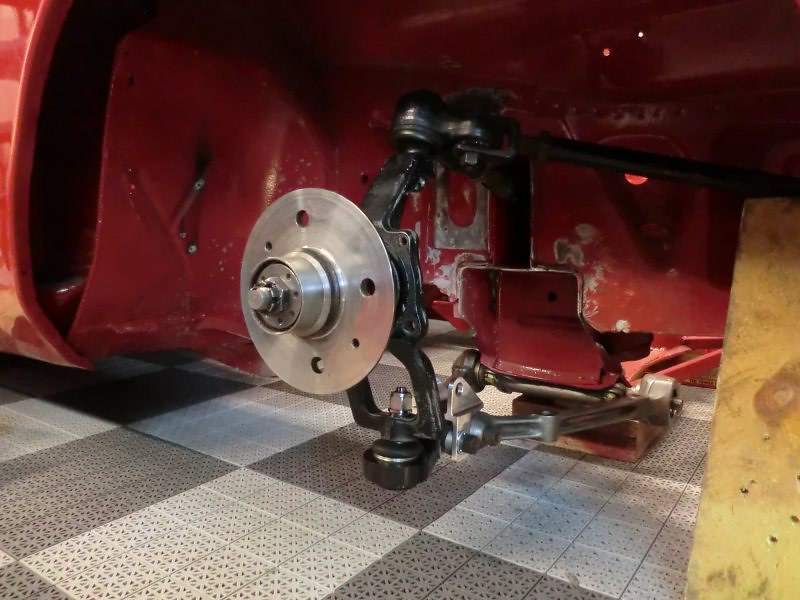

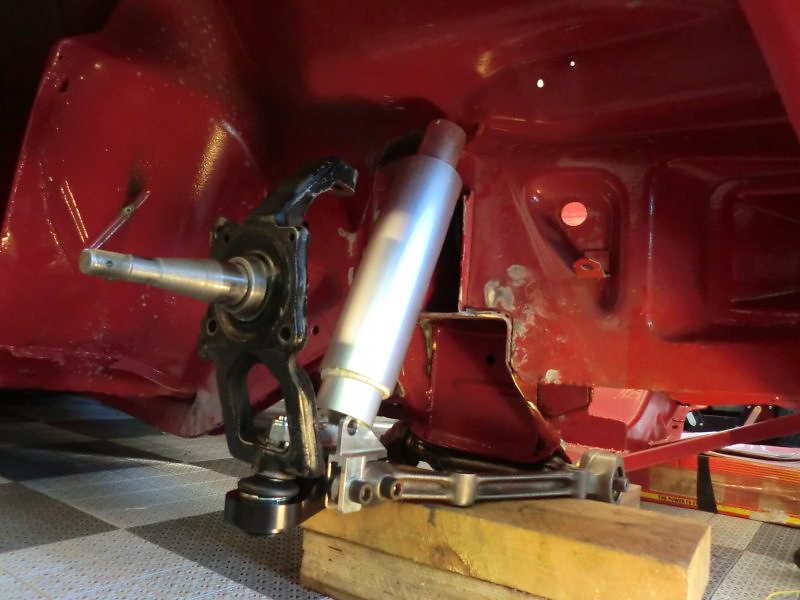

Along the way a few bits were slightly altered:

Final phase of destruction, to an otherwise perfectly good piece of Italian automotive history, is now almost complete:

Edited by CarreraLightweightRacing on Tuesday 27th October 07:58

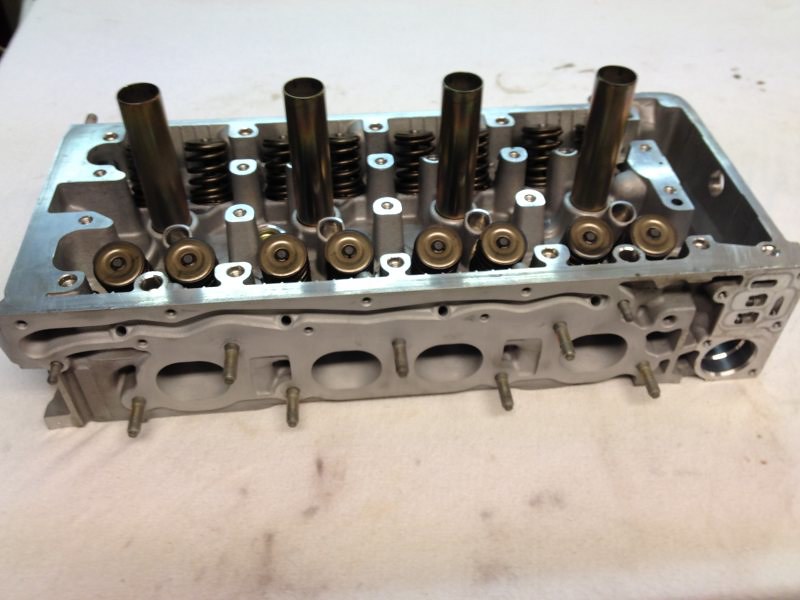

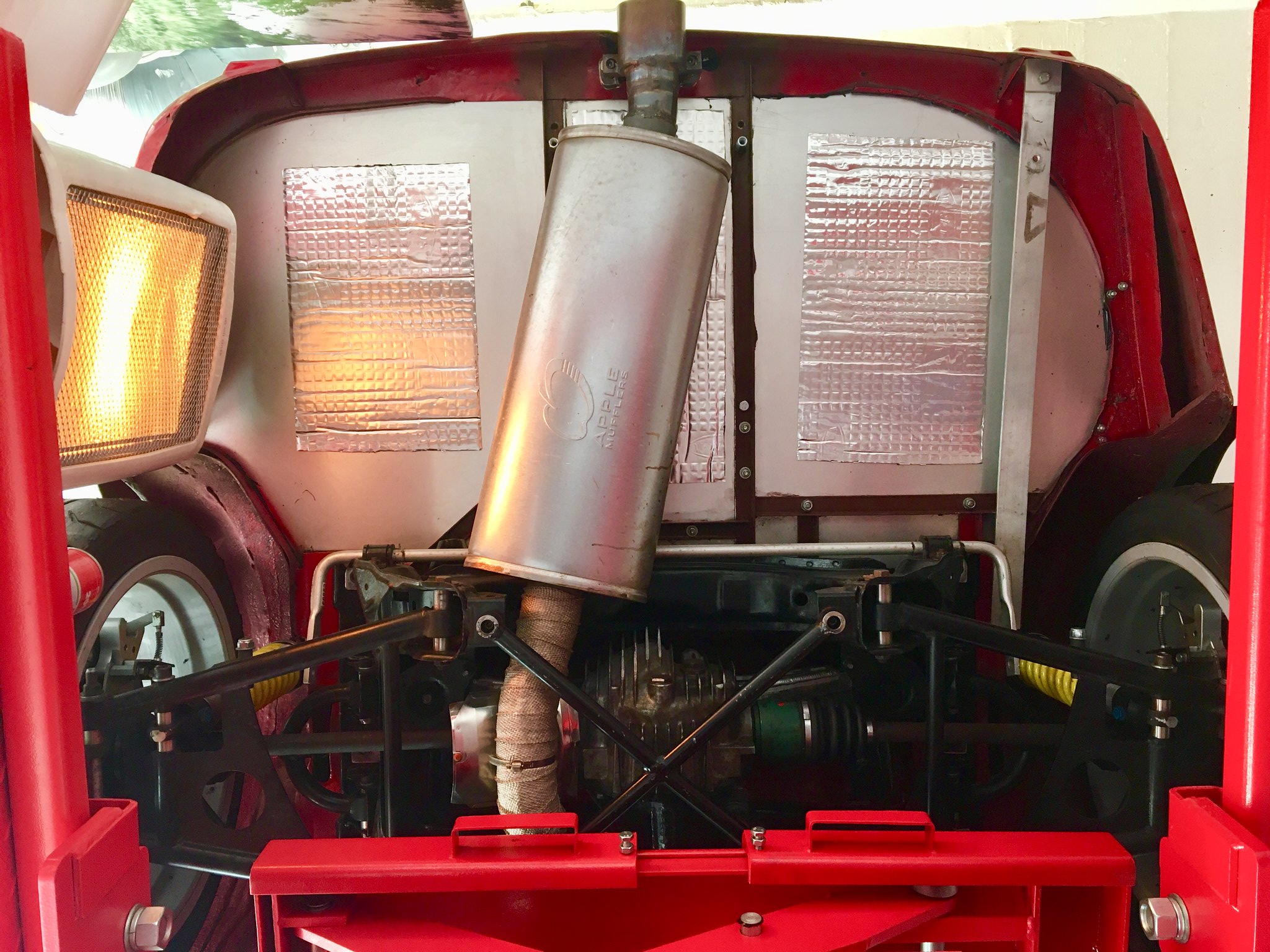

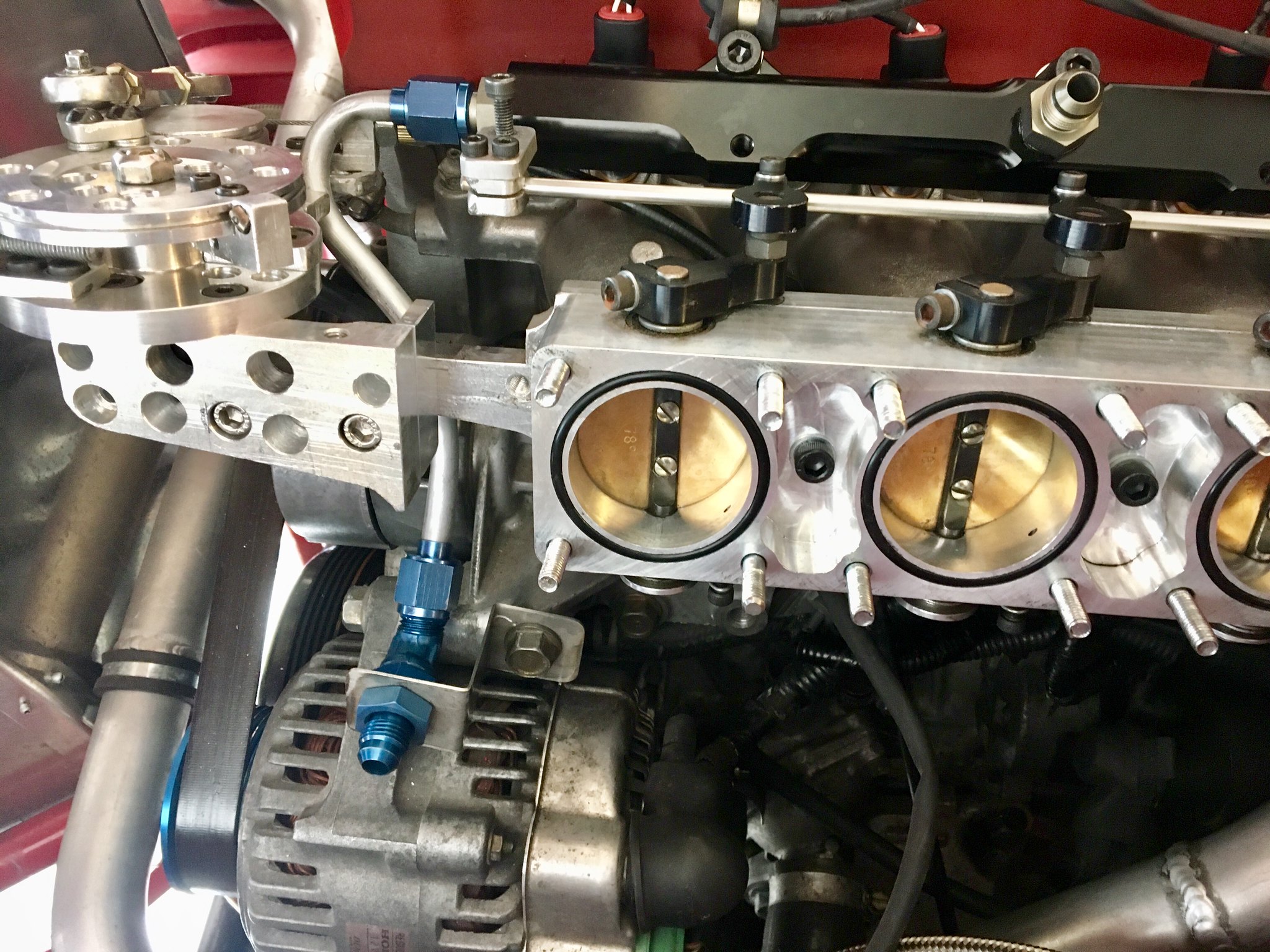

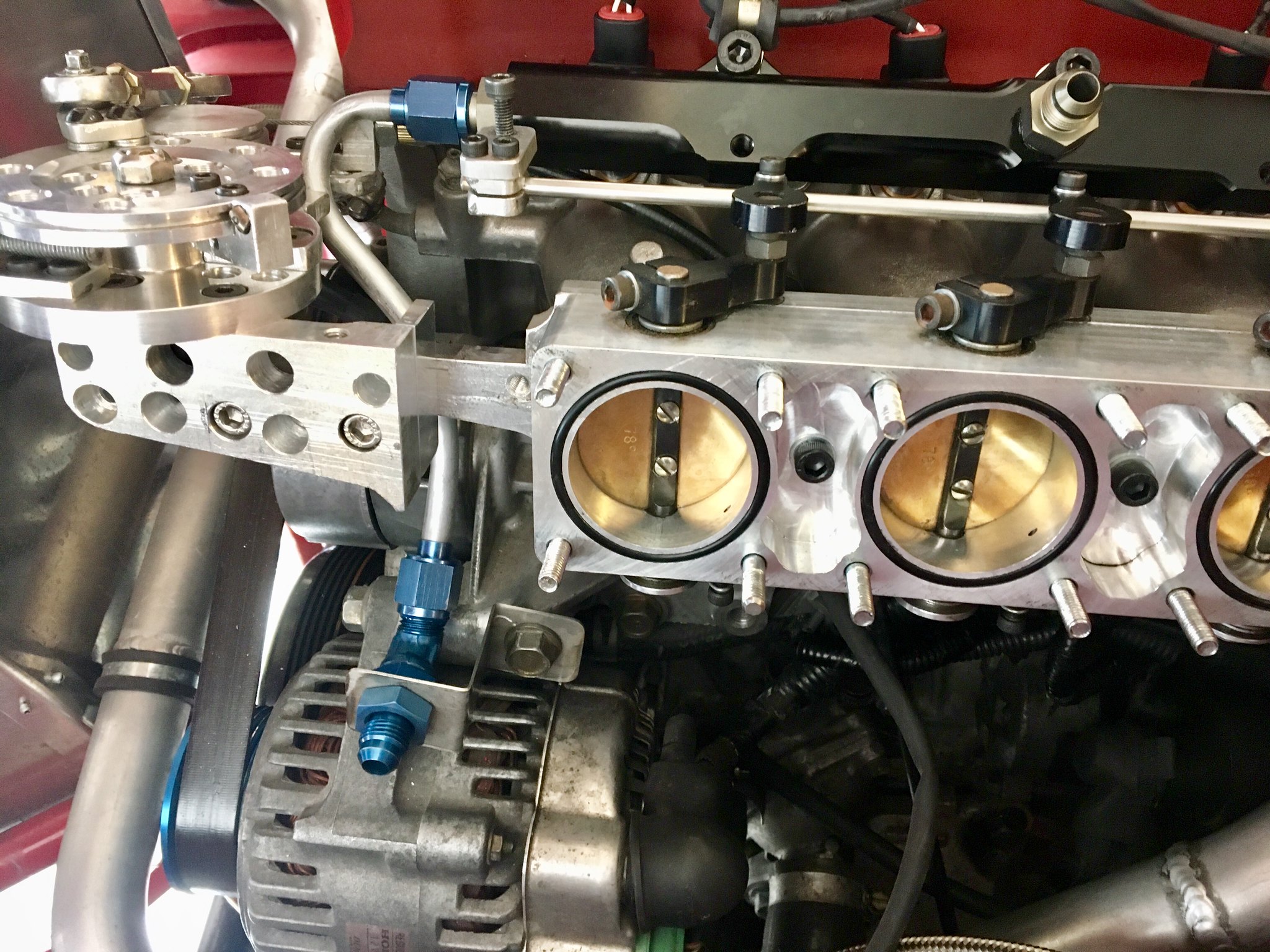

To answer some of the questions, here is a little more detail; due to the depth and attention to detail with this car I’m just going to lightly skim over some of the design and construction pics, I would literally be here forever for the full breakdown. The car started life as a 1975 GT Junior 1600. The project started with a completely restored shell with all the other components in boxes. The early idea was to use the Alfa engine but this was ditched fairly early on. In search for a new powerhouse the F20C was chosen. Those who know a thing or two about NA engines will most probably know Honda's F20C engine held the record for producing the highest specific power output for any mass production naturally aspirated piston engine, at 123.5 HP/L, until Ferrari began production of the 458 Italia in 2010, which produced 124.5 HP/L. The F20C revs to 9000rpm, is unbelievably strong and reliable even at this level of tune. The engine was completely stripped down and rebuilt as new then some special track orientated modifications added, baffled sump etc. A completely unique custom fabricated ITB system was made, not only that it uses Formula1 engine type injection with the injectors housed within the trumpets; a true work of art as you’ll see from the pictures below. The car was mapped and running on E85 so it is a very green machine. In the current state of tune it is making around 265bhp and weighs just under 850kg. Some of the detail and lengths gone to really are somewhat crazy, 180mm wider track for instance… It really is a one-off in the truest sense.

The car has been through various stages of design and some aspects of the early work presented here may no longer be on the car. The pictures are roughly in time order. The final car is fully FIA compliant and certified so can be used in most race series. It has also been road registered which is some achievement. I am now in the process of dialling it back a little in an attempt to make it TUV compliant for registering in Germany.

Apologies in advance if you stumbled across this thread looking for deviated stitching

This is only a short summary but I’m sure that’s enough of my blabbering, I’ll let some pictures do the talking. Let the engineering porn commence!!!

The car has been through various stages of design and some aspects of the early work presented here may no longer be on the car. The pictures are roughly in time order. The final car is fully FIA compliant and certified so can be used in most race series. It has also been road registered which is some achievement. I am now in the process of dialling it back a little in an attempt to make it TUV compliant for registering in Germany.

Apologies in advance if you stumbled across this thread looking for deviated stitching

This is only a short summary but I’m sure that’s enough of my blabbering, I’ll let some pictures do the talking. Let the engineering porn commence!!!

Interior is now pretty much sorted in terms of NVH, test drive will confirm but a lot of attention has gone into sound proofing, carpeting, sliding seats, sealing, and basically making it a far more friendly place to be

Next up major changes to the bodywork and external appearance. Panel beating, welding, painting, wheels, new arches, new ground effect panels made, most crazy race-car aero and diffuser removed revealing the beautiful classic ‘Bertone’ lines:

After the mid section and diffuser were gone the car was left looking like this; front end still very agressive:

So decided to ditch the front end and make some new panels

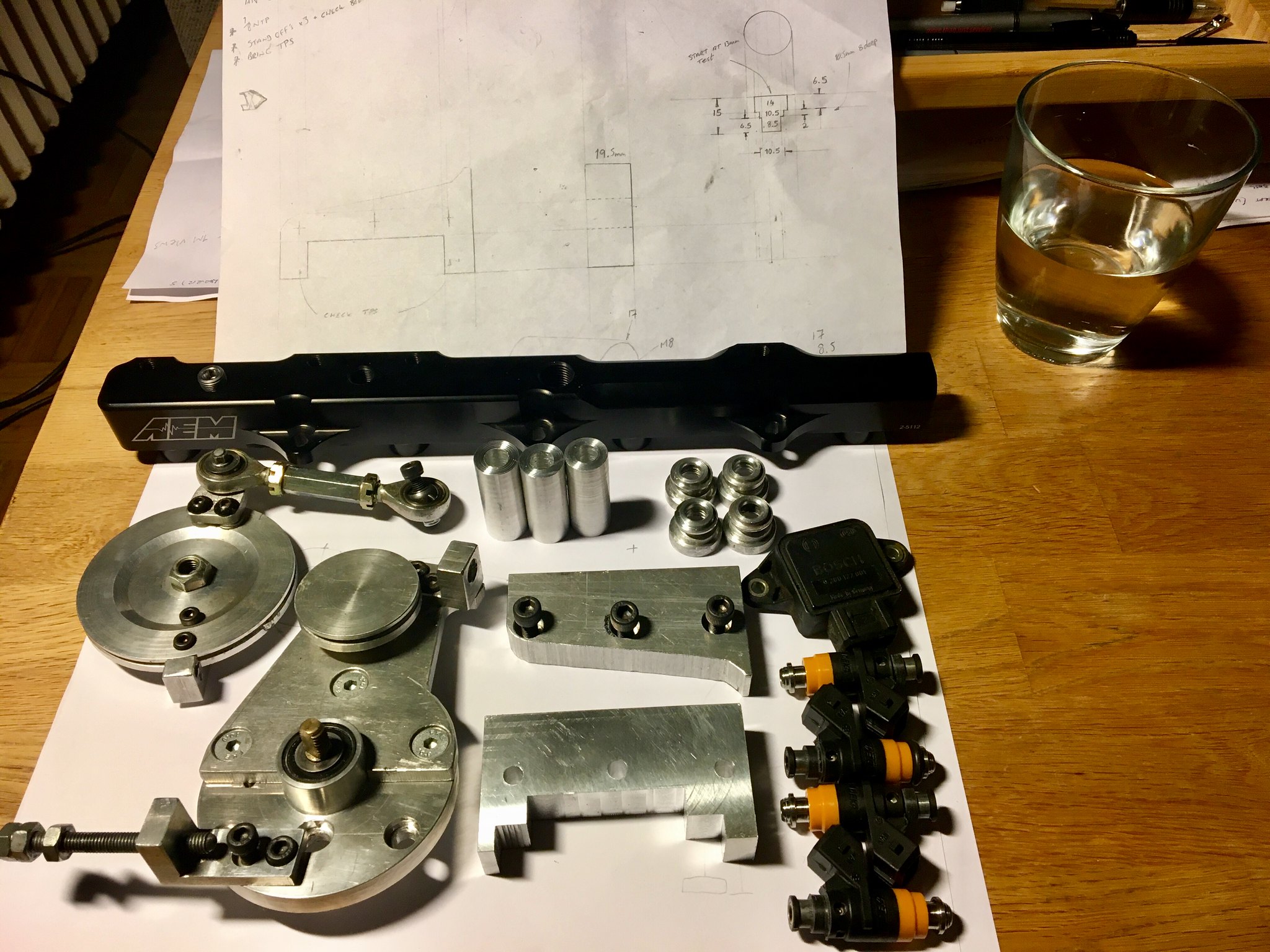

Due to the F1 injector set-up not really being a solution for a road car (Difficult to start or idle when fuel is being squirted onto the face of a butterfly 20cm from the combustion chamber), I have had to completely redesign the injection and throttle system also the car is mapped for E85 fuel so the injectors also need to be changed for normal fuel. Lots of head scratching to find a workable solution but I’m lucky to have a dream workshop at work with every machine you could every think of, so a lathe and milling machine came in very handy for this phase:

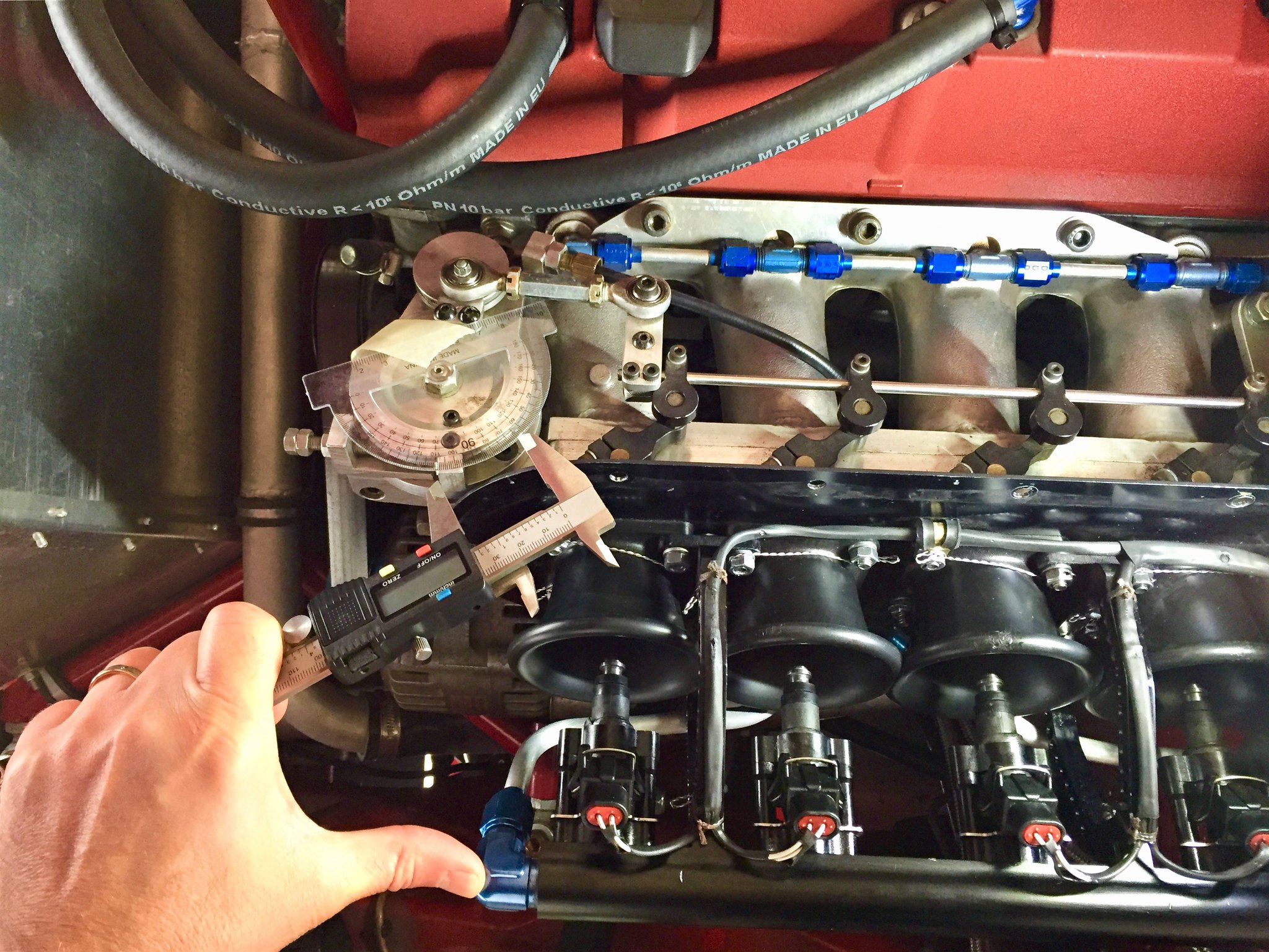

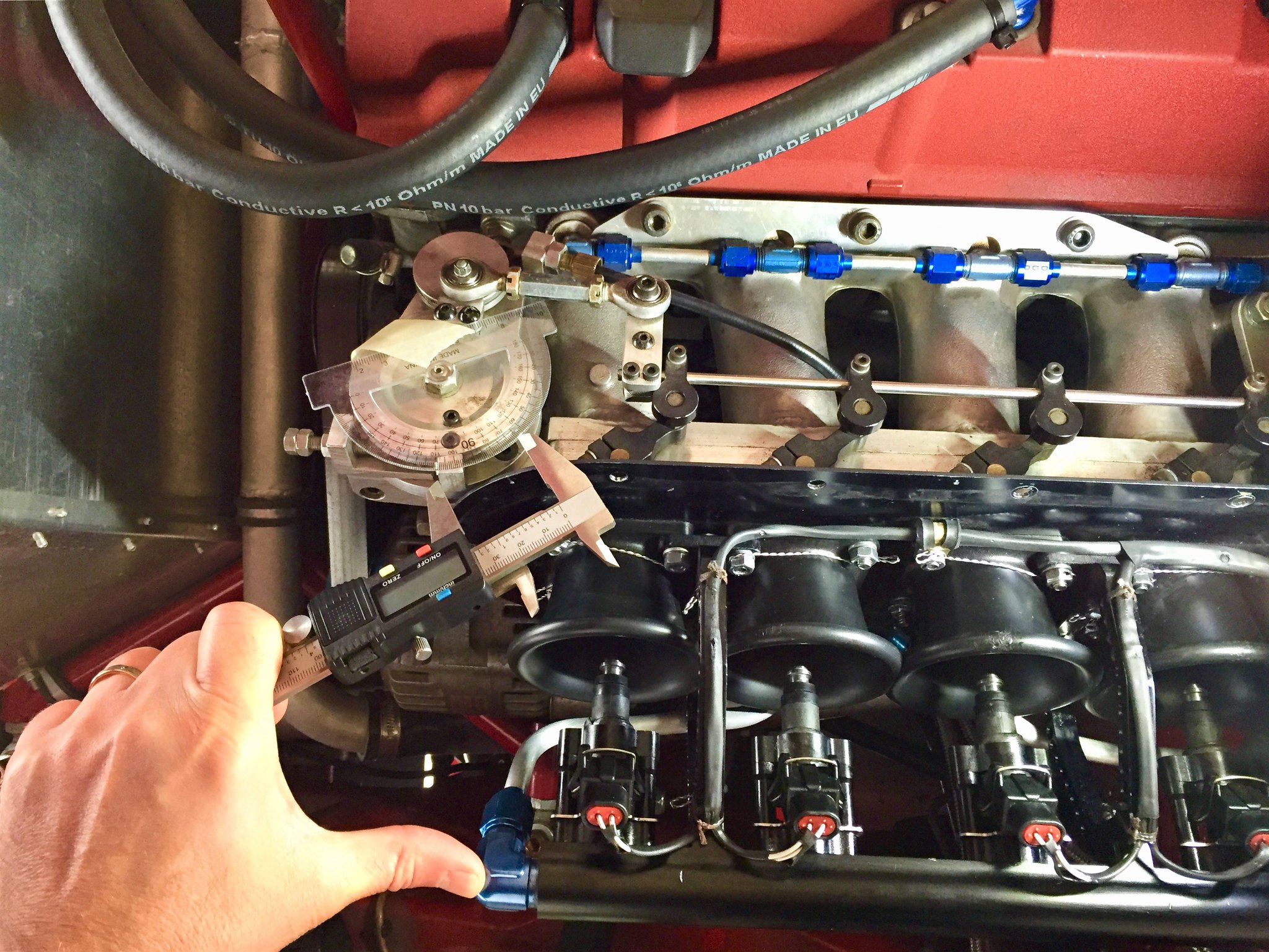

Following the carbon airbox removal (4 hours alone due to inaccessible fasteners…) Started to take some measurements

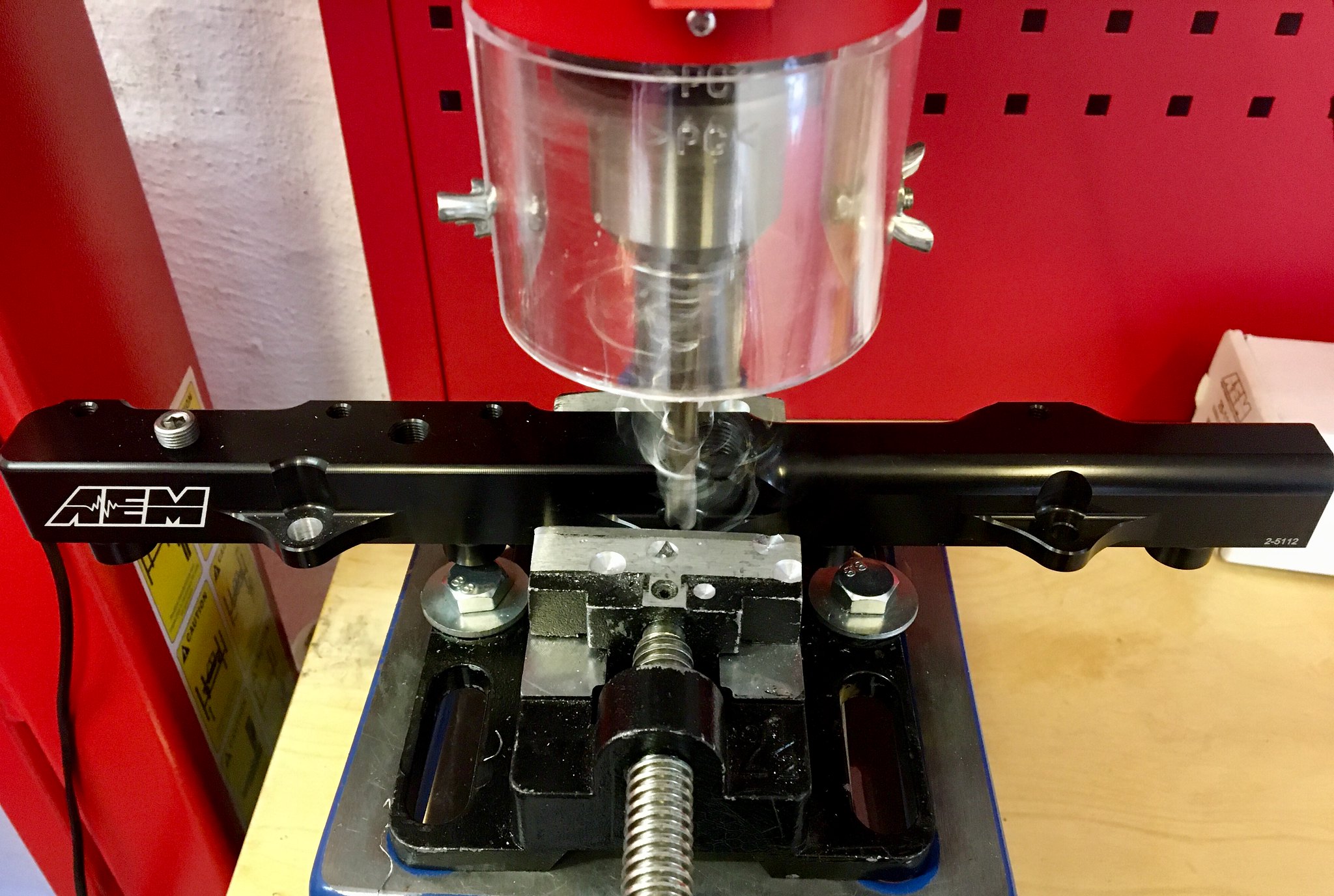

Found some lovely short 440cc injectors only 38mm o-ring to o-ring. Due to all the redesign issues clearance was the biggest headache. I’m literally talking only 1mm or less is some instances between fuel rail and throttle linkages etc. Anyway what’s the first thing you do when you receive some lovely new car parts; chop them up of course, so straight onto the lathe they go

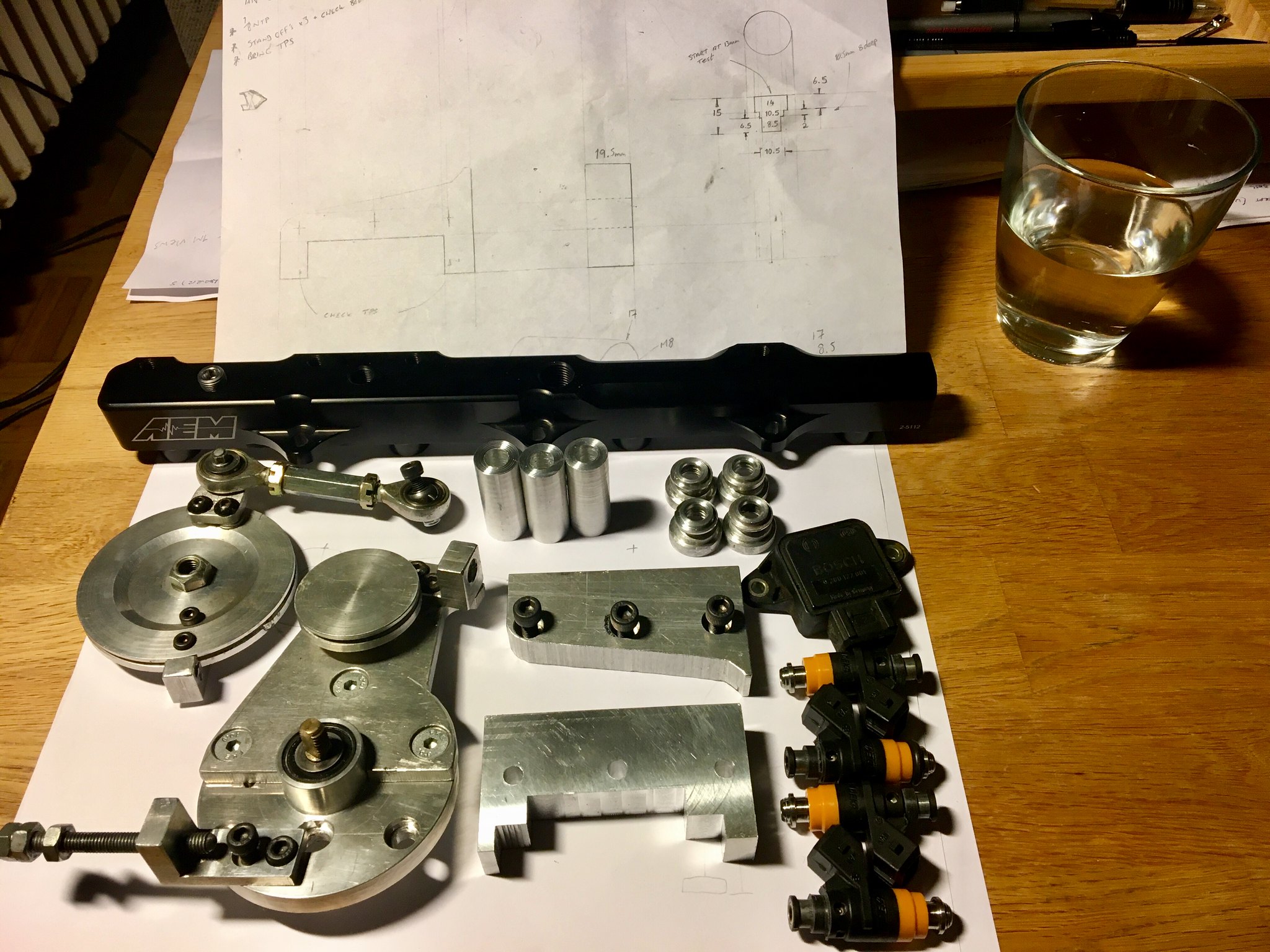

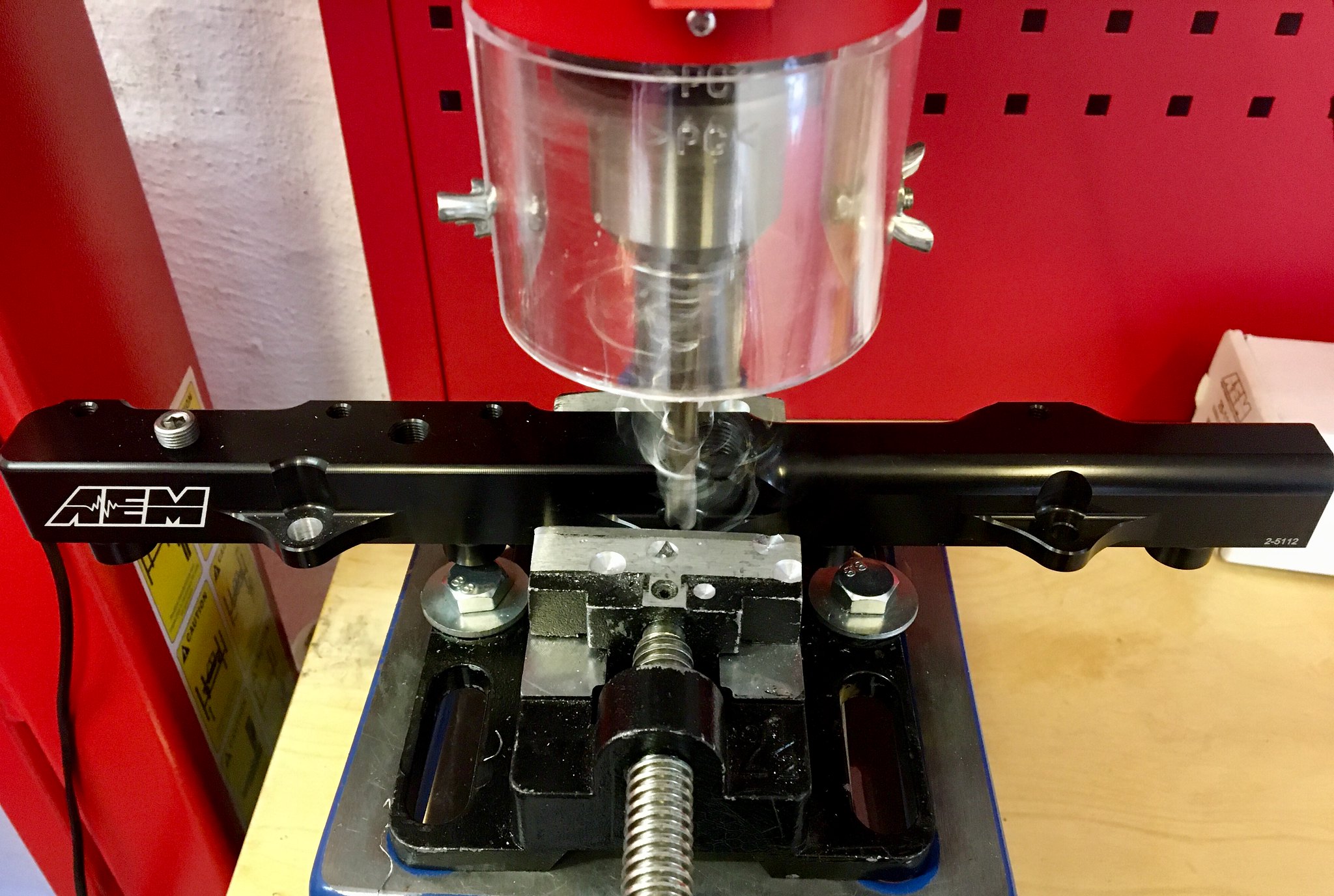

Next up I needed to fabricate some parts to relocate the throttle assembly so an inch thick slab of aircraft aluminium was put to good use

A few of the newly fabricated parts

Throttle assembly parts now made

In CLR fashion I decided they could do with trimming down somewhat

Throttle assembled

Other new parts modified/fabricated

Even made a loom mounting bracket out of titanium

Finally very close to resolving all the design issues now

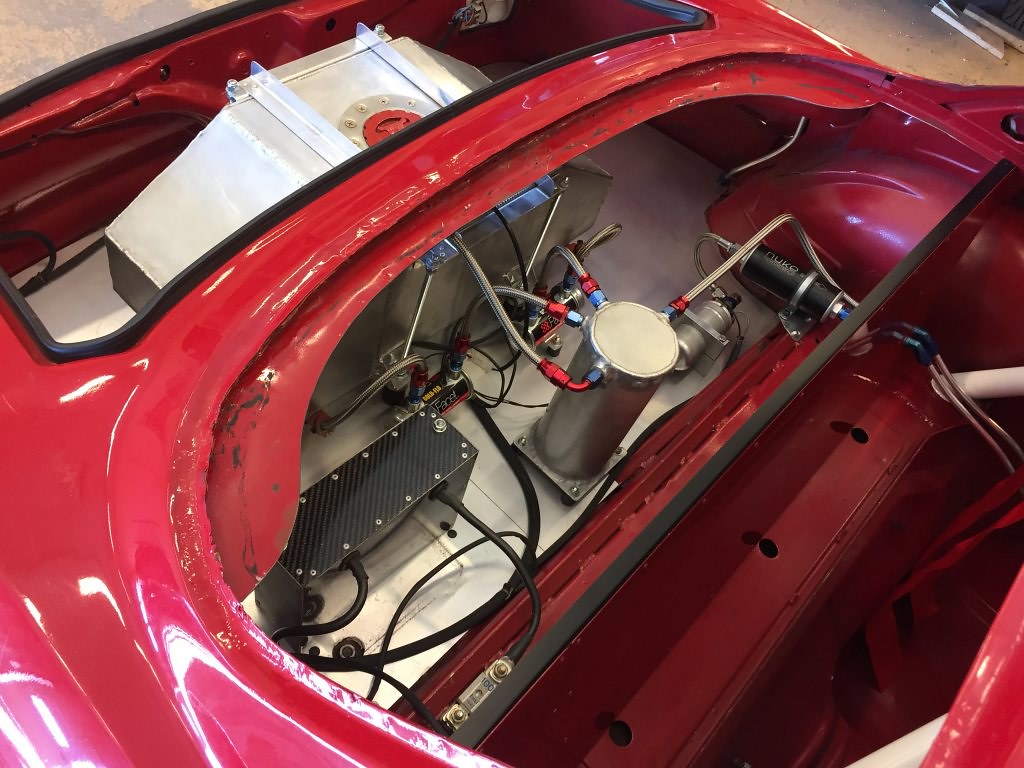

Latest is the fuel system is complete.

Made another little titanium mounting bracket for the rigid section of the fuel return pipe:

Which fits here:

Engine bay fuel lines new layout:

This picture gives a close up high-lighting the tight tolerance clearance issues referred to earlier:

Final assembly:

Next up major changes to the bodywork and external appearance. Panel beating, welding, painting, wheels, new arches, new ground effect panels made, most crazy race-car aero and diffuser removed revealing the beautiful classic ‘Bertone’ lines:

After the mid section and diffuser were gone the car was left looking like this; front end still very agressive:

So decided to ditch the front end and make some new panels

Due to the F1 injector set-up not really being a solution for a road car (Difficult to start or idle when fuel is being squirted onto the face of a butterfly 20cm from the combustion chamber), I have had to completely redesign the injection and throttle system also the car is mapped for E85 fuel so the injectors also need to be changed for normal fuel. Lots of head scratching to find a workable solution but I’m lucky to have a dream workshop at work with every machine you could every think of, so a lathe and milling machine came in very handy for this phase:

Following the carbon airbox removal (4 hours alone due to inaccessible fasteners…) Started to take some measurements

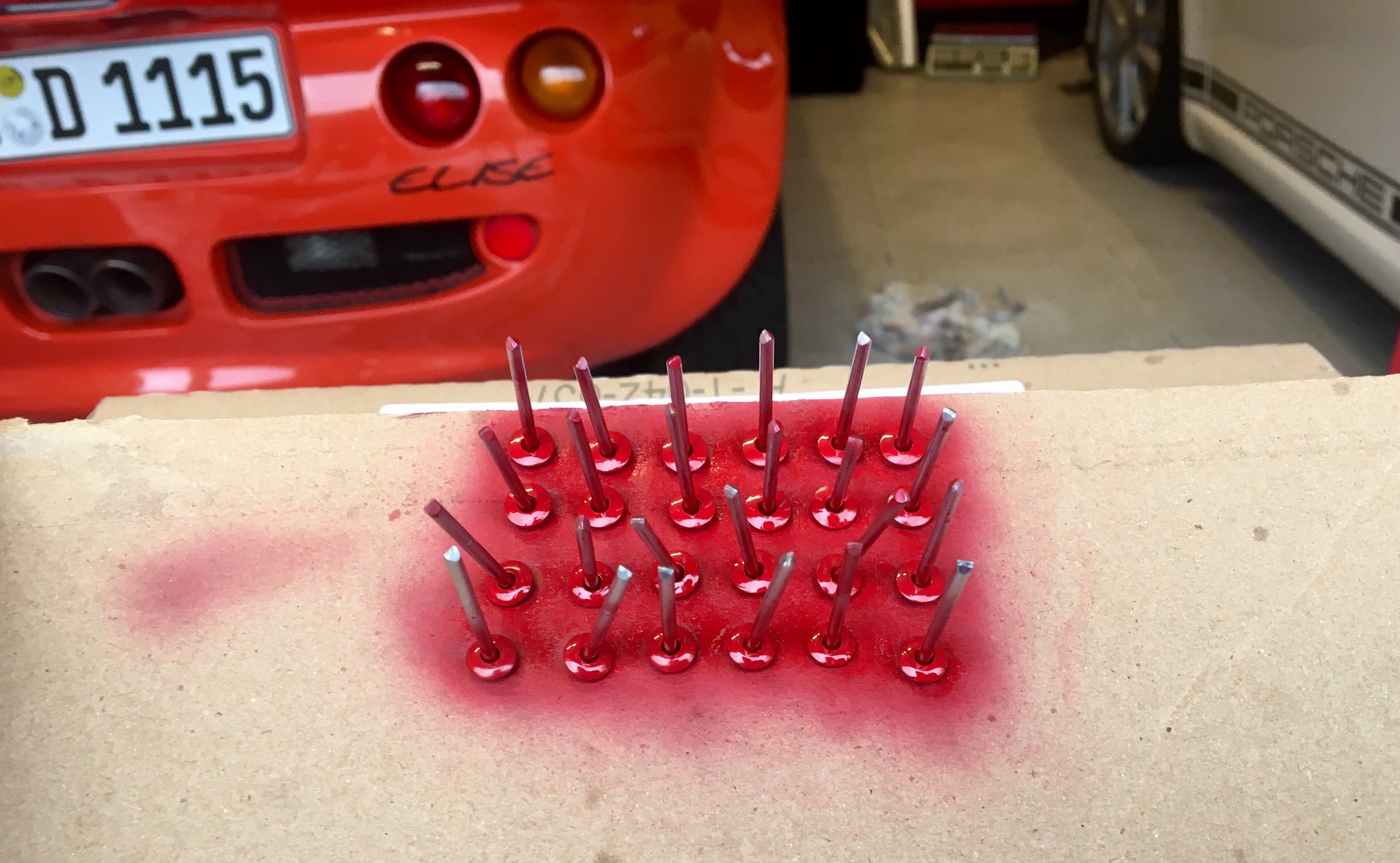

Found some lovely short 440cc injectors only 38mm o-ring to o-ring. Due to all the redesign issues clearance was the biggest headache. I’m literally talking only 1mm or less is some instances between fuel rail and throttle linkages etc. Anyway what’s the first thing you do when you receive some lovely new car parts; chop them up of course, so straight onto the lathe they go

Next up I needed to fabricate some parts to relocate the throttle assembly so an inch thick slab of aircraft aluminium was put to good use

A few of the newly fabricated parts

Throttle assembly parts now made

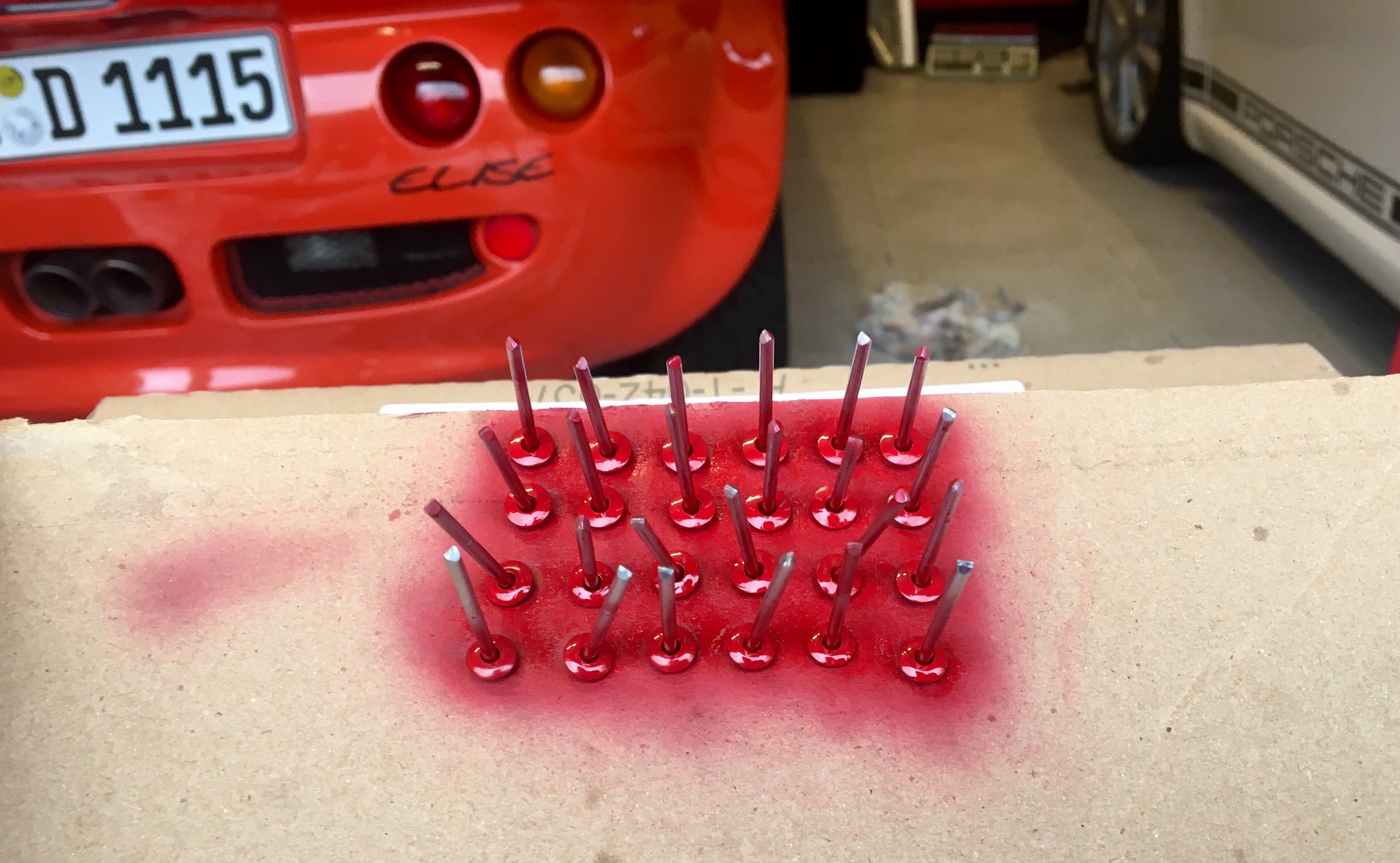

In CLR fashion I decided they could do with trimming down somewhat

Throttle assembled

Other new parts modified/fabricated

Even made a loom mounting bracket out of titanium

Finally very close to resolving all the design issues now

Latest is the fuel system is complete.

Made another little titanium mounting bracket for the rigid section of the fuel return pipe:

Which fits here:

Engine bay fuel lines new layout:

This picture gives a close up high-lighting the tight tolerance clearance issues referred to earlier:

Final assembly:

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff

s off the purists

s off the purists