Alternate history: M96 Cup engine

Discussion

Had to have rods that put the piston where we needed it, which sadly the OEM ones were not going to do. These do look nice, also, which is a bonus.

We're going to run the first engines on Syvecs, specifically the S7Plus - if anyone has an unused S7Plus gathering dust in the garage please let me know and I would very happily buy it from you (chance would be a fine thing, I suspect, but no harm asking).

We're going to run the first engines on Syvecs, specifically the S7Plus - if anyone has an unused S7Plus gathering dust in the garage please let me know and I would very happily buy it from you (chance would be a fine thing, I suspect, but no harm asking).

Stuff is happening, yes - but achingly slowly. We're waiting for the performance tappet chest design (smaller base circle, and all the implications of that for oiling, tappet position and so forth) to reach the head of the queue at the CNC place we're using.

In the meantime we have produced a run of the dual stage scavenge pumps to see if anyone else wants one.

In the meantime we have produced a run of the dual stage scavenge pumps to see if anyone else wants one.

shalmaneser said:

It's a machine for making sure the metal is where the designer said the metal should be.

Yep, pretty standard inspection equipment but it does look impressive, whizzing around, to the untrained eye.

When are you going to get one in a car though Neil??

I told you, you should have bought a GT3. You’d have been enjoying it all this time, instead of standing over CMMs.

Where's the fun in getting the benefit of other people's R&D efforts, when you can forge your own path?

I'm looking forward to hearing about how this gets on as the engine comes together; I really enjoy the ambition and technical detail you're sharing. This really looks like it's being done properly!

Hopefully you're keeping notes, as once the new engine is on the road and running smoothly it feels like it should really become a video or article of some sort, whether a PH Readers Cars vid or elsewhere.

I'm looking forward to hearing about how this gets on as the engine comes together; I really enjoy the ambition and technical detail you're sharing. This really looks like it's being done properly!

Hopefully you're keeping notes, as once the new engine is on the road and running smoothly it feels like it should really become a video or article of some sort, whether a PH Readers Cars vid or elsewhere.

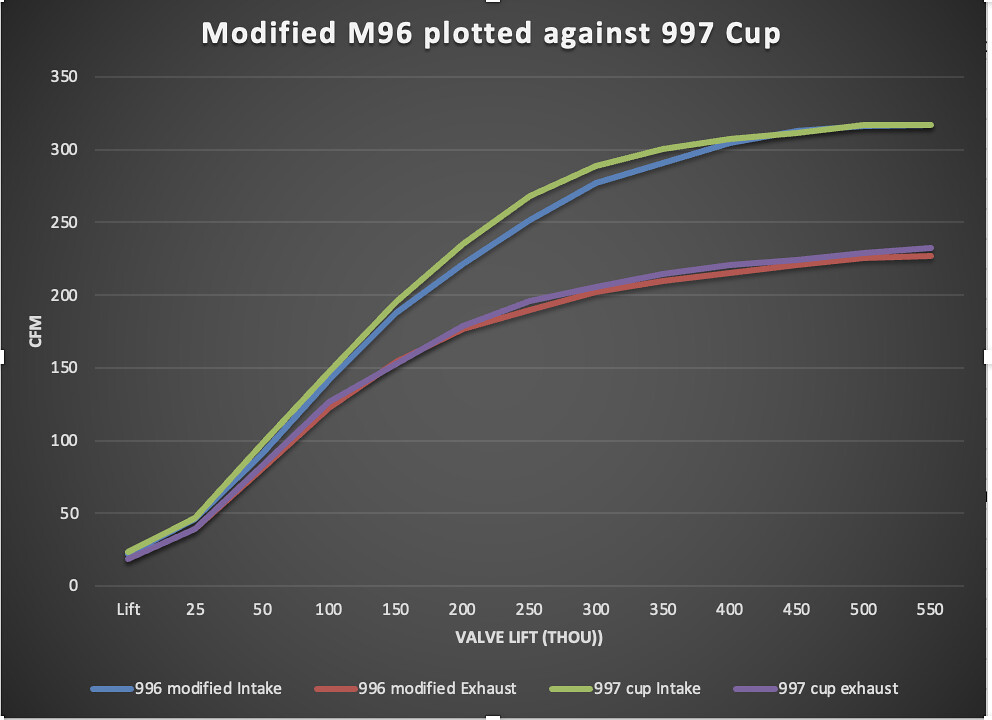

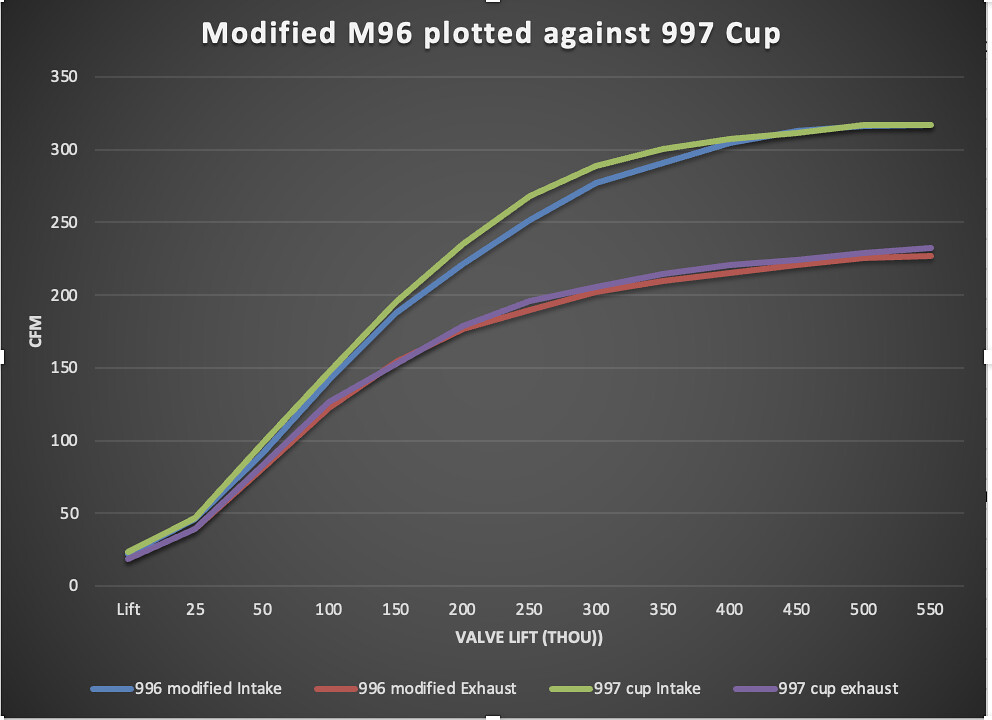

It's late on a Monday, halfway through December - must mean it's time for some charts.

These are all based on flow bench data - and a caveat, before we continue, is that whilst air flow is indicative of likely performance it's absolutely *not* definitive, it's one of a series of inputs that determine overall power and torque.

Therefore the following should be taken in the spirit with which it is presented - as interesting, but nothing more than that.

First, the baseline - a bone stock M96 on a bone stock 96mm bore:

A range of companies now offer a capacity upgrade as part of major engine repair/upgrade which increases the bore size to 100mm, so next we'll look at the effect which that has on flow (in effect, the 3.4 in the previous chart is now a 3.7, with the valves slightly unshrouded by the increase in cylinder diameter):

Close, but there's a definite increase for both intake and exhaust, with the exhaust side increasingly (relatively) more.

Now lets compare the stock 96mm M96 to our modified design, which is on a 100mm bore:

That's showing a significant increase, but what does that really mean?

Lets compare with a couple of different Mezger heads to try to put it into perspective.

First, a GT3 head:

And, because we had the figures for one, here's a 997 Cup head:

These are all based on flow bench data - and a caveat, before we continue, is that whilst air flow is indicative of likely performance it's absolutely *not* definitive, it's one of a series of inputs that determine overall power and torque.

Therefore the following should be taken in the spirit with which it is presented - as interesting, but nothing more than that.

First, the baseline - a bone stock M96 on a bone stock 96mm bore:

A range of companies now offer a capacity upgrade as part of major engine repair/upgrade which increases the bore size to 100mm, so next we'll look at the effect which that has on flow (in effect, the 3.4 in the previous chart is now a 3.7, with the valves slightly unshrouded by the increase in cylinder diameter):

Close, but there's a definite increase for both intake and exhaust, with the exhaust side increasingly (relatively) more.

Now lets compare the stock 96mm M96 to our modified design, which is on a 100mm bore:

That's showing a significant increase, but what does that really mean?

Lets compare with a couple of different Mezger heads to try to put it into perspective.

First, a GT3 head:

And, because we had the figures for one, here's a 997 Cup head:

I think it's unquestionable that the Mezger is a better engine - I imagine Porsche reviewed the X51 program and decided that they wanted something with more headroom for development/more natively suited to being a racing engine.

And, of course, since that point everyone who has ever campaigned a water-cooled Porsche platform has made the logical choice to use the more powerful and reliable engine, for which there's a huge performance aftermarket (try buying a sequential gearbox for an M96, for example).

But I don't race, and I like the "what if" element of the X51 story - and to answer your question I think the people who worked on the X51 project would see a very great degree of similarity with our engines, as we've followed the same route as they have.

Cams with higher lift and more duration, reworked heads, new intake and exhaust manifolds and so forth. We have, I admit, taken things a bit further than they did - when discussing this engine with the friends with whom I am working on the project I tend to refer to it as the X51-Evolution engine as it seems to be a good descriptive fit.

And, of course, our engines may be a total, abject failure when they run up on the dyno for the first time - but the flow-bench results are encouraging.

And, of course, since that point everyone who has ever campaigned a water-cooled Porsche platform has made the logical choice to use the more powerful and reliable engine, for which there's a huge performance aftermarket (try buying a sequential gearbox for an M96, for example).

But I don't race, and I like the "what if" element of the X51 story - and to answer your question I think the people who worked on the X51 project would see a very great degree of similarity with our engines, as we've followed the same route as they have.

Cams with higher lift and more duration, reworked heads, new intake and exhaust manifolds and so forth. We have, I admit, taken things a bit further than they did - when discussing this engine with the friends with whom I am working on the project I tend to refer to it as the X51-Evolution engine as it seems to be a good descriptive fit.

And, of course, our engines may be a total, abject failure when they run up on the dyno for the first time - but the flow-bench results are encouraging.

Yes, that's a great example of raw air flow only being a part of the equation - the Cup motor has no VarioCam, so the design is optimised for race cams with fixed timing. The GT3 engine has more options at it's disposal to manage timing and so forth.

Our billet tappet chests are now done, next on the list is to get the cams ground and (hard to believe I'm typing this, in some ways) then building the short block up to be a complete engine.

Our billet tappet chests are now done, next on the list is to get the cams ground and (hard to believe I'm typing this, in some ways) then building the short block up to be a complete engine.

shalmaneser said:

Interesting that the GT3 exhaust shifts more air than the cup motor... Results certainly look promising but as you say this is just part of the puzzle! Exciting to see progress nevertheless.

I believe the valve sizes are the same on the Cup and GT3 heads, but the ports in the Cup head are bigger, this should theoretically mean the flow numbers would be better, though if the valves are the same size as the GT3 road car, the only way you'll get more flow (and thus power) is to open the valves for longer and open them further, which is exactly what the Cup does with high lift/long duration exhaust cams and the deletion of the Variocam to enable such cams to be utilised reliably.Edited by Slippydiff on Tuesday 14th December 08:21

Dammit said:

But I don't race, and I like the "what if" element of the X51 story - and to answer your question I think the people who worked on the X51 project would see a very great degree of similarity with our engines, as we've followed the same route as they have.

Cams with higher lift and more duration, reworked heads, new intake and exhaust manifolds and so forth. We have, I admit, taken things a bit further than they did - when discussing this engine with the friends with whom I am working on the project I tend to refer to it as the X51-Evolution engine as it seems to be a good descriptive fit.

Good luck to you. It’s a very interesting project.Cams with higher lift and more duration, reworked heads, new intake and exhaust manifolds and so forth. We have, I admit, taken things a bit further than they did - when discussing this engine with the friends with whom I am working on the project I tend to refer to it as the X51-Evolution engine as it seems to be a good descriptive fit.

To understand the value of the X51 on the options list you need to have a fairly deep appreciation of base engine design to see the “value”, as the quoted power rise was fairly low in the brochure vs the cost (almost £10k IIRC).

But unquestionably I would spec it on my car and in time I might accumulate enough parts to build X51 spec motor by piece.

You seem to be putting out some healthy numbers in your charts!

The chaps from Project Binky recommended the engineering place that machine these- for which I’m very grateful as their work is excellent.

We now have a set for each of the three engines we have in build.

Here with the stock version:

And here with the new, larger valves, titanium retainers, and a 3D print of the ITB’s we’ve designed to check dimensions and fit.

We now have a set for each of the three engines we have in build.

Here with the stock version:

And here with the new, larger valves, titanium retainers, and a 3D print of the ITB’s we’ve designed to check dimensions and fit.

Edited by Dammit on Wednesday 22 December 23:15

Gassing Station | 911/Carrera GT | Top of Page | What's New | My Stuff